ISO 9001:2008 Internal Audit Checklist - sample ... - Quality Coach

ISO 9001:2008 Internal Audit Checklist - sample ... - Quality Coach

ISO 9001:2008 Internal Audit Checklist - sample ... - Quality Coach

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

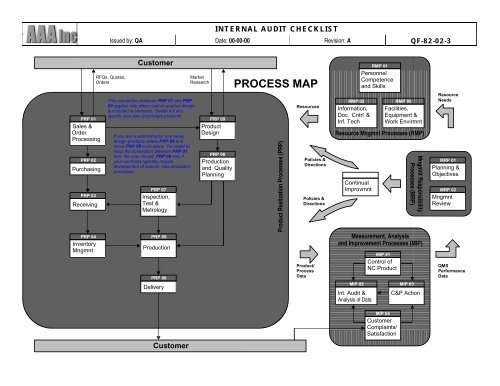

INTERNAL AUDIT CHECKLISTIssued by: QA Date: 00-00-00 Revision: A QF-82-02-3PRP 01Sales &OrderProcessingPRP 02PurchasingPRP 03ReceivingPRP 04InventoryMngmntRFQs, Quotes,OrdersCustomerThis connection between PRP 01 and PRP09 applies only when custom product designis included in contracts. Delete it if youspecify your own proprietary products.If you are a subcontractor and neverdesign products delete PRP 09 andmove PRP 08 to its place. You need tokeep the connection between PRP 01and, the now moved, PRP 08 only ifyour contracts typically requiredevelopment of special, new productionprocesses.PRP 07Inspection,Test &MetrologyPRP 05ProductionPRP 06DeliveryMarketResearchPRP 09ProductDesignPRP 08Productionand <strong>Quality</strong>PlanningPROCESS MAPProduct Realization Processes (PRP)ResourcesPolicies &DirectionsPolicies &DirectionsProduct/ProcessDataRMP 02Information,Doc. Cntrl &Inf. TechRMP 01PersonnelCompetenceand SkillsRMP 03Facilities,Equipment &Work EnvirmntResource Mngmnt Processes (RMP)ContinualImprovmntMngmnt ResponsibilityProcesses (MRP)Measurement, Analysisand Improvement Processes (MIP)MIP 02Int. <strong>Audit</strong> &Analysis of DataMIP 01Control ofNC ProductMIP 03C&P ActionResourceNeedsMRP 01Planning &ObjectivesMRP 02MngmntReviewQMSPerformanceDataCustomerMIP 04CustomerComplaints/Satisfaction

INTERNAL AUDIT CHECKLIST Doc: QF-82-02-3 Revision: A Pg. 3 of 6documented (not communicated in writing),confirm the requirements before acceptingthe order.7.2.2 When changing or amending orders, ensurethat relevant documents are amended andthat changes are communicated to relevantpersonnel.are these orders confirmed? How are such ordersconfirmed?Ask for records (copies) of the confirmations. Interviewpersonnel to find out whether they were consistentlytrained/instructed to confirm verbal orders.How are change orders processed? Is there a systemfor amending documents? Are there writteninstructions, procedures and/or training? How isinformation about order changes communicated torelevant departments/personnel within the company?Review a <strong>sample</strong> of change orders to verify thatprocedures, instructions and/or training are beingfollowed. See if you can uncover any past problemscaused by mishandling of change orders.7.2.3.a7.2.3.bDetermine and implement arrangements for• communicating product information,• handling enquiries, orders and changeorders.Are processes for communicating with customersadequately defined, to include policies, assignment ofauthorities and responsibilities, and methods(procedures, instructions, training)? Are theseprocesses consistently implemented?Verify that product brochures/specifications and otherproduct information (including the internet site) arecurrent.

INTERNAL AUDIT CHECKLIST Doc: QF-82-02-3 Revision: A Pg. 4 of 6Product Realization Process PRP 02 – Purchasing<strong>ISO</strong> <strong>9001</strong> Requirements What to look for and how Comply <strong>Audit</strong>or notes and evidence7.4.1 Control suppliers and the purchased productto ensure that the product conforms tospecified purchase requirements.7.4.1 Evaluate and select suppliers based on theirability to supply products conforming tospecified requirements. Establish evaluationand selection criteria. Maintain records orsupplier evaluations and related actions.7.4.2 In purchasing specifications include, whereappropriate• requirements for approval of product,procedures, processes and equipment;• requirements for approval of personnel,and• quality management system requirements.7.4.2 Ensure adequacy of purchasingspecifications before they are forwarded tosuppliers.How are suppliers controlled: initial selectionevaluations, ongoing monitoring, audits of supplier’sQMS and/or manufacturing processes, requests forcorrective actions?How is purchased product controlled: review of qualityrecords (SPC charts, inspection reports, lab testresults, etc.), receiving inspection? Who makes thesedecisions?Are suppliers evaluated and reviewed before they areapproved? What are the scope, extent and criteria forevaluating and approving suppliers? Who decides?How is the approval documented (an approved vendorlist)? Are there records of initial supplier evaluations?Select randomly and review a <strong>sample</strong> of supplierevaluation and monitoring files. Is their approval statusclearly authorized? Is their performance consistentlymonitored? In the event of nonconforming deliveries,are they required to implement corrective actions? Isthere a follow up?Where appropriate, are there requirements forcertificates, inspection reports, SPC data, approval of<strong>sample</strong>s, etc. included in purchasing documents? Arethere any requirements with regard to supplier’s qualitymanagement system?Review a <strong>sample</strong> of purchase orders, especially thosewhere the product is expected to come with certificates.How is adequacy of purchasing documents ensured?Are the documents reviewed before release? Are therestandard, pre-approved, specifications in the system?What other methods are used?See if you can uncover any past problems caused byerrors or omissions in purchasing documents.

INTERNAL AUDIT CHECKLIST Doc: QF-82-02-3 Revision: A Pg. 6 of 6Measurement and Improvement Process MIP 01 – Control of Nonconforming ProductMeasurement and Improvement Process MIP 02 – <strong>Internal</strong> <strong>Audit</strong>s and Analysis of DataMeasurement and Improvement Process MIP 03 – Corrective and Preventive ActionMeasurement and Improvement Process MIP 04 – Customer Complaints & SatisfactionManagement Responsibility Process MRP 01 – Planning and ObjectivesManagement Responsibility Process MRP 02 – Management ReviewManagement Responsibility Process MRP 03 – Continual ImprovementResource Management Process RMP 01 – Personnel Competence and SkillsResource Management Process RMP 02 – Information, Document Control and ITResource Management Process RMP 03 – Facilities, Equipment and Work EnvironmentFOR MORE INFORMATION AND BUYING OPTIONSPlease follow the link below to learn more and purchase the checklist <strong>ISO</strong> <strong>9001</strong> <strong>2008</strong> <strong>Internal</strong><strong>Audit</strong> & Gap Analysis <strong>Checklist</strong>http://www.qualitycoach.net/products/iso-<strong>9001</strong>-<strong>2008</strong>-internal-audit-gap-analysis-checklist.asp