Trash Flow Trash Pumps - Wastecorp Pumps

Trash Flow Trash Pumps - Wastecorp Pumps Trash Flow Trash Pumps - Wastecorp Pumps

- Page 2 and 3: New Installation or Direct Replacem

- Page 4 and 5: ®Why a Trash Flow ?107121152479816

- Page 6 and 7: Trash FlowSelf Priming Centrifugal

- Page 8: ®Trash Flow Engine Driven SeriesWh

- Page 11: Trash Flow Trash Pumps replaceGorma

New Installation or Direct ReplacementThe <strong>Wastecorp</strong> <strong>Trash</strong> <strong>Flow</strong>® is Your Answer.<strong>Wastecorp</strong> <strong>Trash</strong> <strong>Flow</strong> self priming centrifugal pump products are ideal for a multitude of solids handlingapplications and now replace almost any self priming pump make with no piping changes. The <strong>Trash</strong>-<strong>Flow</strong> isavailable in 3” (75 mm), 4” (100 mm), 6” (150 mm), 8” (200 mm) and 10” (250 mm) sizes with maximumcapacity to 3300 GPM (208.2 lps). Choose from standard cast iron designs or stainless steel and enginedriven mobile pump models for outdoor applications.All the Best Features In the IndustryAvailable in one Pump – The <strong>Trash</strong>-<strong>Flow</strong>.With its large volute design and superior re-priming capabilities,this <strong>Trash</strong> <strong>Flow</strong> series is designed for municipal andindustrial solids handling up to 3” (76 mm). Plus, pump modelsare available with stainless steel internals for food processingapplications.Easy Maintenance, Long Life cycles<strong>Trash</strong> <strong>Flow</strong> components can be adjusted and replaced to renewpump performance. No disassembly or shim requirements arenecessary.Back Pull-Out DesignThe <strong>Trash</strong> <strong>Flow</strong>’s back pull-out design enables maintenancestaff to quickly service the pump safely without the need forspecial tools.Clean-out PortOperators can easily inspect and service the clean-out withoutdraining the pump casing.See trash flow trash pumps on<strong>Wastecorp</strong>’s YouTube video channel.Follow us on Twitter, Flickr andFacebook.Quick Delivery ScheduleWith our state-of- the -art manufacturing process, <strong>Wastecorp</strong> isable to conquer the 16-20 week delivery schedule that has becomecommon at other manufacturers. On average <strong>Wastecorp</strong><strong>Trash</strong>-<strong>Flow</strong> products are available in five to six weeks for standardself priming products.<strong>Wastecorp</strong> <strong>Trash</strong> <strong>Flow</strong>® Quick Facts• Capacities to 3500 GPM• Heads to 135’ (41.2 m)• Temperatures to 160°F (71°C)• Pressures to 85 PSIG (586 kPa)• Suction lift to 25’ (7.6 m)• Spherical solids to 3 inches (76 mm)®1 T R A S H F L O W S E L F P R I M I N G C E N T R I F U G A L T R A S H P U M P S

Applications<strong>Trash</strong> <strong>Flow</strong> pumps are designed for a wide range of wastewaterand solids handling applications. With available impelleroptions and stainless steel self priming centrifugalmodels, there’s no job too tough for <strong>Wastecorp</strong>’s <strong>Trash</strong>-<strong>Flow</strong>. From industrial treatment plants, municipal solidshandling, settling ponds, remote sewage lift stations, onsitetreatment and more, <strong>Trash</strong> <strong>Flow</strong>’s are known for yearsof consistent and reliable pumping.<strong>Trash</strong> <strong>Flow</strong> pumpsare ideal for almostany municipal or industrialapplicationPaper and woodClarifier scum, drainage sumps, underflowto dewatering, coal pile run off, broke pits,paper machine floor sump, white waterservice, black liquor sump.Municipal Solids HandlingSolids handling applications includingwastewater treatment, slurries, sump andmore.Chemical | PetrochemicalDetergent cakes, coke slurries, refinerymud, oil waste, lead oxide slurry, stormdrains, sulfur froth.MiningAcid mine water, coal and sand washing,truck wash down, sand and gravel siltponds, mine dewatering, mill scale runoff,cutting oil transfer.Automotive | Steel FactoriesOil wash down, paint over spray, chromeplating slurries, mill scale, glass and plastic,roll grinder coolant.Theme Parks and ZoosWastewater pump house, themed attractions,general water sanitation services,lagoon water circulation.Orchards | WineriesFrom raw juices and high pulp content applicationsto wastewater, <strong>Trash</strong>-<strong>Flow</strong> pumpsare ideal for wineries and orchard pumpingapplications.Food ProcessingBlood, fleshings, pork, beef, poultry, fat,fish, potato, all vegetables, fish farming,aquaculture applications.EMPOWER YOUR PUMP APPLICATION. 2

®Why a <strong>Trash</strong> <strong>Flow</strong> ?1071211524798163123456PATENTED WASTECORP ADJUSTABLE WEARPLATE CARRIER (U.S. Patent 6,599,086)This unique design allows precise adjustment ofimpeller to wear ring tolerance. The <strong>Trash</strong>-<strong>Flow</strong>’sdesign reduces maintenance costs and canimprove overall pump efficiency without shimmingor premature wear plate replacement.UNIQUE AXIAL RIB DESIGNAxial ribs located on the inner stuffing box,prevent entrapment of solids and vapor nearthe mechanical seal.SOLIDS HANDLING IMPELLERConcentrically designed and computer-balancedimpellers are engineered to pass solids in excessof 50% of the inlet hole.ENLARGED BEARING HOUSINGThe oversized bearing housing gives unsurpassedshaft support, reducing roller bearing fatigue.REAR PUMP OUT VANESRear pump out vanes greatly reduce axial thrust andpressure increases pump performance and overallefficiency.QUICK CLEAN DESIGNThe back-pull design allows for removal of fullrotation assembly without disturbing plumbing. Italso permits replacement of wear plate and accessfor casing inspection.789101112ENLARGED CLEAN OUT PORTLarge sized clean-out holes allow for inspectionof inner casing by a simple twist of the handknobs (no special tools required).STAINLESS STEEL SHAFTING MATERIALThe enlarged shaft reduces deflection and shockloads at the mechanical seal to less than 0.003.CORROSION RESISTANT ROLLER BEARINGSThe oversized ball bearings are oil lubricated,requiring no external cooling and are designedto operate for a minimum of 120,000 hourswithout replacement.REPLACEABLE SUCTION FLAPPERThe heavy duty flapper valve is easily accessiblefor general inspection.FLANGED GAUGE CONNECTIONSStandard gauge connections in accordance toANSI standards allow for recording and monitoringsuction and discharge pressures with the use of<strong>Wastecorp</strong>’s selection of optional pressure gauges.CORROSION RESISTANT CASINGAll <strong>Trash</strong> <strong>Flow</strong>® pumps are designed with thickwalled casings to withstand abrasive sludge andslurries. Most models are available in a variety ofcastable materials, although®3 T R A S H F L O W S E L F PRIMING CENTRIFUGAL TRASH PUMPS

ProvenTrack Record<strong>Wastecorp</strong> <strong>Trash</strong> <strong>Flow</strong> pumps areknown throughout the pump industryfor their long life cycles and highperformance designs.Removable RotatingAssemblyExperience less downtime andmaintenance hassles with the<strong>Trash</strong> <strong>Flow</strong>’s removable rotatingassembly. The pump voluteand piping are not disturbedduring maintenance.Solids Handling Impellers<strong>Trash</strong> <strong>Flow</strong> pump feature our standardpremium two-vane solids handlingimpellers with solids handingcapabilities up to 3” (75mm).Optional Multi-vane ImpellerMulti-vane impellers are available forlow solids content applications or higherhead pumping jobs. These impellersoptimize suction lift and flow rates.Extended Life Mechanical Seals<strong>Wastecorp</strong>’s tungsten titanium carbidemechanical seals are designed for theharsh pumping conditions intoday’s municipal and industrialsolids handling jobs.Operator Friendly Back Pull-OutOptional Suction and DischargeGaugesMonitor operating pressure easilywith <strong>Wastecorp</strong>’s optional suctionand discharge gauges.The <strong>Trash</strong> <strong>Flow</strong>’s power end iscompletely outside of the pumpcasing allowing for easy removal.EMPOWER YOUR PUMP APPLICATION. 4

<strong>Trash</strong> <strong>Flow</strong>Self Priming Centrifugal <strong>Pumps</strong> Products®Sizes Max. Capacity Max. Head Max. temp Max. Solids3”, 4”, 6”, 8”, 10”(75 mm, 100 mm, 150,mm 200 mm, 250 mm)3500 GPM(220 lps)135’(41.2 m)160°F(71°C)3”(75 mm)3” 4” 6” 8” 10”<strong>Trash</strong> <strong>Flow</strong> <strong>Trash</strong> <strong>Flow</strong> <strong>Trash</strong> <strong>Flow</strong> <strong>Trash</strong> <strong>Flow</strong> <strong>Trash</strong> <strong>Flow</strong>Materials of ConstructionMain CasingA48CL30ImpellerA60-40-18Wear PlateSAE1020Cover PlateA48CL30Bearing Housing A48CL30Seal PlateA48CL30Flapper Valve NeopreneShaft SleeveANSI 4140HTInlet/Outlet Flanges A48CL30GasketsBunaImpeller Shaft ANSI 4140HTRemovable CoverplateEasily access the pump interiorwith the <strong>Trash</strong> <strong>Flow</strong>’s standardremovable coverplate. No specialtools are required for removal.Quick Prime FeatureThe <strong>Trash</strong> <strong>Flow</strong>’s quick primechamber can be accessed easilyand provides the connection forthe optional vac assist feature.Mechanical SealOil-Lubricated DoubleFloating, Casing and springSS316, O’rings in Buna &Viton, Faces in Titanium andTungsten Carbide®5 T R A S H F L O W S E L F PRIMING CENTRIFUGAL TRASH PUMPS

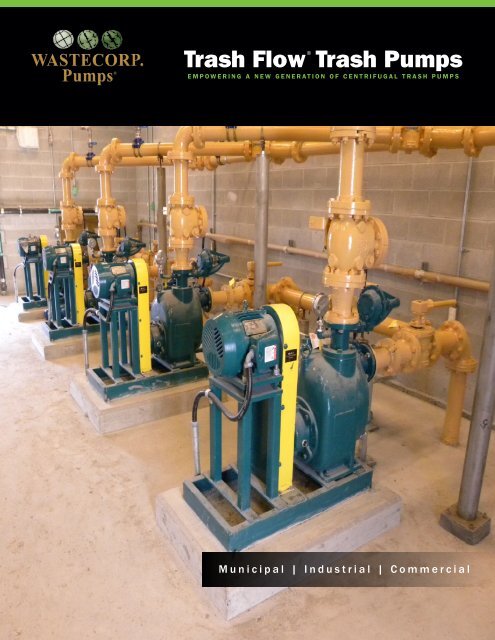

Multiple Configuration<strong>Trash</strong> <strong>Flow</strong> self priming centrifugalpump are available in standard, directflex coupled, horizontal belt drive, verticalbelt drive or as part of a packagedpump station.OptionsDirect Flex CoupledHorizontal Belt DriveVertical Belt Drive<strong>Trash</strong>-<strong>Flow</strong> TFCC-6 shown here ata municipal wastewater treatmentplant with a close coupled NEMAmotor.EMPOWER YOUR PUMP APPLICATION. 6

®<strong>Trash</strong> <strong>Flow</strong> Engine Driven SeriesWhen it comes to tough fluid handling applicationsaround your work site, <strong>Trash</strong>-<strong>Flow</strong> engine driven pumpsprovide self priming pumping power for many municipaland industrial applications. Select from trailer mounted,skid mounted or the <strong>Trash</strong> <strong>Flow</strong> Husher model for pumpingin residential areasAll diesel and gasoline units feature a large capacity fueltank allowing for 24 hour continuous operationwithout refueling. When it comes to engine selection,<strong>Wastecorp</strong> selects high performance and reputablebrands, proven to enhance fluid transferof all kinds. Additional features include the <strong>Trash</strong>-<strong>Flow</strong>’spatented adjustable wear plate carrier, large clean outport for easy maintenance, premium grade silicon carbideseals and your choice of impeller.<strong>Trash</strong> <strong>Flow</strong> engine driven pumps include a five year limitedprotection plan giving you complete confidence that<strong>Wastecorp</strong> <strong>Pumps</strong> is with you every step of the way.<strong>Trash</strong> <strong>Flow</strong> Trailer Mounted Options• 3” (75 mm), to 10” (250 mm) models available• Maximum capacity to 3300 GPM (208.2 lps)• Standard and compact belt driven configurations<strong>Trash</strong> <strong>Flow</strong> Skid Mounted• Available dry prime feature• Designed for drainage, industrial slurries,sewage and more• Engines available up to 85 hp<strong>Trash</strong> <strong>Flow</strong> Husher Silent Pumping Series• Fully Enclosed acousitical canopy hut• Noise levels below 70 dBa• Trailer or skid mounted (shown) models available<strong>Trash</strong> <strong>Flow</strong>® <strong>Trash</strong> Pump Engine Driven FeaturesSelect up to 85 hp gasor diesel engines fromPremium engine manufacturers.3” forged eye hook withsafety chain, complete withfront and rear swivel jacks.Vacuum assist option available for drypriming of pump.Lifting bail for easy mobilityaround your aroundyour work area.®7 T R A S H F L O W S E L F P R I M I N G CENTRIFUGAL TRASH PUMPS

Leadership in PumpManufacturing,Parts and ServicePump repair kits and parts for<strong>Wastecorp</strong> pumps and othermakes.Plunger <strong>Pumps</strong> Since 1928 Submersible Sewage <strong>Pumps</strong> Mud Sucker Diaphragm <strong>Pumps</strong>End Suction Centrifugal <strong>Pumps</strong> In line Circulation <strong>Pumps</strong> Horizontal Split Case <strong>Pumps</strong>More <strong>Pumps</strong> To Explore.TFXCommercial and Residential <strong>Trash</strong> <strong>Pumps</strong>ANSI/ISO Process <strong>Pumps</strong><strong>Trash</strong> <strong>Flow</strong> TFX contractor pumps serve the needs of contractors,homeowners and can be used as a back-up pump for any heavyduty application. You have the choice of 2” ( 50 mm), 3” (75 mm) and 4” (100mm) models with capacities to 425 GPM (27 lps). Select from gas, diesel andsingle phase or three phase electric models.

<strong>Trash</strong> <strong>Flow</strong> <strong>Trash</strong> <strong>Pumps</strong> replaceGorman Rupp T Series, Godwin, Goulds,Vaughn Chopper pumps, AMT pumps,Pioneer trash pumps and other makes.Contact factory for more information.North America: 1-888-829-2783Fax: 1-888-883-3320Worldwide: +1-201-445-2882Fax: +1-201-445-3252E-mail: info@wastecorp.comInternet: www.wastecorp.comContact:PUMPS DESIGNED FOR ONE APPLICATION. YOURS.Specifications, literature and illustrative material are accurate at the time ofpublication but are subject to change without notice.Illustrations may include optional equipment and accessories and may not includeall standard equipment. <strong>Trash</strong>-<strong>Flow</strong>, <strong>Wastecorp</strong> and globes are trademarks of WPCIEnvironmental Brands /<strong>Wastecorp</strong> <strong>Pumps</strong>. <strong>Wastecorp</strong> <strong>Pumps</strong> is the exclusive manufacturerof these brands. Marks are protected in North America and worldwide.© 2011 WPCI. All rights reserved. New York, NY 10024NYC/Brookl.Djs 8/11. Lithographed in the United States of AmericaFor a complete engineering specification on CD-ROM or hardcopy contact<strong>Wastecorp</strong> <strong>Pumps</strong> at 1.888.829.2783 or by E -mail: info@ wastecorp.com.Also on the web at http://www.wastecorp.com