BilgeEconomiser - RWO Marine Water Technology

BilgeEconomiser - RWO Marine Water Technology

BilgeEconomiser - RWO Marine Water Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

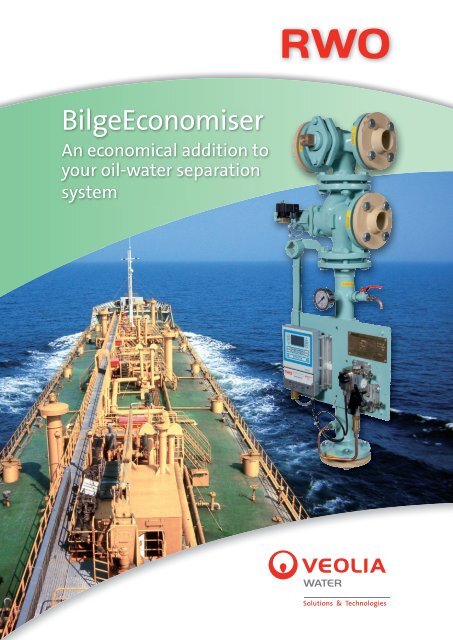

<strong>BilgeEconomiser</strong><br />

An economical addition to<br />

your oil-water separation<br />

system

<strong>BilgeEconomiser</strong><br />

Detect clean drains and economise your oil-water separation<br />

A small issue<br />

with big outcome The <strong>BilgeEconomiser</strong> is an easy to operate standalone<br />

oil monitor with automatic and manual 3-way<br />

Aboard every ship, so called ‘clean drains’ are treated valves and is installed after the discharge pump of the<br />

in oil-water separation systems and strain machines clean drain holding tank. As long as the oil content of<br />

and resources. These clean drains usually consist of the clean drain is below the set discharge limit value,<br />

leakage of and condensate from equipment used for it is discharged directly overboard. Whenever the oil<br />

seawater, fresh water, steam, air conditioning, etc., content exceeds the set limit value it is diverted to<br />

which are usually not contaminated by oil.<br />

the bilge holding tank for further treatment by the<br />

oily water separator.<br />

Based on the IMO guidelines for ‘Integrated bilge<br />

water treatment systems“ (IMO MEPC.1/Circ.642),<br />

<strong>RWO</strong> has developed the <strong>BilgeEconomiser</strong>.<br />

The <strong>BilgeEconomiser</strong> allows ship operators to dis-<br />

charge so called ‘clean drains’ overboard without any<br />

further treatment.<br />

As a consequence the bilge water volume handled<br />

by the oily water separator is much smaller, which<br />

reduces not only operating cost significantly.<br />

Your advantages<br />

Increased cargo capacity due to smaller<br />

bilge holding tank<br />

Fewer operations of OWS required<br />

(not allowed in certain areas/ports)<br />

Smaller oily water separator (reduced capex)<br />

Increased maintenance intervals and<br />

reduced labour cost<br />

<strong>RWO</strong> GmbH<br />

MARINE WATER TECHNOLOGY<br />

Thalenhorststrasse 15 A<br />

28307 Bremen/Germany<br />

Phone: +49 421 53 70 50<br />

Fax: +49 421 53 70 54 40<br />

rwo@veoliawater.com<br />

www.rwo.de · www.veoliawater.com<br />

Working principle<br />

water outlet<br />

air connection<br />

(6 - 8 bar)<br />

pressure<br />

gauge<br />

0 - 10 bar<br />

to the bilge<br />

water tank<br />

sample<br />

cock<br />

sample<br />

water<br />

outlet<br />

fl ushing<br />

water<br />

inlet<br />

bilge<br />

water<br />

inlet<br />

Stand: 8.2012