Food Safety Magazine, February/March 2012

Food Safety Magazine, February/March 2012

Food Safety Magazine, February/March 2012

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

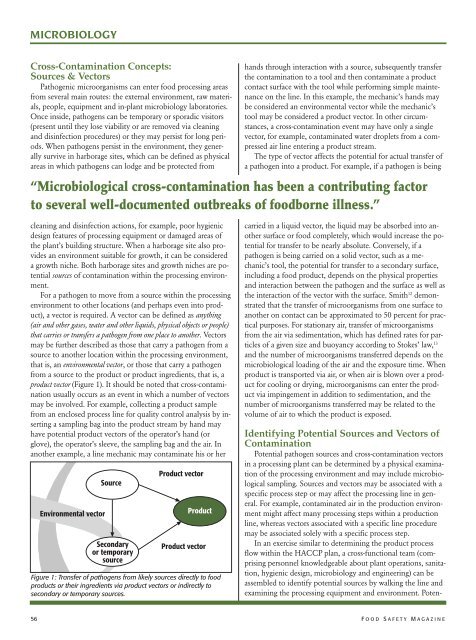

MICROBIOLOGYCross-Contamination Concepts:Sources & VectorsPathogenic microorganisms can enter food processing areasfrom several main routes: the external environment, raw materials,people, equipment and in-plant microbiology laboratories.Once inside, pathogens can be temporary or sporadic visitors(present until they lose viability or are removed via cleaningand disinfection procedures) or they may persist for long periods.When pathogens persist in the environment, they generallysurvive in harborage sites, which can be defined as physicalareas in which pathogens can lodge and be protected fromhands through interaction with a source, subsequently transferthe contamination to a tool and then contaminate a productcontact surface with the tool while performing simple maintenanceon the line. In this example, the mechanic’s hands maybe considered an environmental vector while the mechanic’stool may be considered a product vector. In other circumstances,a cross-contamination event may have only a singlevector, for example, contaminated water droplets from a compressedair line entering a product stream.The type of vector affects the potential for actual transfer ofa pathogen into a product. For example, if a pathogen is being“Microbiological cross-contamination has been a contributing factorto several well-documented outbreaks of foodborne illness.”cleaning and disinfection actions, for example, poor hygienicdesign features of processing equipment or damaged areas ofthe plant’s building structure. When a harborage site also providesan environment suitable for growth, it can be considereda growth niche. Both harborage sites and growth niches are potentialsources of contamination within the processing environment.For a pathogen to move from a source within the processingenvironment to other locations (and perhaps even into product),a vector is required. A vector can be defined as anything(air and other gases, water and other liquids, physical objects or people)that carries or transfers a pathogen from one place to another. Vectorsmay be further described as those that carry a pathogen from asource to another location within the processing environment,that is, an environmental vector, or those that carry a pathogenfrom a source to the product or product ingredients, that is, aproduct vector (Figure 1). It should be noted that cross-contaminationusually occurs as an event in which a number of vectorsmay be involved. For example, collecting a product samplefrom an enclosed process line for quality control analysis by insertinga sampling bag into the product stream by hand mayhave potential product vectors of the operator’s hand (orglove), the operator’s sleeve, the sampling bag and the air. Inanother example, a line mechanic may contaminate his or herFigure 1: Transfer of pathogens from likely sources directly to foodproducts or their ingredients via product vectors or indirectly tosecondary or temporary sources.carried in a liquid vector, the liquid may be absorbed into anothersurface or food completely, which would increase the potentialfor transfer to be nearly absolute. Conversely, if apathogen is being carried on a solid vector, such as a mechanic’stool, the potential for transfer to a secondary surface,including a food product, depends on the physical propertiesand interaction between the pathogen and the surface as well asthe interaction of the vector with the surface. Smith 12 demonstratedthat the transfer of microorganisms from one surface toanother on contact can be approximated to 50 percent for practicalpurposes. For stationary air, transfer of microorganismsfrom the air via sedimentation, which has defined rates for particlesof a given size and buoyancy according to Stokes’ law, 13and the number of microorganisms transferred depends on themicrobiological loading of the air and the exposure time. Whenproduct is transported via air, or when air is blown over a productfor cooling or drying, microorganisms can enter the productvia impingement in addition to sedimentation, and thenumber of microorganisms transferred may be related to thevolume of air to which the product is exposed.Identifying Potential Sources and Vectors ofContaminationPotential pathogen sources and cross-contamination vectorsin a processing plant can be determined by a physical examinationof the processing environment and may include microbiologicalsampling. Sources and vectors may be associated with aspecific process step or may affect the processing line in general.For example, contaminated air in the production environmentmight affect many processing steps within a productionline, whereas vectors associated with a specific line proceduremay be associated solely with a specific process step.In an exercise similar to determining the product processflow within the HACCP plan, a cross-functional team (comprisingpersonnel knowledgeable about plant operations, sanitation,hygienic design, microbiology and engineering) can beassembled to identify potential sources by walking the line andexamining the processing equipment and environment. Poten-56 F O O D S A F E T Y M A G A Z I N E

![Otomatik indirilmez ise tıklayınız [Download]](https://img.yumpu.com/44170525/1/190x190/otomatik-indirilmez-ise-taklayanaz-download.jpg?quality=85)