Socket detailing - Rigips

Socket detailing - Rigips

Socket detailing - Rigips

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

October 2006Plasterboard baffleHilti CP617 Putty Pad<strong>Socket</strong> <strong>detailing</strong>White Book supplement

<strong>Socket</strong> <strong>detailing</strong><strong>Socket</strong> <strong>detailing</strong>Internal partition system socket <strong>detailing</strong>2

<strong>Socket</strong> <strong>detailing</strong>Internal partition system socket <strong>detailing</strong>Fixing electrical socket boxes into British Gypsum partitions can affect fire,acoustic and air leakage performance, but careful <strong>detailing</strong> can minimisethis. The Building Regulations Approved Document E and Robust Detailsoffer specific guidance on the installation of socket boxes in separating walls,particularly with regard to the avoidance of back-to-back services.✓✓60 120minsSectorOffice / commercialEducational<strong>Socket</strong> <strong>detailing</strong>This document details solutions using both the traditional ‘plasterboardbaffle’ backing method and the Hilti CP617 Putty Pad.✓ResidentialPlasterboard baffle✓Healthcare✓Leisure✓IndustrialHilti CP617 Putty PadPlasterboardbaffleORHilti CP617Putty PadKey facts●Approved by the Robust Details manual●Tested under UKAS laboratory conditions●Up to 120 minutes fire resistance●Can be incorporated into British GypsumSpecSure ® warranted systems●Maintains fire and acoustic performance ofa perforated partition3

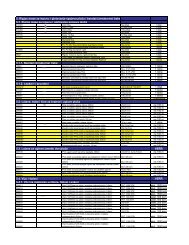

www.british-gypsum.com<strong>Socket</strong> <strong>detailing</strong>System componentsGyproc board productsGyproc SoundBlocThicknessWidthGyproc FireLineThicknessWidth15mm1200mm15mm1200mmFixing and finishing productsGyproc SealantFor sealing air paths for optimum soundinsulation.Gypframe metal productsGA1 Steel Angle(25 x 25 x 0.5mm)ORGA2 Steel Angle(25 x 25 x 0.7mm)ORGA3 Steel Angle(19 x 32 x 0.7mm)ORGA4 Steel Angle(25 x 50 x 0.7mm)Isover APR 120025mm and 50mm, for improved acousticperformance.By othersHilti CP617 Putty Pad9” x 9” (23 x 23cm)For two gang socketsOR6” x 7” (15 x 18cm)For single socketsAlways use genuine branded British Gypsum components to qualify for SpecSure ® lifetime warranty4

T 08705 456123 F 08705 456356 E bgtechnical.enquiries@bpb.comInstallation overview<strong>Socket</strong> <strong>detailing</strong>‘Plasterboard baffle’ - backing methodHoles in plasterboard linings for socket boxes should always beneatly cut and Gyproc Sealant should be applied where optimumacoustic performance and/or minimum air leakage is required. Infire-rated walls, the fire stopping design is dependant on theperiod of fire resistance required. The depth of ‘plasterboard baffle’should be approximately 150mm. Whilst the following exampledetails relate to 60 and 90 minute fire resistant specifications, theprinciple of the details can generally be adopted for 120 minutespecifications.In all instances, it is strongly recommended that the number ofpenetrations are minimised and back-to-back sockets should beavoided.Hilti CP617 Putty PadThe self-adhesive pad can be applied to either the rear of the backbox or as a liner to the inside.When applying to the rear, prior to installation, ensure the area ofapplication is free of excess dust, dirt, oil and water. Remove labelfrom one side of the pad and then apply to the rear of the box,ensuring an even overlap all the way round. Mould the overlapdown the sides of the box and then press firmly to thesurrounding plasterboard. Remove the remaining label.When fixing to the inside of a back box, ensure that the box hasbeen fully fitted with the socket screws in place. This is to ensurethat the fixing lugs that grip the plasterboard are not blocked bythe installation of the pad. Remove the label from one side of thepad. Line the box with the pad, neatly trimming any excessmaterial. Remove the remaining label.Where sockets are fitted in positive pressure areas such as firefighting shafts, it is recommended that the pads always be fittedto the inside of the box.In all installation cases, any insulation material that is in place mustnot be removed.Finally, ensure that as cables are drawn through, the pad ismoulded around them to ensure smoke tightness.Robust Details / PCTBoth the 'plasterboard baffle' backing method and the Hilti CP617Putty Pad method are recognised by Robust Details Ltd and can beused within the British Gypsum GypWall QUIET IWL system(E-WS-2 see figure 1) without the need for Pre-Completion Testing.The Hilti CP617 Putty Pad has been accepted by Robust Details Ltdas an alternative mechanism for sealing the rear of electricalservice penetrations in Robust Detail timber frame and metal frameseparating walls, as published in the Robust Details Part EHandbook.‘Sacrifial linings’The Robust Details pattern book also offers the alternative of a‘sacrificial’ lining in front of a separating wall to create a zone forservice installation. These service zones remove the need for servicepenetration of the actual Robust Detail separating wallconstruction, which in turn removes the risk of a loss in acousticperformance as a result of service penetrations.This method is increasingly migrating to projects where Pre-Completion Testing is being used, as best practice. However, it canlead to a downgrading of the D ntw + C tr performance of the basewall due to the introduction of additional cavities within the overallconstruction. Robust Detail walls are designed to exceed theApproved Document Part E requirement so the slight potentialdowngrade in performance caused by the ‘sacrificial’ lining wouldnot lead to system failure.Where Pre-Completion Testing is required however, depending onthe system specified, there may not be this level of ‘safety margin’,particularly at lower frequencies. Therefore, where additional‘sacrificial’ service installation zone linings have been specified innon Robust Details systems the most appropriate solution isdetailed below.British Gypsum recommend the following as a minimumspecification to ensure no reduction in the acoustic performance ofthe base partition: 70mm cavity with 25mm Isover APR 1200 anda single layer 15mm Gyproc SoundBloc board lining installed onone or both sides of the base partition construction.The Hilti CP617 Putty Pad can be used on metal back boxes inmuch the same way as with plastic ones. However, when fitting tothe rear of the metal box, the box should be unscrewed from thenogging, the pad applied and then the box re-fixed.For full installation details, refer to the British Gypsum SiteBook or visit www.british-gypsum.com5

www.british-gypsum.com<strong>Socket</strong> <strong>detailing</strong>DesignPerformanceFire resistance and sound insulationThe plasterboard baffle backing is a traditional method that isrecognised to maintain both fire resistance and sound insulationperformance. Tests have been carried out and the Robust Detailsmanual approves this method.Fire and acoustic tests have been carried out on British GypsumGypWall metal stud partitions drylined with Gyproc plasterboardincorporating sockets lined with Hilti CP617 Putty Pads. The testsindicate that Hilti CP617 Putty Pads have the potential tomaintain both the fire and acoustic performance of a perforatedpartition when tested under UKAS laboratory conditions, incomparison to an imperforate partition of the same specification.Both methods are suitable for use up to 120 minutes fireresistance and to the level of sound insulation performancerequired by Robust Details Ltd.performance or acoustic integrity. Hilti CP617 Putty Pads cantherefore by used in British Gypsum proprietary systems whichare covered by the SpecSure® lifetime system warranty providedthat the Hilti CP617 Putty Pads are installed in accordance withthe manufacturer’s recommendations and following guidancecontained in this White Book supplement.Hilti contact details:Hilti (Gt.Britain) Limited1 Trafford Wharf Road,Trafford Park,ManchesterM17 1BYFreephone 0800 886 100Freefax 0800 886 200Hilti Web site: www.hilti.co.ukDurabilityThe Hilti CP617 Putty Pad has been successfully subjected to anaccelerated age testing process to assess its long-term resistance.Products which have passed this test according to the definedcriteria have a long-term functionality of 25 to 30 years.Design considerationsWhilst the <strong>detailing</strong> of socket box penetrations is important,there are a number of other factors which could cause adowngrade in performance, such as sound transmission viaflanking elements and direct transmission via doors, glazing, etcas the weakest element acoustically will dominate the overallperformance. To obtain the optimum sound insulation, airtightness is essential, and whilst most junctions will be sealedusing standard jointing techniques, any gaps or other small airpaths should be sealed using Gyproc Sealant. It is important tonote, however, that in order for separating wall and floorconstructions to be fully effective, care must be taken tocorrectly detail the junctions between the separating wall orfloor and associated elements such as external walls, otherseparating elements and penetrations or door openings. Ifjunctions are incorrectly detailed, the acoustic performance willbe limited and the Building Regulations requirements will not beachieved in practice. Please refer to ‘Section 2 - Basic principlesof system design’ of the White Book or British Gypsum'sHomeSpec 4 residential sector guide, 'Flanking Sound' sectionat www.british-gypsum.com, for good practice <strong>detailing</strong>.Further guidancePlease contact Hilti for advice and confirmation on productwarranty, specifications, installation and performancesubstantiation for the Hilti CP617 Putty Pad. Relevant test dataWF 143566, WF 150013A and BTC 14020A refers.A technical data sheet on the Hilti CP617 Putty Pad is availablefrom Hilti, on request.The Hilti CP617 Putty Pad has been thoroughly tested in BritishGypsum proprietary systems with no downgrade in the firePlease refer to 2 - Basic principles of system design for general guidance.6

T 08705 456123 F 08705 456356 E bgtechnical.enquiries@bpb.comConstruction details1 Robust Details ‘plasterboard baffle’ in GypWall QUIET IWL(E-WS-2)1232Robust Details ‘plasterboard baffle’ in GypWall AUDIO123<strong>Socket</strong> <strong>detailing</strong>3 British Gypsum ‘plasterboard baffle’ in GypWall QUIET SF 4 British Gypsum ‘plasterboard baffle’ in GypWall STAGGERED3132125Hilti CP617 Putty Pad in GypWall QUIET IWL6Hilti CP617 Putty Pad in GypWall QUIET SF441234Fire resistant seal where required by Part B of the BuildingRegulationsGyproc SealantDouble layer or plasterboard equal to partition lining boardsHilti CP617 Putty Pad7

www.british-gypsum.com<strong>Socket</strong> <strong>detailing</strong>7Hilti CP617 Putty Pad in GypWall STAGGERED18Robust Details ‘sacrificial’ lining where a slight performancedowngrade is not detrimental to the system239British Gypsum ‘sacrifial’ lining in GypWall QUIET SF456123456Hilti CP617 Putty Pad‘Sacrificial lining’ - 15mm Gyproc FireLine / 12.5mm WallBoardTimber‘Sacrificial lining’ - 15mm Gyproc SoundBlocMinimum 25mm Isover APR 1200GypLyner UNIVERSAL framing - minimum stand-off 70mm8

T 08705 456123 F 08705 456356 E bgtechnical.enquiries@bpb.com<strong>Socket</strong> <strong>detailing</strong>9

Gyproc, Thistle, Gypframe, Glasroc and Arteco are all registered trade names of BPB United Kingdom Limited. Isover is a registered trade name of Saint-Gobain.British Gypsum reserve the right to revise product specification without notice. The information given is correct to the best of our knowledge at the time of publication, but it is the usersresponsibility to ensure it remains current prior to use. Please refer to our Health and Safety Guidance Sheet which is available on request.For a comprehensive and up to date library of information visit our website at: www.british-gypsum.comTechnical enquiriesBritish Gypsum LimitedDrywall Academy Advice CentreEast LeakeLoughboroughLeicestershireLE12 6JTTelephone: 08705 456123#1 (Literature), #2 (Specifiers), #3 (Merchants), #4 (Contractors)For quality and security reasons, calls may be recorded.Fax: 08705 456356E-mail: bgtechnical.enquiries@bpb.comTraining enquiries: 08702 406040FM 52358© British Gypsum October 2006 WBS-SD-01www.british-gypsum.com