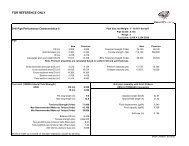

Operational Limits (Connection at Recommended MUT = 84600 ft-lbs)

Operational Limits (Connection at Recommended MUT = 84600 ft-lbs)

Operational Limits (Connection at Recommended MUT = 84600 ft-lbs)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Drill-Pipe Configur<strong>at</strong>ion<br />

Nominal Pipe Body OD<br />

Nominal Pipe Body Wall Thickness<br />

Pipe Body Grade<br />

Drill-Pipe Length<br />

Tool Joint<br />

Tool Joint OD<br />

Tool Joint ID<br />

Pin Tong<br />

Box Tong<br />

SlipProof Landing String R<strong>at</strong>ing (<strong>lbs</strong>) 2,446,400<br />

SlipProof Drill-Pipe Performance Sheet<br />

Warning: Weld cross sectional area is lower than acceptable. Note: <strong>Connection</strong> torsional strength is less than 80% pipe<br />

body torsional strength. Elev<strong>at</strong>or Capacity is weaker than tube in tension.<br />

(in) 6.625<br />

SlipProof Section Length (in) 72<br />

(in) 0.938<br />

Nominal Pipe Body Wall<br />

56.95<br />

UD-165<br />

Pipe Body Minimum Yield Strength (psi) 165,000<br />

Range2<br />

Pipe Body Minimum Ultim<strong>at</strong>e Tensile Strength (psi) 170,000<br />

6-5/8 FH<br />

Drill-Pipe Approxim<strong>at</strong>e Length<br />

(<strong>ft</strong>) 32.04<br />

(in) 8.688<br />

Upset IEU<br />

(in) 3.250<br />

Elev<strong>at</strong>or OD (in) 3/32 Raised<br />

(in) 11<br />

(in) 14<br />

Tool Joint Specified Minimum Yield Strength (psi) 135,000<br />

Based on: 90 % Inspection Class SlipProof, 90 % Inspection Class Pipe Body,<br />

tool joint <strong>at</strong> recommended make-up torque, elev<strong>at</strong>or OD, no applied drilling torque.<br />

SlipProof Section Slip Crushing Capacity<br />

SlipProof Section Slip Crushing Capacity (<strong>lbs</strong>) 3,064,700 2,695,500 2,338,400<br />

SlipProof Section Tensile Strength (<strong>lbs</strong>) 3,937,200 3,415,900 2,923,000<br />

Assumed Slip Length<br />

Transverse Load Factor (K)<br />

SlipProof Configur<strong>at</strong>ion ( 6.906 OD (in) 3.250 ID (in) 135,000 Min Yield (psi) )<br />

(in)<br />

20<br />

2.6<br />

SlipProof Section Specified Minimum Yield Strength (psi) 135,000<br />

Pipe Body Slip Crushing Capacity<br />

Slip Crushing Capacity<br />

Assumed Slip Length<br />

Transverse Load Factor (K)<br />

Drill-Pipe Performance<br />

(<strong>lbs</strong>)<br />

(in)<br />

20<br />

2.6<br />

Performance for Drill-Pipe with Pipe Body <strong>at</strong><br />

90 % Inspection Class<br />

Applied Make-up Applied Drilling Max Tension<br />

Torque (<strong>ft</strong>-<strong>lbs</strong>) Torque (<strong>ft</strong>-<strong>lbs</strong>)<br />

(<strong>lbs</strong>)<br />

84,600<br />

0<br />

84,600<br />

2,446,400<br />

2,341,700<br />

82,700<br />

0<br />

2,446,400<br />

2,346,500<br />

82,700<br />

<strong>Recommended</strong> Make-up Torque 84,600<br />

Minimum <strong>Recommended</strong> Make-up Torque 82,700<br />

Nominal 90 % Inspection Class 80% Inspection Class<br />

Note: Slip manufacturer should provide Slip Length and Transverse Load Factor.<br />

Note: Slip crushing calcul<strong>at</strong>ion from Spiri Reinhold, Why Does Drill Pipe Fail in the Slip Area,<br />

World Oil 1959.<br />

Pipe Body Configur<strong>at</strong>ion ( 6.625 OD (in) 0.938 Wall (in) UD-165 )<br />

Nominal 90 % Inspection Class API Premium<br />

2,174,100 1,937,900<br />

1,705,500<br />

Note: Slip manufacturer should provide Slip Length and Transverse Load Factor.<br />

Note: Slip crushing calcul<strong>at</strong>ion from Spiri Reinhold, Why Does Drill Pipe Fail in the Slip<br />

Area, World Oil 1959.<br />

Drill-Pipe Adjusted Weight<br />

Fluid Displacement<br />

Fluid Capacity<br />

Fluid Capacity<br />

Dri<strong>ft</strong> Size<br />

Drill-Pipe Length Range2<br />

(<strong>lbs</strong>/<strong>ft</strong>)<br />

(gal/<strong>ft</strong>)<br />

(gal/<strong>ft</strong>)<br />

(Bbls/<strong>ft</strong>)<br />

(in)<br />

Best Estim<strong>at</strong>es<br />

(without Co<strong>at</strong>ing) (with Co<strong>at</strong>ing)<br />

75.72<br />

1.157<br />

0.759<br />

0.753<br />

0.01807 0.01793<br />

3.125<br />

Note: Drill pipe assembly values are best estim<strong>at</strong>es and may vary due to pipe body mill tolerance, internal plastic<br />

co<strong>at</strong>ing, and other factors.<br />

Note: Oil field barrel equals 42 US gallons.<br />

Tool Joint Performance 6-5/8 FH ( 8.688 X 3.250 ) 135,000<br />

Tension <strong>at</strong> Shoulder Tension <strong>at</strong> <strong>Connection</strong> Tool Joint Dimensions<br />

Tool Joint Torsional Strength<br />

Applied Make-up<br />

Torque<br />

Separ<strong>at</strong>ion<br />

(<strong>ft</strong>-<strong>lbs</strong>)<br />

Yield<br />

(<strong>lbs</strong>) (<strong>lbs</strong>)<br />

3,063,200 3,063,200<br />

3,130,100 3,132,700<br />

Note for TurboTorque connections: Turbo Make-up Torque is an acceptable increased make-up torque if additional torque is required for drilling.<br />

(in) (in) (psi)<br />

Bevel Diameter (in) 7.703<br />

Balanced OD (in) 8.691<br />

Minimum Tool Joint OD for API<br />

Premium Class<br />

(in)<br />

Not Applicable<br />

165,400 Tool Joint Tensile Strength<br />

3,132,700<br />

(<strong>ft</strong>-<strong>lbs</strong>) (<strong>lbs</strong>)<br />

Elev<strong>at</strong>or Shoulder Inform<strong>at</strong>ion<br />

Box OD <strong>at</strong> Elev<strong>at</strong>or (no wear) 8.875<br />

Elev<strong>at</strong>or OD Nominal Tool Joint Worn to Bevel<br />

3/32 Raised<br />

OD<br />

Diameter<br />

Box OD (in) 8.875<br />

8.688 7.703<br />

Not Applicable<br />

Elev<strong>at</strong>or Capacity<br />

(<strong>lbs</strong>) 2,536,200<br />

2,251,500 856,100<br />

0<br />

Assumed Elev<strong>at</strong>or Bore<br />

(in) 7.031<br />

(in)<br />

Worn to Min TJ OD for<br />

API Premium Class<br />

Note: Elev<strong>at</strong>or capacity based on assumed Elev<strong>at</strong>or Bore, no wear factor, and contact stress of 110,100psi.<br />

Note: A raised elev<strong>at</strong>or OD increases elev<strong>at</strong>or capacity without affecting make-up torque.

Pipe Body Performance<br />

Pipe Body Configur<strong>at</strong>ion ( 6.625 OD (in) 0.938 Wall (in) UD-165 )<br />

Nominal 90 % Inspection Class API Premium Class<br />

Pipe Tensile Strength (<strong>lbs</strong>) 2,763,900 2,446,400 2,137,900<br />

Pipe Torsional Strength<br />

(<strong>ft</strong>-<strong>lbs</strong>) 333,400 292,400<br />

253,400<br />

TJ/PipeBody Torsional R<strong>at</strong>io 0.50<br />

0.57<br />

0.65<br />

80% Pipe Torsional Strength<br />

Burst<br />

Collapse<br />

(<strong>ft</strong>-<strong>lbs</strong>) 266,700<br />

(psi) 40,883<br />

(psi) 40,108<br />

233,900<br />

42,051<br />

37,601<br />

202,700<br />

37,378<br />

34,865<br />

Note: Nominal Burst<br />

calcul<strong>at</strong>ed <strong>at</strong> 87.5% RBW<br />

per API.<br />

Pipe Body Geometry<br />

Pipe Body Configur<strong>at</strong>ion ( 6.625 OD (in) 0.938 Wall (in) UD-165 )<br />

Nominal 90 % Inspection Class API Premium Class<br />

Pipe OD (in) 6.625<br />

6.437<br />

6.250<br />

Wall Thickness<br />

(in) 0.938<br />

0.844<br />

0.750<br />

Nominal Pipe ID<br />

(in) 4.750<br />

4.750<br />

4.750<br />

Cross Sectional Area of Pipe Body<br />

(sq in) 16.751 14.826 12.957<br />

Cross Sectional Area of OD<br />

(sq in) 34.472 32.547<br />

30.678<br />

Cross Sectional Area of ID<br />

(sq in) 17.721 17.721<br />

17.721<br />

Section Modulus<br />

(cubic in) 21.003 18.426<br />

15.969<br />

Polar Section Modulus<br />

(cubic in) 42.006 36.852<br />

31.939<br />

Note: The technical inform<strong>at</strong>ion contained herein, including the product performance sheet and other <strong>at</strong>tached documents, is for reference only and should not<br />

be construed as a recommend<strong>at</strong>ion. The user is fully responsible for the accuracy and suitability of use of the technical inform<strong>at</strong>ion. NOV Grant Prideco cannot<br />

assume responsibility for the results obtained through the use of this m<strong>at</strong>erial. No expressed or implied warranty is intended. Drill pipe assembly properties are<br />

calcul<strong>at</strong>ed based on uniform OD and wall thickness. No safety factor is applied. The inform<strong>at</strong>ion provided for various inspection classes and for various wear<br />

conditions (remaining body wall) is for inform<strong>at</strong>ion only and does not represent or imply acceptable oper<strong>at</strong>ing limits. It is the responsibility of the customer and<br />

the end user to determine the appropri<strong>at</strong>e performance r<strong>at</strong>ings, acceptable use of the product, maintain safe oper<strong>at</strong>ional practices, and to apply a prudent safety<br />

factor suitable for the applic<strong>at</strong>ion.

Tenssion<br />

(<strong>lbs</strong>)<br />

3,500,000<br />

3,000,000<br />

2,500,000<br />

2,000,000<br />

1,500,000<br />

1,000,000<br />

500,000<br />

0<br />

Torque‐Tension Graph<br />

Tool Joint: 6‐5/8 FH (8.688 X 3.250) SMYS = 135,000 psi<br />

Pipe Body: 90% Inspection Class, 6.625 inch OD, 0.938 inch wall thickness, UD‐165 Pipe Grade<br />

Drilling Torque (<strong>ft</strong>‐<strong>lbs</strong>)<br />

Pipe Body in Combined Loading<br />

Pipe Body Yield <strong>at</strong> 90%<br />

Inspection Class<br />

Tool Joint Applied Make‐up Torque<br />

Tool Joint Yield<br />

Tool Joint Shoulder Separ<strong>at</strong>ion<br />

<strong>Recommended</strong> <strong>MUT</strong><br />

Min <strong>Recommended</strong> <strong>MUT</strong>

Tennsion<br />

(<strong>lbs</strong>)<br />

3,000,000<br />

2,500,000<br />

2,000,000<br />

1,500,000<br />

1,000,000<br />

500,000<br />

0<br />

<strong>Oper<strong>at</strong>ional</strong> <strong>Limits</strong> (<strong>Connection</strong> <strong>at</strong> <strong>Recommended</strong> <strong>MUT</strong> = 84,600 <strong>ft</strong>‐<strong>lbs</strong>)<br />

Tool Joint: 6‐5/8 FH (8.688 X 3.250) SMYS = 135,000 psi<br />

Pipe Body: 90% Inspection Class, 6.625 inch OD, 0.938 inch wall thickness, UD‐165 Pipe Grade<br />

Safe Oper<strong>at</strong>ing Zone<br />

Drilling Torque (<strong>ft</strong>‐<strong>lbs</strong>)<br />

Overload Zone

Tennsion<br />

(<strong>lbs</strong>)<br />

3,000,000<br />

2,500,000<br />

2,000,000<br />

1,500,000<br />

1,000,000<br />

500,000<br />

<strong>Oper<strong>at</strong>ional</strong> <strong>Limits</strong> (<strong>Connection</strong> <strong>at</strong> Min <strong>Recommended</strong> <strong>MUT</strong> = 82,700 <strong>ft</strong>‐<strong>lbs</strong>)<br />

0<br />

Tool Joint: 6‐5/8 FH (8.688 X 3.250) SMYS = 135,000 psi<br />

Pipe Body: 90% Inspection Class, 6.625 inch OD, 0.938 inch wall thickness, UD‐165 Pipe Grade<br />

Safe Oper<strong>at</strong>ing Zone<br />

Drilling Torque (<strong>ft</strong>‐<strong>lbs</strong>)<br />

Overload Zone

Tool Joint<br />

Pipe Body<br />

0<br />

4,500<br />

8,900<br />

13,400<br />

17,800<br />

22,300<br />

26,700<br />

31,200<br />

35,600<br />

40,100<br />

44,500<br />

49,000<br />

53,400<br />

57,900<br />

62,300<br />

66,800<br />

71,200<br />

75,700<br />

80,100<br />

84,600<br />

6-5/8 FH Tool Joint OD (in) 8.688<br />

90 % Inspection Class Pipe Body OD (in) 6.625<br />

2,446,400<br />

2,446,100<br />

2,445,200<br />

2,443,800<br />

2,441,800<br />

2,439,200<br />

2,436,100<br />

2,432,400<br />

2,428,200<br />

2,423,200<br />

2,417,900<br />

2,411,800<br />

2,405,200<br />

2,397,900<br />

2,390,200<br />

2,381,700<br />

2,372,700<br />

2,362,900<br />

2,352,800<br />

2,341,700<br />

Tension <strong>at</strong><br />

Pipe Body<br />

Yield (<strong>lbs</strong>)<br />

2,446,400<br />

2,446,100<br />

2,445,200<br />

2,443,800<br />

2,441,800<br />

2,439,200<br />

2,436,100<br />

2,432,400<br />

2,428,200<br />

2,423,200<br />

2,417,900<br />

2,411,800<br />

2,405,200<br />

2,397,900<br />

2,390,200<br />

2,381,700<br />

2,372,700<br />

2,362,900<br />

2,352,800<br />

2,341,700<br />

Tension <strong>at</strong><br />

Shoulder<br />

Separ<strong>at</strong>ion (<strong>lbs</strong>)<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

<strong>Oper<strong>at</strong>ional</strong> drilling torque is limited by the Make-up Torque.<br />

Tension <strong>at</strong><br />

<strong>Connection</strong><br />

Yield (<strong>lbs</strong>)<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

3,063,200<br />

Note: Drill-Pipe porperties are calcul<strong>at</strong>ed based on uniform OD and wall thickness. No safety factor applied.<br />

This performance sheet is for reference only.<br />

Note: <strong>Recommended</strong> <strong>MUT</strong> should always be used when possible. If not possible, <strong>MUT</strong> should be as close<br />

to <strong>Recommended</strong> <strong>MUT</strong> as possible.<br />

For Turbo Torque connections: Turbo <strong>MUT</strong> is an acceptable increased <strong>MUT</strong> if additional torque is reqired for<br />

drilling.<br />

Tool Joint ID (in)<br />

3.250<br />

Tool Joint Specified Minimum<br />

Yield Strength (psi)<br />

135,000<br />

Wall Thickness (in) 0.938 Pipe Body Grade<br />

UD-165<br />

0<br />

4,400<br />

8,700<br />

13,100<br />

17,400<br />

21,800<br />

26,100<br />

30,500<br />

34,800<br />

39,200<br />

43,500<br />

47,900<br />

52,200<br />

56,600<br />

60,900<br />

65,300<br />

69,600<br />

74,000<br />

78,300<br />

82,700<br />

2,446,400<br />

2,446,100<br />

2,445,300<br />

2,443,900<br />

2,442,000<br />

2,439,600<br />

2,436,600<br />

2,433,000<br />

2,429,000<br />

2,424,300<br />

2,419,100<br />

2,413,300<br />

2,407,100<br />

2,400,100<br />

2,392,700<br />

2,384,600<br />

2,376,000<br />

2,366,700<br />

2,357,000<br />

2,346,500<br />

Tension <strong>at</strong><br />

Pipe Body<br />

Yield (<strong>lbs</strong>)<br />

2,446,400<br />

2,346,500<br />

Tension <strong>at</strong><br />

Shoulder<br />

Separ<strong>at</strong>ion<br />

(<strong>lbs</strong>)<br />

3,130,100<br />

2,446,100 3,130,100<br />

2,445,300 3,130,100<br />

2,443,900 3,130,100<br />

2,442,000 3,130,100<br />

2,439,600 3,130,100<br />

2,436,600 3,130,100<br />

2,433,000 3,130,100<br />

2,429,000 3,130,100<br />

2,424,300 3,130,100<br />

2,419,100 3,130,100<br />

2,413,300 3,130,100<br />

2,407,100 3,130,100<br />

2,400,100 3,130,100<br />

2,392,700 3,130,100<br />

2,384,600 3,130,100<br />

2,376,000 3,130,100<br />

2,366,700 3,130,100<br />

2,357,000 3,130,100<br />

3,130,100<br />

Tension <strong>at</strong><br />

<strong>Connection</strong><br />

Yield (<strong>lbs</strong>)<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

3,132,700<br />

<strong>Oper<strong>at</strong>ional</strong> drilling torque is limited by the Make-up Torque.<br />

Tension <strong>at</strong><br />

Pipe Body<br />

Yield (<strong>lbs</strong>)<br />

Tension <strong>at</strong><br />

Shoulder<br />

Separ<strong>at</strong>ion<br />

(<strong>lbs</strong>)<br />

Tension <strong>at</strong><br />

<strong>Connection</strong><br />

Yield (<strong>lbs</strong>)<br />

Note: Table above le<strong>ft</strong> intentionally blank. Turbo <strong>MUT</strong> and performance<br />

properties only apply to Turbo Torque connections.

Min <strong>MUT</strong><br />

Max <strong>MUT</strong><br />

82,700<br />

82,900<br />

83,100<br />

83,300<br />

83,500<br />

83,800<br />

84,000<br />

84,200<br />

84,400<br />

84,600<br />

Make-up Torque and Max Tension Table<br />

Tension <strong>at</strong> Shoulder<br />

Separ<strong>at</strong>ion (<strong>lbs</strong>)<br />

3,130,200<br />

3,127,800<br />

3,120,200<br />

3,112,600<br />

3,105,000<br />

3,093,600<br />

3,086,100<br />

3,078,500<br />

3,070,900<br />

3,063,300<br />

Tool Joint<br />

Tool Joint 6-5/8 FH Tool Joint OD (in) 8.688 Tool Joint ID (in) 3.250 Tool Joint Specified Minimum<br />

Yield Strength (psi)<br />

135,000<br />

Tension <strong>at</strong> <strong>Connection</strong><br />

Yield (<strong>lbs</strong>)<br />

3,132,800<br />

3,127,800<br />

3,120,200<br />

3,112,600<br />

3,105,000<br />

3,093,600<br />

3,086,100<br />

3,078,500<br />

3,070,900<br />

3,063,300<br />

Note: <strong>Recommended</strong> <strong>MUT</strong> should always be used when possible. If not possible, <strong>MUT</strong> should be as close to <strong>Recommended</strong> <strong>MUT</strong> as possible.<br />

0<br />

2,446,400<br />

26,600<br />

2,436,200<br />

Pipe Body<br />

Combined Loading Table (Torque-Tension)<br />

Pipe Body 90 % Inspection Class Pipe Body OD (in) 6.625 Wall Thickness (in) 0.938 Pipe Body Grade<br />

UD-165<br />

53,200<br />

2,405,500<br />

79,700<br />

2,353,700<br />

106,300<br />

2,279,000<br />

132,900<br />

2,179,000<br />

159,500<br />

2,050,300<br />

186,100<br />

1,886,800<br />

212,600<br />

1,679,400<br />

239,200<br />

1,406,800<br />

265,800<br />

1,019,100<br />

292,300<br />

56,400

Torque T (<strong>ft</strong>‐<strong>lbs</strong>)<br />

250,000<br />

200,000<br />

150,000<br />

100,000<br />

50,000<br />

0<br />

Tool Joint Wear for 6‐5/8 FH (8.688 X 3.250)<br />

M<strong>at</strong>erial SMYS (specified minimum yield strength) = 135,000 psi<br />

Tool Joint OD (inches)<br />

Tool Joint<br />

Torsional Strength<br />

<strong>Recommended</strong> <strong>MUT</strong><br />

Min <strong>Recommended</strong> <strong>MUT</strong><br />

Pipe Body<br />

80% of Premium Pipe<br />

Body Torsional Strength<br />

Pipe Body: 6.625 inch OD, 0.938 inch wall<br />

thickness, UD‐165 Pipe Grade

Tool Joint<br />

Wear<br />

New OD<br />

Worn OD<br />

Tool<br />

Joint OD<br />

(in)<br />

8.6875<br />

8.619<br />

8.551<br />

8.483<br />

8.415<br />

8.347<br />

8.278<br />

8.21<br />

8.142<br />

8.074<br />

8.006<br />

7.9375<br />

<strong>Recommended</strong> Make-up Torque<br />

Rec <strong>MUT</strong><br />

(<strong>ft</strong>-<strong>lbs</strong>)<br />

84,600<br />

84,600<br />

84,600<br />

84,600<br />

82,800<br />

78,900<br />

74,900<br />

71,000<br />

67,200<br />

63,400<br />

59,600<br />

55,900<br />

Tension <strong>at</strong><br />

Shoulder<br />

Separ<strong>at</strong>ion (<strong>lbs</strong>)<br />

3,063,300<br />

2,982,900<br />

2,890,200<br />

2,782,300<br />

2,745,600<br />

2,813,500<br />

2,893,800<br />

2,981,000<br />

3,073,400<br />

3,093,400<br />

2,908,800<br />

2,733,600<br />

Torsional<br />

Strength<br />

(<strong>ft</strong>-<strong>lbs</strong>)<br />

165,400<br />

158,400<br />

151,500<br />

144,700<br />

138,000<br />

131,400<br />

124,800<br />

118,300<br />

111,900<br />

105,600<br />

99,400<br />

93,200<br />

Tension <strong>at</strong><br />

<strong>Connection</strong><br />

Yield (<strong>lbs</strong>)<br />

3,063,300<br />

2,982,900<br />

2,890,200<br />

2,782,300<br />

2,745,600<br />

2,813,500<br />

2,893,800<br />

2,981,000<br />

3,073,400<br />

3,123,300<br />

3,007,300<br />

2,891,500<br />

Minimum Make-up Torque<br />

Tension <strong>at</strong><br />

Min <strong>MUT</strong> Shoulder<br />

(<strong>ft</strong>-<strong>lbs</strong>) Separ<strong>at</strong>ion (<strong>lbs</strong>)<br />

Tension <strong>at</strong><br />

<strong>Connection</strong><br />

Yield (<strong>lbs</strong>)<br />

82,700 3,130,200 3,132,800<br />

79,200 3,067,200 3,132,800<br />

75,800 3,006,500 3,132,800<br />

72,400 2,944,700 3,132,800<br />

69,000 2,881,800 3,132,800<br />

65,700 2,821,800 3,132,800<br />

62,400 2,761,800 3,132,800<br />

59,200 2,703,900 3,132,800<br />

56,000 2,644,700 3,132,800<br />

52,800 2,576,200 3,123,300<br />

49,700 2,425,700 3,007,300<br />

46,600 2,278,800 2,891,500<br />

Note for API <strong>Connection</strong>s: Tension <strong>at</strong> shoulder separ<strong>at</strong>ion and Tension <strong>at</strong> connection failure may<br />

fluctu<strong>at</strong>e as OD decreases due to <strong>Recommended</strong> make-up toqure exceeding T3.<br />

0<br />

2,446,400<br />

Tool<br />

Joint OD<br />

(in)<br />

8.6875<br />

8.619<br />

8.551<br />

8.483<br />

8.415<br />

8.347<br />

8.278<br />

8.21<br />

8.142<br />

8.074<br />

8.006<br />

7.9375<br />

26,600<br />

2,436,200<br />

Pipe Body<br />

Combined Loading Table (Torque-Tension)<br />

53,200<br />

2,405,500<br />

79,700<br />

2,353,700<br />

106,300<br />

2,279,000<br />

132,900<br />

2,179,000<br />

159,500<br />

2,050,300<br />

186,100<br />

1,886,800<br />

Turbo Make-up Torque<br />

Tension <strong>at</strong><br />

Turbo <strong>MUT</strong><br />

Tension <strong>at</strong><br />

Shoulder <strong>Connection</strong><br />

(<strong>ft</strong>-<strong>lbs</strong>) Separ<strong>at</strong>ion (<strong>lbs</strong>)<br />

Yield (<strong>lbs</strong>)<br />

Note: Table above le<strong>ft</strong> intentionally<br />

blank. Turbo <strong>MUT</strong> and performance<br />

properties only apply to Turbo Torque<br />

connections.<br />

Pipe Body 90 % Inspection Class Pipe Body OD (in) 6.625 Wall Thickness (in) 0.938 Pipe Body Grade<br />

UD-165<br />

212,600<br />

1,679,400<br />

239,200<br />

1,406,800<br />

265,800<br />

1,019,100<br />

292,300<br />

56,400