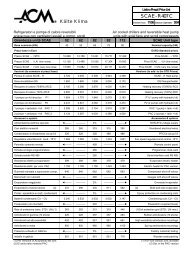

TECHNICAL MANU AL CD 30÷520 06.06 M T E 0 11 2 5 6 ... - Chiller

TECHNICAL MANU AL CD 30÷520 06.06 M T E 0 11 2 5 6 ... - Chiller

TECHNICAL MANU AL CD 30÷520 06.06 M T E 0 11 2 5 6 ... - Chiller

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CD</strong> 30 ÷ 5206.3 Pulse width modulate (PWM)During half period of output voltage, the output voltage wave is divided into some pulse waves. Dueto the average output voltage and pulse duty ratio (pulse width dividing the pulse period is duty ratio)is direct ratio, when modulating the frequency, not change the pulse width but change the pulse dutyratio, thus realize variable frequency and variable voltage.6.4 Principle of Digital Scroll CompressorThe fixed vortex plate on the top is allowed to move upwards about 1mm during the operation of the Digital Scroll. Lifting the top vortexplate ensures that there is no pumping through the vortex plate, andthere is no mass flow through the compressor. This is the period ofzero capacity for the compressor. This state is called the “UnloadingState” of the compressor. The “Loading State” is the normal statewhen the scrolls are operating normally like a standard scroll and the capacity is 100%. It isimportant to point out that there is no bypass of gas in this operation. The principle of achievingmodulation is by alternately lifting and engaging the top vortex plate. A cycle time consists of a“Loading State” time and “Unloading State” time. The duration of these 2 time segment determinethe capacity modulation of the compressor.13