SUPRApak L Series Filter Systems - AMCO Instruments, SRL

SUPRApak L Series Filter Systems - AMCO Instruments, SRL

SUPRApak L Series Filter Systems - AMCO Instruments, SRL

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

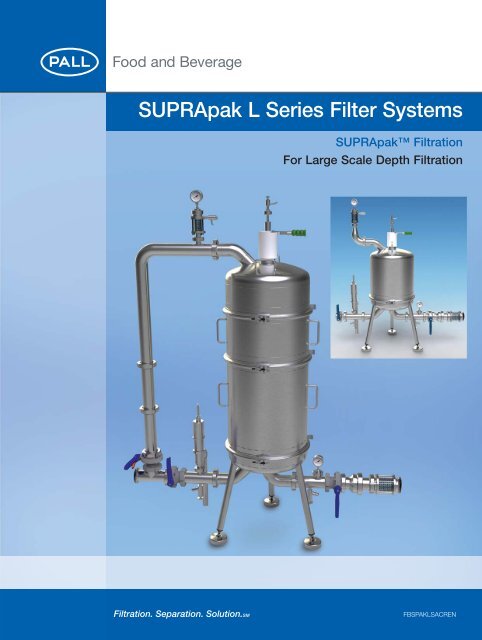

<strong>SUPRApak</strong> L <strong>Series</strong> <strong>Filter</strong> <strong>Systems</strong><strong>SUPRApak</strong> FiltrationFor Large Scale Depth FiltrationFBSPAKLSACREN

<strong>SUPRApak</strong> <strong>Series</strong><strong>SUPRApak</strong> L <strong>Series</strong>-SA <strong>Filter</strong> <strong>Systems</strong>Technical Information<strong>SUPRApak</strong> L <strong>Series</strong>-SA filtration units areturn-key systems designed for use with<strong>SUPRApak</strong> L filter modules. They revolutionizedepth filtration applications in the food andbeverage industry, providing a cost-effectivealternative to classical sheet filtration.Description<strong>SUPRApak</strong> L filtration units provide a closed system approach to highcapacity depth filtration, maximizing product protection and minimizingproduct losses. Lower cost of ownership is achieved due to higherthroughput, yield improvement, and reduced handling, cleaning,maintenance and downtime costs, when compared to sheet filtration.FeaturesClosed filtrationsystemInstallation packagewith standardaccessoriesCompact design withhigh filtration areaDrainable, low hold-upvolume assemblyHigh quality internalsurface finish, sanitaryand crevice-freedesignQuick release V-bandhousing closureFlexible modulardesignExternal tensioningdevice with presettorque limitDual inlet connectionson sizes exceeding3 modulesSimple, quickinstallation andservicing<strong>Filter</strong> module liftingdevice available onrequestATEX (94/9/EC) GroupII, Category 2documentation—by specific orderBenefits• Increased process safety andproduct quality; minimizedproduct losses, productcontamination risk andpersonnel exposure toprocess fluids• Turn-key installation allowsquick integration into existingsystem• Extremely high throughput atlow investment cost• Higher product yield;minimized cleaning costs• Enhanced cleanability• Ease of handling during filterchange-out and cleaning• Production volumes can bematched to equipmentcapacity; capability for futureexpansion• Provides secure operationwithout bypass• Minimizes product mixingzones• Reduced labor, maintenanceand downtime costs• Eases filter installation andremoval• Suitable for use in potentiallyexplosive environments<strong>SUPRApak</strong> L technology is ideal for use in distilled spirits, beer, sweetener,enzyme, gelatin, yeast extract, and other food and beverage applications.<strong>SUPRApak</strong> L <strong>Series</strong>-SA units provide a complete installation packageincluding standard accessories, which allows quick integration into anexisting system. They hold from one to six <strong>SUPRApak</strong> L modules,representing up to approximately 60 m 2 (646 ft 2 ) of filtration area in avery compact and low hold-up volume design. They are available eitherin single dome or flexible modular design.SpecificationsMinimum/MaximumDesign Pressure 1, 2Minimum/MaximumOperating Temperature 1Materials of ConstructionSealing Materials 3Internal Surface FinishInternal WeldsConnectionsHousingPipingInlet/OutletFeed FluidVentFiltrate Vent(optional)Drains – PipingDrain – SafetyValve<strong>Filter</strong> Module Compatibility 4Liquids: -1 to 8 barg (-14.5 to 116 psig)Gases: -1 to 3.5 barg (-14.5 to 50.8 psig)-10 to 150 °C (14 to 302 °F)Wetted parts 1.4404 (AISI 316L stainless steel)EPDM elastomer

WALTON ROAD, PORTSMOUTH, PO6 1TD U.K.SPLSA()()()()()ANON-HAZARDOUS GAS SERVICEp = -1/3.5 bar go-14.5/50.8 psi gt = -10/150 Co14/302 FNON-HAZARDOUS LIQUID SERVICEp = -1/8 bar go-14.5/116 psi gt = -10/150 Co14/302 FV =LUS Gal0038 II 2 GDPPORHSG-01-XWALTON ROAD, PORTSMOUTH, PO6 1TD U.K.SPLWA()()()()()()NON-HAZARDOUS GAS SERVICEp = -1/3.5 bar go-14.5/50.8 psi gt = -10/150 Co14/302 FNON-HAZARDOUS LIQUID SERVICEp = -1/8 bar go-14.5/116 psi gt = -10/150 Co14/302 FV =LUS Gal0038 II 2 GDPPORHSG-01-X<strong>SUPRApak</strong> L <strong>Series</strong>-SA <strong>Filter</strong> <strong>Systems</strong>Technical Information<strong>SUPRApak</strong> L <strong>Series</strong>-SA systems are supplied with standardaccessories, which include different components depending on thehousing height.Required space for dome/module removal1 to 3-High Housings:• An inlet and an outlet butterfly valve, a safety device with drainassembly, a feed fluid vent assembly including sight glass, vent andpressure gauge, a downstream drain assembly with pressure gauge,and a downstream non-return valve4 to 6-High Housings:ABCG• Two inlet and one outlet butterfly valves, a safety device with drainassembly, a vertical riser pipe with feed fluid vent assembly includingsight glass, vent and pressure gauge, a downstream drainassembly with pressure gauge, and a downstream non-return valveDFor additional accessories, see Optional Accessories.Nominal Dimensions in mm (inches) —For specific dimensions, please contact Pall 5 .L-100 L-200 L-300 L-400 L-520 L-630L-210 L-311 L-421 L-531 L-632L-320 L-430EFFigure 1: Dimensional information, 1 to 3-high housingsRequired space for dome/module removalA 1337 (52.6) 1827 ( 71.9) 2333 (91.9) 2870 (113) 3604 (141.9) 4113 (161.9)B 1017 (40) 1277 (50.3) 1537 (60.5) 1797 (70.7) 2057 (81) 2317 (91.2)C 872 (34.3) 1132 (44.6) 1392 (54.8) 1652 (65.0) 1912 (75.3) 2172 (85.5)D 6 320 (12.6) 320 (12.6) 320 (12.6) 320 (12.6) 320 (12.6) 320 (12.6)AE 7 600 (23.6) 600 (23.6) 600 (23.6) 794 (31.3) 794 (31.3) 794 (31.3)BCF 7,8 773 (30.4) 773 (30.4) 773 (30.4) 773 (30.4) 773 (30.4) 773 (30.4)G 457.2 (18) 457.2 (18) 457.2 (18) 457.2 (18) 457.2 (18) 457.2 (18)G5Pall Corporation reserves the right to make dimensional modifications at any time, maintaining the samefit, form, and function. Please request a general arrangement drawing if exact dimensions are required.6Adjustable (leg height adjustment)7Indicated dimensions are for installations requiring DIN connections. For installations requiring clampcoupling connections, an optional DIN-TC adaptor is additionally available. See Optional Accessories.If adaptors are added to the inlet and outlet connections, add 105 mm (4.1 in) for each adaptor.8Dimension includes optional pipeline sight glass. Subtract 162 mm (6.4 in) from this dimension forinstallations without sight glass.EFigure 2: Dimensional information, 4 to 6-high housingsFDVolume and Weight 9L-100 L-200 L-210 L-300 L-311 L-320 L-400 L-421 L-430 L-520 L-531 L-630Volume L 60 101 101 144 144 144 194 194 194 232 232 282(US gal) (15.9) (26.7) (26.7) (38) (38) (38) (51.3) (51.3) (51.3) (61.3) (61.3) (74.5)Weight kg 86 96 102 106 119 113 128 140 135 150 157 160(lb) (189.6) (211.6) (224.9) (233.7) (262.4) (249.1) (282.2) (308.6) (297.6) (330.7) (346.1) (352.7)9Volumes and weights include housing, pipework, standard accessories.Standard Documentation 10• Certificate of Conformity to Quality Standards • Final Inspection Certificate • Installation/Operating Manual (IOM)10Additional documentation packages can be ordered.Please request PPD004BRONZ, PPD004SILVER, or PPD004GOLD.

<strong>SUPRApak</strong> <strong>Series</strong><strong>SUPRApak</strong> L <strong>Series</strong>-SA <strong>Filter</strong> <strong>Systems</strong>Ordering InformationThis is a guide to the part numbering structure and possible options only.For availability of specific options, please contact Pall.Part Number: SPL SATable 1Note: See bold reference codes in the tables.Table 2 Table 3Example Part Number: SPLSA421TVATable 1CodeBowl Heightand ConfigurationNumber of<strong>SUPRApak</strong> Modules100 1-High Bowl 1200 2-High Bowl 2210 2-High Split Bowl 1 or 2300 3-High Bowl 3311 3-High Split Bowl 1, 2, or 3320 3-High Split Bowl 1 or 3400 4-High Bowl 4421 4-High Split Bowl 1, 2, 3, or 4430 4-High Split Bowl 1 or 4520 5-High Split Bowl 3 or 5531 5-High Split Bowl 1, 2, 4, or 5630 6-High Split Bowl 3 or 6632 6-High Split Bowl 1, 3, 4, or 6Optional AccessoriesPart No. Description DetailsACS1035AA Sight Glass DN 65 For filtrate side piping25590-0226 11 Hot Fluid Core 1.4404 (AISI 316L SS)25590-0226-01 11 Hot Fluid Core Extension Z1 1.4404 (AISI 316L SS)25590-0226-02 11 Hot Fluid Core Extension Z2 1.4404 (AISI 316L SS)ACS1036AA Hook Spanner DN 10-20ACS1037AA Hook Spanner DN 25-10020040118-12 1-2 High Lifting Device (incl. Stand) Supplied with spacer20040118-34 3-4 High Lifting Device (incl. Stand) Supplied with spacer20040118-56 5-6 High Lifting Device (incl. Stand) Supplied with spacerACS1034GMInlet/Outlet Adaptor (DN 65 – 2 ½ inchclamp coupling)Adaptor for pipingadaption from DN to ISO2852 clamp couplingconnection11For hot fluid filtration (>40 °C/ >104 °F) select Hot Fluid Core for the top module in the stackand add Hot Fluid Core Extension Z1 (1-high section) and/or Hot Fluid Core Extension Z2(2-high section) as required. A 1-high housing will only require the Hot Fluid Core.Table 2Code Filtrate Vent OptionTW No ventTV With vent, DN 6 hose tailTable 3Code ATEX DocumentationATEX (94/9/EC) Classification: Group II,ACategory 2, (Zones 1/21 and 2/22)DocumentationN No ATEX DocumentationFigure 3: Stainless steelcore for hot fluid filtrationFigure 4a (top): Lifting device enables insertion andremoval of the entire stack of modules. Figure 4b(bottom): Hooks on the lifting device grab the bottomof the <strong>SUPRApak</strong> module stack for easy handling.L-630 L-531 L-520 L-430 L-421 L-400 L-320 L-311 L-300 L-210 L-200 L-100Figure 5: Single and split bowl designs offer flexibility.

<strong>SUPRApak</strong> <strong>Series</strong><strong>SUPRApak</strong> L <strong>Series</strong>-SA <strong>Filter</strong> <strong>Systems</strong>Ordering InformationSpare PartsPart No. Description DetailsACS1038AA 12 Z1 Extension Extension piece onlyACS1030AM 12 Z1 Extension Kit Extension piece, V-band, O-RingACS1031AM 12 Z2 Extension Kit Extension piece, V-band, O-RingACS1032AM 12 Z3 Extension Kit Extension piece, V-band, O-RingACS1054AA 13 Riser Pipe 1-High Extension Kit1-high pipe extension, for 4 or5-high housings only, when requiredACS1055AA 13 Riser Pipe 2-High Extension Kit2-high pipe extension, for 4-highhousings only, when requiredACS1033AM Housing V-Band Kit Housing V-Band and O-RingACS1039EM Housing O-Ring EPDMACS0951AM Pressure Gauge DN 25 For feed fluid and filtrate sidesACS1045AASight glass DN 25 and Vent DN 6AssemblyKit including sight glass, feed fluidvent, pressure gaugeACS1047CA Butterfly Valve DN 65 For feed fluid and filtrate side pipingACS1035AA Sight Glass DN 65 For filtrate side pipingACS1049AA Non Return Valve DN 65 For filtrate side pipingACS1050EA DN65 Seal EPDM, for pipingACS1052EA DN25 Seal EPDM, for pressure gaugesACS1051EA DN32 Seal EPDM, for safety valveACS1046AA Vent Elbow DN65/DN25 For 1-3 high housings onlyACS1053AA Torque Unit (unvented) Torque unit without filtrate ventACS1040AA Torque Unit (vented) Torque unit with filtrate ventACS1041AA Torque Unit Rod Seal EPDMACS1042AA Torque WrenchACS1043AA Torque Unit Guide BushACS1044AA Torque Unit Clamp Nut12The PED Category 2 Module H classification limits the maximum allowable housing height to6-high. New extension additions, which result in 4 to 6-high housings will require the incorporationof a suitable riser pipe assembly. Please consult Pall for best options.13Order in conjunction with Z1 or Z2 extension kits for 4 or 5-high housings, to complete the riserpipe assembly.Vent elbowRiser pipeSight glass andvent assemblySight glass andvent assemblyFigure 6a (top) and 6b (bottom): The sightglass and vent assembly, mounted on thefeed fluid side of the housing, enablesventing of the installation at its highest point,upsteam pressure measurement, andvisualization of the feed fluid. The mountingconfiguration shown in Figure 6a is for 1 to3-high housings, and the one in Figure 6b isfor 4 to 6-high housings.FiltrateventFigure 7 (right): The torque unit is an externaltensioning device with preset torque limit, whichprovides reliable and secure operation withoutbypass. The optional filtrate vent, mounted onthe torque unit, enables release of air from thefiltrate inside the module core.TorqueunitPall Food and BeveragePallcommunicative name (optional)New York – USA+1 516 484 3600 telephone+1 866 905 7255 toll freefoodandbeverage@pall.comVisit us on the Web at www.pall.comPall Corporation has offices and plants throughout the world. For Pall representativesin your area, please go to www.pall.com/contactPlease contact Pall Corporation to verify that the product conforms to your nationallegislation and/or regional regulatory requirements for water and food contact use.Because of technological developments related to the products, systems, and/orservices described herein, the data and procedures are subject to change withoutnotice. Please consult your Pall representative or visit www.pall.com to verify thatthis information remains valid.© Copyright 2011, Pall Corporation. Pall and <strong>SUPRApak</strong> are trademarks of Pall Coporation.® Indicates a trademark registered in the USA. Filtration. Separation. Solution.SM is a service markof Pall Corporation.FBSPAKLSACREN October 2011