Bonding, Sealing and Coating Solutions for Mobile Devices - Loctite

Bonding, Sealing and Coating Solutions for Mobile Devices - Loctite

Bonding, Sealing and Coating Solutions for Mobile Devices - Loctite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 5Application: Touch panel /windows bonding to coverProduct: HF8600/HF8800/HF6005,3542/3572/3573/3580Benefits:• Structural strength• Quick assembly <strong>and</strong> processing• Impact <strong>and</strong> shear loading resistanceApplication: Speaker assemblyProduct: 3541/3542, Light Cure AdhesiveBenefits:• High strength• Thin bondlines• Easy operation <strong>and</strong> reliabilityApplication: Camera lens bondingProduct: 3541/3542, HF8600/HF8000, 4305Benefits:• High strength• Thin bondlines• Easy operation <strong>and</strong> reliabilityApplication: Plastic / metal trim bondingProduct: 3541/3542/3572, HF8600/HF8800Benefits:• One part adhesive <strong>for</strong> structural bonding• High strengthApplication: Battery cell moldingProduct: Macromelt ®Benefits:• Water tightness• Low costs• Good thermal resistanceApplication: Overmolding / insertmoldingProduct: OM4501, OM4101Benefits:• Structural strength• Fast fixture with molding process• Resist impact <strong>and</strong> shear loading

6 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>Structural <strong>Bonding</strong>Application OverviewLOCTITE ® PRODUCTAPPLICATIONS1-part products3542, 3572, 3573, 3580,ME35702-part productsHF8600, HF8800• Window to cover• Touch panel to cover1-part products3541, 3542, 3572,ME35702-part productsHF8600, HF8800• Bezel to cover1-part products3542, 3572, ME35702-part productsHF8075LV, HF8600,HF8800• Battery cover bonding• Decoration to coverMake your devices thinner, lighter<strong>and</strong> more reliable!

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 7FEATURES AND BENEFITSSUBSTRATES• Good adhesion to plastic, metal, glass <strong>and</strong> composite• Fast fixturing• High peel strength• High impact strength• Very thin bond lines• Long open time• Wide variety of <strong>for</strong>mulations available• Allow automation• Chemical resistance• PMMA, PC, Glass + PC• PMMA, PC, Glass + Metal• Good adhesion to plastic, metal, glass <strong>and</strong> composite• Fast fixturing• High peel strength• High impact strength• Very thin bond lines• Long open time• Wide variety of <strong>for</strong>mulations available• Allow automation• Chemical resistance• PC + PC• Metal (SUS, Al, Mg) + PC• Metal + Metal (SUS + SUS, Mg + Mg)• Good adhesion to plastic, metal, glass <strong>and</strong> composite• Fast fixturing• High peel strength• High impact strength• Very thin bond lines• Long open time• Wide variety of <strong>for</strong>mulations available• Allow automation• Chemical resistance• PC + PC• Metal (SUS, Al, Mg) + PC• Metal + Metal (SUS + SUS, Mg + Mg)

8 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>Structural AdhesivesPUR Hotmelt Adhesives> > One-part, solvent free> > Good adhesion to plastic, metal, glass <strong>and</strong> composite> > Fast fixturing> > Very thin bondlines> > Long open time> > Low cost> > Wide variety of <strong>for</strong>mulations availableLower overall assembly costwith improved productivity<strong>and</strong> yield.< <strong>Loctite</strong>® 400D BenchtopRobot Dispense System<strong>Loctite</strong> ® Adhesives Compared to PSA TapeCharacteristics <strong>Loctite</strong> ® PUR Hotmelts <strong>Loctite</strong> ® Cyanoacrylates PSA TapeBond very thin joints Yes, bonds > 0.4 mm May flow beyond bond areaCan’t bond very thin joints because of die-cutting design limitation,insufficient strengthStrength of bonding plastic Very strong Quite strong but can crack Weak bond, especially in very small areaFills gap caused by partsvariationYes, liquid fills gap easily Yes, liquid fills gap easily No, tape does not fill these gapsAppearance of bonded edges Very good Good GoodComplete seal Yes Yes Difficult, depend on design <strong>and</strong> parts tolerance<strong>Bonding</strong> curved surfaces Yes Yes NoTotal applied cost Low Low High (die-cutting cost)Selector GuideCharacteristics <strong>Loctite</strong> ® 3541 <strong>Loctite</strong> ® 3542 <strong>Loctite</strong> ® 3572 <strong>Loctite</strong> ® 3573 <strong>Loctite</strong> ® 3580 <strong>Loctite</strong> ® ME3570Bond strengthPlastic to plastic Very high High High High High Very highPlastic to metal High Very high High High High Very highPlastic to glass Moderate Very high Very high Very high High HighMetal to glass Moderate Very high Very high Very high High HighGap fill Medium Medium High High High HighSpeed of dispense / flow rate Fast Fast Fast Fast Medium MediumFixture time * 1 - 2 minutes 1 - 2 minutes - - - -Open time * 1 - 2 minutes 2 - 4 minutes > 4 minutes > 4 minutes UV Control > 4 minutesBead sizeThin* Fixture time <strong>and</strong> open time: vary upon the operating environment conditions; high temperatures will lengthen open times, while lower temperatureswill shorten open time, <strong>and</strong> low humidity condition may extend fix time.

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 9Structural AdhesivesUV Pre-activatedPUR Hotmelt Adhesives1Dispensing as st<strong>and</strong>ardPUR Hotmelt AdhesivesUV Pre-activatedPUR Hotmelt Adhesives2 3UV exposure toactivate adhesiveLight SourceAssemble parts at a later timeAchieve initial strength quicklyKey Feature – Fast Curing ProfileComparison between <strong>Loctite</strong> ® 3580 <strong>and</strong> <strong>Loctite</strong> ® 35422.51.221Strength (MPa)1.51Strength (MPa)0.80.60.4<strong>Loctite</strong> ® 3580<strong>Loctite</strong> ® 35420.500.200 300 600 900 1200 1500 0 10 20 30 40 50 60Time (minutes)Time (minutes)* SS + Glass** <strong>Bonding</strong> strength measuredcross-bead push test• Curing behavior is much changed due to UV activation• Much higher initial strength than st<strong>and</strong>ard PUR Hotmelt Adhesives• Final bonding strength is quite similarRecommended Operation Conditions• UV Lamps type: UVA LED Flood System• UV light wavelength: UVA 375 nm• UV intensity: 25 - 75 mW/cm 2• Open time suggestion: no longer than 2 minutes <strong>for</strong> both be<strong>for</strong>e & after UV curing (as shorter as good)• Assembling tips: UV curing be<strong>for</strong>e bonding, curing time: 10 - 60 seconds• SOP will be released soon

10 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>Structural Adhesives2-Part Acrylic Adhesives> > 2-part acrylates> > Superior shear strength> > Excellent impact strength> > High temperature / humidity per<strong>for</strong>mance> > Fast fixture> > Halogen-free<strong>Loctite</strong> ® Structural Adhesives help you optimize yourdesign, improve reliability & reduce assembly cost.Equipment Selector Guide<strong>Loctite</strong> ® 4530-HC Robot Dispensing System<strong>Loctite</strong> ® 400D 2-Part Acrylates Dispensing RobotSemi-automatic dispenser (1 : 1, 2 : 1, 10 : 1)Mix nozzleADV (anti-drip valve)NeedleHenkel dedicated technical service provides assembly solution on siteto improve your product & productivity.• Design specification <strong>and</strong> testing• Process set up <strong>and</strong> optimization• Application equipment <strong>and</strong> system integrationSelector GuideCharacteristics <strong>Loctite</strong> ® HF8000 <strong>Loctite</strong> ® HF8025 <strong>Loctite</strong> ® HF8600 <strong>Loctite</strong> ® HF8800 <strong>Loctite</strong> ® HF8075LVMix ratio (A : B) 10 : 1 10 : 1 2 : 1 2 : 1 10 : 1Shear strength of An.AI(psi, 24 H @ RT)Viscosity be<strong>for</strong>e mix (cps, 25 °C)2,800(steel)Part A: 160,000 - 250,000Part B: 20,000 - 50,0002,800(steel)2,120(steel)Part A: 19,200Part B: 15,2002,936(cured 20 min @ 80°Cplus 24 H @ RT)Part A: 28,130Part B: 16,0352,100(steel)Part A: 70,000 - 100,000Part B: 50,000 - 70,000Working time 4 - 8 minutes 2 - 4 minutes > 5 minutes 2 - 4 minutesStorage temperature 2 - 8 °C 8 - 25 °CCuring condition<strong>Loctite</strong> ® dispensing equipmentRoom temperature<strong>Loctite</strong> ® 4530-HC Robot Dispensing System<strong>Loctite</strong> ® 400D Benchtop Robot (50 ml Dual Cartridge Dispenser)

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 11Structural Adhesives2-Part PU Adhesives> > 2-part polyurethane> > Superior flexibility> > Excellent impact strength> > Excellent shear strength> > High temperature / humidity per<strong>for</strong>mance> > Fast fixture> > Halogen-freeCompetitorLight Source<strong>Loctite</strong> ® HF6005Light Source<strong>Loctite</strong> ® HF6005 is a two-component urethane designed <strong>for</strong>low modulus & high impact resistance. Once mixed, it curesat room temperature or can be accelerated via heat.Selector GuideCharacteristics<strong>Loctite</strong> ® HF6005Mix ratio (A : B) 1 : 2Viscosity be<strong>for</strong>e mix (cps, 25 °C)Working timePart A (resin): 300 - 1,100Part B (hardener): 90,000 - 215,0004 minutesCuring condition Room temperature or 80 °CLap shear strength (IXEF, psi) 700Side impact (IXEF, J) 9.2Storage temperature 21 - 28 °C

12 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>Structural AdhesivesReach Compliant AdhesivesREACHCOMPLIANCEREACH st<strong>and</strong>s <strong>for</strong> Registration, Evaluation, Authorization<strong>and</strong> restriction of CHemicals. It is the European Communityregulation on chemicals <strong>and</strong> their safe use.Below is a selection of <strong>Loctite</strong> ® Structural Adhesives <strong>for</strong> h<strong>and</strong>held devices <strong>and</strong> displays.These products offer following key benefits in compliance with REACH.Additional Benefits• Eliminate costly mechanical fastening methods• Improve anesthetics compared to welds• Increase high temperature/humidity resistanceSelector GuideCharacteristics <strong>Loctite</strong> ® HF8000R <strong>Loctite</strong> ® HF8025R* <strong>Loctite</strong> ® HF8150R*Mix ratio (A : B) 10 : 1 10 : 1 10 : 1Viscosity be<strong>for</strong>e mix(cps, 25 °C)Part A: 20,000 - 40,000Part B: 10,000 - 20,000Part A: 160,000 - 250,000Part B: 20,000 - 50,000Part A: 50,000 - 80,000Part B: 10,000 - 20,000Work time 4 - 8 minutes 4 - 8 minutes 3 - 4 minutesCuring conditionHenkel dispensing equipmentRoom temperature<strong>Loctite</strong> ® 400D Benchtop Robot (50 ml Dual Cartridge Dispenser)Storage temperature 2 - 8 °C* HF8025R / HF8150R: under development

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 13Instant AdhesivesHalogen-free*Instant AdhesivesGeneralPurposeLight Cure Toughened Low Odor / Low Bloom<strong>Loctite</strong> ® Product HF382 HF4305 1 HF4307 1 435 1 438 1 HF480 HF403 HF460FeaturesPlastics• Highper<strong>for</strong>mancewire tacking 2• Rubber, plastic<strong>and</strong> metalbonding• Halogen-free*• Light (UV / visible)<strong>and</strong> moisture curemechanism• Fast cure with UVminimizes blooming• Rubber, plastic <strong>and</strong>metal bonding• Halogen-free*• Light (UV / visible)<strong>and</strong> moisture curemechanism• Fast cure with UVminimizes blooming• Positive under UVlight• Rubber, plastic <strong>and</strong>metal bonding• Halogen-free*• Surfaceinsensitive• Hightemperatureresistant• Rubber, plastic<strong>and</strong> metalbonding• Surfaceinsensitive• Hightemperatureresistant• Rubber, plastic<strong>and</strong> metalbonding• Surfaceinsensitive• Hightemperatureresistant• Rubber, plastic<strong>and</strong> metalbonding• Halogen-free*• Surfaceinsensitive• Rubber, plastic<strong>and</strong> metalbonding• Halogen-free*• Surfaceinsensitive• Low viscosity<strong>for</strong> close-fittingparts• Rubber, plastic<strong>and</strong> metalbonding• Halogen-free*SubstrateElastomersMetalsAcidic Surfaces3PolyolefinsColor Clear Clear / pale green Clear / pale green Clear Black Black Clear ClearViscosity High Medium Medium Low Low Low High LowTypical PropertiesMax Gap Fill (mm) 0.20 0.20 0.20 0.15 0.15 0.15 0.20 0.10Chemical Type Ethyl Ethyl Ethyl Ethyl Ethyl Ethyl Alkoxy AlkoxyViscosity (cP) 5,000 900 900 200 200 200 1,200 45Shear Strength (psi) 4 3,200 2,000 5 2,000 52,700 2,800 3,800 2,600 2,600Temperature Range (°C) -54 to 99 -40 to 80 -40 to 80 -54 to 107 -54 to 107 -54 to 82 -54 to 99 -54 to 99Fixture Speed (s) 630 < 5 < 5 30 30 90 50 50OrderingInfoItem Number 1653293 1675272 1675285 871787 871819 1658082 1659527 1659525Package Type / Size 20 g bottle 20 g bottle 20 g bottle 20 g bottle 20 g bottle 20 g bottle 20 g bottle 20 g bottleLEGEND= Good= Very Good= Good in Combination with <strong>Loctite</strong> ® 770 Primer1 Halogen-free* compliance available on request2 In combination with <strong>Loctite</strong> ® 712 or 7452 Accelerator3 Accelerator required4 For grit-blasted steel5 For polycarbonate6 Full cure = 24 hours without UV / VIS exposure; with UV / VIS exposure, see technical datasheets Fixture speed varies by substrate, gap <strong>and</strong> humidityProducts specifically designed to meet the halogen-free* specification.* Products whose halogen content has not been tested on a batch to batch basis. As batch variationsexist, some batches may there<strong>for</strong>e exceed the specified limits as set out under halogen-free definition.Henkel shall not be liable <strong>for</strong> any <strong>and</strong> all consequences (direct or consequential) resulting from (i) theabsence of test with regard to the halogen content or (ii) the products halogen content exceeding thespecified limits or (iii) batch to batch variations of the product.PLEASE NOTE: A complete line of surface primers, accelerators <strong>and</strong> cleaners is available tofurther enhance the per<strong>for</strong>mance of <strong>Loctite</strong> ® Instant Adhesives.The above in<strong>for</strong>mation is presented as a guideline only. Henkel recommends evaluating the selected product in your application to determine suitability.Henkel shall not be liable <strong>for</strong> any <strong>and</strong> all inaccuracy or omission which may exist in the actual test data generated by the <strong>for</strong>egoing a<strong>for</strong>ementioned third party laboratory.

14 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>OvermoldingAdhesivesOvermolding adhesives are primers or adhesion promoters used toenhance adhesion between multiple substrates during co-molding orinsert molding process.• The method replaces traditional assembly process to achieve a morecompact, light, seamless <strong>and</strong> elegant design.• <strong>Loctite</strong> ® overmolding adhesives can help to increase the adhesion strengthof the injected material to the parts surface.• Typical materials that can be processed are anodized aluminum, steel, TPU,certain plastics <strong>and</strong> glass surface.Selector GuideCharacteristics <strong>Loctite</strong> ® OM4501 <strong>Loctite</strong> ® OM4101 <strong>Loctite</strong> ® OM8200Vehicle Solvent based polyurethane Water based urethane Water based polyurethaneSolid content 50 ± 2% 40% 30 - 32%Color Clear to turbid, yellow to brown (to reddish) White WhiteViscosity(RVT #3 @ 20 rpm @ 25 °C)90 - 350 m·Pas(Brookfield LVT, spindle 2, 30 rpm at 20 °C)Remark 1 component 1 component2,100 cPs 10 - 15 cPsOM8200 can be used with OM5887 toenhance the aging resistance after cured.Mixing ratio 20 : 1 by weight

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 15Liquid Optically Clear AdhesivesTouch Panel Sensor AssemblyEnhance displays with superior per<strong>for</strong>mance<strong>and</strong> easy processability.Key Benefits• Improving the viewing experienceWith LOCA <strong>and</strong> A/R glass you can increase contrast ratioby 400% in sunlight. Henkel has minimized loss due toreflection by matching the refractive index (1.5) to glass <strong>and</strong>PMMA.• Increasing display ruggednessFor large gaps up to 1 mm, you can increase the falling ballimpact resistance by up to 3X.• Extending battery lifeBy reducing light loss due to reflection, the end user can geta superior viewing experience with less power consumptiongreatly extending battery life.• Extending display product lifeLOCA makes a display more durable to heat, moisture <strong>and</strong>temperature cycling.• Enabling thinner designsLOCA will absorb the impact of a given load when comparedto an assembly with an air gap, allowing <strong>for</strong> thinner designswhile protecting the display surface.Cover Lens <strong>Bonding</strong>Touch Panel SensorAssemblyDirect <strong>Bonding</strong>Cover LensPlastic / GlassLOCAITOPlastic / GlassLOCAITOPlastic / GlassLOCALCDModule

16 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>Equipment Selector GuideAcrylic AdhesivesH<strong>and</strong> HeldDesiredApplicationMethodManualPneumatic50 ml 200 ml/400ml 50 ml 200 ml 400 mlSolutionDispensePatternViscosityRange98472 1372751 97042 983437 983439/985249<strong>Loctite</strong> ® 50 ml DualCartridge Manual Applicator<strong>Loctite</strong> ® Universal ManualDispenser <strong>for</strong>200 ml/400 ml Cartridges<strong>Loctite</strong> ® 50 ml DualCartridge Pneumatic Applicator<strong>Loctite</strong> ® 200 ml DualCartridge Pneumatic ApplicatorDot, Bead Dot, Bead Dot, Bead Dot, Bead Dot, BeadLow - High High - Paste Low - High High - Paste High - Paste<strong>Loctite</strong> ® 400 ml DualCartridge Pneumatic ApplicatorDispensingCapabilityTwo-ComponentEpoxies, Urethanes,MethacrylatesTwo-ComponentEpoxies, Urethanes,MethacrylatesTwo-ComponentEpoxies, Urethanes,MethacrylatesTwo-ComponentEpoxies, Urethanes,MethacrylatesTwo-ComponentEpoxies, Urethanes,MethacrylatesPackageTypes & Sizes50 ml Dual Cartridge200 ml <strong>and</strong> 400 mlDual Cartridge50 ml Dual Cartridge 200 ml Dual Cartridge 400 ml Dual CartridgeFeatures• Provides a convenient, costeffectivemethod to applyproduct with minimal waste• Compatible with 1 : 1 <strong>and</strong>1 : 2 mix ratio products• 983533 - Replacement Plunger,1 : 1 Ratio• 983534 - Replacement Plunger,2 : 1 Ratio• 984209 - Optional Plunger,4 : 1 Ratio• 986086 - Optional Plunger,10 : 1 Ratio• Accepts 200 ml <strong>and</strong> 400 mltwo-component cartridges• Mix ratios of 1 : 1, 2 : 1,4 : 1 <strong>and</strong> 10 : 1• Interchangeable plungerbuttons allow application of allmix ratios• Dispenses low, medium <strong>and</strong>high viscosity materials• Lightweight, well balanceddesign <strong>for</strong> easy use• Pneumatic assist assuresreduced operator fatigue <strong>and</strong>consistent adhesive application• Integrated air pressure regulator• Conveniently positionedthumb wheel with 5 pressureadjustments to controldispense rate• Quick acting trigger insuresprecise bead control <strong>and</strong>minimizes product waste• Versatile cartridge holderaccepts dual 50 ml cartridgeswith 1 : 1, 2 : 1 <strong>and</strong> 10 : 1 ratios• Ideally suited <strong>for</strong> production lineapplications, these applicatorsprovide a convenient, costeffectivemethod <strong>for</strong> applyingproduct with minimal waste• The adjustable dispense rate isset via the integral air pressureregulator• Available <strong>for</strong> 1 : 1, 2 : 1 mix ratioproducts• Ideally suited <strong>for</strong> production lineapplications, these applicatorsprovide a convenient, costeffectivemethod <strong>for</strong> applyingproduct with minimal waste• The adjustable dispense rate isset via the integral air pressureregulator• Available ratios:983439: 1 : 1, 2 : 1985249: 10 : 1For more in<strong>for</strong>mation please contact us at: www.loctiteequipment.com or mail us at loctite.equipment@henkel.com.

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 17ManualH<strong>and</strong> HeldPneumaticLight Cure <strong>and</strong> Cyanoacrylate AdhesivesSemi - AutomaticDesiredApplicationMethod98026 1294304 97006 883976 1390321/1390322 98548<strong>Loctite</strong> ® 30 ml ManualSyringe Applicator<strong>Loctite</strong> ® Pneumatic H<strong>and</strong>-Held Cartridge Dispenser<strong>Loctite</strong> ® Precision SyringeDispensing System<strong>Loctite</strong> ® Digital SyringeDispensing System<strong>Loctite</strong> ® Integrated DispensingSystemDot, Bead Dot, Bead Dot, Bead Dot, Bead Dot, Bead Dot, BeadLow - High Medium - High Low - Paste Low - Paste Low - High 0 - 5,000 cP<strong>Loctite</strong> ® Benchtop PeristalticDispenserSolutionDispensePatternViscosityRangeAny Fluid in a 30 mlSyringe Including25 ml SyringesGel Cyanoacrylates,Anaerobic Gasketing,Thread <strong>Sealing</strong>,Light Cure / Acrylics, SiliconesGel Adhesives,Instant Adhesives,Light Cure / AcrylicsGel Adhesives,Instant Adhesives,Light Cure / AcrylicsCyanoacrylate,Anaerobic <strong>and</strong> UV AdhesivesInstant Adhesives,Light Cure / Acrylics,Retaining Compounds,ThreadlockersDispensingCapability30 ml Syringe300 ml Cartridge/250 ml Tube(Used with Tube Adapter)3 ml/5 ml/10 ml/30 ml/55 ml Syringe3 ml/5 ml/10 ml/30 ml/55 ml Syringe250 ml/500 g/1 Litre/2 kg AnyPackageTypes & Sizes• Pistol configuration <strong>for</strong>ease of application• Full-h<strong>and</strong> triggerminimizes operatorfatigue• Easy syringe loading• Smooth dispensing• Simple, quick operation• Built-in air pressureregulator allows <strong>for</strong>easy adjustment toaccommodate variousproduct viscosities• Rotating air hose fittingwith quick disconnectfitting included• Instant dump valve <strong>for</strong>pressure relief• Drawn aluminum barrel• Quick release end cap• For use with 250 ml tubes,order <strong>Loctite</strong> ® 250 mlSqueeze Tube Adapter989347• Precision air pressureregulator <strong>for</strong> preciseapplication of small dots• Precise digital display ofdispense pressure, 0 to100 psi• Digital timer display, <strong>for</strong>precise timer settings• Vacuum suck-backfeature to preventdripping <strong>and</strong> stringing• “St<strong>and</strong>-up” design,requires minimal benchspace• Detects ± 10% variationfrom set pressure <strong>and</strong>alerts operator if detected• Vacuum suck-backcan effectively controlproduct dripping orstringing• Manual, Incremental,<strong>and</strong> Timed modes allowa choice of adhesivedispensing methods• Convenient “teachmode” to set timerequired <strong>for</strong> desireddispense amount orvolume• Cycle counter is clearlydisplayed in the LCDscreen• The unit can beintegrated intocustomer’s PLCprogramming to initiatea dispense cycle• Units can be stackedsecurely to saveworkspace• Integrated reservoir &controller design <strong>for</strong> simplesetup <strong>and</strong> space economy• Operates 1 or 2 dispensevalves, independently orsimultaneously• Equipped with precisionpressure regulator <strong>for</strong>reliable dispensing,eliminating air pressurefluctuations• 1390321: 0 - 7 bar,<strong>for</strong> medium to high viscosity1390322: 0 - 1 bar,<strong>for</strong> low viscosity• Timer-controlled solenoidvalve <strong>for</strong> air-actuation ofdispense valve• Level sensor to give emptywarning, visual & digital• Air-free dispensingeliminates air in product,avoiding prematureproduct clogging ofcyanoacrylates• Instant reverse <strong>for</strong> vacuumsuck-back that shuts off theflow of liquid <strong>and</strong> preventsdripping• Adjustable post-delay time<strong>for</strong> vacuum setting• Simple <strong>and</strong> convenient loadmechanism provides <strong>for</strong>easy tube changes• Continuous or timed modeof dispense• Large digital LED display• Includes four (4) differentfeed line tubing sizes toaccommodate variousproduct viscositiesFeatures

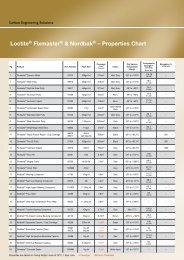

18 | <strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong>Product Selector Chart<strong>Loctite</strong> ®productProductfamilyAppearance Mix ratio Viscosity FixturetimeShear strength Max temp.Color Resin : Hardener cP psi (N/mm²) ºF (ºC)Products specifically designed to meet the halogen-free* specification. Each batch is tested to confirm halogen-free* compliance.3261 2-step AcrylicTransparent yellow tolight amber1 Component + Primer 7,500 < 15 seconds 1,450 (10.0) 230 (110)3662 2-step AcrylicTransparent yellow tolight amber1 Component + Primer 9,000 < 15 seconds > 1,500 (10.3) N/A3351 Acrylate Optical clear 1 Component 1,0005 seconds@ 100 mW/cm 2 1.1 Mpa (Tensile strength) N/AHF8075LV Acrylate Green 10 : 1Part A: 70,000 - 100,000Part B: 50,000 - 70,00060 seconds 2,038 (14.1) 251.6 (122)Acrylate Silicone10 seconds5121Optical clear 1 Component 4,300Hybrid@ 100 mW/cm 2 > 2.5 Mpa (Tensile strength) N/AAcrylate Silicone10 seconds5122Optical clear 1 Component 3,000Hybrid@ 100 mW/cm 2 > 2.5 Mpa (Tensile strength) N/A6485 Anaerobic Green 1 Component + Primer 525 5 minutes 3,300 (22.8) 350 (177)HF382 Cyanoacrylic Clear 1 Component 5,000 30 seconds 3,200 (22.1) 180 (82)HF403 Cyanoacrylic Clear 1 Component 1,200 50 seconds 2,600 (17.9) 180 (82)HF460 Cyanoacrylic Clear 1 Component 45 50 seconds 2,600 (17.9) 180 (82)HF480 Cyanoacrylic Black 1 Component 200 90 seconds 3,800 (26.2) 180 (82)HDD210294B Epoxy Green (mixed) 2 : 1 6,000 30 minutes 2,500 (17.2) 266 (130)3987 Heat Cure Epoxy Grey 1 Component 87,000 30 minutes @ 170 °C 3,300 (22.8) 390 (199)Light CureHF4305CyanoacrylateClear to pale green 1 Component 900 < 5 seconds 1,480 (10.2) 240 (116)Light CureHF4307CyanoacrylateClear to pale green 1 Component 900 < 5 seconds 1,480 (10.2) 240 (116)HF8150R Methacrylate Green 10 : 1 60,000 (Mixed) 60 seconds 3,800 (26.2) on An-Al to Mg-Al N/AHF8000 Methyl Methacrylate Green 10 : 1 N/A 5 - 10 minutes 2,912 (20.0) 230 - 300.2 (110 - 149)HF8000R Methyl Methacrylate Green 10 : 1 N/A 5 - 10 minutes 2,912 (20.0) 230 - 300.2 (110 - 149)HF8025 Methyl Methacrylate Green 10 : 1Part A: 160,000 - 250,000Part B: 20,000 - 50,00025 - 30 minutes 3,590 (24.8) 230 - 300.2 (110 - 149)HF8025R Methyl Methacrylate Green 10 : 1Part A: 160,000 - 250,000Part B: 20,000 - 50,00025 - 30 minutes 3,590 (24.8) 230 - 300.2 (110 - 149)HF8600 Methyl Methacrylate Light blue 2 : 1Part A: 15,000 - 30,000Part B: 15,000 - 30,0005 - 10 minutes 1,500 (10.3) 225 (107)HF8800 Methyl Methacrylate Light blue 2 : 1Part A: 18,000 - 40,000Part B: 18,000 - 40,0005 - 10 minutes 1810 (12.5) 225 (107)HF6005 Polyurethane Light Blue 1 : 2Part A: 300 - 1,100Part B: 90,000 - 215,0005 - 10 minutes 700 (4.8) N/A3541354235723573ME3570PolyurethaneHotmeltPolyurethaneHotmeltPolyurethaneHotmeltPolyurethaneHotmeltPolyurethaneHotmeltTransparent when molten,light ivory after coolingTransparent when molten,light ivory after coolingTransparent when molten,light ivory after coolingBlackTransparent when molten,light ivory after cooling1 Component1 Component1 Component1 Component1 Component11,000 ± 1,500 mPa·s@ 110 °C4,000 - 7,000 mPa·s@ 100 °C4,000 - 7,000 mPa·s@ 101 °C4,000 - 7,000 mPa·s@ 101 °C4,000 - 7,000 mPa·s@ 100 °C3193HS UV Acrylic Optical clear 1 Component 4,600 - 6,8003195 UV Acrylic Optical clear 1 Component 3,000 - 4,0003195DM UV Acrylic Optical clear 1 Component 38,000 - 44,0003196 UV Acrylic Optical clear 1 Component 3,200 - 4,200N/A1.3 Mpa (Cross Pull Test, PC + PC,Curing 24 Hours, 23 ± 5 °C <strong>and</strong>50% ± 5% RH)N/A0.8 Mpa (Cross Pull Test,N/ASS + Glass, Curing 24 Hours, N/A23 ± 5 °C <strong>and</strong> 50% ± 5% RH)1.5 Mpa (Cross Pull Test, PCABS +N/APMMA, Curing 24 Hours, N/A23 ± 5 °C <strong>and</strong> 50% ± 7% RH)1.5 Mpa (Cross Pull Test, PCABS +N/APMMA, Curing 24 Hours, N/A23 ± 5 °C <strong>and</strong> 50% ± 7% RH)1.6 Mpa (Cross Pull Test, PCABS +N/APMMA, Curing 24 Hours, N/A23 ± 5 °C <strong>and</strong> 50% ± 5% RH)< 5 seconds@ 70 mW/cm 2 > 0.5 Mpa (Tensile strength) N/A< 5 seconds@ 70 mW/cm 2 > 0.5 Mpa (Tensile strength) N/A< 10 seconds@ 70 mW/cm 2 > 0.2 Mpa (Tensile strength) N/A< 5 seconds@ 70 mW/cm 2 > 0.2 Mpa (Tensile strength) N/A

<strong>Bonding</strong>, <strong>Sealing</strong> <strong>and</strong> <strong>Coating</strong> <strong>Solutions</strong> <strong>for</strong> <strong>Mobile</strong> <strong>Devices</strong> | 19<strong>Loctite</strong> ®productProductfamilyAppearance Mix ratio Viscosity FixturetimeShear strength Max temp.Color Resin : Hardener cP psi (N/mm²) ºF (ºC)Products specifically designed to meet the halogen-free* specification. Each batch is tested to confirm halogen-free* compliance.3344 UV Cure Epoxy Straw 1 Component 17,500 < 3 seconds N/A 390 (199)3580UV Pre-activePolyurethaneHotmeltTransparent when molten,light ivory after cooling1 Component4,000 - 7,000 mPa·s@ 100 °C5192DM UV Silicone Optical clear 1 Component 40,000 - 60,0005192UV / Moisture CureSiliconeOptical clear 1 Component 4,0003192 UV / Thermal Acrylic Optical clear 1 Component 4,000 - 5,000General product line. Individual batch halogen-free* compliance available on request.N/A2.5 Mpa (Cross Pull Test, PCABS +PMMA, Curing 24 Hours,23 ± 5 °C <strong>and</strong> 50% ± 6% RH)N/A< 30 seconds@ 70 mW/cm 2 > 0.2 Mpa (Tensile strength) N/A< 30 seconds@ 70 mW/cm 2 > 0.4 Mpa (Tensile strength) N/A< 5 seconds@ 70 mW/cm 2 > 0.5 Mpa (Tensile strength) N/A3050 2-step Acrylic Yellow 2 : 1 75,000 17 minutes 2,900 (20.0) 400 (204)331 2-step Acrylic Cream 1 Component + Activator 20,000 20 seconds 3,100 (21.4) 350 (177)401 / 770 Cyanoacrylic Colorless to straw 1 Component 110 15 seconds 3,200 (22.1) 180 (82)420 Cyanoacrylic Clear 1 Component 2 20 seconds 2,900 (20.0) 180 (82)435 Cyanoacrylic Clear 1 Component 200 30 seconds 2,700 (18.6) 240 (116)438 Cyanoacrylic Black 1 Component 200 30 seconds 2,800 (19.3) 240 (116)454 Cyanoacrylic Clear 1 Component Gel 15 seconds 3,200 (22.1) 180 (82)480 Cyanoacrylic Black 1 Component 200 90 seconds 3,800 (26.2) 180 (82)Hotmelt ReactiveR-513CUrethaneCream 1 Component 15,000 @ 120 °C 5 minutes 900 (6.2) 250 (121)Light Cure4305CyanoacrylateClear to pale green 1 Component 900 < 5 seconds 1,480 (10.2) 240 (116)Light Cure4307CyanoacrylateClear to pale green 1 Component 900 < 5 seconds 1,480 (10.2) 240 (116)5055 Silicone Light yellow, transparent 1 Component 350 < 30 seconds 795 (5.5) N/A (High)5056 Silicone Light yellow, transparent 1 Component 1,800 < 30 seconds 900 (6.2) N/A (High)5623 Silicone Ultra clear 2 Components 7001 hour @ 25 °C10 minutes @ 100 °CN/A 350 (177)U-09FL Urethane Clear 1 : 1 5,000 120 minutes 1,459 (10.1) 350 (177)363 UV Acrylic Clear to pale straw 1 Component 250 < 15 seconds 1,740 (12.0) 356 (180)3103 UV AcrylicTransparent to slightlyhazy1 Component 10,000 5 seconds 1,600 (11.0) 300 (149)3106 UV Acrylic Clear to pale straw 1 Component 5,000 < 5 seconds 3,392 (23.4) 300 (149)LEGENDREACH= = =* Ask <strong>for</strong> products designed specifically to meet these st<strong>and</strong>ards.Products whose halogen content has not been tested on a batch to batch basis. As batch variations exist, some batches may there<strong>for</strong>e exceed the specified limits as set out under Halogen Free Definition, Henkelshall not be liable <strong>for</strong> any <strong>and</strong> all consequences (direct or consequential) resulting from (i) the absence of test with regard to the halogen content or (ii) the products halogen content exceeding the specified limitsor (iii) batch to batch variations of the product. Henkel offers halogen content certified batches on request.Henkel shall not be liable <strong>for</strong> any <strong>and</strong> all inaccuracy or omission which may exist in the actual test data generated by the <strong>for</strong>egoing a<strong>for</strong>ementioned third party laboratory.