PLUNGER LIFT SYSTEM - National Oilwell Varco

PLUNGER LIFT SYSTEM - National Oilwell Varco

PLUNGER LIFT SYSTEM - National Oilwell Varco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

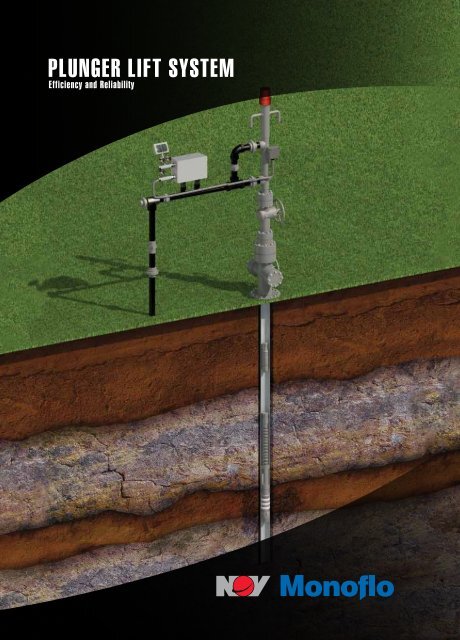

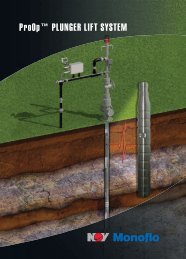

<strong>PLUNGER</strong> <strong>LIFT</strong> <strong>SYSTEM</strong><br />

Efficiency and Reliability

<strong>PLUNGER</strong> <strong>LIFT</strong> <strong>SYSTEM</strong>S<br />

One Company, Unlimited Solutions<br />

Since 1841, <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong>® has been dedicated to ensuring customers receive the highest quality oilfield<br />

products and services. <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> is a worldwide leader in the design, manufacture and sale of equipment<br />

and components used in oil and gas drilling and production operations, the provision of oilfield services, and supply<br />

chain integration services to the upstream oil and gas industry. NOV® also provides supply chain services through its<br />

network of more than 200 distribution service centers located near major drilling and production activity worldwide.<br />

We continue to build upon our unlimited, customer-focused solutions and are proud to deliver our Artificial Lift Systems<br />

through the NOV Monoflo division.<br />

NOV Monoflo<br />

Artificial Lift Systems<br />

Coverage<br />

The NOV Monoflo division is a true partner and worldwide source for complete Artificial Lift equipment and packaged<br />

solutions. Our Artificial Lift professionals collaborate with you to properly evaluate well conditions and provide customized<br />

artificial lift solutions that will optimize your production.<br />

• Professional Well Evaluation<br />

• Surface and Subsurface Equipment<br />

• Controllers and Production Automation<br />

• All Production Accessories and Expendables<br />

• Global Supply Chain and Service Solutions<br />

LLOYDMINSTER, CANADA HOUSTON, TEXAS

Plunger Lift Systems<br />

Plunger Lift Technology is a cost effective and efficient technique that optimizes oil and gas production in wells<br />

which have nominal flow trends.<br />

As slugs of fluid travel to the surface, as much as 75% of the fluid may fall back and continue to accumulate downhole.<br />

More accumulation equals slower production. The accumulation of fluid is known as “liquid loading” and can be<br />

detrimental to well production. Without assistance, the column of fluid will grow too heavy to pass through and the<br />

well stops producing.<br />

A Plunger Lift System is an ideal solution for these well conditions. It uses an interface seal between the accumulated<br />

fluid and the stored gas in the annulus. The well is shut-in to allow the plunger to travel to the bottom which creates<br />

a bottomhole seal and well pressure to build. After a period of shut-in time, the head gas is blown down creating<br />

differential pressure across the plunger which brings the plunger to surface. As the plunger travels up the tubing, it<br />

lifts the fluid column to the surface and a turbulent seal is formed which practically eliminates liquid fall back. The<br />

fluid column is lifted up and out allowing the well to produce again.<br />

The system is comprised of a well specific plunger, a bottom hole bumper spring, a specialized lubricator and<br />

catcher assembly, an electronic controller, motor valve and an arrival sensor. With the Plunger Lift System advanced<br />

controls and wide variety of optimization solutions, NOV Monoflo is able to offer a cost effective solution and<br />

environmentally friendly method of artificial lift.<br />

The NOV Monoflo Plunger Lift System is the most economical and environmentally friendly form of artificial lift<br />

technology on the market today.<br />

Applications<br />

The NOV Monoflo Plunger Lift System is the ideal solution for a wide range of applications and conditions including:<br />

• Dewatering liquid loading gas wells<br />

• Wells with high gas-to-oil ratio<br />

• Wells that are currently being soaped<br />

• Paraffin and hydrate control<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PLUNGER</strong> <strong>LIFT</strong> <strong>SYSTEM</strong><br />

Plungers<br />

NOV Monoflo plungers are available in a variety of designs and models, manufactured with the objective of<br />

improving production rates and operating in various well conditions.<br />

Overview<br />

Features and<br />

Benefits<br />

Sweet Service<br />

Sour Service<br />

Solid Plunger Pad Plunger Brush Plunger<br />

Our solid plungers are<br />

low maintenance and<br />

are ideal for wells that<br />

require paraffin and<br />

scale control.<br />

• The raised shoulder<br />

design on the fish<br />

neck gives additional<br />

durability and energy<br />

displacement<br />

• Built in wear grooves<br />

for easy service<br />

• Can be easily modified<br />

for a variety of tubing<br />

conditions<br />

• Designed to create<br />

superior turbulent seal<br />

to reduce liquid fall<br />

back<br />

Our pad plungers utilize<br />

a unique pad design to<br />

provide superior seal<br />

efficiency and rugged<br />

durability for clean well<br />

bore fluid conditions.<br />

• The raised shoulder<br />

design on the fish<br />

neck gives additional<br />

durability and energy<br />

displacement<br />

• Available in Dual and<br />

Single pad designs<br />

• Interlocking pad<br />

design provides<br />

superior gas and fluid<br />

seal<br />

• Built rugged utilizing<br />

a dual support rail<br />

design<br />

• Simple design using<br />

minimal parts ruggedly<br />

built<br />

• AISI 4140 Alloy Steel • AISI 4140 Alloy Steel<br />

• 17-4PH Stainless Steel<br />

Pads<br />

• 17-4PH Stainless Steel • 17-4PH Stainless Steel<br />

Mandrel and End Cap<br />

• 17-4PH Stainless Steel<br />

Pads<br />

• Inconel X750 springs<br />

• AISI 304 Stainless Steel<br />

Sleeves<br />

Our brush plungers are<br />

designed for maximum<br />

sealing efficiency<br />

while cycling in sandy<br />

conditions.<br />

• The raised shoulder<br />

design on the fish<br />

neck gives additional<br />

durability and energy<br />

displacement<br />

• Excellent sealing<br />

efficiency<br />

• Ideal for use in<br />

wells that require<br />

sand removal both<br />

produced and Frac<br />

• Durable 6.6 Nylon<br />

Brush design for harsh<br />

conditions<br />

• Designed with a<br />

replaceable brush for<br />

superior economics<br />

• AISI 4140 Alloy Steel<br />

Mandrel and End Cap<br />

• AISI 304 Stainless Steel<br />

Brush Carrier<br />

• 6.6 Nylon Brush<br />

• 17-4PH Stainless Steel<br />

Mandrel and End Cap<br />

• AISI 304 Stainless Steel<br />

Brush Carrier<br />

• 6.6 Nylon Brush

Bottom Hole Bumper Springs<br />

NOV Monoflo bottomhole bumper spring<br />

assemblies are designed to absorb the impact of<br />

the plunger when it reaches the bottom of the well.<br />

Various seating assemblies can be used (e.g.: hold<br />

down, seal stop, tubing stop, collar stop) depending<br />

on the application. We offer bumper springs in<br />

various sizes and materials suitable for use in sweet<br />

and sour service environments. All of our bumper<br />

springs are designed for maximum flow area without<br />

compromising strength. A ball and seat can also be<br />

used to retain liquids in the tubing string.<br />

• Easy to set and retrieve<br />

• Large flow area<br />

• The raised shoulder design on the fish<br />

neck gives additional durability and energy<br />

displacement<br />

• Stainless steel material<br />

• Spring material available in Inconel X750, and<br />

MP35<br />

Lubricators<br />

NOV Monoflo lubricators are spring-loaded receivers<br />

designed to cushion the arrival of the plunger at the<br />

surface. The lubricator has a catcher designed to catch<br />

the plunger upon arrival which will allow the operator<br />

to retrieve and inspect the plunger. Available in a<br />

variety of sizes and in special materials built rugged for<br />

the harshest environments.<br />

• Built to API 6A specifications<br />

• Field serviceable<br />

• Suitable for high pressure applications<br />

• Sweet and Sour service available<br />

• Cold temperature material good to -50°C<br />

• Threaded and Flanged available<br />

• Single and Dual Port available<br />

• Threaded and Bowen Union available<br />

• Extensive testing, pressure, hydro, and X-ray<br />

• Complete and comprehensive quality and Control<br />

packages<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

Corporate Headquarters<br />

7909 Parkwood Circle Drive<br />

Houston, Texas 77036<br />

United States<br />

Phone: 713 375 3700<br />

Fax: 713 346 7687<br />

Sales<br />

8708 West Little York Road<br />

Suite 100<br />

Houston, Texas 77040<br />

United States<br />

Phone: 281 854 0300<br />

Fax: 281 854 0301<br />

<strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> has produced this brochure for general information only, and it is not<br />

intended for design purposes. Although every effort has been made to maintain the accuracy and<br />

reliability of its contents, <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> in no way assumes responsibility for liability for<br />

any loss, damage or injury resulting from the use of information and data herein. All applications<br />

for the material described are at the user’s risk and are the user’s responsibility.<br />

All brands listed are trademarks of <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong>.<br />

One Company . . . Unlimited Solutions<br />

Downhole Solutions<br />

Drilling Solutions<br />

Engineering and Project Management Solutions<br />

Lifting and Handling Solutions<br />

Production Solutions<br />

Supply Chain Solutions<br />

Tubular and Corrosion Control Solutions<br />

Well Service and Completion Solutions<br />

MonofloALS@nov.com www.nov.com/ArtificialLift<br />

© 2011 <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong><br />

D392002611-MKT-001 Rev. 03