Operating_instruction_CXEAVE_CXG-2448AVE.pdf - Systemair

Operating_instruction_CXEAVE_CXG-2448AVE.pdf - Systemair

Operating_instruction_CXEAVE_CXG-2448AVE.pdf - Systemair

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

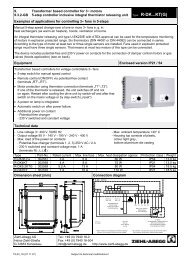

<strong>Operating</strong> <strong>instruction</strong>s Unicon type-lines CXE Date 0851UniconTyp CXE/AV(E) & <strong>CXG</strong>-24/48AV(E)Universal control moduleManufacturer: ZIEHL-ABEGG AGHeinz-Ziehl-StraßeD-74653 KünzelsauTelefon: +49 (0) 7940 16-0Telefax: +49 (0) 7940 16-504e-mail: info@ziehl-abegg.deinternet: http://www.ziehl-abegg.deSoftware D 1260A00 from version 1.07R-TBL05_33-GB 0851Part.-No 00163250-GBPage 1 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851Contents1. General...................................................................................................................................................................42. Safety measures ...................................................................................................................................................43. General description ..............................................................................................................................................53.1 Scope of applications............................................................................................................................................53.2 Technical data.......................................................................................................................................................53.3 Versions Unicon....................................................................................................................................................54. Installation .............................................................................................................................................................64.1 Wall-mounting, installation in a switching cabinet ................................................................................................64.2 Outdoor installation...............................................................................................................................................64.3 Installation location for agriculture ........................................................................................................................64.4 Temperature influences during commissioning ....................................................................................................64.5 Potential at control voltage connections ...............................................................................................................65. Electrical connections..........................................................................................................................................75.1 Mains connection + potential separation .............................................................................................................75.2 Signal cable (sensor cable) ..................................................................................................................................75.3 Signal connection to analog inputs (Analog IN1, Analog IN2, ..).........................................................................75.4 Output voltage 0-10 V (Analog OUT1 und Analog OUT2)....................................................................................75.5 Voltage supply for external devices (+24 V, GND)...............................................................................................75.6 Relay outputs (K1, K2)..........................................................................................................................................75.7 Digital inputs (D1 .. D3).........................................................................................................................................85.8 RS-485 interface for MODBUS.............................................................................................................................86. Controls .................................................................................................................................................................86.1 Multipurpose LC display........................................................................................................................................87. Jumper and/or switches for input signal............................................................................................................97.1 External Setpoint / External speed setting in manual operation.........................................................................108. Mode selection ....................................................................................................................................................118.1 Selection of the mode of operation .....................................................................................................................118.2 Menu operation ...................................................................................................................................................128.3 Setting Mode and menu language......................................................................................................................139. Programming.......................................................................................................................................................149.1 Speed controller 1.01..........................................................................................................................................149.1.1 Basic setting 1.01 ....................................................................................................................................................... 149.1.2 Setting for operation 1.01 ........................................................................................................................................... 149.1.3 Menu speed controller 1.01 ........................................................................................................................................ 159.2 Temperature control 2.01 .. 2.05 ........................................................................................................................179.2.1 Basic setting 2.01 .. 2.05 ............................................................................................................................................ 179.2.2 Settings for operation modes 2.01 .. 2.05 ................................................................................................................... 189.2.3 Functional diagrams temperature control ................................................................................................................... 199.2.4 For mode 2.03 temperature controller with additional functions: Signal output 0-10 V ............................................... 209.2.5 For mode 2.03 Relay output for Heating or Cooling.................................................................................................... 219.2.6 For mode 2.03 Relay output for temperature monitoring ............................................................................................ 229.2.7 Menu for temperature controller 2.01 ..2.05............................................................................................................... 239.3 Pressure control for condensers refirgeration 3.01 .. 3.04 ................................................................................259.3.1 Basic setting 3.01 .. 3.04 ............................................................................................................................................ 259.3.2 Setting for operation 3.01 .. 3.04................................................................................................................................. 269.3.3 Menu for pressure control refrigeration 3.01 .. 3.04 ................................................................................................... 279.4 Pressure control for ventilation systems 4.01..4.02............................................................................................299.4.1 Basic setting 4.01..4.03 .............................................................................................................................................. 299.4.2 Setting for operation modes 4.01 and 4.02................................................................................................................. 309.4.3 Menu for pressure control airconditioning 4.01 ..4.03 ................................................................................................ 319.5 Volume control 5.01, 5.02...................................................................................................................................339.5.1 Basic setting 5.01, 5.02 .............................................................................................................................................. 339.5.2 Setting for operation modes 5.01 and 5.02................................................................................................................. 349.5.3 Menu for air volume control 5.01 ..5.02 ...................................................................................................................... 35R-TBL05_33-GB 0851Part. No. 00163250-GBPage 2 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.6 Air velocity control 6.01.......................................................................................................................................379.6.1 Basic setting 6.01 ....................................................................................................................................................... 379.6.2 Settings for operation modes 6.01 .............................................................................................................................. 379.6.3 Menu for air velocity control 6.01 ................................................................................................................................3810. Menu group Start ..............................................................................................................................................4011. Menu group Info................................................................................................................................................4012. Controller Setup................................................................................................................................................4112.1 PIN Protection...................................................................................................................................................4112.2 Set protection....................................................................................................................................................4112.3 Save user settings ............................................................................................................................................4112.4 Sensor Alarm ON / OFF....................................................................................................................................4212.5 Limit...................................................................................................................................................................4212.6 Minimum speed cut off......................................................................................................................................4212.7 Second Group...................................................................................................................................................4312.8 Reverse action of the control function (actual Value>Set = n+) .....................................................................4312.9 Controller configuration (controller type) and controller action ).......................................................................4413. IO Setup .............................................................................................................................................................4513.1 Analog Outputs A1 and A2 ...............................................................................................................................4513.1.1 Function analog output A1 (Analog OUT 1) and A2 (Analog OUT 2)........................................................................ 4513.1.2 Adjustment analog output A1 and A2 ....................................................................................................................... 4613.2 Digital inputs D1 ..D3 ........................................................................................................................................4713.2.1 Enable ON / OFF function 1D .......................................................................................................................4713.2.2 External fault Function 2D ........................................................................................................................................ 4813.2.3 Limit ON / OFF Function 3D ..................................................................................................................................... 4813.2.4 Switch over E1 / E2 Funktion 4D ............................................................................................................................. 4813.2.5 Set Intern 1 / Set Intern 2 or. Setpoint 1/2 Function 5D ............................................................................................ 4913.2.6 Switch over: “Set Intern / “Set extern” or “Setpoint1” / “External Setpoint” = Function 6D ........................................ 5013.2.7 Automatic control / speed manual Funktion 7D ........................................................................................................ 5113.2.8 Reverse action of control function actual value>Set = n+ or actual value>Set = n- Funktion 8D ............................. 5113.2.9 Reset Function 10D.................................................................................................................................................. 5213.2.10 Setting “Max. Speed” ON / OFF function 11D ........................................................................................................ 5213.3 Inverting analog inputs E1 and E2....................................................................................................................5313.4 Function and inverting for relay outputs K1 and K2..........................................................................................5413.5 Network by MODBUS .......................................................................................................................................5514. Limits..................................................................................................................................................................5614.1 Limit indication depending on modulation.........................................................................................................5614.2 Limit indication depending on setting or sensor signal .....................................................................................5714.3 Limit indication depending on offset to Setpoint ...............................................................................................5815. Timer option with Z-modul-RTC ......................................................................................................................5915.1 Setting the time and date.................................................................................................................................5915.2 Automatic summer/winter time .........................................................................................................................5915.3 Timer function ...................................................................................................................................................5915.4 Enter switching times........................................................................................................................................6016. Diagnostics menu .............................................................................................................................................6117. Enclosure...........................................................................................................................................................6217.1 Connection diagram..........................................................................................................................................6217.2 Dimension sheet ...............................................................................................................................................6318. Events ................................................................................................................................................................6419. Messages and trouble shooting......................................................................................................................6420. Index...................................................................................................................................................................65R-TBL05_33-GB 0851Part. No. 00163250-GBPage 3 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08511. GeneralBefore installation and start-up, read this manual carefully to ensure a correct use.Attention! Hazardous area!Danger owing to electric current or voltage!Important information!• The copyright for these operating <strong>instruction</strong>s remains to ZIEHL-ABEGG AG, Künzelsau.• The device is constructed in accordance with the current state of technology and the recognised safety regulations.Nevertheless, use of the device is associated with dangers which may cause death or injury to users or third parties aswell as damage to the system and other objects.• The device is intended exclusively for the tasks listed in the order confirmation. Any other or extraordinary uses of thedevice (unless previously agreed by contract) are considered contrary to regulations. The manufacturer is not liable fordamages resulting from incorrect use. The operating company alone bears the risk.• To allow for future developments, construction methods and technical data given are subject to alteration. We do notaccept any liability for possible errors or omissions in the information contained in data, illustrations or drawingsprovided.• The controllers are packed ex factory to suit the transport method previously agreed. Always use the originalpackaging materials when transporting the controller. When transporting by hand, ensure that personnel possess thestrength required to lift and carry the device. Avoid shocks and impacts to the device. Check the packaging andcontroller for damage.• Store the controller in its original packaging in a dry and weather-proof room. The device must not be exposed toextreme heat and low temperatures.2. Safety measuresIn the case of a malfunction or a failure of the equipment check all functions with alarms in order to preventinjury to persons or property. Note possibility of back-up operation.If used in intensive animal environments, any malfunctions in the air supply must be detected as soon aspossible to prevent the development of a life-threatening situation for the animals. The design and installationof the system must comply with local regulations and directives. In Germany these include DIN VDE 0100, theanimal protection and the keeping of working animals ordinance and the pig-keeping ordinance etc.Also note the <strong>instruction</strong>s of AEL, DLG, VdS.• Apart from the operating <strong>instruction</strong>s and the obligatory regulations to be followed by users relating to accidentprevention, the recognised technical regulations must also be observed (safety and branch-related work as per UVV,VBG, VDE, etc.).• These devices are potentially dangerous if they are used incorrectly by untrained personnel or are not implementedaccording to their specified use.• Work on electric components/modules may only be carried out by trained electricians in accordance withelectro-technical regulations (e.g. EN 60204, DIN VDE 0100/0113/0160).• The contractor or owner must also ensure that the electric systems and equipment are operated and maintained inaccordance with electro-technical regulations. The owner is obliged to ensure that the device are operated in perfectworking order only.• It is forbidden to carry out work on electrically live parts. The rating given in the enclosure for the device whenopen is IP00! It is possible to inadvertently touch components carrying hazardous voltages!• During operation, the device must be closed or installed in a control cabinet.• Fuses may only be replaced by new ones and must not be repaired or bypassed. The data for the maximum line fuseare to be considered absolutely ( Technical data). Use only fuses specified in schematic diagrams.• The safe isolation from the supply must be checked using a two-pole voltage detector.• Any faults detected in the electric system/modules/operating equipment must be corrected immediately. If these faultsare not corrected, the device/system is potentially very dangerous. The device/system must therefore not be operatedwhen it is faulty.R-TBL05_33-GB 0851Part. No. 00163250-GBPage 4 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08514. Installation4.1 Wall-mounting, installation in a switching cabinet◦ For CXE/AV Housing version for wall mountingAssemble the device on a clean and stable base. Do not distort during assembly! Use the appropriate mountingdevices for proper installation of the unit!◦ For CXE/AVE for panel mountingThe installation cutout of the controller amounts to 159 x 99 mm ( dimensions). Stretch enclosed seal (O-ring) onfront frame. Bring the controller into the installation cutout and hang up you the enclosed clamps laterally.Subsequently, you screw the threaded rods with a screwdriver against the housing.◦ Do not mount equipment on vibrating base!◦ Install the device away from transport routes. However, ensure however that the device is still easily accessible!◦ Cable ducts must remain freely accessible!◦ Protect the device from direct exposure to sunlight!◦ The device is designed for vertical installation A reclined installation is only permissible after consultation with themanufacturer.4.2 Outdoor installationOutdoor installation is possible up to -25°C when the controller supply is not switched off.Installation must be protected from the effects of weather as much as possible, including protection from direct sunlight!4.3 Installation location for agricultureIn order to avoid damage caused by ammoniac vapours (NH 3 ), the controller shall not be installed in the stable, but ratherin an outhouse wherever possible.4.4 Temperature influences during commissioningAvoid condensation in the controller and hence functional faults attributable to condensation by storing the controller atroom temperature!4.5 Potential at control voltage connectionsThe control voltage connections (

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08515. Electrical connections5.1 Mains connection + potential separationIt must be strictly observed that the mains voltage lies within the allowable tolerance specifications ( Generaldescription: Technical data and nameplate affixed to the side).!• CXE/AV(E)Power from the mains is connected for version with 1~ 230 V to terminals: PE, L1 and N. Potential separationbetween the control voltage connections and line connection by internal transformator.Connection using a connector plug is also possible, “L1” and “N” are interchangeable. A connection between twophase conductors is possible for 3 ∼ 230 V supply networks.• <strong>CXG</strong>-48AV(E)Connection for voltage supply (48V DC or 24 V AC) to terminals (+) and (-).No potential separation between voltage supply and control voltage connections.• <strong>CXG</strong>-24AV(E)Connection for voltage supply (24 V DC) to terminals (+) and (-).No potential separation between voltage supply and control voltage connections.5.2 Signal cable (sensor cable)Pay attention to sufficient distance from powerlines and motor wires to prevent interferences.The control cables may not be longer than 30 m. Screened control cables must be used when the cable length is longerthan 20 m. When using a screened cable, the screen must be connected to the protective conductor at one end, i.e. onlyat the control unit (as short and of as low an inductance as possible!).5.3 Signal connection to analog inputs (Analog IN1, Analog IN2, ..)The unit has 2-analog inputs• Input 1 (Analog IN1) terminals „E1“ and „GND“• Input 2 (Analog IN2) terminals „E2“ and „GND“Ensure correct polarity when connecting; a 24 V DC power supply is integrated for sensors. For sensors in two-wiretechnology(4-20 mA signal), the connection is made on the +24 V and „E1“ or „E2“ terminals (the GND terminal isomitted).The connection is independent of the programmed operating mode and from the sensor signal employed.Place the internal switch or jumpers for the external default signal in the correct position (factory setting 0-10V).(Switch or jumpers for Input signal Pos. 7)5.4 Output voltage 0-10 V (Analog OUT1 und Analog OUT2)Analog output 1 (Analog OUT 1) is pre-programmed control outpute.g. for controlling a speed controller for fans.Connection to terminal „A1“ - „GND“ = Analog OUT (I max 10 mA)output A1 +0..10 V GNDe.g. Ziehl-Abegg speed controller1~ PAE10-M, PASTE6/103~ PKDT, PKDM, PXDM, FXDMEC EATE, ETXDFREvent, ETAvent0-100 %Analog output 2 (Analog OUT 2) is pre-programmed for contsant voltage +10 V. E.g. supply for external potentiometerconnection to terminals „A2“ - „GND“ = Analog OUT 2 (I max 10 mA)Both 0-10 V analog outputs can be allocated with various functions (IO Setup: Analog output A1 or A2).5.5 Voltage supply for external devices (+24 V, GND)A voltage supply is integrated for external devices, e.g., for a sensor. Terminal: +24 V DC max. load current 120 mA.Tolerance of output voltage for 230 V and 48 V version +/- 20 %. For 24V version directly depending on supply voltage.During an overload or short-circuit (24 V ↔ GND), the control voltage (and thus the controller) is disconnected(Multifuse). Automatic start after elimination of the cause of error.5.6 Relay outputs (K1, K2)Various functions can be allocated to the relay outputs K1 and K2( IO Setup: Function and inversion of the relay outputs). Max. contact load 5A / 250 V ACConnection of the floating contacts of relay K1 to the terminals 11, 14, 12Connection of the floating contacts of relay K2 to the terminals 21, 24, 22R-TBL05_33-GB 0851Part. No. 00163250-GBPage 7 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08515.7 Digital inputs (D1 .. D3)Various functions can be allocated to the digital inputs D1 ..D3( IO Setup: Functions summary of the digital inputs).Activation via floating contacts (a low voltage of ca. 24 V DC is connected).Never apply external voltage to the digital inputs!5.8 RS-485 interface for MODBUSThe device comes equipped via a RS-485 interface for networking via a MODBUS. The data connection lead isconnected to D+, D- and GND.You must ensure correct connection; i.e. „D+“ must also be connected on the following devices to „D+“.The same applies to „D-“.In addition, a GND connection must be established, as dissimilar potential (over 10 V!) will lead to thedestruction of the RS-485 interface (e.g. lightning).Connection at terminals of plug (D-, D+, GND). Do not use wire shield, pay attention to sufficient distance from powerlines and motor wires. Max. allowed wire length 1000 m.Recommended wire types:1. CAT5 / CAT7 cables2. J-Y (St) 2x2x0.6 (telephone wire)3. AWG22 (2x2 twisted pair)UniconUniconExamplesMODBUSThe data line must be conducted from one device into the next. No other type of wiring is allowed.Always use only two wires of one lead for the connection.When using telephone flex with four cable cores, we recommend the following allocation:“D+“ = red “D-“ = black “GND“ = whiteA maximum of 247 network users can be connected to the data bus .MODBUS6. Controls6.1 Multipurpose LC display1 Moon-Symbol for set point 22 Alarm-Symbol (fault indication)3 Fire-Symbol (heating operation)4 Antenna-Symbol (Remote-Control active)5 STOP-Symbol (enable)6 Bargraph (intern control output)7 Text line 3 figures (display unit, etc.)8 Text line 16 figures (display text menu.)9 Numeric display 5 digit91 2 3 4 5 6A B C78A P-key (program key, open menu)B arrow -down-key (Menu down, reduce value)C arrow-up-key (Menu up, increase value)DD ESC-key combination (↑ + ↓) Escape, leave menu)R-TBL05_33-GB 0851Part. No. 00163250-GBPage 8 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851n7. Jumper and/or switches for input signalJumper or sliding switches (depending on device version) position factory setting for 0 - 10 V signal. Fortemperature sensors (TF..) or sensors with 4 - 20 mA bring the internal jumper or sliding switches for theexternal signal in the correct position. Caution- not under voltage! Observe the savety notices! When using“other sensors” bring the jumper or switches in the correct position. A corresponding adaption of the type ofsignal and measuring range is necessary.• A = Version with jumper: „E1“ for input 1 and „E2“ for input 2• B = Version with switches: „E1“ for input 1, „E2“ for input 2AB°CmAE2E1VE2E1°CVmA°CVmA17.04.2008v_jumper_switch_cxe.VSDE1 Analog In (factory setting 0 - 10 V)E2 Analog In for modes with twosensorsTF.. (KTY)4-20 mA, (0-20 mA)0-10 VTF.. (KTY)4-20 mA, (0-20 mA)0-10 V0-10 VE2.1E2.2E2.1E2.2E1.1E1E1.2A E1 GND°CVmAE1.10-10 V TF..E1E1E1.2GND°CVmAE1.124VE1E1.2MBG..-IE1°CVmAE1.1E1E1.2DSG 0-10 V24V E1 GND°CVmAE1.1E1E1.2MAL 0-10 V24V E1 GND°CVmA°CVmAE2TF..E2 GND°CVmAE2MBG..-I24V E20-10 VTF..TF..10 k1BN3GNMBG..(4 -20 mA)BNYEDSG..(0 -10 V)WH13MAL1/10(0 -10 V)21BN3GNMBG..(4 -20 mA)16.05.2007v_stecker_schalter_e1.vsd16.05.2007v_stecker_schalter_e2.vsdR-TBL05_33-GB 0851Part. No. 00163250-GBPage 9 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08517.1 External Setpoint / External speed setting in manual operationExternal Setpoint or external manual operation is possible by 0 - 10 V (0 - 20 mA, 4 - 20 mA) Signal at terminals “E2”and “GND”.Place internal Jumper or switches E2 for Analog In 2 in correct position. “E2” Configuration in base setup. ForPotentiometer Analog Out2 (terminal “A2”) program to function 1A = “+10 V” (like factory setting IO Setup).Analog IN 2A E2 GND0-10 VAnalog IN 2E2.1 E2.2E2.1 E2.2E2°CVmA10 k16.05.2007v_extern_stecker_schalter_v.vsd16.05.2007v_extern_stecker_schalter_a.vsdE2°CVmAExternal Setpoint via external signal instead of “Setpoint 1”. The “external Setpoint” function must be activated in basesetup 1E for E2 function”. The active external Setpoint value is displayed in the “info” menu group.External speed settingThe “external manual operation” function must be activated in the basic settings 2E for E2| for “E2 function”.Switchover between settings on the device and external manual operation via the digital input ( IOSetup: “Internal / ExternalR-TBL05_33-GB 0851Part. No. 00163250-GBPage 10 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08518. Mode selection8.1 Selection of the mode of operationSimple installation is possible through the selection of the preprogrammed mode of operation. This determines the basicfunction of the device; factory setting 1.01 = speed controller (activation via 0-10 V signal).The controller configuration is automatically carried out during selection of the application related mode of operation. Thefactory presets in accordance with the mode of operation are based on many years of experience, which is suitable formany applications. Under special circumstances, these can be individually adapted ( Controller Setup: ControllerConfiguration).The purpose of the device is to reach and maintain the target values set. To accomplish this, the measured actual value(sensor value) is compared with the adjusted target value, and the controlled value (modulation) is deduced from this.ModeSignal or Sensor(input)Function1.01 Signal 0-10 V( E1) Speed controller, two step operation (factory setting)2.01 Sensor TF..(E1)Temperature control airconditioning and refrigeration (preset set-point 20.0 °C,P-band 5K)2.02 Sensor TF..(E2)Temperature control depending on outdoor temperature (preset set-point 5.0 °C, - P-band 20 K2.03 Sensor TF..(E1) Temperature control with additional functions (shutter and heating)1x Sensor TF..(E1)2.041x Sensor TF..(E2)Temperature control with two sensors, comparison or average1x Sensor TF..(E1)2.051x Sensor TF..(E2)Temperature control with two sensors differential temperature3.01 Sensor MBG.. (E1) Pressure control condensers (refrigeration)3.02 Sensor MBG..(E1) Pressure control for condensers with input for refrigerant3.033.041x Sensor MBG..(E1)1x Sensor MBG..(E2)1x Sensor MBG..(E1)1x Sensor MBG..(E2)Pressure control for two circuit condensersPressure control for two circuit condensers with input for refrigerant4.014.024.035.015.02Sensor DSG..(E1)1x Sensor DSG..(E1)1x Sensor TF..(E2)1x Sensor DSG..(E1)1x BUS RS 485Sensor DSG..(E1)1x Sensor DSG..(E1)1x Sensor TF..(E2)Pressure control for ventilation systemsPressure control depending on outdoor temperaturePressure control depending on outdoor temperature, MODBUS for outdoortemperature and remote control by central operating device type AXE-200Volume control (constant) for ventilation systemsVolume control with setpoint depending on outdoor temperature6.01 Sensor MAL.. (E1) Air velocity controlR-TBL05_33-GB 0851Part. No. 00163250-GBPage 11 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08518.2 Menu operationDisplay after turning on the mains voltageSwitch-over between Fanlevel and Start or actual value with the key shortcut for Escape (Esc = ↑ + ↓).Example for mode 1.01 (speed controller)+= EscOne reaches the menu item START by pushing the P key.One moves up and down within the menu group using thearrow keys.One returns to the menu group using the ESC (↑ + ↓)shortcut keys.Selection of the menu group to the right through the downkey, to the left through the up key.The menu groups consist of one area for the user (usermenu) and one area for installation (service).The service area can be protected against unauthorizedaccess by using a PIN.In order to simplify the initial start-up operation, the servicelevel is enabled at first (i.e., not protected by the PIN 0010,see Controller Setup, PIN protection = OFF).UserlevelPINServicelevelIf PIN protection is activated (ON), the service menu remainsenabled after input of PIN 0010 as long as one is pressingkeys. If no keys are pressed for ca. 15 minutes, the PIN isautomatically erased, i.e. the service level is blocked.After installation of the device has been carried out, PIN protection should be activated!R-TBL05_33-GB 0851Part. No. 00163250-GBPage 12 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08518.3 Setting Mode and menu language..User level Service levelPIN0010With OptionZ-Modul-RTC..............If necessary select menu language(factory default - English)Selection mode of operation(factory setting 1.01 = speed controller)Caution! When saving the operating mode, the respectivepreset factory operating-mode setting is loaded. That means,the settings you have made, e.g., in „IO Setup“ are lost. Anexception: the menu language setting remains preserved.R-TBL05_33-GB 0851Part. No. 00163250-GBPage 13 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519. Programming9.1 Speed controller 1.019.1.1 Basic setting 1.019.1.2 Setting for operation 1.01↓P ↑ ESC↓P ↑ ESC↓ ↑Factory setting Mode 1.01↓ ↑Manual speed settingSet Internal 1↓ ↑Factory setting 0-10 VSelection : 0-20 mA, 4-20 mA,BusInverting in IO Setup↓ ↑Set internal 2Swich over1/2 by external contactAnalog input 2 „E2“ factory set atOFF↓ ↑Minimal speed0 - 100 %• For operation with a second signal and switch over viafloating contact( IO Setup) set to function 1 E.• For operation with a second signal and automatic controlat the higher level. Set E2 Funktion to 4E.↓ ↑↓ ↑Maximal speed100% - Min.ON = (factory setting)speed setting by external signalOFF =Set internal 1Diagram default signal and output voltageIdealized principle diagram0-100% = 0-10V100 %Min. 0 % Max. = 100 %Min. = 35 % Max. = 85 %50 %Min.R-TBL05_33-GB 0851Part. No. 00163250-GBPage 14 / 65Signal0 1 2 3 4 5 6 7 8 9 10 0-10 V10 9 8 7 6 5 4 3 2 1 0 10-0 V0 2 4 6 8 10 12 14 16 18 20 0-20 mA20 18 16 14 12 10 8 6 4 2 0 20-0 mA4 5,6 7,2 8,8 10,4 12 13,6 15,2 16,8 18,4 20 4-20 mA20 18,4 16,8 15,2 13,6 12 10,4 8,8 7,2 5,6 4 20-4 mA

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.1.3 Menu speed controller 1.01StartS e ttin g In foEventsB ase setupController SetupParameterFactorysetting User SettingPIN Input .----LanguageGBResetOFFMode 1.01 Only DisplayUnicon 1.04Fanlevel 0%Set external1 0%Set Intern 1 80%Set Intern 2 .-----Min. Speed 0%Max. Speed 100%Set external 1 ONExternal Error ***INSTALLATIONMode 1.01E1 Analog IN 0-10V E2 FunctionE2 Function OFF 1E E1/E2 switch overE2 Analog IN .---- 4E E1/E2 autom. control to higher valuePIN Protection OFFSet protection OFFSave User Setup OFFLimit .----ON Value Group 2 .----nminm at Group 2 .----R-TBL05_33-GB 0851Part. No. 00163250-GBPage 15 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851Limits IO SetupTimer Option Z-Modul-RTCA1 Function2AA1 min.0.0 VA1 / A2 FunctionA1 max. 10.0 V 1A Constant voltage + 10VA1 Inverting OFF 2A proportional modulationA2 Function 1A 3A proportional signal E1A2 min. 0.0 V 4A proportional signal E2A2 max. 10.0 V 5A Group controlA2 InvertingOFFD1 FunctionOFFD1..D3 FunktionD1 Inverting .----- 1D Enable ON / OFFD1 Busmode .----- 2D External faultD2 Function OFF 3D Limit ON / OFFD2 Inverting .---- 4D Switch over Singnal E1/E2D2 Busmode .----- 5D switch over Intern 1 / 2D3 Function OFF 6D switch over:Set Intern / ExternD3 Inverting .---- 10D ResetD3 Busmode .---- 11D Setting max. Speed ON / OFFE1 InvertingOFFE2 Inverting .----K1 / K2 FunctionK1 Function 1K 1K Operation indicationK1 Inverting OFF 2K Fault indicationK2 Function 2K 3K external faultK2 Inverting OFF 4K Limit modulationBUS Address 247 5K Limit E1Addressing OFF 6K Limit E2Level. Function OFF 8K Group controlLevel min. .----Level max. .---- Limits (Lmt. Function)Level Delay .---- 1L Indication with centralized faultLmt E1 Function OFF 2L Indication as messageLmt E1 min. .---- 3L Indication "Filter" with centralized faultLmt E1 max. .---- 4L Indication "Filter" as messageLmt E1 Hyst. .----Lmt E1 Delay .----Lmt E2 Function .----Lmt E2 min. .----Lmt E2 max. .----Lmt E2 Hyst. .----Lmt E2 Delay .----Time 13:25Date 18.07 05Summertime Auto. OFFTimer Function OFFMonMon ON1 .--:--Mon OFF1 .--:--Mon ON2 .--:--Mon OFF2 .--:--Diagnostics Menu see chapter 16R-TBL05_33-GB 0851Part. No. 00163250-GBPage 16 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2 Temperature control 2.01 .. 2.059.2.1 Basic setting 2.01 .. 2.05↓P ↑ ESCFunction analog Input 2↓ ↑↓ ↑In all group 2 operating modes(2.01, 2.02, 2.03, ....)E1 analogue input IN factory setto „TF“Alternative selection “MTG120V”(aktive sensor with 0 - 10 V outputand proportional measuringrange: -10...+120 °C)• External setpoint = Function 1Eby external signal (0-10 V) instead of„Set point 1“For sensor type „E1 TF“..: 0-10 V ^ -27°C..+75.0°CFor sensors with active signal:0-10 V ^ 0-100 % sensor measuring range• External manual operation via external signal (0-10V) =function 2ESwitch over between settings on the device and externalmanual operation via digital input ( IO Setup).Alternative selection signal: 0-10 V, 0-20 mA, 4-20 mA,switch accordingly positon. The sensor measurementrangemust be entered in order to correctly display theactual value. Example with a0-10 V sensor and 0-100° C measurement rangeInitial value measuring rangeFinal value measuring rangeDecimal placesdisplay unit• Measurement value = function 7Ee.g. for limit indication, display in Info menu “E2 actual”• Modes with two sensorsThe function is automatically jointly programmed in operatingmodes using 2 sensors. The second analog input is thusallocated and additional function allocations are not possible.2.04E2 Function at 4E preprogrammed = comparison value withcontrol to higher temperature.alternative: average of 2 measuring points for this must bereprogrammed on function 3E preprogrammed sensor typeTF..2.05E2 Function at 5E preprogrammed = regulation ondifference temperature between sensor 1 and sensor 2.Preprogrammed sensor type TF..Sensor calibration with calibratedcomparison deviceR-TBL05_33-GB 0851Part. No. 00163250-GBPage 17 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2.2 Settings for operation modes 2.01 .. 2.052.01Temperature control2.02Temperature control depending on outdoor temperature2.03Temperature control with additional functions (heating, shutter, temp. monitoring)2.04Temperature control with two sensors.- comparison with control to higher value „E2 Function“ set to comparison 4EDisplay during operation: "Control value".- Alternative: Average calculation of 2 measuring placesDisplay during operation: "Average E1 / E2” („E2 Function“ set to 3E )2.05Temperature control with 2 sensors, regulation on difference temperatureDisplay during operation: "Value of E1 - E2 in K, E1 = reference temperatur, E2 causes positiv (E2E1) difference↓P ↑ ESCSetpoint 1Setting range: -27.0 .. 75°C↓ ↑↓ ↑↓ ↑↓ ↑Setpoint 2„Setpoint 2“ (factory setting OFF)e.g. reduced value for night operation. Switch over by digital input.(As long as no allocation has been carried out: Display: - - - - - IO Setup).Pband (Control range)The control response can be adjusted to the system conditions- small control range = greater amplification and shorter control times- big control range = longer control times and higher controller stabilitySetting range: 0-102,0 KMin. Speed „n-min“ (minimum output voltage )If required setting of a minimum output voltage e. g. basic speed (minimum airflow rate) of fans.Setting range: 0 % up to 100 % (or Max. speed).Max. Speed „n-max“ (maximum output voltage)If required setting of a maximum output voltage, e. g. speed limiter.Setting range: 100 % down to „Min speed“.↓ ↑↓ ↑Manual modeOFF = automatic control as function of the set parametersON = automatic control without function, speed setting in menu “Speed manual“Speed manualManual speed setting without influence by the external signalActivation by menu „Manual mode“ or external contact at digital input ( IO Setup).For information about deactivated regulation the adjusted value for manualspeed is indicated alternating with the actual valueR-TBL05_33-GB 0851Part. No. 00163250-GBPage 18 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2.3 Functional diagrams temperature controlExample 1:Temperature control in factory setting „Cooling function“ (Controller Setup: Ist>Soll= n+ ON)(Idealized principle diagram)1Modulation100 %Min.= 0 % Max. = 100 %Min. = 35 % Max = 85 %50 %Istwert / Actual20 °CSollwertSetpoint10 KRegelbereichPband30 °CExample 2 :Temperature control in „Heating function“ (Controller Setup: Ist>Soll= n+ OFF)(Idealized principle diagram)2Modulation100 %Max.Min. 0 % Max. = 100 %50 %Min.Min. = 35 % Max. = 85 %10 °C10 KRegelbereichPband20 °CSollwertSetpointIstwert / ActualR-TBL05_33-GB 0851Part. No. 00163250-GBPage 19 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2.4 For mode 2.03 temperature controller with additional functions: Signal output 0-10 VThe 0-10 V output signal can, e.g., be used for triggering a shutter or heating.↓ ↑The target value for this output is the target value (Setpoint) for the ventilation ±offset setting.Adjustment range ±10 K relative to the active Setpoint.Example for triggering a shutter servomotor:At factory setting „0 K“ = synchronous operation.The analog output is factory set to increasing activation during increasing temperature.Reprogramming to „Heating function“, i.e., increasing modulation during decreasing temperatureis possible ( IO Setup).Pband = separately adjustable range of control (P-band) for 0-10 V output↓ ↑Min Analog Out = Minimal output voltage, setting range 0-100 % = 0-10 V↓ ↑Max. Analog Out = Maximal output voltage, setting range 100-0 % = 10-0 VExample for signal out 0-10 V- Setpoint ventilation 25°C- Offset -5 K- Pband 10 KA2 10 V100 %Max. Analog OutMin. = 0 % Max. = 100 %Min. = 35 % Max. = 85 %50 %Min. Analog Out+/- Offset = 20 °CSollwertSetpoint10 KRegelbereichPband30 °CIstwert / ActualR-TBL05_33-GB 0851Part. No. 00163250-GBPage 20 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2.5 For mode 2.03 Relay output for Heating or CoolingOffset Digital Out = Offset for relay output (K2 is pre-programmed by the factory )The relay operating point deviates by the adjusted offset of the Setpoint of the ventilation (ifrelay K2 not inverted, terminal „21“-„24“ bridged).0.0 K set, i.e. heating „ON“ when: actual value = SetpointDuring negative offset value heating „ON“ when: actual value = Setpoint - offsetDuring positive offset value heating „ON“ when: actual value = Setpoint + offsetThe switching hysteresis of the relay is set to 1 K at factory Hyst. Digital Out.Example 1Temperature variation with factory setting 9 K in IO Setup e. g. for controlling a HeatingIf the ambient temperature is lower than the set operating point, the heating remains switched on. If the ambienttemperature exceeds the set operating point of the heating by 2 K, the heating is switched off. I.e., the release point issituated at the hysteresis value over the operating point.The activated heating is indicated over the fire symbol in the displayExample 2Temperature variation with reprogramming to 10K in IO Setup, e.g., for activation of the coolingIf the ambient temperature is higher than the set operating point, the cooling remains switched on.If the ambient temperature falls below the set operating point of the cooling by 2 K, it is switched off. I.e., the OFF point issituated at the hysteresis value under the ON point.IO Setup K2 Function for Heating = 9KExample 1: Setpoint 15°C, Offset +5K, Hysteresis 2 KExample 1: Setpoint 20°C, Offset -5K, Hysteresis 2 K[°C]3028262422201816141210ON = 15°C + 5K = 20 °C OFF = 20°C + 2K = 22 °C1 3 5 7 9 11 13 15 17 19 21 23 25 27 29[min]ONONON[°C]3028262422201816141210OFF= 15°C + 2K = 17 °C ON= 20°C - 5K = 15 °C1 3 5 7 9 11 13 15 17 19 21 23 25 27 29[min]ONONIO Setup K2 Function for Cooling = 10KExample 2: Setpoint 15°C, Offset +5K, Hysteresis 2 K[°C]30282624222018161412101 3 5 7 9 11 13 15 17 19 21 23 25 27 29[min]OFF= 20°C - 2K = 18 °CON= 15°C + 5K = 20 °CR-TBL05_33-GB 0851ON ON ONPart. No. 00163250-GBPage 21 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2.6 For mode 2.03 Relay output for temperature monitoringIf the set value for the minimum alarm is not reached or the set value for the maximum alarm is exceeded, a message isgenerated via the alarm symbol in the display. In addition, „Lmt E1 min“ is displayed alternately with the actual value forthe minimum alarm and Lmt E1 max for the „Maximum alarm“. An external message follows via the factory-assigned K1relay. (IO Setup : K1 function = 2K)↓ ↑Example for display if temperature is falling below setting „Alarm Minimum“Relay K1 disengages (if not inverted)11 14 12K1Example for display if temperature is exceeding setting „Alarm Maximum“Relay K1 disengages (if not inverted)11 14 12K1R-TBL05_33-GB 0851Part. No. 00163250-GBPage 22 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.2.7 Menu for temperature controller 2.01 ..2.05StartC o n tro lle r S e tu p Base setupEventsSettingIn foParameterfactory settingUser SettingPIN Input .---- .---- .---- .---- .----Language GB GB GB GB GBReset OFF OFF OFF OFF OFFMode 2.01 2.02 2.03 2.04 2.05Unicon 1.04 1.04 1.04 1.04 1.04 Only DisplayValue E1-E2-2.4°CControl value26.1°CE1 Actual 30°C 10°C 30.0°C 22.9°C 21.9°CE2 Actual .----- .----- .----- 26.1°C 24.3°CSetpoint 1 20.0°C 5.0°C 20.0°C 20.0°C 0.0°CFanlevel 0% 0% 0% 0% 0%Msco. OFF OFF OFF OFF OFFSetpoint 1 20.0°C 5.0°C 20.0°C 20.0°C 0.0°CSetpoint 2 .----- .----- .----- .----- .-----Pband 5.0 K 20.0 K 5.0 K 5.0 K 5.0 KMin. Speed 0% 0% 0% 0% 0%Max. Speed 100% 100% 100% 100% 100%Manual mode OFF OFF OFF OFF OFFSpeed manual 100% 100% 100% 100% 100%Offset AnalogOut 0.0KPband AnalogOut 2.0KMin. AnalogOut 0%Max. AnalogOut 100%OffsetDigitalOut-1.0KHyst.DigitalOut 1.0KAlarm Minimum0.0°CAlarm Maximum40.0°CExternal Error * * * *Sensor 1 * * * *INSTALLATIONMode 2.01 2.02 2.03 2.04 2.05E1 Analog IN TF TF TF TF TFE1 Min. .---- .---- .---- .---- .---- 2.01 Temperature controlE1 Max. .---- .---- .---- .---- .----E1 Decimals .---- .---- .---- .---- .---- 2.02 Temperature control depending on outdoor temperatureE1 unit .---- .---- .---- .---- .----E1 Offset 0.0K 0.0K 0.0K 0.0K 0.0K 2.03 Temperaturre control with additional functions:E2 Function OFF OFF OFF 4E 5E Heating, shutter, temp. MonitoringE2 Analog IN .---- .---- .---- TF TFE2 Min. .---- .---- .---- .---- .---- 2.04 Temperature control with two SensorsE2 Max. .---- .---- .---- .---- .---- comparison with control to higher valueE2 Decimals .---- .---- .---- .---- .---- average calculation of 2 measuring placesE2 Unit .---- .---- .---- .---- .----E2 Offset .---- .---- .---- 0.0K 0.0K 2.05 Temperature control of 2 sensorsPIN Protection OFF OFF OFF OFF OFF regulation on difference temperatureSet protection OFF OFF OFF OFF OFFSave User Setup OFF OFF OFF OFF OFFE2 FunktionAlarm Sensors OFF OFF OFF OFF OFF 1E 0-10 V external SetpointLimit .---- .---- OFF .---- .---- 2E external manual modeMsco. OFF OFF OFF OFF OFF 3E Sensor average to E1ON Value Group2 .---- .---- .---- .---- .---- 4E Sensor comparison to E1nminm bei Gruppe2 .---- .---- .---- .---- .---- 5E Sensor difference to E1Val>Set = n+ ON ON ON ON ON 6E Sensor for setpoint loweringType of control P P P P P (only for mode 4.02 and 5.02)KP 50% 50% 50% 50% 50% 7 E measurement value for indication and displayKI 50% 50% 50% 50% 50%KD 50% 50% 50% 50% 50%TI 0% 0% 0% 0% 0%R-TBL05_33-GB 0851Part. No. 00163250-GBPage 23 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851IO S e tu pLimitsTimer O ption Z-Modul-RTC2.01 2.02 2.03 2.04 2.05 User SettingA1 Function 2A 2A 2A 2A 2AA1 min. 0.0 V 0.0 V 0.0 V 0.0 V 0.0 VA1 / A2 FunctionA1 max. 10.0 V 10.0 V 10.0 V 10.0 V 10.0 V 1 A Constant voltage + 10VA1 Inverting OFF OFF OFF OFF OFF 2 A proportional modulationA2 Function 1A 1A 6A 1A 1A 3 A proportional signal E1A2 min. 0.0 V 0.0 V 0.0 V 0.0 V 0.0 V 4 A proportional signal E2A2 max. 10.0 V 10.0 V 10.0 V 10.0 V 10.0 V 5 A Group controlA2 Inverting OFF OFF OFF OFF OFF 6 A only 2.03 coolingD1 Function OFF OFF OFF OFF OFF 7 A only 2.03 HeatingD1 Inverting .----- .----- .----- .----- .-----D1 Busmode .----- .----- .----- .----- .-----D1..D3 FunctionD2 Function OFF OFF OFF OFF OFFD2 Inverting .---- .---- .---- .---- .---- 1 D Enable ON / OFFD2 Busmode .---- .---- .---- .---- .---- 2 D External faultD3 Function OFF OFF OFF OFF OFF 3 D Limit ON / OFFD3 Inverting .---- .---- .---- .---- .---- 4 D Switch over Singnal E1/E2D3 Busmode .---- .---- .---- .---- .---- 5 D switch over Setpoint 1 / 2E1 Inverting OFF OFF OFF OFF OFF 6 D switch over:Set Intern / ExternE2 Inverting .---- .---- .---- .---- .---- 7 D Controlling / Manual internK1 Function 1K 1K 1K 1K 1K 8 D switch over:ActualValue>Set=n+/n-K1 Inverting OFF OFF OFF OFF OFF 10D ResetK2 Function 2K 2K 9K 2K 2K 11D Setting max. Speed ON / OFFK2 Inverting OFF OFF OFF OFF OFFBUS Address 247 247 247 247 247Addressing OFF OFF OFF OFF OFFK1..K2 FunctionLevel. Function OFF OFF OFF OFF OFF 1 K Operation indicationLevel min. .---- .---- .---- .---- .---- 2 K Fault indicationLevel max. .---- .---- .---- .---- .---- 3 K external faultLevel Delay .---- .---- .---- .---- .---- 4 K Limit modulationLmt E1 Function OFF OFF 1L OFF OFF 5 K Limit E1Lmt E1 min. .---- .---- 0.0°C .---- .---- 6 K Limit E2Lmt E1 max. .---- .---- 40.0°C .---- .---- 7 K Setpoint OffsetLmt E1 Hyst. .---- .---- 1.0K .---- .---- 8 K Group controlLmt E1 Delay .---- .---- 2sec .---- .---- 9 K only 2.03 heating funktionLmt E2 Function .---- .---- .---- .---- .---- 10 K only 2.03 cooling functionLmt E2 min. .---- .---- .---- .---- .----Lmt E2 max. .---- .---- .---- .---- .----Lmt E2 Hyst. .---- .---- .---- .---- .----Lmt E2 Delay .---- .---- .---- .---- .---- Limits (Lmt. Function)Offset Function OFF OFF OFF OFF OFF 1 L Indication with centralized faultOffset 1 .---- .---- .---- .---- .---- 2 L Indication as messageOffset 2 .---- .---- .---- .---- .---- 3 L Indication "Filter" with centralized faultOffset Hyst. .---- .---- .---- .---- .---- 4 L Indication "Filter" as messageOffset Delay .---- .---- .---- .---- .----Time 13:25 13:25 13:25 13:25 13:25Date 18.07 05 18.07 05 18.07 05 18.07 05 18.07 05Summertime Auto. OFF OFF OFF OFF OFFTimer Function OFF OFF OFF OFF OFFMonMon ON1 .--:-- .--:-- .--:-- .--:-- .--:--Mon OFF1 .--:-- .--:-- .--:-- .--:-- .--:--Mon ON2 .--:-- .--:-- .--:-- .--:-- .--:--Mon OFF2 .--:-- .--:-- .--:-- .--:-- .--:--Diagnostics Menu see chapter 16R-TBL05_33-GB 0851Part. No. 00163250-GBPage 24 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.3 Pressure control for condensers refirgeration 3.01 .. 3.049.3.1 Basic setting 3.01 .. 3.04Function Analog Input 2↓P ↑ ESC↓ ↑For all Modes in Group 3 (3.01, 3.02, 3.03 ....)Analog input E1 factory setting to “MBG-30I”(measuring range 0-30 bar, proportional output 4-20 mA).Selection sensor: MBG-30I DSF2-25Alternative selection signal: 0-10 V, 0-20 mA, 4-20 mA,switch or jumpers accordingly positon. The sensormeasurement range must be entered in order to displaythe actual value correctly.Example: 0-10 V sensor and range 20 barInitial value measuring rangeFinal value measuring range• External setpoint = Function 1Eby external signal (0-10 V) instead of „Setpoint 1“0-10 V ^ sensor measuring range• External manual = function 2Eoperation via external signal (0-10V)Switch over between settings on the device and externalmanual operation via digital input( IO Setup).• Measurement value = function 7Ee.g. for limit indication, display in Info menu “E2 actual”• Modes with two sensorsThe function is automatically jointly programmed inoperating modes using 2 sensors. The second analoginput is thus allocated and additional function allocationsare not possible.3.04 + 3.03E2 Function at 4E preprogrammed = comparison value withcontrol to higher value (two circuit condensers).Decimal placesdisplay unitSensor calibration with calibratedcomparison device3.02 and 3.04 operating modes with refrigerant for use withZiehl-Abegg pressure sensor type MBG-30/50I or DSF2-25Upon input of the refrigerant, the device automaticallycalculates the corresponding temperature for themeasured pressure. The settings for offset, target valueand the controlling range are then carried out in °C or K.Calculation for relative pressure (differential measurementof pressure relative to ambient pressureNo further settings are necessary for pressure sensorsfrom Ziehl-Abegg model e.g. MBG-30I / 50I (measurementrange 0-30 / 0-50 bar). In the case of sensors with othermeasurement ranges, the „E1 Min value“ and the „E1 MaxValue“ must be entered. Setting in “bar” although display ofunit in °C. To do this, convert the bar values for min andmax into °C.Selection refrigerant :R12 R13 R13b1 R22 R23 R32 R114 R134a R142BR227 R401 R401A R401B R402 R402A R402B R404A R407AR407B R407C R410A R500 R502 R503 R507 R717R-TBL05_33-GB 0851Part. No. 00163250-GBPage 25 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.3.2 Setting for operation 3.01 .. 3.043.01 Pressure control condensers, Setpoint in bar3.02 Pressure control for condensers with input for refrigerant, Setpoint in °C3.03 t w o sensors for dual circuit condenser, automatic regulation to the highest pressure (selection amplifier integrated)operation display: „Control value“, Setpoint in bar3.04 t w o sensors for dual circuit condenser with input for refrigerant automatic regulation to the highest pressure(selection amplifier).Setpoint in °C , also for different refrigerants suitably there comparison of the temperatures. Display duringoperation: „Control value“↓P ↑ ESC3.01 and 3.03 setting in bar 3.02 and 3.04 input for refrigerant setting in °CSetpoint 1 (factory setting 12.0 bar)Setpoint 1 (factory setting 35.0.°CSetting range:Setting range:in measuring range of sensorin measuring range of sensorSetpoint 2Switch over 1/2 by external contact( IO SetupControl range „Pband“small range = great amplification andshort control timeBig range = longer control times(higher controller stability)Minimal speed0-100 %Setpoint 2Switch over 1/2 by external contact( IO SetupControl range „Pband“small range = great amplification andshort control timeBig range = longer control times (highercontroller stability)Minimal speed0-100 %Maximal speed100% - Min.Maximal speed100% - Min.OFF = automatic controlON = manual speed setting0 - 100%Manual speed setting0 - 100 % if manual mode = ONOFF = automatic controlON = manual speed setting0 - 100Manual speed setting0 - 100 % if manual mode = ONModulation100 %Modulation100 %n-min = 0% n-max = 100 %n-min = 0% n-max = 100 %50 %50 %actualactualPband 5 barSetpoint 12 bar(Idealized prinziple diagram)17 barSet point 35.0°C(Idealized prinziple diagram)Pband 7 K42.0 °CThe factory default presets must be adapted to match the system conditions by a competent person.R-TBL05_33-GB 0851Part. No. 00163250-GBPage 26 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.3.3 Menu for pressure control refrigeration 3.01 .. 3.04StartEvents SettingInfoBase setupC ontroller S etupParameterfactory settingUser SettingPIN Input .---- .---- .---- .----Language GB GB GB GBReset OFF OFF OFF OFFMode 3.01 3.02 3.03 3.04Unicon 1.04 1.04 1.04 1.04Control value 10.91 bar 22.6°CE1 Actual 10.00 bar 19.5°C 9.95 bar 19.4 °Conly displayE2 Actual .----- .----- 10.91bar 22.5°CSetpoint 1 12.00 bar 35.0°C 12.00 bar 35.0°CFanlevel 0 0 0 0Msco. OFF OFF OFF OFFSetpoint 1 12.00 bar 35.0°C 12.00 bar 35.0°CSetpoint 2 .----- .----- .----- .-----Pband 5.0 bar 7.0 K 5.00 bar 7.0 K 3.01 Pressure control condensersMin. Speed 0% 0% 0% 0% Setpoint in barMax. Speed 100% 100% 100% 100%Manual mode OFF OFF OFF OFF 3.02 Pressure control condensers with input for refrigerantSpeed manual 100% 100% 100% 100% Setpoint in °CExternal Error * * * *Sensor 1 * * * * 3.03 2 sensors for dual circuit condensersregulation to the highest actual value(selection amplifier integrated)Setpoint in barINSTALLATIONMode 3.01 3.02 3.03 3.04 User Setting 3.04 2 sensors for dual circuit condensers with input forE1 Analog IN 0-30 MBG 0-30 MBG 0-30 MBG 0-30 MBG refrigerant regulation to the highest actual valueE1 Refrigerant R507 R507 (selection amplifier integrated)E1 Min. .---- .---- .---- .---- Setpoint in °CE1 Max. .---- .---- .---- .---- also for different refrigerants suitablyE1 Decimals .---- .---- .---- .---- there comparison of the temperaturesE1 Unit .---- .---- .---- .----E1 Offset 0.00 bar 0.0K 0.00 bar 0.0KE2 Function OFF OFF 4 E 4EE2 FunctionE2 Analog IN .---- .---- 0-30 MBG 0-30 MBGE2 Refrigerant R507 1E 0-10 V external SetpointE2 Min. .---- .---- .---- .---- 2E external manual modeE2 Max. .---- .---- .---- .---- 3E Sensor average to E1E2 Decimals .---- .---- .---- .---- 4E Sensor comparison to E1E2 Unit .---- .---- .---- 0.0K 5E Sensor difference to E1E2 Offset .---- .---- 0.00 bar 0.0K 6E Sensor for setpoint loweringPIN Protection OFF OFF OFF OFF (only for mode 4.02 and 5.02)Set protection OFF OFF OFF OFF 7 E measurement value for indication and displaySave User Setup OFF OFF OFF OFFAlarm Sensors OFF OFF OFF OFFLimit .---- .---- OFF .----Msco. OFF OFF OFF OFFON Value Group2 .---- .---- .---- .----nminm bei Gruppe2 .---- .---- .---- .----Val>Set = n+ ON ON ON ONType of control P P P PKP 50% 50% 50% 50%KI 50% 50% 50% 50%KD 50% 50% 50% 50%TI 0% 0% 0% 0%R-TBL05_33-GB 0851Part. No. 00163250-GBPage 27 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851IO S etupTimer Option Z-Modul-RTC Limits3.01 3.02 3.03 3.04A1 Function 2A 2A 2A 2AA1 min. 0.0 V 0.0 V 0.0 V 0.0 VA1 / A2 FunctionA1 max. 10.0 V 10.0 V 10.0 V 10.0 V 1 A Constant voltage + 10VA1 Inverting OFF OFF OFF OFF 2 A proportional modulationA2 Function 1A 1A 6A 1A 3 A proportional signal E1A2 min. 0.0 V 0.0 V 0.0 V 0.0 V 4 A proportional signal E2A2 max. 10.0 V 10.0 V 10.0 V 10.0 V 5 A Group controlA2 Inverting OFF OFF OFF OFF 6 A only 2.03 coolingD1 Function OFF OFF OFF OFF 7 A only 2.03 HeatingD1 Inverting .----- .----- .----- .-----D1 Busmode .----- .----- .----- .-----D2 Function OFF OFF OFF OFFD1..D3 FunctionD2 Inverting .---- .---- .---- .---- 1 D Enable ON / OFFD2 Busmode .----- .----- .----- .----- 2 D External faultD3 Function OFF OFF OFF OFF 3 D Limit ON / OFFD3 Inverting .----- .----- .----- .----- 4 D Switch over Singnal E1/E2D3 Busmode .---- .---- .---- .---- 5 D switch over Setpoint 1 / 2E1 Inverting OFF OFF OFF OFF 6 D switch over:Set Intern / ExternE2 Inverting .---- .---- .---- .---- 7 D Controlling / Manual internK1 Function 1K 1K 1K 1K 8 D switch over:ActualValue>Set=n+/n-K1 Inverting OFF OFF OFF OFF 10D ResetK2 Function 2K 2K 2K 2K 11D Setting max. Speed ON / OFFK2 Inverting OFF OFF OFF OFFBUS Address 247 247 247 247Addressing OFF OFF OFF OFFK1..K2 FunctionLevel. Function OFF OFF OFF OFF 1 K Operation indicationLevel min. .---- .---- .---- .---- 2 K Fault indicationLevel max. .---- .---- .---- .---- 3 K external faultLevel Delay .---- .---- .---- .---- 4 K Limit modulationLmt E1 Function OFF OFF 1L OFF 5 K Limit E1Lmt E1 min. .---- .---- 0.0°C .---- 6 K Limit E2Lmt E1 max. .---- .---- 40.0°C .---- 7 K Setpoint OffsetLmt E1 Hyst. .---- .---- 1.0K .---- 8 K Group controlLmt E1 Delay .---- .---- 2sec .---- 9 K only 2.03 heating funktionLmt E2 Function .---- .---- .---- .---- 10 K only 2.03 cooling functionLmt E2 min. .---- .---- .---- .----Lmt E2 max. .---- .---- .---- .----Lmt E2 Hyst. .---- .---- .---- .---- Limits (Lmt. Function)Lmt E2 Delay .---- .---- .---- .---- 1 L Indication with centralized faultOffset Function OFF OFF OFF OFF 2 L Indication as messageOffset 1 .---- .---- .---- .---- 3 L Indication "Filter" with centralized faultOffset 2 .---- .---- .---- .---- 4 L Indication "Filter" as messageOffset Hyst. .---- .---- .---- .----Offset Delay .---- .---- .---- .----Time 13:25 13:25 13:25 13:25Date 18.07 05 18.07 05 18.07 05 18.07 05Summertime Auto. OFF OFF OFF OFFTimer Function OFF OFF OFF OFFMonMon ON1 .--:-- .--:-- .--:-- .--:--Mon OFF1 .--:-- .--:-- .--:-- .--:--Mon ON2 .--:-- .--:-- .--:-- .--:--Mon OFF2 .--:-- .--:-- .--:-- .--:--Diagnostics Menu see chapter 16R-TBL05_33-GB 0851Part. No. 00163250-GBPage 28 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.4 Pressure control for ventilation systems 4.01..4.029.4.1 Basic setting 4.01..4.03Function Analog Input 2↓P ↑ ESC↓ ↑• External setpoint = Function 1Eby external signal (0-10 V) instead of„Setpoint 1“0-10 V ^ sensor measuring range• External manual operation via external signal (0-10V) =function 2ESwitch over between settings on the device and externalmanual operation via digital input( IO Setup).Analog In E1 factory setting to DSG200Selection sensor measuring range: DSG 50, *DSG100DSG200, *DSG300 DSG500, DSG1000, DSG2000,DSG4000, DSG6000(* no Ziehl-Abegg standard type)For sensors with 0-20 mA, 4-20 mA signal put Switch orjumpers accordingly and select measuring range DSG50.. DSG6000.For not preprogrammed measuring range the sensormeasurement range must be entered in order to displaythe actual value correctly.Example with a 0-10 V sensor and 0-400 Pameasurement range (proportional output signal)Initial value measuring range• Measurement value = function 7Ee.g. for limit indication, display in Info menu “E2 actual”• Modes with two sensorsThe function is automatically jointly programmed inoperating modes using 2 sensors. The second analoginput is thus allocated and additional function allocationsare not possible.4.02E2 Function at 6E preprogrammed = sensor for setpointlowering.preprogrammed sensor type TF..4.03E2 Function at 6E preprogrammed = sensor for setpointlowering.- preprogrammed sensor type “BUS”- measuring range -35.0.. +65.0 °CFinal value measuring rangeDecimal placesdisplay unitSensor calibration withIn IO SetupFor enable ON / OFF via Bus- D1 function = 1D,- D1 Busmode = ONFor switch over setpoint 1 /2 via Bus- D2 function = 5D- D2 Busmode = ONcalibrated comparison deviceR-TBL05_33-GB 0851Part. No. 00163250-GBPage 29 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.4.2 Setting for operation modes 4.01 and 4.024.01 pressure control, setpoint in Pa4.02 + 4.03 Pressure control for ventilation systemssetpoint depending on outdoor temperature Setpoint inPa (hPa, mbar) and temperature in °C.↓P ↑ ESC↓ ↑↓ ↑↓ ↑Setpoint 1Setting range:in measuring range of sensorSetpoint 2Switch over 1/2 by externalcontact IO SetupControl range „Pband“small range = great amplificationand short control timeBig range = longer control times(higher controller stability)Additional menu item for mode 4.02 + 4.03 with outsidetemperaturedependent target-setpointAn outside temperature compensation can be activated(sensor connection E2 to analog IN 2) when being operatedas a pressure regulation device. An optimal building climate,e.g., can be achieved through this. Through this function, theset and active Setpoint1/2 is automatically changedproportional to the measured outside temperature ( Info:“Setpoint control“).↓ ↑↓ ↑Temperature range in which thesetpoint change continiously withoutside temperatureSetpoint reducing will start below thisoutside temperature (start point)Minimum pressure for very lowoutside temperatureMinimal speed0-100 %↓ ↑↓ ↑Maximal speed100% - Min.Setpoint 1↓ ↑OFF = automatic controlON = manual speed setting0 - 100 %Manual speed setting0 - 100 % if manual mode = ON50 %P-min SAOut door temp °C-15° Cmin. Temperature+15° CT-StartR-TBL05_33-GB 0851Part. No. 00163250-GBPage 30 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.4.3 Menu for pressure control airconditioning 4.01 ..4.03Info StartSettingEventsBase setupC ontroller S etupParameterfactory settingPIN Input .---- .---- .----Language GB GB GBReset OFF OFF OFFMode 4.01 4.02 4.02Unicon 1.04 1.04 1.04E1 Actual 88.7 Pa 88.7 Pa 88.7 PaE2 Actual .----- 21.0 °C 21.0 °CSetpoint 1 100.0 Pa 100.0 Pa 100.0 PaSetpint control 100.0 Pa 100.0 PaFanlevel 0 0 0Msco. OFF OFF OFFSetpoint 1 100.0 Pa 100.0 Pa 100.0 PaSetpoint 2 .----- .----- .-----Pband 100.0 Pa 100.0 Pa 100.0 PaMin. Speed 0% 0% 0%Max. Speed 100% 100% 100%Manual mode OFF OFF OFFSpeed manual 100% 100% 100%T-Band SD 30.0 K 30.0 KT-Start SD 15.0°C 15.0°CP-Min SD 70.0 Pa 70.0 PaExternal Error * * *Sensor 1 * * *User Settingonly displayINSTALLATIONMode 4.01 4.02 4.03 4.01 Pressure control airconditioningE1 Analog IN 200 DSG 200 DSG 200 DSGE1 Min. .---- .---- .---- 4.02 Pressure control depending on outdoor temperatureE1 Max. .---- .---- .----E1 Decimals .---- .---- .---- 4.03 Pressure control depending on outdoor temperature,E1 unit .---- .---- .---- MODBUS for outdoor temperature and remote controlE1 Offset 0.0 Pa 0.0 Pa 0.0 Pa by central operating device type AXE-200E2 Function OFF 6 E 6 EE2 Analog IN .---- TF BusE2 Min. .---- .---- -35.0 °CE2 FunctionE2 Max. .---- .---- 65.0 °C 1E 0-10 V external SetpointE2 Decimals .---- .---- .---- 2E external manual modeE2 unit .---- .---- .---- 3E Sensor average to E1E2 Offset .---- 0.0 K 0.0 K 4E Sensor comparison to E1PIN Protection OFF OFF OFF 5E Sensor difference to E1Set protection OFF OFF OFF 6E Sensor for setpoint loweringSave User Setup OFF OFF OFF (only for mode 4.02 and 5.02)Alarm Sensors OFF OFF OFF 7 E measurement value for indication and displayLimit .---- .---- .----Msco. OFF OFF OFFON Value Group2 .---- .---- .----nminm bei Gruppe2 .---- .---- .----Val>Set = n+ OFF OFF OFFType of control Pid Pid PidKP 50% 50% 50%KI 50% 50% 50%KD 50% 50% 50%TI 0% 0% 0%R-TBL05_33-GB 0851Part. No. 00163250-GBPage 31 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851Timer Option Z-Modul-RTC LimitsIO Setup4.01 4.02 4.03 User SettingA1 Function 2A 2A 2AA1 / A2 FunctionA1 min. 0.0 V 0.0 V 0.0 V 1 A Constant voltage + 10VA1 max. 10.0 V 10.0 V 10.0 V 2 A proportional modulationA1 Inverting OFF OFF OFF 3 A proportional signal E1A2 Function 1A 1A 1A 4 A proportional signal E2A2 min. 0.0 V 0.0 V 0.0 V 5 A Group controlA2 max. 10.0 V 10.0 V 10.0 V 6 A only 2.03 coolingA2 Inverting OFF OFF OFF 7 A only 2.03 HeatingD1 Function OFF OFF OFFD1 Inverting .----- .----- .-----D1 Busmode .----- .----- .-----D1..D3 FunctionD2 Function OFF OFF OFF 1 D Enable ON / OFFD2 Inverting .---- .---- .---- 2 D External faultD2 Busmode .----- .----- .----- 3 D Limit ON / OFFD3 Function OFF OFF OFF 4 D Switch over Singnal E1/E2D3 Inverting .---- .---- .---- 5 D switch over Setpoint 1 / 2D3 Busmode .----- .----- .----- 6 D switch over:Set Intern / ExternE1 Inverting OFF OFF OFF 7 D Controlling / Manual internE2 Inverting .---- .---- .---- 8 D switch over:ActualValue>Set=n+/n-K1 Function 1K 1K 1K 10D ResetK1 Inverting OFF OFF OFF 11D Setting max. Speed ON / OFFK2 Function 2K 2K 2KK2 Inverting OFF OFF OFFK1..K2 FunctionBUS Address 247 247 247Addressing OFF OFF OFF 1 K Operation indicationLevel. Function OFF OFF OFF 2 K Fault indicationLevel min. .---- .---- .---- 3 K external faultLevel max. .---- .---- .---- 4 K Limit modulationLevel Delay .---- .---- .---- 5 K Limit E1Lmt E1 Function OFF OFF OFF 6 K Limit E2Lmt E1 min. .---- .---- .---- 7 K Setpoint OffsetLmt E1 max. .---- .---- .---- 8 K Group controlLmt E1 Hyst. .---- .---- .---- 9 K only 2.03 heating funktionLmt E1 Delay .---- .---- .---- 10 K only 2.03 cooling functionLmt E2 Function .---- .---- .----Lmt E2 min. .---- .---- .----Lmt E2 max. .---- .---- .----Lmt E2 Hyst. .---- .---- .---- Limits (Lmt. Function)Lmt E2 Delay .---- .---- .---- 1 L Indication with centralized faultOffset Function OFF OFF OFF 2 L Indication as messageOffset 1 .---- .---- .---- 3 L Indication "Filter" with centralized faultOffset 2 .---- .---- .---- 4 L Indication "Filter" as messageOffset Hyst. .---- .---- .----Offset Delay .---- .---- .----Time 13:25 13:25 13:25Date 18.07 05 18.07 05 18.07 05Summertime Auto. OFF OFF OFFTimer Function OFF OFF OFFMonMon ON1 .--:-- .--:-- .--:--Mon OFF1 .--:-- .--:-- .--:--Mon ON2 .--:-- .--:-- .--:--Mon OFF2 .--:-- .--:-- .--:--Diagnostics Menu see chapter 16R-TBL05_33-GB 0851Part. No. 00163250-GBPage 32 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.5 Volume control 5.01, 5.029.5.1 Basic setting 5.01, 5.02↓P ↑ ESCFunction Analog Input 2↓ ↑↓ ↑For all modes in group 5 (5.01 and 5.02 ....)Analog In E1 factory setting to DSG200Selection sensor measuring range: DSG 50, *DSG100DSG200, *DSG300 DSG500, DSG1000, DSG2000,DSG4000, DSG6000(* no Ziehl-Abegg standard type)For sensors with 0-20 mA, 4-20 mA signal put Switch orjumpers accordingly and select measuring range DSG50.. DSG6000.• External setpoint = Function 1E by external signal(0-10 V) instead of „Setpoint 1“0-10 V ^ 0-100 % setting range• External manual operation via external signal (0-10V)= function 2ESwitch over between settings on the device andexternal manual operation via digital input( IO Setup).• Measurement value = function 7Ee.g. for limit indication, display in Info menu “E2 actual”• Modes with two sensorsThe function is automatically jointly programmed inoperating modes using 2 sensors. The second analoginput is thus allocated and additional functionallocations are not possible.5.02E2 Function at 6E preprogrammed = sensor for setpointlowering. Pre-programmed sensor type TF....Input of the K of factor dependent onthe fan (inlet duct)setting range 0..7.000Sensor calibration with calibratedcomparison deviceSetpoint 1Setpoint 250 %P-min SAOut door temperature °C-15° Cmin. Temperature+15° CT-StartR-TBL05_33-GB 0851Part. No. 00163250-GBPage 33 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.5.2 Setting for operation modes 5.01 and 5.025.01 Volume control, Setpoint in m3/h (m3/s)5.02 Volume control with setpoint depending on outdoortemperatureSetpoint in Pa (hPa, mbar) and temperature in °C.Additional menu item for mode 5.02 with outsidetemperaturedependent target-setpoint↓P ↑ ESC↓ ↑↓ ↑↓ ↑↓ ↑↓ ↑↓ ↑Setpoint 1Setting range:in measuring range of sensor and“K” factorSetpoint 2Switch over 1/2 by external contact( IO Setup)Control range „Pband“small range = short control timeBig range = longer control times(higher controller stability)Minimal speed0-100 %Maximal speed100% - Min.OFF = automatic controlON = manual speed setting 0 - 100%Manual speed setting0 - 100 % if manual mode = ONAn outside temperature compensation can be activated(sensor connection E2 to analog IN 2) when beingoperated as a pressure regulation device. An optimalbuilding climate, e.g., can be achieved through this.Through this function, the set and active Setpoint1/2 isautomatically changed proportional to the measuredoutside temperature ( Info: “Setpoint control“).↓ ↑↓ ↑Temperature range in which thesetpoint change continiously withoutside temperatureSetpoint reducing will start belowthis outside temperature (startpoint)Minimum air volume for very lowoutside temperatureR-TBL05_33-GB 0851Part. No. 00163250-GBPage 34 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 08519.5.3 Menu for air volume control 5.01 ..5.02Controller SetupBase setupEventsSettingInfo StartParameter factory setting User SettingPIN Input .---- .----Language GB GBReset OFF OFFMode 5.01 5.02Unicon 1.04 1.04E1 Actual 712 m3h 712 m3hE2 Actual .----- 21.0 °CSetpoint 1 530m3h% 530m3h%Setpint control530m3h%Fanlevel 0 0Msco. OFF OFFSetpoint 1 530m3h 530m3hSetpoint 2 .----- .-----Pband 530m3h 530m3hMin. Speed 0% 0%Max. Speed 100% 100%Manual mode OFF OFFSpeed manual 100% 100%T-Band SD30.0 KT-Start SD15.0°CP-Min SD70.0 PaExternal Error * *Sensor 1 * *only displayINSTALLATIONMode 5.01 5.02 5.01 Volume control (constant) for ventilation systemsE1 Analog IN 200 DSG 200 DSGE1 K-Factor 75 75E1 Min. .---- .---- 5.02 Volume control depending on outdoor temperatureE1 Max. .---- .----E1 Decimals .---- .----E1 unit .---- .----E1 Offset 0 m3h 0 m3hE2 Function OFF 6 EE2 Analog IN .---- TFE2 FunctionE2 K-Factor .---- 1E 0-10 V external SetpointE2 Min. .---- .---- 2E external manual modeE2 Max. .---- .---- 3E Sensor average to E1E2 Decimals .---- .---- 4E Sensor comparison to E1E2 unit .---- .---- 5E Sensor difference to E1E2 Offset .---- 0.0 K 6E Sensor for setpoint loweringPIN Protection OFF OFF (only for mode 4.02 and 5.02)Set protection OFF OFF 7 E measurement value for indication and displaySave User Setup OFF OFFAlarm Sensors OFF OFFLimit .---- .----Msco. OFF OFFON Value Group2 .---- .----nminm bei Gruppe2 .---- .----Val>Set = n+ OFF OFFType of control Pid PidKP 50% 50%KI 50% 50%KD 50% 50%TI 0% 0%R-TBL05_33-GB 0851Part. No. 00163250-GBPage 35 / 65

<strong>Operating</strong> <strong>instruction</strong>s type-lines CXE Date 0851IO SetupLimitsTimer Option Z-Modul-RTC5.01 5.02 User SettingA1 Function 2A 2AA1 / A2 FunctionA1 min. 0.0 V 0.0 V 1 A Constant voltage + 10VA1 max. 10.0 V 10.0 V 2 A proportional modulationA1 Inverting OFF OFF 3 A proportional signal E1A2 Function 1A 1A 4 A proportional signal E2A2 min. 0.0 V 0.0 V 5 A Group controlA2 max. 10.0 V 10.0 V 6 A only 2.03 coolingA2 Inverting OFF OFF 7 A only 2.03 HeatingD1 Function OFF OFFD1 Inverting .----- .-----D1 Busmode .----- .-----D1..D3 FunctionD2 Function OFF OFF 1 D Enable ON / OFFD2 Inverting .---- .---- 2 D External faultD2 Busmode .----- .----- 3 D Limit ON / OFFD3 Function OFF OFF 4 D Switch over Singnal E1/E2D3 Inverting .---- .---- 5 D switch over Setpoint 1 / 2D3 Busmode .----- .----- 6 D switch over:Set Intern / ExternE1 Inverting OFF OFF 7 D Controlling / Manual internE2 Inverting .---- .---- 8 D switch over:ActualValue>Set=n+/n-K1 Function 1K 1K 10D ResetK1 Inverting OFF OFF 11D Setting max. Speed ON / OFFK2 Function 2K 2KK2 Inverting OFF OFFK1..K2 FunctionBUS Address 247 247Addressing OFF OFF 1 K Operation indicationLevel. Function OFF OFF 2 K Fault indicationLevel min. .---- .---- 3 K external faultLevel max. .---- .---- 4 K Limit modulationLevel Delay .---- .---- 5 K Limit E1Lmt E1 Function OFF OFF 6 K Limit E2Lmt E1 min. .---- .---- 7 K Setpoint OffsetLmt E1 max. .---- .---- 8 K Group controlLmt E1 Hyst. .---- .---- 9 K only 2.03 heating funktionLmt E1 Delay .---- .---- 10 K only 2.03 cooling functionLmt E2 Function .---- .----Lmt E2 min. .---- .----Lmt E2 max. .---- .----Lmt E2 Hyst. .---- .----Limits (Lmt. Function)Lmt E2 Delay .---- .---- 1 L Indication with centralized faultOffset Function OFF OFF 2 L Indication as messageOffset 1 .---- .---- 3 L Indication "Filter" with centralized faultOffset 2 .---- .---- 4 L Indication "Filter" as messageOffset Hyst. .---- .----Offset Delay .---- .----Time 13:25 13:25Date 18.07 05 18.07 05Summertime Auto. OFF OFFTimer Function OFF OFFMonMon ON1 .--:-- .--:--Mon OFF1 .--:-- .--:--Mon ON2 .--:-- .--:--Mon OFF2 .--:-- .--:--Diagnostics Menu see chapter 16R-TBL05_33-GB 0851Part. No. 00163250-GBPage 36 / 65