Dolphin Jan-Feb 2012.pdf - Jurong Shipyard Pte Ltd

Dolphin Jan-Feb 2012.pdf - Jurong Shipyard Pte Ltd

Dolphin Jan-Feb 2012.pdf - Jurong Shipyard Pte Ltd

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

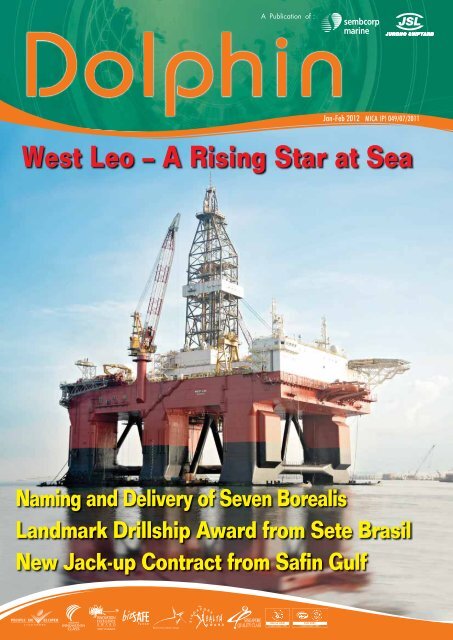

<strong>Jan</strong>-<strong>Feb</strong> 2012 MICA (P) 049/07/2011West Leo – A Rising Star at SeaNaming and Delivery of Seven BorealisLandmark Drillship Award from Sete BrasilNew Jack-up Contract from Safin Gulf

COVER STORYWest Leo - First Rig Delivery in 2012Sembcorp Marine’s subsidiary <strong>Jurong</strong><strong>Shipyard</strong> marks its first rig delivery of theyear in <strong>Jan</strong>uary 2012 with the successfulcompletion of West Leo, the second MossMaritime CS50 MKII semi-submersible rigbuilt from a six-column bare-deck hull bythe yard for Seadrill.Bound for offshore Ghana, West Leo is expected tocommence operations in the second quarter of 2012 undera one-year contract with Tullow Oil Ghana, a subsidiaryof Tullow Oil. One of the largest harsh-environment ultradeepwatersixth generation semi-submersible drilling rigswith DP3 capabilities, the rig has the multi-region fl exibilityto operate worldwide. It also has the ability to drill 35,000feet and operate in up to 10,000 feet water depth, withan accommodation capacity for 192 persons.At the naming ceremony held in November 2011, MrWong Weng Sun, Sembcorp Marine’s President & CEOand <strong>Jurong</strong> <strong>Shipyard</strong>’s Managing Director, said: “TheWest Leo is similar to the West Pegasus delivered byus in March 2011 and currently in operations in Mexico.It came to us as a bare-deck hull and we had theresponsibility to complete the engineering, installationof the topside and equipment as well as integrate thediverse equipment packages into a DP3 rig designed forthe harsh-environment. It is yet another testament of<strong>Jurong</strong> <strong>Shipyard</strong>’s ability to deliver a wide range of semisubmersibledesigns and confi gurations. Special thanksgoes to the Seadrill project team led by Mr Alex Monsenand Mr Bob Dawson, the <strong>Jurong</strong> <strong>Shipyard</strong> project teamsled by Mr Wang Zijian as well as our partners who havecontributed to the project success.”West Leo is destined for operations in Ghana.Snapshot of West LeoTypeHarsh-environment semi-submersibleDesignMoss Maritime CS50 MK IILength Overall118.56 mBeam72.20 mHeight (Keel to Main Deck) 38.65 mWater Depth10,000 ftDrilling Depth Below Rotary 35,000 ftAccommodation192 personsCommemorating the successful delivery of West Leo: (front row from right) Mr Wong Weng Sun, Sembcorp Marine’sPresident & CEO and <strong>Jurong</strong> <strong>Shipyard</strong>’s Managing Director, Mr Bob Dawson, Seadrill Management’s Project Director,Mr Don Lee, <strong>Jurong</strong> <strong>Shipyard</strong>’s Senior General Manager of Offshore, and Mr Alex Monsen, Seadrill Management’s VicePresident of Newbuild Projects, together with representatives from Seadrill Management and <strong>Jurong</strong> <strong>Shipyard</strong>.Yusheng tossing to usher in another year of stellarpartnership.02<strong>Jan</strong>-<strong>Feb</strong> 2012

FEATUREFirst Drillship Contract for Estaleiro <strong>Jurong</strong> AracruzSembcorp Marine’s wholly-ownedBrazilian shipyard Estaleiro <strong>Jurong</strong>Aracruz has secured an approximatelyUS$792.5 million contract on <strong>Feb</strong>ruary6, 2012 to design and construct adrillship based on <strong>Jurong</strong> <strong>Shipyard</strong>’sproprietary <strong>Jurong</strong> Espadon design forGuarapari Drilling BV, Netherlands, asubsidiary of Sete Brasil ParticipaçõesS.A. (Sete Brasil).Representatives from Sete Brasil, Guarapari Drilling and Estaleiro <strong>Jurong</strong> Aracruz toasting to the start ofa firm partnership.The 82.5-hectare Integrated New Brazilian Yard Facility is scheduled for full completionend 2014.Planned shipyard facilities include a 380m x 120m drydock and a 1km berthing quay.Representing the next generation of highspecification drillships, the unit offers advancedcapabilities for ultra-deepwater operationsworldwide. Designed for operational effi ciency,the drillship is equipped with state-of-the-artdrilling facilities, a larger 40-metre wide maindeckarea, effi cient deck arrangement as wellas a huge moon pool for enhanced drillingoperations. It also features Dynamic Positioningclass 3 capabilities, superior motion featuresas well as Azimuth thrusters for improvedoperability. With accommodation facilities tohouse a crew of 180 personnel, the drillship alsohas the ability to operate at 10,000 feet waterdepth and drill to depths of 40,000 feet.Scheduled for delivery no later than the secondquarter of 2015, the ultra-deepwater drillshipwill be among a series of drillships to be builtin Brazil to cater to the recent oil and gasdiscoveries in the country’s offshore giant presaltfi elds.Mr Wong Weng Sun, Sembcorp Marine’sPresident and CEO and <strong>Jurong</strong> <strong>Shipyard</strong>’sManaging Director, said: “This is a verysignifi cant milestone as this order not onlyrepresents the fi rst drillship that our Group isbuilding for Brazil but it is also the fi rst projectsecured by our new shipyard in Aracruz. Thefact that Sete Brasil has chosen our design isa testament to the drillship’s high-specifi cationcapabilities and innovative design as comparedto its peers. We believe this order will be thefi rst of many orders in Sete Brasil’s ambitiousdrillship expansion programme to develop thegiant Brazilian pre-salt oil fi elds.”Sembcorp Marine’s new Brazilian shipyard Estaleiro <strong>Jurong</strong> Aracruz will be well-positioned to meet the needs of Brazil’sthriving marine and offshore sector.Estaleiro <strong>Jurong</strong> Aracruz is a wholly-ownedsubsidiary of <strong>Jurong</strong> <strong>Shipyard</strong> and the Group’sfi rst overseas Integrated New Yard Facility inthe state of Espirito Santo, Brazil. Earlier inDecember 2011, the yard broke ground in aceremony offi ciated by the Governor of EspiritoSanto, His Excellency Renato Casagrande.<strong>Jan</strong>-<strong>Feb</strong> 201203

YARD NEWSCapricorn VoyagerʼsGrand VoyageCapricorn Voyager was the first alliance repairvessel of the year to take off from <strong>Jurong</strong> <strong>Shipyard</strong>in <strong>Feb</strong>ruary 2012 after completing her drydockingrepairs, as part of the strategic alliance betweenChevron Shipping Company and the yard.Visit by Los Andes BridgeLos Andes Bridge, a 2,450 TEU containershipmanaged by Temm Maritime Co <strong>Ltd</strong>, was usheredinto the docks of <strong>Jurong</strong> <strong>Shipyard</strong> for a scheduledstopover in <strong>Jan</strong>uary 2012.The 104,611 dwt tanker, measuring 243.56m x 42.00m x 21.30m,underwent renewal of her deck seal sea water pipes and mooringwinches brake lining as well as modifi cations on her bunker tanks anddeck steam piping. In addition, cleaning, blasting and painting wereperformed on the vessel hull prior to her sail-away. Throughout thevessel’s stay, the Chevron and <strong>Jurong</strong> <strong>Shipyard</strong> teams remainedcommitted towards excellence in health, safety, security andenvironment to ensure that the repairs proceeded smoothly.Los Andes Bridge at the dock for repairs.Capricorn Voyager setting off from the yard.Alina Regains StrengthAdding finishing touches to Alina XXIII.Alina XXIII, the 96,920 dwt oil tanker owned by SoechiLines, took on a series of repairs during her maiden visitto <strong>Jurong</strong> <strong>Shipyard</strong>.On top of routine main engine works and steel repairs on the cargo oiltanks, the vessel also underwent overhaul of stern tube seals followingtailshaft withdrawal, modifi cation of the bow mooring arrangementand repair of the heating coils in the cargo and slop tanks. Measuring243.18m x 41.83m x 20.00m, Alina XXIII also received a fresh coat ofpaint and hull blasting before leaving the yard in <strong>Jan</strong>uary 2012.In addition to repairs on the main engine, other jobs on the33,003 dwt vessel comprised renewing the windlass, winchesbrake lining, bow thruster gratings and diesel generator governorsas well as cleaning and reinforcement treatments. The repair teamalso conducted grit blasting and painting works on her hull beforethe 199.93m x 32.30m x 16.60m vessel continued her journeywithin the month.Sima Sapphire Sparkles<strong>Jurong</strong> <strong>Shipyard</strong> welcomed the arrival of SimaSapphire, a 20,291 dwt container vessel ownedby Simatech Shipping LLC (Dubai) Middle East,in <strong>Jan</strong>uary 2012.Signifi cant operations on the 1,440 TEU vessel measuring170.05m x 25.00m x 14.20m included extensive steel repairsbelow the water line and overhaul of sea water pumps. In addition,the vessel’s ship side was also blasted and coated with new paintbefore her departure in <strong>Feb</strong>ruary 2012.A polished Sima Sapphire ready for sail.04<strong>Jan</strong>-<strong>Feb</strong> 2012

YARD NEWSRickmers Twin SistersCheck InA majestic-looking ANL Windarra.ANL Windarra, a 50,629 dwt containership ownedby Rickmers Reederei Gmbh & Cie, called at <strong>Jurong</strong><strong>Shipyard</strong> in <strong>Feb</strong>ruary 2012 for her first special survey,a month after the arrival of sistership ANL Warringa.Sonangol Namibe CallsOwned by Sonangol Shipping Namibe <strong>Ltd</strong> andmanaged by International Tanker ManagementTexas Inc, Sonangol Namibe arrived in<strong>Jurong</strong> <strong>Shipyard</strong> in <strong>Jan</strong>uary 2012 for her firstdrydocking and special survey before departingin <strong>Feb</strong>ruary 2012.The repair treatments on the 274m x 48.04m x 23.70m tankerinvolved overhaul of cylinder units along with coolers and pumps aswell as assistance with cabling works for the installation of bearingwear sensors and propeller shaft torque meter. In addition, the158,425 dwt vessel underwent steel repairs on her water ballasttanks and cleaning, blasting and painting works on her hull. The yardteam’s performance on the tanker earned the praise from both herowner and ship manager.The 4,250 TEU vessels, each measuring 260.05m x 32.30m x 19.30m,received similar treatments including propeller repairs and polishingas well as overhaul of bow thruster, engine room piping and valves.In addition, the two gearless container vessels also had their cargohold air ducts and cell dividers renewed. Both vessels departed theyard in <strong>Feb</strong>ruary upon completion of repair works.ANL Warringa in the midst of repairs.Providing care and support for Sonangol Namibe.Kota Hadiah Shaping UpKota Hadiah, a 1,088 TEU container vessel ownedby Pacific International Lines (<strong>Pte</strong>) <strong>Ltd</strong> (Singapore),returned to <strong>Jurong</strong> <strong>Shipyard</strong> to undergo a seriesof maintenance jobs in <strong>Jan</strong>uary 2012, three yearsafter her last visit in 2009.Among the critical repairs on the 17,626 dwt vessel which measures159.50m x 25.00m x 12.80m were cell guides and wing tank verticalladder renewal, anchor chain renewal, stern tube seal overhaul aswell as cleaning works. Before the vessel took off in <strong>Feb</strong>ruary 2012,the team carried out hull blasting and applied a new coat of paint torefresh her appearance.Kota Hadiah ready to scale new heights.<strong>Jan</strong>-<strong>Feb</strong> 201205

YARD NEWSLNG Gemini on CourseFernao De MagalhaesRepairsFernao De Magalhaes, the 2,680 dwt cuttersuction dredger owned by <strong>Jan</strong> De Nul N.V.,docked in <strong>Jurong</strong> <strong>Shipyard</strong> from December 2011until <strong>Jan</strong>uary 2012 for renewal works.LNG Gemini’s repair operation in progress.The stay at <strong>Jurong</strong> <strong>Shipyard</strong> from December 2011to <strong>Jan</strong>uary 2012 gave LNG Gemini, a tanker ownedby PRONAV Ship Management GmbH & Co. KG,renewed strength to continue her course.During the repair and maintenance process, the vessel measuring285.30m x 45.67m x 25.00m had her cargo main pumps and coolingdownpumps overhauled. Upon completion, the 72,472 dwt tankercontinued on the next leg of her journey.Taking a break at the yard.Measuring 138.50m x 26.00m x 8.80m, the vessel visited theyard for the modifi cation of her steering nozzle and ladder hoistingsheaves, extra seafastening on the movable bow as well asfabrication and installation of skegs and headboxes. To completethe repairs, Fernao de Magalhaes received ship side blasting &painting prior to her take-off.Ultra Ace Back in ActionLeo Mono Roars OnLeo Mono, a 2,011 TEU vessel measuring 199.88m x30.50m x 16.40m, checked into <strong>Jurong</strong> <strong>Shipyard</strong> fora series of maintenance jobs, following her last visitin 2009.Repair works such as partial steel renewal and twist lock boxesrepairs were carried out on the 29,304 dwt containership belongingto Tokei Kaiun <strong>Ltd</strong>. Renewal of the rubber packing and matingplates as well as hydroblasting and coating were also done on thehatch covers. After hull blasting and painting, Leo Mono left theyard in <strong>Jan</strong>uary 2012.Ultra Ace ready for a recharge.Ultra Ace, a 150.52m x 26.00m x 13.20m bulkcarrier owned by NS United Marine Corporation,set sail from <strong>Jurong</strong> <strong>Shipyard</strong> in <strong>Jan</strong>uary 2012following damage repair works.Arriving in December 2011, Ultra Ace had her windlass and anchorchains repaired for both the port and starboard. After completionof the necessary works, the 23,649 dwt vessel left the yard andresumed her journey with renewed energy.A rejuvenated Leo Mono at the dock.06<strong>Jan</strong>-<strong>Feb</strong> 2012

SCM : AROUND THE YARDSCelebrating the Newbuilding Success of Seven BorealisSembcorp Marine’s subsidiarySembawang <strong>Shipyard</strong> successfullydelivered Seven Borealis, the world’slargest heavy lift crane carrier, toSubsea 7, a leading global seabedto-surfaceengineering, constructionand services contractor to theoffshore energy industry worldwide,on <strong>Feb</strong>rurary 22, 2012.Commemorating the significant milestone are Lady Sponsor Mrs Filomena Oliveira (centre), flankedby Mr Carlos Saturnino, Somamet’s Chairman, on her right and Mr Jean Cahuzac, Subsea 7’s ChiefExecutive Officer, together with representatives from Sembawang <strong>Shipyard</strong> and key partners.Mr Jean Cahuzac and Mr Ong Poh Kwee, Sembawang <strong>Shipyard</strong>’s Managing Director,at the memento presentation ceremony.Tour onboard the Seven Borealis.Prior to delivery, Seven Borealis was christenedby Lady Sponsor Mrs Filomena Oliveira in aceremony held at Sembawang <strong>Shipyard</strong> on<strong>Jan</strong>uary 7, 2012. The auspicious event wasattended by more than 250 guests includingMr Jean Cahuzac, Chief Executive Offi cer ofSubsea 7, Mr Carlos Saturnino, Chairman ofSomamet – the vessel’s charterer, as well assenior executives and managers from Subsea7, Sembawang <strong>Shipyard</strong> and other key partnersinvolved in this milestone newbuilding project.In his opening speech, Mr Jean Cahuzac said:“We appreciate the excellent co-operation andteamwork by project teams from both Subsea 7and Sembawang <strong>Shipyard</strong> for the completion ofthis highly challenging and sophisticated project.Seven Borealis is the jewel of our fl eet.”as well as many other specialist suppliers andequipment manufacturers.In sharing the scope of work faced by the jointproject team, Mr Ong Poh Kwee, Sembawang<strong>Shipyard</strong>’s Managing Director, said: “Thisproject has indeed presented many challenges.One of the greatest was the decision to executemajor changes in the work scope when Subsea7 took over the project from Nordic Heavy Lifton December 16, 2009. The improvementsincluded increasing the capability of the 600-tonne tension S-lay of up to 46-inch pipediameter as well as the addition of a 1,000-tonne tension J-lay system of up to 24-inch pipediameter and a fl ex-lay system.I am pleased to say that our team, jointly withthe owner’s team, has risen to the occasionand recorded noteworthy milestones for thishighly sophisticated project including thesuccessful delivery of the hull from China underour shipyard’s management and supervisionin December 2009, the installation of theworld’s largest 5,000-tonne mast crane andits successful load test, a very successful seatrialjust before Christmas last year and, notforgetting, the auspicious naming ceremony.”Indeed, the newly built dynamic positioning 3(DP3) 5000-tonne pipelay and heavy lift vessel– Seven Borealis – is a state-of-the-art strategicenabler ideally suited to meeting the exactingrequirements of ultra-deep and deepwaterprojects in the world’s harshest environments.The vessel is the result of three years of closeteamwork and collaboration, hard work anddedication of many partners, including Subsea7, Sembawang <strong>Shipyard</strong>, Huisman, Imtech,Kongsberg, Rolls Royce, NMD, Det NorskeVeritas (DNV) with which the vessel is classedThree cheers to the Seven Borealis Project Management Team members.<strong>Jan</strong>-<strong>Feb</strong> 201207

SCM : AROUND THE YARDSSafin Gulf Awards PPL <strong>Shipyard</strong> US$213M ContractSembcorp Marine’s subsidiary PPL <strong>Shipyard</strong> has signed a US$213 million contract in <strong>Feb</strong>ruary 2012 to build aPacific Class 400 jack-up rig for Safin Gulf.The jack-up, based on PPL <strong>Shipyard</strong>’s proprietaryPacifi c Class 400 design, represents the latestgeneration of high-specifi cation jack-up drillingrigs with greater capacities and capabilities thancurrent conventional units. It is also suitable fordeployment in most of the world’s challengingregions. Upon completion, the rig will be capableof operating in water depths of 400 feet anddrilling to depths of 35,000 feet. Equipped withtechnologically advanced drilling equipment,the unit also provides single- and double-roomaccommodation for 150 personnel with fullhostelry services.proprietary design just as it did with our Pacifi cClass 375 design.”Mr Raimonds Namikis, Executive Vice Presidentof Safi n Gulf, said: “Safi n Gulf is undergoingdynamic development with strategic focus inexploring and investing in new markets andopportunities. We see the development of theoffshore business as one of such businessopportunities. Having strong ambitions withinour group and rapid expansion policy in ourroadmap, we are confi dent that Safi n Gulfwould be able to expand its offshore fl eet andpresence in the Middle East.”Dr Benety Chang, Deputy Chairman of PPL<strong>Shipyard</strong>, said: “We are pleased that Safi n Gulfhas chosen PPL <strong>Shipyard</strong>’s Pacifi c Class 400design for their rig fl eet as part of its strategicexpansion into the offshore business andevolution into a leading rig-operating company.With the rig due for delivery in November2012, Safi n Gulf is expected to be successfulin securing a charter contract for the rig. Theconfi dence in this design and its capabilitiescould lead to more of such orders for ourToasting to the successful completion of the Pacific Class 400 jack-up rig.Construction Milestone for PTTEPIʼs Zawtika ProjectConstruction work for PTTEP International Limited’s (PTTEPI) Zawtika Field Development Project commenced in<strong>Jan</strong>uary 2012 at both Sembcorp Marine’s subsidiary SMOE and its associate yard Shenzhen Chiwan Sembawang<strong>Shipyard</strong> (CSE), following the strike-steel ceremony held on December 8, 2011 at CSE.Representatives from PTTEPI, SMOE and CSE at the first steel-cut ceremony in CSE.Working in close collaboration,SMOE is responsible for thefabrication of the main deck andupper deck of the 15,000 metrictonnetopside at its Singaporeyard while CSE has the task offabricating the eight-legged jacketwith piles, weighing 20,000 metrictonnes. The topside is scheduled foroffshore completion in November2013 while the jacket with pilesis expected to sail-away to BlockM9, in the Andaman Sea, offshoreMyanmar, in <strong>Jan</strong>uary 2013.08<strong>Jan</strong>-<strong>Feb</strong> 2012

SCM : NEWSNet Profit for Full Year 2011 at $752 MillionSembcorp Marine turned in a net profit of$752 million for the full year ended December 312011, amid the uncertain and volatile globalmacroeconomic environment.Turnover for 2011 was $3,960 million, down 13% as comparedwith $4,555 million in 2010. Although there was higher revenuefrom ship conversion and offshore projects, rig building projectsrecorded lower revenue recognition. The decrease also tookinto account that 2010 witnessed the resumption of revenuerecognition on the delivery of PetroRig III semi-submersible rigand the sale of CJ70 harsh-environment jack-up rig.Analysts and media at Sembcorp Marine’s full-year 2011 results announcement.Group operating profi t at $737 million was 22% lower as compared with $943 million.At pre-tax level, Group profi t decreased 20% from $1,078 million in 2010 to $860 millionin 2011.The decline in net profi t in 2011 was due to lower operating profi t from rigbuilding projects as well as the receipt of the full and fi nal amicable settlement ofthe disputed foreign exchange transactions with Societe Generale in 2010. Thisdecrease was partially offset by the higher interest income received in 2011 fordeferred payment granted to customers and the write-back of prior years’ taxover-provisions.The Board of Directors of Sembcorp Marine has proposed a special dividend of14 cents per share on top of a fi nal dividend of 6 cents per share. Including the2011 interim dividend of 5 cents per share, that brings the total dividend for 2011to 25 cents per share, representing a 69% payout ratio.Financial HighlightsYear%DescriptionFY 2011 FY 2010($’m)Change 4Q 2011 4Q 2010 %ChangeTurnover 3,960.00 4,555.00 (13) 998.00 983.00 2Gross Profi t 866.00 1,129.00 (23) 217.00 368.00 (41)EBITDA 821.00 1,026.00 (20) 224.00 319.00 (30)Operating Profi t 737.00 943.00 (22) 201.00 298.00 (33)Pre-tax Profi t 860.00 1,078.00 (20) 223.00 314.00 (29)Net Profi t 752.00 860.00 (13) 229.00 239.00 (4)Net Profi t, exclude Nol* 700.00 807.00 (13) 177.00 239.00 (26)EPS, basic (cents) 36.13 41.55 (13) 10.99 11.54 (5)NAV (cents) 115.90 125.10 (7) - - -*Nol: non-operating items & tax write-backs.Turnover ($’m) FY 2011 FY 2010%Change 4Q 2011 4Q 2010 %ChangeShip Repair 644.0 646.0 (0.3) 159.0 158.0 0.6Rig Building 2,205.0 3,048.0 (27.7) 602.0 656.0 (8.1)Ship Conversion/Offshore1,073.0 820.0 30.8 226.0 152.0 48.8Others 38.0 41.0 (5.4) 10.0 17.0 (41.0)Total 3,960.0 4,555.0 (13.1) 998.0 983.0 1.5Outlook Highlights• Net order book of $6.3 billion as at end <strong>Feb</strong>ruary 2012,with completion and deliveries till 2015.• Fundamentals of the offshore oil and gas industry remainintact underpinned by healthy oil prices and expectedgrowth in exploration and production spending.• The offshore market continues to display signs ofcyclical improvement, especially in the deep and ultradeepwatersegments.• With Sete Brasil’s drillship expansion programme todevelop Brazil’s oil fi elds, more orders are expectedfollowing the Group’s win of its fi rst ultra-deepwaterdrillship.• In the US Gulf of Mexico, deepwater drilling activitiesremain robust with ongoing drilling programmes andstrengthening day rates for oil rigs.• Ship repair services at the Group’s bigger dockscontinue to be in strong demand.• Sembcorp Marine’s ship repair and ship conversion &offshore capacity is expected to nearly double from thecurrent 1.9 million deadweight tonnes, when operationsin the Integrated New Yard Facility in Tuas ViewExtension begin in 2013.• Overall, enquiries for the various market segmentsremain healthy.(For details, please refer to the full year 2011 fi nancialstatements at www.sembcorpmarine.com.sg)Sharing the year’s performance and outlook with analysts andmedia.<strong>Jan</strong>-<strong>Feb</strong> 201209

HAPPENINGSEnvironmental Outreach though Green WaveSembawang <strong>Shipyard</strong>’s 9th Green Wave Environmental Care Competition 2011 witnessed 52 winning projects,which were chosen from a record total of 401 projects by 1,429 students, given due recognition during an awardpresentation ceremony held on <strong>Jan</strong>uary 20, 2012.Refl ecting Sembawang <strong>Shipyard</strong>’s commitment towards environmentalsustainability, the yard aims to provide a dynamic platform through theGreen Wave competition to encourage students to proactively preserveand protect the environment.The annual competition saw strong support from the schools with a recordnumber of 1,429 participants and 401 project entries received – thehighest since the event’s launch in 2003. From these submissions, a totalof 52 winning projects from primary, secondary, junior college/Institute ofTechnical Education (ITE) and tertiary levels were recognised at the awardspresentation ceremony graced by Guest-of-Honour MG (NS) Chan ChunSing, Acting Minister for Community Development, Youth and Sports &Minister of State, Ministry of Information, Communications and the Arts.Demonstrating a passion for the green cause, the project entries this yearcovered a wide variety of green issues, ranging from environmental pollutionand global warming to resource scarcity and environmental conservation. Theywere also assessed based on their originality, relevance as well as impacttowards environmental change and improvement by a panel of judges fromSembawang <strong>Shipyard</strong>, Shell, BP Shipping, governmental and environmentalLaunching the next Green Wave Challenge 2012: Guest-of-Honour MG (NS)Chan Chun Sing, Acting Minister for Community Development, Youth andSports & Minister of State, Ministry of Information, Communications andthe Arts, and Mr Ong Poh Kwee, Sembcorp Marine’s Deputy President andSembawang <strong>Shipyard</strong>’s Managing Director.bodies, environmentalists as well as professors and lecturers from tertiaryinstitutions. Both Shell and BP Shipping also lent further support throughtheir sponsorship of fi rst-prize awards in two categories as well as one-monthattachment programmes at their offi ces.Mr Ong Poh Kwee, Sembcorp Marine’s Deputy President and ManagingDirector of Sembawang <strong>Shipyard</strong>, said: “The record level of participationseen testifi es to the programme’s success in reaching out and promotinga deep sense of environmental awareness among the young generation.This positive response is indeed heartening as it shows our students’active involvement and committed efforts in making our earth greenerand better for all. Students are our future leaders and if Sembawang<strong>Shipyard</strong> can, through this programme, inspire in them the passion forenvironmental improvement, this would bode well for Singapore’s longtermsustainability.”Viewing the winning entries: MG (NS) Chan Chun Sing together with Mr GohGeok Ling, Sembcorp Marine’s Chairman, and Mr Ong Poh Kwee.Continuing its environmental responsibility efforts, Sembawang <strong>Shipyard</strong>launched the Green Wave Environmental Care Competition 2012 duringthe award ceremony and invited students and schools to participate andshare more ideas on greening the environment.Representatives from Sembawang <strong>Shipyard</strong> and its partners commemorating another successful Green Wave competition.10<strong>Jan</strong>-<strong>Feb</strong> 2012

HAPPENINGSFromGreen IdeastoWinning SolutionsTop winners fromeach student categoryshowing their passiontowards environmentalsustainability.1st Prize Award (Primary Level)Hougang Primary SchoolSoiless Vertical GardeningIn need of space for gardening in the school, the students at Hougang Primary School developeda unique and practical idea of a vertical garden using biological lamps and a rainwater harvestingsprinkler-pump system powered by a solar photovoltaic system. This winning ecosystem providesan alternative urban gardening possibility in land-scarce Singapore.1st Prize Award (Secondary Level)Hwa Chong InstitutionGreen Synthesis of Silver Nanoparticles Using Waste and WeedHwa Chong Institution students have found an environmentally friendly and greener method tosynthesise silver nanoparticles, an element which is useful for applications such as micro-electronics,medical devices and chemical engineering. Instead of toxic chemical ingredients, natural productslike fruit peel waste and lalang plants were successfully utilised by the students to produce similarnanoparticles.1st Prize Award (Junior College/ITE)ITE College Central (Balestier Campus)Used Cutting Oil Repossess MachineITE students invented a machine primarily to recover and reuse cutting oil from disposed metal chipsgenerated during a Computer Numerical Control machining process. Adopting the centrifugal forceprinciple similar to the dry-spinning method used in a washing machine, a signifi cant amount of usedoil was recovered for reuse. The students hope that their invention can encourage manufacturingindustries to do more in adopting environmentally-friendly and sustainable processes.2nd Prize Award (Tertiary Level)Ngee Ann PolytechnicGreen Power Socket for Usage Control, Monitoring & RestraintThis project from Ngee Ann Polytechnic aims to build a prototype “green power socket” that willprovide real-time energy consumption and usage cost. Users can even control the sockets remotelyvia a notebook, an iPad or a smart phone over the internet. Besides creating awareness on usagelevels, the application aims to encourage users to conserve energy.2nd Prize Award (Tertiary Level)Singapore PolytechnicWater Wheel of EnergyHarvesting fast-moving rainwater into a useful source of energy was the winning idea from SingaporePolytechnic. To prove this concept, a prototype using a micro-hydro turbine in a downpipe to generateelectricity was successfully developed. The electricity produced using this environmentally-friendlyprocess could then be stored in batteries to power outdoor signage or lighting.<strong>Jan</strong>-<strong>Feb</strong> 201211

HAPPENINGSTop Accolades for Sembcorp MarineHonoured for its sound business practices and strong financial performance, Sembcorp Marine received the“Best Managed Company in Asia” award under the construction sector category from Euromoney and wasalso named the 10th largest company in Singapore based on overseas revenue by DP Information Group in<strong>Jan</strong>uary 2012.Voted Best Managed Company in AsiaThis is the fi rst time that the Group was conferred this prestigiousaward by Euromoney, a leading fi nancial and business magazine.Sembcorp Marine was nominated by analysts from leading banks andresearch institutes based on its market strength, profi tability, growthpotential and quality of management during an annual poll conductedby the publication.Sembcorp Marine honoured as the Best ManagedCompany (Construction Sector) in Asia.Ranked among the Top 10Sembcorp Marine was recognised as one of the top ten performingcompanies in Singapore based on its overseas revenue in DP InformationGroup’s Singapore International 100 (SI100) Ranking published in <strong>Jan</strong>uary2012. The SI100 listing ranks companies that have successfully goneglobal and played their part in growing Singapore’s external economy and isco-produced by Ernst & Young.Sembcorp Marine was the 10th largestcompany in the SI100 Ranking based onits overseas revenue.2Extending Helping HandsCommitted to supporting worthy causes,volunteers from Sembcorp Marine gave theirtime to spring clean the homes of needyelderly from Sunshine Welfare ActionMission (SWAMI) on <strong>Jan</strong>uary 7, 2012.Winning hearts through giving and sharing: Employees from Sembcorp Industriesand Sembcorp Marine together with representatives from the Singapore Table TennisAssociation.Sembcorp Marine’s staff volunteers, together withstaff from Sembcorp Industries and national playersfrom Singapore’s Men and Women Table Tennis Teams,participated in this meaningful project to bring festivecheer to 25 beneficiaries in Marsiling. This heartwarminginitiative was organised by Sembcorp Industries andSWAMI, a non-profit organisation providing nursing careand shelter for the sick, aged and handicapped from lessfortunate backgrounds.12<strong>Jan</strong>-<strong>Feb</strong> 2012

HAPPENINGSWinning Ideas from Sembawang <strong>Shipyard</strong>Sembawang <strong>Shipyard</strong> held its 12th Innovation Carnival from <strong>Feb</strong>ruary 7 to8, 2012, in line with efforts to drive process improvements within the yard.The two-day event kicked off with awelcome speech by Mr Ong Poh Kwee,Sembawang <strong>Shipyard</strong>’s Managing Director,who emphasised the importance and meritsof a strong innovation culture. Followingthat, Mr Chew Hwee Hong, Ecospec GlobalTechnology’s Managing Director, presentedthe company’s latest environmental solutionswhile Hull Department shared the highlights oftheir winning project, “Standard Weights forAccommodation Ladder Testing”. An awardpresentation was also held to recognise teamswho had introduced creative solutions inenhancing safety, effi ciency and cost savings.Demonstrating the features of the project.Commemorating another successful Innovation Carnival.Aimed at promoting innovation and sharingof know-how among the staff, the carnivalshowcased a total of 50 exhibits from variousdepartments with representatives on hand toexplain the innovative features. Other highlightsof the event included exciting games at thebooths as well as stage activities which keptthe spirits high at the carnival.Join the Fight Against HIV & AIDS<strong>Jurong</strong> <strong>Shipyard</strong> staff learnt more about HIV and AIDS preventionduring a health workshop conducted by the Health Promotion Boardon <strong>Feb</strong>ruary 10, 2012.Through an interesting cabaret skit put up by two presenters, participants gained insightson the risks of sexually transmitted infections as well as precautionary measures to lead anAIDS-free life.Prevention is better than cure.Staying Fit TogetherStrengthening bonds while enjoying nature, SMOE’s employees and family members as well as clientsfrom ConocoPhillips and PTTEPI had a wonderful time at the two Tree Top Walks held on <strong>Jan</strong>uary 8 and<strong>Feb</strong>ruary 4, 2012.These walks at MacRitchie Reservoir provided unforgettable experiences for all as the participants took in the mesmerising view of the picturesquescenery and experienced the thrill of walking through the canopy of trees with their family and colleagues.Beaming with smiles before the flag-off.<strong>Jan</strong>-<strong>Feb</strong> 201213

HAPPENINGSRecognising Loyalty and Long ServiceSembcorp Marine and its group of subsidiaries paid tribute to 538 employees at the yards’ Long Service Award eventsheld in December 2011 and <strong>Jan</strong>uary 2012 in recognition of their committed service and invaluable contributions.Sembcorp Marine and <strong>Jurong</strong> <strong>Shipyard</strong>At the annual Long Service Awards Ceremony, 206 employees fromSembcorp Marine and <strong>Jurong</strong> <strong>Shipyard</strong> who have been in service for 10,15, 20, 25, 30, 35, 40 and 45 years were given due recognition forplaying a key role in the Group’s continued growth and progress.45YearsLong ServiceAwardCongratulations to the stalwarts for their 45 years of service.Mr Tan Kwi Kin, Sembcorp Marine’s Senior Advisor, receiving his 45-yearlong service award from Mr Wong Weng Sun, Sembcorp Marine’s Presidentand Chief Executive Officer.40YearsLong ServiceAwardA proud moment for employees who have served for 40 years.SMOE<strong>Jan</strong>uary 13, 2012 was a significant day for the 45 employees who have worked five to forty years at SMOE.Their contributions were recognised at the annual Long Service Awards Ceremony.Special recognition to the long-serving staff.Mr Ho Nee Sin, SMOE’s Managing Director,presenting Mr Prathaban, General Managerof FPSO Operations, with his 40-year longservice award.14<strong>Jan</strong>-<strong>Feb</strong> 2012

HAPPENINGS35YearsLong ServiceAward30YearsLong ServiceAwardAll smiles at the joyous occasion.Cheers to the staff for their 30 years of dedication.In honour of their 25 years of contributions.25YearsLong ServiceAwardMarking their 20 th year in Sembcorp Marine.20YearsLong ServiceAwardSembawang <strong>Shipyard</strong>A total of 287 staff from Sembawang <strong>Shipyard</strong>were honoured for their years of dedication tothe yard at its annual Long Service AwardsCeremony. Besides helping themselves to asumptuous luncheon, they also received giftsand tokens of appreciation.Luncheon celebration at Sembawang <strong>Shipyard</strong>.Celebrating together with long-time colleagues.Enjoying good food and company.<strong>Jan</strong>-<strong>Feb</strong> 201215

HAPPENINGSWelcoming Newcastle University Students<strong>Jurong</strong> <strong>Shipyard</strong> hosted about 70 students and lecturers from Newcastle University on <strong>Feb</strong>ruary 17, 2012 andprovided them with insights on the yard’s marine and offshore engineering operations.Highlights of the visit included an opening speech by Mr Lee Yeok Hoon, <strong>Jurong</strong> <strong>Shipyard</strong>’s Executive Director of New Yard Development, and severalpresentations on the yard’s capabilities. The visitors were also given a fi rst-hand introduction to the facilities during the walking yard tour.Mr Lee Yeok Hoon, <strong>Jurong</strong> <strong>Shipyard</strong>’s Executive Director of New Yard Development, sharinginsights with the professors and students.Showing keen interest in the yard’s operations.Building Teamwork through FutsalEight teams from <strong>Jurong</strong> <strong>Shipyard</strong>’s Machinery Fitting andHVAC & Hydraulic departments held a friendly futsal matchat <strong>Jurong</strong> Outdoor Futsal Centre on <strong>Feb</strong>ruary 18, 2012.Each team, comprising footballers from the two departments, fought hard toclinch the top spot. At the end of the exciting competition, the “KHS Donkey”team claimed the Challenge Trophy while the “Newcastle Pandas” and “Kiwis”teams emerged first and second runners-up respectively after a tough fight.Besides having a great workout, the players also forged closer friendship andrapport during the fast-paced game.Sharing strong team spirit and camaraderie.No More Pains<strong>Jurong</strong> <strong>Shipyard</strong>’s employees took part in the yard’s first wellnessworkshop of the year on <strong>Jan</strong>uary 13, 2012 and discovered a new way torelieve neck and shoulder tensions.Besides understanding the underlying causes, participants also picked up useful yoga exercisesto relax the neck and shoulder areas.Learning yoga techniques from the master.Relaxing neck and shoulder muscles together.About Preventing AchesCauses• Prolonged hours of sitting in frontof the computer• Muscle and ligament injuries• Poor sitting posture• Incorrect sleeping postureDIY Techniques• Neck exercises• Shoulder rotations• Maintain proper standing, sitting,lying and sleeping positions• Practise yoga<strong>Dolphin</strong> is a bi-monthly publication of Sembcorp Marine <strong>Ltd</strong> (Reg. No. 196300098Z)and its subsidiary <strong>Jurong</strong> <strong>Shipyard</strong> <strong>Pte</strong> <strong>Ltd</strong> (Reg. No. 199908265G). No part of thisnewsletter may be reproduced or transmitted by any means or stored in anyinformation storage and retrieval system without the publishers’ written permission.Contact us :The Editorial Team • 29 Tanjong Kling RoadSingapore 628054 • ir@sembcorpmarine.com.sgFor more information, visit us at : www.sembcorpmarine.com.sg • www.jspl.com.sg