Success Story - Hot-Mix Magazine

Success Story - Hot-Mix Magazine

Success Story - Hot-Mix Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

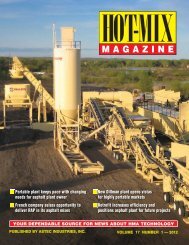

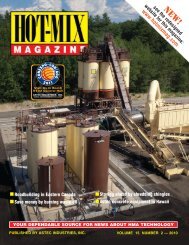

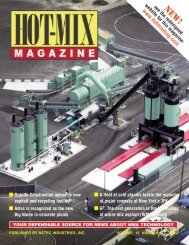

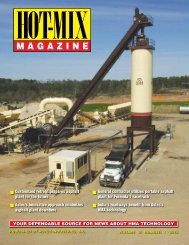

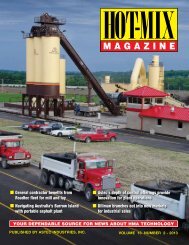

E&B Paving continuesU1U2U3 U4 U5HOT-MIX MAGAZINE 12 VOLUME 9, NUMBER 2

AKEY ELEMENT IN GROWTHis learning to understand thetechnology that is availablein your field of work and then touse that technology as often aspossible. For E&B Paving, Inc., oneof the technologies that helped thecompany achieve remarkablegrowth is the Astec Double Barrelhot-mix asphalt (HMA) plant. Andthe company has indeed usedthat technology often during itsgrowth: In recent years, E&BPaving has purchased eight ofthese state-of-the-art plants.The company got its start in 1968and it has been growingsteadily ever since that time.E&B Paving currently operates15 hot-mix asphalt plants...8 of which are Double Barrel ® plants.ture sensor at the discharge. The10 x 14-ft. (3 x 4.3-m) seven-bincold-feed system and a singlecompartmentrecycle feed systemgive the operation a variety ofaggregate options to choose from.“This new plant has somethingthat we have never had before: acomputerized inventory system,”he said. “We are just now startingto play with that feature, andwe find it to be great. Especiallywhen we compare it to the oldmanual method of keeping trackof inventory—we really like whatAstec has built into the load-outsystem for keeping track of ourproduction inventory.”been getting along with it verywell with no real problems.”Evans said that in the rare caseswhere they do encounter somekind of a problematic situation,Astec has always been availableto help resolve the issues. “TheAstec support is phenomenal,”said Evans. “They have been avery good partner for our firm.”In addition to the plant’s ease ofuse, Evans said he particularlyappreciates how quietly the Astecplant operates. “That really makesa difference to all of us,” he said.“Even though most of our plantsare tucked away in quarries, theyare still close to residential areas.I remember how loud the oldplants used to be—but this oneis quite a bit quieter. We find it tobe a big benefit.”E&B Paving maintains its headquartersin Anderson, Indiana.The company identifies itself as afull-service contractor, handling Once the mix is produced, it iscontracts for concrete as well as stored in the New Generationasphalt applications. The company Storage System, which includescurrently operates 15 HMA plants two 300-ton (272-tonne) silos.in Indiana. The addition of their They can add a third sile at aEvans also pointed to the Doublemost recent Astec Double Barrel future date. Each of the silos hasBarrel drum-mixer’s ability toa pattern of growth...came about after purchasing acompany that already had a fullyestablished operation in the FortWayne market. According to TonyEvans, vice president of E&BPaving, the old plant had outlivedits useful service life.“We knew the existing plant wouldneed to be replaced eventually,”said Evans. “It was a mixture ofdifferent components. They hadput together a drum from onemanufacturer and a baghousefrom another. I’m not sure exactlyhow you would have classifiedthat old plant.”The new HMA plant that took itsplace is classified as a 400 tph(363 tonnes per hour) M-Pack ®HMA plant from Astec, Inc. Itfeatures a relocatable 8 x 40-ft.(2.4 x 12.2-m) Double Barrel drummixerwith an infrared temperaelectric-blanketheat on the conesand hot-oil heat on the drag-slatconveyor. The cones and thebatcher each have ceramic lining.Another interesting feature of thenew plant is the presence of threeHeatec 30,000-gal. (113,560-L)vertical asphalt-storage tanks withheating coils and 6-in. (15-cm)of insulation. A Heatec helicalcoilhot-oil heater and 1,000-gal.(3,785-L) automatic calibrationtank are included in the plant’sliquid-asphalt-cement set up.The plant operations are run froma relocatable Command IA splitlevelcontrol center, with a ProcessMate 96 computer control system.The computerized control of theplant was a little challenging forthe operators at first, said Evans,but now they are realizing thebenefits of this new technology.Adjusting to the changes in thetechnology was something forwhich the plant’s crew was wellprepared. “Some of the controlsin the control center had theoperators a little taken back atfirst, I think,” said Evans. “Butthey have grown accustomed toit and they really excel at it.”A quick start-up of the new plantand a heavy usage ever since hasreally tested the crew’s ability toadapt and the plant’s ability toperform. Evans said both thecrew and the plant have risen tothe occasion. “We started the newplant right around the first ofAugust, and we have probablyrun double shifts out of it threefourthsof the time since then,”he said. “It has been very reliable.We have trained two operatorson it already—one for days andone for nights—and they havereduce the moisture content intheir aggregates as another majorbenefit for the company.“With the new volumetric specsthat we are seeing in Indiana andin the Superpave specifications, wehave to produce our mixes undermuch tighter guidelines than inthe past,” he said. “That includesmoisture guidelines. Limestonewill absorb moisture. If you don’tget that moisture out, then whenyou coat the rock with asphalt,the rock is hot enough that thewater will bleed out after the mixis produced—which can causedensity and stripping problems.“We have found that the AstecDouble Barrel drum-mixers do anexcellent job of getting the moistureout of the virgin aggregateso that those moisture problemsare avoided.” ▼▲▼The components of E&B Paving’s newest HMA plant represent a dependabletechnology base: [1] the Astec relocatable baghouse; [2] the Astec CommandIA split-level control center; [3] the Astec cold-feed bins; [4] the 900-ton(816-tonne) New Generation Storage System with electric-blanket heat onthe cones and hot-oil heat on the drag-slat conveyor; and [5] the relocatableAstec Double Barrel drum-mixer.FOR MORE INFORMATIONabout Astec’s HMA plants or storage silos, call Diane Hunt at Astec:423 - 867-4210Fax: 423-867-3570E-mail: dhunt@astecinc.comHOT-MIX MAGAZINE 13 VOLUME 9, NUMBER 2