Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

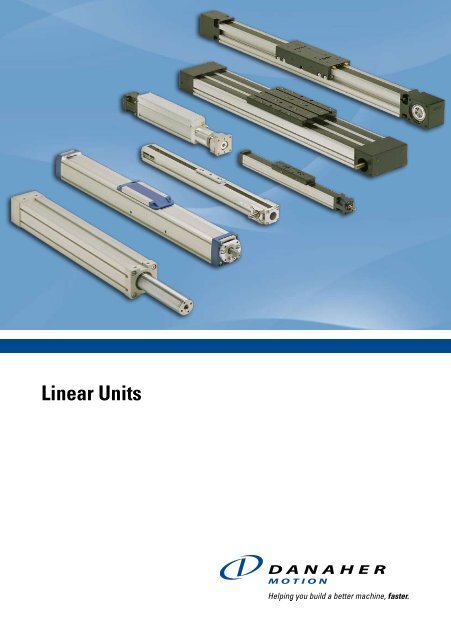

<strong>Linear</strong> <strong>Units</strong>

<strong>Linear</strong> <strong>Units</strong>Table of ContentsIntroduction...................................................................................................... 5Introduction.............................................................................................. 5How to Choose a Unit.........................................................................6 - 7Technical Introduction......................................................................8 - 11<strong>Linear</strong> <strong>Units</strong> with Ball Screw Drive and Ball Guide............................... 13Introduction............................................................................................. 13Overview...........................................................................................14 - 15WM40S..............................................................................................16 - 17WM40D.............................................................................................18 - 19WM60D.............................................................................................20 - 21WM60S..............................................................................................22 - 23WM60X..............................................................................................24 - 25WM80D.............................................................................................26 - 27WM80S..............................................................................................28 - 29WM120D...........................................................................................30 - 31WV60.................................................................................................32 - 33WV80.................................................................................................34 - 35WV120...............................................................................................36 - 37MLSM60D.........................................................................................38 - 39MLSM80D.........................................................................................40 - 412HBE10..............................................................................................42 - 432HBE20..............................................................................................44 - 45<strong>Linear</strong> <strong>Units</strong> with Ball Screw Drive and Slide Guide............................. 47Introduction............................................................................................. 47Overview...........................................................................................48 - 49WB40.................................................................................................50 - 51WB60.................................................................................................52 - 53M55....................................................................................................54 - 55M75....................................................................................................56 - 57M100..................................................................................................58 - 59M75D..................................................................................................60 - 61M100D................................................................................................62 - 63<strong>Linear</strong> <strong>Units</strong> with Belt Drive and Ball Guide............................................ 65Introduction............................................................................................. 65Overview...........................................................................................66 - 67WH40.................................................................................................68 - 69WM60Z..............................................................................................70 - 71WM80Z, standard carriage............................................................72 - 73WM80Z, short carriage..................................................................74 - 75M55....................................................................................................76 - 77M75....................................................................................................78 - 79M100..................................................................................................80 - 81MLSM80Z..........................................................................................82 - 83<strong>Linear</strong> <strong>Units</strong> with Belt Drive and Slide Guide.......................................... 85Introduction............................................................................................. 85Overview...........................................................................................86 - 87M50....................................................................................................88 - 89M55....................................................................................................90 - 91M75 ...................................................................................................92 - 93M100..................................................................................................94 - 95<strong>Linear</strong> <strong>Units</strong> with Belt Drive and Wheel Guide....................................... 97Introduction............................................................................................. 97Overview...........................................................................................98 - 99WH50.............................................................................................100 - 101WH80.............................................................................................102 - 103WH120...........................................................................................104 - 105MLSH60Z.......................................................................................106 - 107MLSH80Z.......................................................................................108 - 109<strong>Linear</strong> Lifting <strong>Units</strong>...................................................................................... 111Introduction........................................................................................... 111Overview...................................................................................... 112 - 113WHZ50...........................................................................................114 - 115WHZ80...........................................................................................116 - 117Z2....................................................................................................118 - 119Z3....................................................................................................120 - 121ZB...................................................................................................122 - 123<strong>Linear</strong> Rod <strong>Units</strong>.......................................................................................... 125Introduction........................................................................................... 125Overview.......................................................................................126 - 127WZ60..............................................................................................128 - 129WZ80..............................................................................................130 - 131T90..................................................................................................132 - 133T130................................................................................................134 - 135Accessories................................................................................................. 137Accessory index................................................................................... 137Mounting Kits...............................................................................138 - 143Cover and Protection Kits..........................................................144 - 146Motors, Gears and Transmission Kits......................................147 - 171Electrical Feedback Devices.....................................................172 - 181Non Driven <strong>Units</strong>.........................................................................182 - 187Dynamic Servo Actuators................................................................... 188Multi Axis System Kits......................................................................... 189Additional Technical Data......................................................................... 191Additional Technical Data Tables.............................................191 - 195Drive Calculations.......................................................................196 - 197Deflection Calculations..............................................................198 - 199Ordering........................................................................................................ 201How to Order......................................................................................... 201Keys for <strong>Units</strong> with Ball Screw and Ball Guides....................202 - 205Keys for <strong>Units</strong> with Ball Screw and Slide Guides..................206 - 208Keys for <strong>Units</strong> with Belt Drive and Ball Guides......................209 - 212Keys for <strong>Units</strong> with Belt Drive and Slide Guides............................. 213Keys for <strong>Units</strong> with Belt Drive and Wheel Guides.................214 - 215Keys for <strong>Linear</strong> Lifting <strong>Units</strong>.......................................................216 - 217Keys for <strong>Linear</strong> Rod <strong>Units</strong>.................................................................... 218Keys for Non Driven <strong>Units</strong>..........................................................219 - 220www.danahermotion.com

www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>IntroductionDanaher Motions linear units range consists of products from world known brandssuch as Thomson, Neff and Tollo. These three companies have been a part of thelinear unit development elite for decades and are now forming one group of productsoffered to the market under the brand name Danaher Motion. Regardless of yourapplication you can be sure that Danaher Motion can offer you a product to matchyour linear motion needs.NeffThomsonDanaher MotionTolloNeff was founded in 1905 offering products for the linear motionmarket and over the decades Neff has become a market leaderthe ball screw technology. The first linear unit from Neff waspresented in 1981 at the FAMETA show in Stuttgart.Thomson dates back to the 1940s when the first ball bushingbearing in the world was presented to the market. The productporfolio expanded and in the 1980s Thomson built their firstcomplete linear unit.Danaher Motion has now selected the most competitiveproducts from each brand resulting in a state of the art productrange. The range covers the smallest and most compact linearunits to the biggest and most robust. Danaher Motion canmatch your linear motion needs with a wide range of ball screwand belt driven units using a variety of guide technologies,designed to work in harsh environments, at high speeds or inhigh precision systems.Tollo was founded in 1981 and started as a lifting equipmentmanufacturer. The product potfolio grew rapidly and in 1982Tollo presented their first linear unit at the Technical Fair inStockholm.www.danahermotion.com

How to Choose a UnitDanaher Motion offer a wide range of linear units, each designedfor a specific purpose and with its own unique features. Onwww.danahermotion.com/PosSlides_Lin<strong>Units</strong>_advisor you canfind a product advisor that will help you specify the unit you need,and our application engineers will be happy to help you withfurther technical advice.Ball Screw Driven, Ball Guided <strong>Units</strong>VelocityNoiseAccelerationThe diagrams shown here give you a brief overview of the keystrengths of each group.MaintenanceRepeatabilityCostForceGuide Robustness Load TorqueStiffness<strong>Units</strong> designed for high thrust, payload, high precision andstiffness.• Force up to 12000 N• Repeatability down to 0,005mmBall Screw Driven, Slide Guided <strong>Units</strong>Belt Driven, Ball Guided <strong>Units</strong>VelocityVelocityNoiseAccelerationNoiseAccelerationMaintenanceRepeatabilityMaintenanceRepeatabilityCostForceCostForceGuide Robustness Load TorqueStiffnessGuide Robustness Load TorqueStiffnessDesigned for low cost, high thrust operations in demandingenvironments.• Cost efficient units • Washdown protected versions• Durable guide systemSmooth running units for dynamic applications with high speed,high acceleration and high loads requiring a long lifetime.• Speed up to 5 m/s• Acceleration up to 40 m/s 2www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>Belt Driven, Slide Guided <strong>Units</strong>Belt Driven, Wheel Guided <strong>Units</strong>Velocity VelocityNoiseAccelerationNoiseAccelerationMaintenanceRepeatability MaintenanceRepeatabilityCostForceCostForceGuide Robustness Load TorqueStiffnessGuide Robustness Load TorqueStiffness<strong>Units</strong> for dynamic applications requiring high speed, high acceleration,low maintenance and smooth travel.• Cost efficient guide system• Chemically protected versions<strong>Units</strong> for dynamic applications with high speed, high acceleration,smooth motion and medium to high loads.• Speed up to 10 m/s• Acceleration up to 40 m/s 2<strong>Linear</strong> Lifting <strong>Units</strong><strong>Linear</strong> Rod <strong>Units</strong>Developed for lifting applications<strong>Linear</strong> units with rodTelescopic modelsavailableModels with ballscrew or belt drivePerfect for hydraulicsreplacementHigh accuracyball screw driveLoad up to750 kgHighrepeatabilityLoad up to40 000 NHighrepeatabilitySpeed up to10 m/sStroke up to3000 mmSpeed upto 2 m/sStroke up to2000 mmBall, slide orwheel guided modelsLarge rangeof accessoriesBall or slideguided modelsLarge rangeof accessoriesLoad torqueup to 2000 NmModels withIP65 sealing<strong>Units</strong> for lifting applications. Often used in X-Y configurations incombination with other linear units.<strong>Units</strong> designed for lifting applications or for the replacement ofhydraulic and pneumatic cylinders.www.danahermotion.com

Technical IntroductionBasic <strong>Linear</strong> Unit TerminologyScrew Driven UnitBelt Driven UnitDouble CarriagesRear Bearing HousingSingle CarriageTension StationCover BandProfileDrive shaftFront Bearing HousingT-slot/mounting grooveDrive StationDrive shaftBall Screw DriveA ball screw is made up of a rotating screw and a moving ball nut.The ball nut is attached to the carriage of the unit. It does not have anormal thread, instead balls circulate inside the nut making it work as anefficient ball bearing that travels along the screw. Ball screws come ina large variety of leads, diameters and tolerance classes. The toleranceclass (T3, T5, T7 or T9) indicates the lead tolerance of the screw. Thelower the number, the higher the tolerance. High load capability andhigh accuracy are typical of ball screw driven units.Belt DriveA belt drive consists of a toothed belt which is attached to the carriageof the unit. The belt runs between two pulleys positioned at either endof the profile. One pulley is attached to the motor while the other ismounted in a tensioning station. The belts are made of plastic reinforcedwith steel cords. High speeds, long stroke, low noise and low overallweight are typical features of belt driven units.www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>Technical IntroductionBall GuidesA ball guide consists of a ball rail and a ball bushing. The ball rail is madeof hardened steel and runs along the inside of the profile. The ball bushingis attached to the carriage of the unit and contains balls that roll againstthe rail. The balls in the bushing can be recirculating or have fixed ballpositions depending on the type of ball guide. The recirculating type has alonger life and better load capability while the fixed type typically is muchsmaller. Danaher Motion uses three major types of ball guides in its linearunits. Either the compact single rail type with recirculating ball bushing(A), the stronger double rail type also with recirculating ball bushings (B)or the fixed ball position ball bushings type (not shown) which requirevery little space and are used in the smallest units. Ball guides offer highaccuracy, high loads and medium speed.Wheel GuidesA wheel guide consists of ball bearing wheels that run on a hardenedsteel rail. Wheel guides are a simple and robust guiding method offeringhigh speeds, high loads and medium accuarcy.AScrew SupportsScrew supports allow screw driven units to travel at high speed evenwhen stroke becomes longer. The supports reduce the unsupportedlength of the screw, that otherwise would be subjected to vibrations.Screw supports come in single (one screw support on each side of thecarriage) or double (two supports on each side) versions. Screw supportunits will have a slightly shorter stroke for a given overall length.BSlide GuidesA slide guide consist of a guide attached to the inside of the profile anda slide bushing attached to the carriage. The guide can be made ofdifferent materials (e.g. polished hardened steel, anodized aluminium)while the bushing is made of a polymer material. There are two typesof bushings, fixed and prism. Prism bushings can move in relation tothe guide which results in longer life and higher load capabilities. Slidebushings are silent, simple, reliable and robust and can be used in dirtyand dusty environments. They are also resistant to shock loads, have along life expectancy and require little or no maintenance.Ball Screw <strong>Units</strong> with Double Ball NutsUsing double ball nuts will increase the repeatability of the unit. Theball nuts are installed so that they are pre-tensioned against each othereleminating the play between the nuts and the screw. A double nut unitwill have a slightly shorter stroke for a given overall length.www.danahermotion.com

Technical IntroductionSingle CarriageSingle carriage units have one carriage. Some linear unit models alsohave the option of long or short single carriage. The long carriage handlehigher loads but will have a longer overall length for a given stroke.Double CarriagesDouble carriage units have two carriages which gives them higher loadcapabilites than single carriage units. When ordering a double carriageunit the distance between the two carriages needs to be defined. Thisdistance is called La or Lc depending on the model.Cover BandCover bands are used on some units to protect then from the ingress offoreign objects through the opening in the profile where the carriageruns. They are made of plastic (A) or stainless steel (B). In the case ofplastic the cover band seals the profile by snapping into small groovesrunning along the carriage opening. In the case of stainless steel thecover band seal the profile magnetically using magnet strips mountedon each side of the carriage opening. Some units equipped with coverbands also have a self-adjusting cover band tensioning mechanism. Thiseleminates any slack in the cover band that can occur from temperaurechanges, thus improving the sealing degree and the expected life of thecover band.Theoretical Stroke and Practical StrokeThe theoretical maximum stroke (S max) is the length that the carriagecan travel from one end of the unit to the other. However, using themaximum stroke means that the carriage will collide with the ends ofthe profile. The practical stroke is therefore shorter. We recommendthat you specify a unit that have at least 100 mm longer stroke than themaximum stroke you need so that the unit can stop before colliding withthe ends and also allow for some adjustment of the unit postition at themounting.A<strong>Units</strong> with Left/right Moving Carriages<strong>Units</strong> with left/right moving carriages have two carriages moving inopposite directions when the drive shaft is rotated. This type of unit hasa ball screw where half of the screw has a left hand thread and the otherhalf a right hand thread.B10 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>Technical IntroductionMaintenanceMost units require lubrication. General lubrication requirements can befound in the general specifications table on the product data pages. Thelubrication intervals, grease qualities and specific lubrication instructionscan be found in the installation and service manual of each unit. Noother regular maintenance is needed except for normal cleaning andinspection. <strong>Units</strong> with a cover band may also require irregular cover bandreplacement due to wear. The belt in belt driven units should not requirere-tensioning under normal operating conditions.Mounting PositionMost units can be mounted in any direction. Any restrictions on mountingpositions are shown on the product presentation pages at the beginningof each product category chapter. Even where units may be mounted inany direction there are some considerations. None of the units are selflockingwhich means that a vertical unit will drop the carriage/load if noexternal brake (such as a brake in the motor, etc.) is applied to the driveshaft of the unit. In the case of belt driven units care must be taken as thecarriage/load will drop immediately in the case of a belt breakage. This isparticularly important in vertical applications. All ball screw driven unitsare equipped with a safety nut to prevent the carriage/load being releasedin case of ball breakage.Working EnvironmentAll units are designed for use in normal industrial environments. <strong>Units</strong>which have an open profile (i.e. have no cover band) are more sensitive todust, dirt and fluids. These units require some kind of cover if they are usedin environments where dust, dirt or fluids are present. Optional bellows/shrouds are available for some of our open profile units. Enhanced washdownor chemical protection can be ordered for our closed profile units.Please refer to the accessory pages. In all cases where a unit will beexposed to aggressive chemicals, heavy vibrations or other potentiallyharmful processes we recommend that you contact us for further advice.Duty CycleAll units are designed for a 100% duty cycle. However, where the unitruns at extreme load, speed, acceleration and temperature or for longoperating periods the expected life time may be reduced.Operation and Storage TemperatureOperational temperature limits can be found in the performance tableson the product data pages. <strong>Units</strong> can be stored or transported within thesame temperature range. Please contact us if the unit will be exposedto higher/lower temperatures than recommended during storage ortransportationLoad and Load Torque ValuesFor some units the load and load torque values are given for both the completeunit and the guiding system. The values for the complete unit arethe values under which the unit can operate. The values for the guidingsystem should only be used when comparing different units and do notdescribe the actual performance of the complete unit.Deflection of the ProfileSome units require support along the whole profile whilst some areself supporting over a specified span. Further details can be found onthe product data pages. The recommended support intervals shouldbe followed to minimise deflection of the unit. The maximum distancebetween the support points is shown on the product data pages. Thedeflection of the unit can also be calculated using the information in theAdditional data and calculations chapter.Lifetime ExpectancyWhen determining the lifetime for a linear unit it is necessary to evaluateall forces and moments that are acting on the unit. The data and formulasgiven in this catalogue serve as a basis for this. For a more detailed lifetimecalculation please use our sizing and selection software. Please contactus for further guidance.End of Stroke Limit SwitchesIf a unit runs at speed to the ends of its stroke there is a risk of damage.Damage can be prevented by using end of stroke limit switches to detectand engage a brake and/or cut power to the motor when the unit nears theend of the unit. You must ensure that there is sufficient distance betweenthe end of stroke limit switch and the end of the unit, to allow the carriageto come to a complete stop before colliding with the end. The requiredstopping distance depends on the speed and the load and will have to becalculated for each application. The stopping distance must be taken intoaccount when defining the necessary stroke.Position FeedbackThe position of the carriage/rod/lifting profile can be obtained in manyways. The most common way is to equip the unit with an encoder or touse a motor which has a built in feed back device (encoder, resolver, etc.).To many units there are encoders or/and encoder mounting kits available.See the accessory chapter.Packages and Multi Axis KitsDanaher Motion can offer complete pre-defined packages (linear unit,gear and servo motor assembled and shipped with servo drive and cables)as well as mounting kits for the creation of two and three axis systemsPlease contact us for further information.www.danahermotion.com11

12 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong><strong>Linear</strong> <strong>Units</strong> with Ball Screw Drive and Ball GuidePowerLine, ForceLine, Microstage, AccuSlideVelocityNoiseAccelerationMaintenanceRepeatabilityCostForceGuide RobustnessLoad TorqueStiffnessTypical ApplicationsTypical applications are where high accuracy and load capability is required butwhere speed is less important. Typical examples are machining operations and inthe handling of heavy goods that need accurate positioning.www.danahermotion.com13

PowerLine WMWM40Features• Can be installed in all directions• Patented guide system• Patented self-adjusting plastic cover band• Patented screw support systemParameter WM40S WM40D WM60D WM60S WM60X WM80D WM80S WM120DProfile size (width × height) [mm] 40 × 40 40 × 40 60 × 60 60 × 60 60 × 60 80 × 80 80 × 80 120 × 120Stroke length (S max), maximum [mm] 2000 2000 11000 5000 10340 11000 5000 11000<strong>Linear</strong> speed, maximum [m/s] 0,25 0,25 2,5 2,5 0,25 2,5 2,5 2,0Dynamic carriage load (Fz), maximum [N] 600 600 2000 1400 2000 3000 2100 6000Remarkssingle ballnutdouble ballnutsdouble ballnutssingle ballnutleft/rightscrewdouble ballnutssingle ballnutdouble ballnutsPage 16 18 20 22 24 26 28 30PowerLine WVWV80Features• Can be installed in all directions• Patented self-adjusting plastic cover band• Patented screw support system• The units require external guidesParameter WV60 WV80 WV120Profile size (width × height) [mm] 60 × 60 80 × 80 120 × 120Stroke length (S max), maximum [mm] 11000 11000 11000<strong>Linear</strong> speed, maximum [m/s] 2,5 2,5 2,0Dynamic carriage load (Fz), maximum [N] - - -Remarksdouble ball nutsthe units has no guidesdouble ball nutsthe units has no guidesdouble ball nutsthe units has no guidesPage 32 34 36ForceLine MLSMMLSM80DFeatures• Can be installed in all directions• Patented guide system• Patented plastic cover band• Patented screw support systemParameter MLSM60D MLSM80DProfile size (width × height) [mm] 160 × 65 240 × 85Stroke length (S max), maximum [mm] 5500 5200<strong>Linear</strong> speed, maximum [m/s] 2,5 2,0Dynamic carriage load (Fz), maximum [N] 6000 8000Remarks double ball nuts double ball nutsPage 38 4014 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>AccuSlide 2HBE2HBE20Features• Can be installed in all directions• High load capablities• Low profile height• Play free ball screw offer high repeatabilityParameter 2HBE10 2HBE20Profile size (width × height) [mm] 100× 33,5 200 × 44Stroke length (S max), maximum [mm] 850 2800<strong>Linear</strong> speed, maximum [m/s] 0,5 1,3Dynamic carriage load (Fz), maximum [N] 8250 38000Remarksno cover band, bellows or shrouds optionavailableno cover band, bellows or shrouds optionavailablePage 42 44WM-Series Technical PresentationScrew supportPatented screw support systempermits high speed at long strokelengths while reducing the strokewith a minimum.Double ball nutsDouble pre-tensioned ball nutsimprove the accuracy and allowsre-tensioning increasing thelifetime of the unit.Central lubricationOne central lubrication point onthe carriage services the entireunit resulting in a minimummaintenace required.Ball guidesIntegrated patented ball guideswith hardened steel tracks foroptimum performance.www.danahermotion.comBall cagesThe balls in the ball guides areprotected by a ball cage whichensures a long life.Cover bandThe patented self-adjustingcover band protect the unit fromthe penetration of dirt, dust andliquids.15

WM40SBall Screw Drive, Ball Guide, Single Ball Nut» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM40SProfile size (w × h) [mm] 40 × 40Input speed [rpm]Screw lead [mm]p = 5Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with single nutself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,31500 0,53000 0,8M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM40SStroke length (S max), maximum [mm] 2000<strong>Linear</strong> speed, maximum [m/s] 0,25Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,02Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Critical SpeedOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 1000Dynamic load (Fy), maximum [N] 450 1 / 5300 2Dynamic load (Fz), maximum [N] 600 1 / 6790 2Dynamic load torque (Mx), maximum [Nm] 10 1 / 30 2Dynamic load torque (My), maximum [Nm] 30 1 / 230 2Dynamic load torque (Mz), maximum [Nm] 30 1 / 230 2Drive shaft force (Frd), maximum [N] 100Drive shaft torque (Mta), maximum [Nm] 3Definition of ForcesBall screw diameter (d0) [mm] 12Ball screw lead (p) [mm] 5Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]1,500,300,3616 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM40SBall Screw Drive, Ball Guide, Single Ball NutA1: depth 7A2: lubricating nipple on both sides DIN3405 D 1/AStroke length (S max) [mm] A [mm] B [mm] C [mm]0 – 500 (0 – 450) 65 35 270 (320)501 – 1100 (451 – 1050) 65 45 280 (330)1101 – 2000 (1051 – 1950) 70 60 300 (350)Values between brackets = for units with long carriageA3: socket cap screw ISO4762-M5×12 8.8A4: ENF inductive sensor rail option kit (optional)Double CarriagesParameterWM40SMinimum distance between carriages (L A) [mm] 175Dynamic load (Fy), maximum [N] 900Dynamic load (Fz), maximum [N] 1200Dynamic load torque (My), maximum [Nm] L A 1 × 0,45Dynamic load torque (Mz), maximum [Nm] L A 1 × 0,6Force required to move second carriage [N] 40Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com17

WM40DBall Screw Drive, Ball Guide, Double Ball Nuts, Long Carriage» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM40DProfile size (w × h) [mm] 40 × 40Input speed [rpm]Screw lead [mm]p = 5Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,41500 0,63000 0,9M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM40DStroke length (S max), maximum [mm] 1950<strong>Linear</strong> speed, maximum [m/s] 0,25Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Critical SpeedOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 1000Dynamic load (Fy), maximum [N] 450 1 / 5300 2Dynamic load (Fz), maximum [N] 600 1 / 6790 2Dynamic load torque (Mx), maximum [Nm] 10 1 / 30 2Dynamic load torque (My), maximum [Nm] 30 1 / 230 2Dynamic load torque (Mz), maximum [Nm] 30 1 / 230 2Drive shaft force (Frd), maximum [N] 100Drive shaft torque (Mta), maximum [Nm] 3Definition of ForcesBall screw diameter (d0) [mm] 12Ball screw lead (p) [mm] 5Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]1,900,300,6018 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM40DBall Screw Drive, Ball Guide, Double Ball Nuts, Long CarriageA1: depth 6A2: lubricating nipple on both sides DIN3405 D 1/AA3: socket cap screw ISO4762-M5×12 8.8A4: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 – 500 65 35 320501 – 1100 65 45 3301101 – 2000 70 60 350Double Long CarriagesParameterWM40DMinimum distance between carriages (L A) [mm] 225Dynamic load (Fy), maximum [N] 900Dynamic load (Fz), maximum [N] 1200Dynamic load torque (My), maximum [Nm] L A 1 × 0,45Dynamic load torque (Mz), maximum [Nm] L A 1 × 0,6Force required to move second carriage [N] 40Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com19

WM60DBall Screw Drive, Ball Guide, Double Ball Nuts» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM60DProfile size (w × h) [mm] 60 × 60Input speed [rpm]Screw lead [mm]p = 5 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,8 1,3 1,61500 1,4 2,0 2,43000 1,8 2,3 2,6M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM60DStroke length (S max), maximumscrew lead 5, 20 mmscrew lead 50 mm[mm]110005000<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 6300 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 4000Dynamic load (Fy), maximum [N] 2000 1 / 45980 2Dynamic load (Fz), maximum [N] 2000 1 / 42320 2Dynamic load torque (Mx), maximum [Nm] 100 1 / 740 2Dynamic load torque (My), maximum [Nm] 200 1 / 2990 2Dynamic load torque (Mz), maximum [Nm] 200 1 / 3250 2Drive shaft force (Frd), maximum [N] 500Drive shaft torque (Mta), maximum [Nm] 35Ball screw diameter (d0) [mm] 20Ball screw lead (p) [mm] 5, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]6,160,651,9920 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM60DBall Screw Drive, Ball Guide, Double Ball NutsA1: depth 11A2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 695 (0 - 505) 115 65 460 (650)696 - 1335 (506 - 1145) 165 115 560 (750)1336 - 2075 (1146 - 1885) 185 135 600 (790)2076 - 2780 (1886 - 2590) 210 160 650 (840)Values between brackets = for units with long carriageA4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]2781 - 3545 (2591 - 3355) 230 180 690 (880)3546 - 4285 (3366 - 4095) 250 200 730 (920)4286 - 5015 (4096 - 4825) 275 225 780 (970)5016 - 11000 (4826 - 10810) contact customer serviceLong CarriageParameterWM60DCarriage length [mm] 450Dynamic load torque (My), maximum [Nm] 500Dynamic load torque (Mz), maximum [Nm] 500Weight [kg] 3,1A1: depth 11Double CarriagesParameterWM60DMinimum distance between carriages (L A) [mm] 335Dynamic load (Fy), maximum [N] 4000Dynamic load (Fz), maximum [N] 4000Dynamic load torque (My), maximum [Nm] L A 1 × 2Dynamic load torque (Mz), maximum [Nm] L A 1 × 2Force required to move second carriage [N] 200Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com21

WM60SBall Screw Drive, Ball Guide, Single Ball Nut, Short Carriage» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM60SProfile size (w × h) [mm] 60 × 60Input speed [rpm]Screw lead [mm]p = 5 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with single nutself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,7 1,0 1,41500 1,1 1,6 2,03000 1,5 1,8 2,2M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM60SStroke length (S max), maximum [mm] 5000<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 10Repeatability [± mm] 0,02Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 2800Dynamic load (Fy), maximum [N] 1400 1 / 25920 2Dynamic load (Fz), maximum [N] 1400 1 / 23860 2Dynamic load torque (Mx), maximum [Nm] 50 1 / 410 2Dynamic load torque (My), maximum [Nm] 100 1 / 320 2Dynamic load torque (Mz), maximum [Nm] 100 1 / 320 2Drive shaft force (Frd), maximum [N] 500Drive shaft torque (Mta), maximum [Nm] 35Ball screw diameter (d0) [mm] 20Ball screw lead (p) [mm] 5, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]3,800,651,0022 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM60SBall Screw Drive, Ball Guide, Single Ball Nut, Short CarriageA1: depth 11A2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 580 95 20 335581 - 1140 110 60 3901141 - 1805 130 80 4301806 - 2460 155 105 480A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]2461 - 3125 175 125 5203126 - 3780 200 150 5703781 - 4445 220 170 6104446 - 5000 240 190 650Double Short CarriagesParameterWM60SMinimum distance between carriages (L A) [mm] 255Dynamic load (Fy), maximum [N] 2800Dynamic load (Fz), maximum [N] 2800Dynamic load torque (My), maximum [Nm] L A 1 × 1,4Dynamic load torque (Mz), maximum [Nm] L A 1 × 1,4Force required to move second carriage [N] 180Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com23

WM60XBall Screw Drive, Ball Guide, Left/right Moving Carriages» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM60XProfile size (w × h) [mm] 60 × 60Input speed [rpm]Screw lead [mm]p = 5Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 1,61500 2,83000 3,6M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM60XStroke length (S max), maximum [mm] 10340<strong>Linear</strong> speed, maximum [m/s] 0,25Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000Operation temperature limits [°C] 0 – 80A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 5400 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesDynamic load (Fx), maximum [N] 4000Dynamic load (Fy), maximum [N] 2000 1 / 45980 2Dynamic load (Fz), maximum [N] 2000 1 / 42320 2Dynamic load torque (Mx), maximum [Nm] 100 1 / 740 2Dynamic load torque (My), maximum [Nm] 200 1 / 2990 2Dynamic load torque (Mz), maximum [Nm] 200 1 / 3250 2Drive shaft force (Frd), maximum [N] 500Drive shaft torque (Mta), maximum [Nm] 35Ball screw diameter (d0) [mm] 20Ball screw lead (p) [mm] 5Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]10,330,651,9924 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM60XBall Screw Drive, Ball Guide, Left/right Moving CarriagesA1: depth 11A2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm] X [mm] Y [mm] Z [mm]0 - 1390 (0 - 1200) 115 65 60 80 620 8001391 - 2670 (1201 - 2480) 165 115 210 230 770 10502671 - 4150 (2481 - 3960) 185 135 250 270 810 11304151 - 5560 (3961 - 5370) 210 160 300 320 860 12305561 - 10340 (5371 - 10150) contact customer seviceValues between brackets = for units with long carriageLong CarriageParameterWM60XCarriage length [mm] 450Dynamic load torque (My), maximum [Nm] 500Dynamic load torque (Mz), maximum [Nm] 500Weight [kg] 3,1A1: depth 11www.danahermotion.com25

WM80DBall Screw Drive, Ball Guide, Double Ball Nuts» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM80DProfile size (w × h) [mm] 80 × 80Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 1,1 1,5 1,8 2,31500 1,7 2.1 2,3 3,03000 2,1 2,5 2,6 3,6M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM80DStroke length (S max), maximumscrew lead 5, 10, 20 mmscrew lead 50 mm[mm]110005000<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 6300 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 5000Dynamic load (Fy), maximum [N] 3000 1 / 57420 2Dynamic load (Fz), maximum [N] 3000 1 / 54950 2Dynamic load torque (Mx), maximum [Nm] 350 1 / 1360 2Dynamic load torque (My), maximum [Nm] 300 1 / 4230 2Dynamic load torque (Mz), maximum [Nm] 300 1 / 4220 2Drive shaft force (Frd), maximum [N] 700Drive shaft torque (Mta), maximum [Nm] 55Ball screw diameter (d0) [mm] 25Ball screw lead (p) [mm] 5, 10, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]11,571,084,2626 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM80DBall Screw Drive, Ball Guide, Double Ball NutsA1: depth 12 mmA2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 780 (0 - 610) 120 80 500 (670)781 - 1535 (611 - 1365) 170 125 595 (765)1536 - 2375 (1366 - 2205) 190 145 635 (805)2376 - 3205 (2206 - 3035) 215 170 685 (855)Values between brackets = for units with long carriageA4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of three alternative lubrication points by customerStroke length (S max) [mm] A [mm] B [mm] C [mm]3206 - 4045 (3036 - 3875) 235 190 725 (895)4046 - 4885 (3876 - 4715) 255 210 765 (935)4886 - 5000 (4716 - 4830) 280 235 815 (985)5001 - 11000 (4717 - 10830) contact customer serviceLong CarriageParameterWM80DCarriage length [mm] 450Dynamic load torque (My), maximum [Nm] 750Dynamic load torque (Mz), maximum [Nm] 750Weight [kg] 6,4A1: depth 12 mmDouble CarriagesParameterWM80DMinimum distance between carriages (L A) [mm] 360Dynamic load (Fy), maximum [N] 6000Dynamic load (Fz), maximum [N] 6000Dynamic load torque (My), maximum [Nm] L A 1 × 3Dynamic load torque (Mz), maximum [Nm] L A 1 × 3Force required to move second carriage [N] 250Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com27

WM80SBall Screw Drive, Ball Guide, Singel Ball Nut, Short Carriage» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM80SProfile size (w × h) [mm] 80 × 80Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with single nutself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,9 1,1 1,3 2,01500 1,3 1,5 1,8 2,43000 1,7 1,8 2,0 2,9M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM80SStroke length (S max), maximum [mm] 5000<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,02Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 3500Dynamic load (Fy), maximum [N] 2100 1 / 37440 2Dynamic load (Fz), maximum [N] 2100 1 / 35830 2Dynamic load torque (Mx), maximum [Nm] 150 1 / 890 2Dynamic load torque (My), maximum [Nm] 180 1 / 580 2Dynamic load torque (Mz), maximum [Nm] 180 1 / 600 2Drive shaft force (Frd), maximum [N] 700Drive shaft torque (Mta), maximum [Nm] 55Ball screw diameter (d0) [mm] 25Ball screw lead (p) [mm] 5, 10, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]7,01,11,628 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM80SBall Screw Drive, Ball Guide, Singel Ball Nut, Short CarriageA1: depth 12 mmA2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 680 95 35 350681 - 1310 125 80 4251311 - 2065 150 105 4752066 - 2830 170 125 515A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of three alternative lubrication points by customerStroke length (S max) [mm] A [mm] B [mm] C [mm]2831 - 3590 195 150 5653591 - 4355 215 170 6054356 - 5000 235 190 645Double CarriagesParameterWM80SMinimum distance between carriages (L A) [mm] 280Dynamic load (Fy), maximum [N] 4200Dynamic load (Fz), maximum [N] 4200Dynamic load torque (My), maximum [Nm] L A 1 × 2,1Dynamic load torque (Mz), maximum [Nm] L A 1 × 2,1Force required to move second carriage [N] 225Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com29

WM120DBall Screw Drive, Ball Guide, Double Ball Nuts» Ordering key - see page 202» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWM120DProfile size (w × h) [mm] 120 × 120Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 40Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 1,4 2,0 2,3 2,41500 2,5 3,0 3,3 3,83000 3,0 3,7 4,0 4,3M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWM120DStroke length (S max), maximumscrew lead 5, 10, 20 mmscrew lead 40 mm[mm]110005000<strong>Linear</strong> speed, maximum [m/s] 2,0Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 5400 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximumscrew lead 5, 10, 20 mmscrew lead 40 mm[N]120008000Dynamic load (Fy), maximum [N] 6000 1 / 74890 2Dynamic load (Fz), maximum [N] 6000 1 / 71670 2Dynamic load torque (Mx), maximum [Nm] 500 1 / 2890 2Dynamic load torque (My), maximum [Nm] 600 1 / 6660 2Dynamic load torque (Mz), maximum [Nm] 600 1 / 6960 2Drive shaft force (Frd), maximum [N] 1000Drive shaft torque (Mta), maximum [Nm] 80Ball screw diameter (d0) [mm] 32Ball screw lead (p) [mm] 5, 10, 20, 40Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]25,911,939,2530 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WM120DBall Screw Drive, Ball Guide, Double Ball NutsA1: depth 22A2: socket cap screw ISO4762-M8×20 8.8Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 890 (0 - 710) 155 100 595 (775)891 - 1695 (711 - 1515) 225 170 735 (815)1696 - 2625 (1516 - 2445) 260 205 805 (985)2626 - 3555 (2446 - 3375) 295 240 875 (1055)Values between brackets = for units with long carriageA3: tapered lubricating nipple to DIN71412 M8×1 on fixed-bearing side as standard featureA4: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]3556 - 4485 (3376 - 4305) 330 275 945 (1125)4486 - 5000 (4306 - 4820) 365 310 1015 (1195)5001 - 11000 (4307 - 10820) contact customer serviceLong CarriageParameterWM120DCarriage length [mm] 500Dynamic load torque (My), maximum [Nm] 1500Dynamic load torque (Mz), maximum [Nm] 1500Weight [kg] 14,2A1: depth 22Double CarriagesParameterWM120DMinimum distance between carriages (L A) [mm] 450Dynamic load (Fy), maximum [N] 12000Dynamic load (Fz), maximum [N] 12000Dynamic load torque (My), maximum [Nm] L A 1 × 6Dynamic load torque (Mz), maximum [Nm] L A 1 × 6Force required to move second carriage [N] 300Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com31

WV60Ball Screw Drive, No Guides» Ordering key - see page 203» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWV60Profile size (w × h) [mm] 60 × 60Input speed [rpm]Screw lead [mm]p = 5 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,7 0,9 1,11500 1,3 1,5 1,53000 1,7 1,9 2,1M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWV60Stroke length (S max), maximumscrew lead 5, 20 mmscrew lead 50 mm[mm]110005000<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 6300 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 4000Dynamic load (Fy), maximum [N] 0Dynamic load (Fz), maximum [N] 0Dynamic load torque (Mx), maximum [Nm] 0Dynamic load torque (My), maximum [Nm] 0Dynamic load torque (Mz), maximum [Nm] 0Drive shaft force (Frd), maximum [N] 500Drive shaft torque (Mta), maximum [Nm] 35Ball screw diameter (d0) [mm] 20Ball screw lead (p) [mm] 5, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage[kg]4,720,551,4232 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WV60Ball Screw Drive, No GuidesA1: depth 11A2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 690 130 80 430691 - 1415 155 105 4801416 - 2155 175 125 5202156 - 2885 200 150 570A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]2886 - 3625 220 170 6103626 - 4355 245 195 6604256 - 5095 265 215 7005096 - 11000 contact customer servicewww.danahermotion.com33

WV80Ball Screw Drive, No Guides» Ordering key - see page 203» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWV80Profile size (w × h) [mm] 80 × 80Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,9 1,1 1,3 1,41500 1,6 1,9 2,1 2,33000 2,0 2,4 2,6 3,0M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWV80Stroke length (S max), maximumscrew lead 5, 10, 20 mmscrew lead 50 mm[mm]110005000<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 6300 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 5000Dynamic load (Fy), maximum [N] 0Dynamic load (Fz), maximum [N] 0Dynamic load torque (Mx), maximum [Nm] 0Dynamic load torque (My), maximum [Nm] 0Dynamic load torque (Mz), maximum [Nm] 0Drive shaft force (Frd), maximum [N] 700Drive shaft torque (Mta), maximum [Nm] 55Ball screw diameter (d0) [mm] 25Ball screw lead (p) [mm] 5, 10, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage[kg]7,950,992,2534 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WV80Ball Screw Drive, No GuidesA1: depth 12 mmA2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 775 125 50 395776 - 1670 145 95 4601671 - 2505 170 115 5052506 - 3340 190 140 550A4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of three alternative lubrication points by customerStroke length (S max) [mm] A [mm] B [mm] C [mm]3341 - 4175 210 160 5904176 - 5015 235 180 6355016 - 11000 contact customer servicewww.danahermotion.com35

WV120Ball Screw Drive, No Guides» Ordering key - see page 203» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWV120Profile size (w × h) [mm] 120 × 120Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 40Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsself-adjusting plastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 1,0 1,1 1,4 1,51500 2,1 2,2 2,5 2,83000 2,4 2,6 3,0 3,5M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWV120Stroke length (S max), maximumscrew lead 5, 10, 20 mmscrew lead 40 mm[mm]110005000<strong>Linear</strong> speed, maximum [m/s] 2,0Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information. <strong>Units</strong> with a profile length over 5400 mm consists of twoprofiles where the joint between the two profiles must be addequately supported on bothsides.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximumscrew lead 5, 10, 20 mmscrew lead 40 mm[N]120008000Dynamic load (Fy), maximum [N] 0Dynamic load (Fz), maximum [N] 0Dynamic load torque (Mx), maximum [Nm] 0Dynamic load torque (My), maximum [Nm] 0Dynamic load torque (Mz), maximum [Nm] 0Drive shaft force (Frd), maximum [N] 1000Drive shaft torque (Mta), maximum [Nm] 80Ball screw diameter (d0) [mm] 32Ball screw lead (p) [mm] 5, 10, 20, 40Weightof unit with zero strokeof every 100 mm of strokeof each carriage[kg]18,101,944,7536 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WV120Ball Screw Drive, No GuidesA1: depth 22A2: socket cap screw ISO4762-M8×20 8.8Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 940 145 50 465941 - 1860 180 120 5701861 - 2790 215 155 6402791 - 3720 250 190 710A3: tapered lubricating nipple to DIN71412 M8×1 on fixed-bearing side as standard featureA4: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]3721 - 4650 285 225 7804651 - 5000 320 255 8455001 - 11000 contact customer servicewww.danahermotion.com37

MLSM60DBall Screw Drive, Ball Guide» Ordering key - see page 204» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterMLSM60DProfile size (w × h) [mm] 160 × 65Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 50Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsplastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 1,0 1,6 1,9 2,71500 1,6 2,2 2,3 3,43000 2,0 2,6 2,6 4,0M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterMLSM60DStroke length (S max), maximum [mm] 5500<strong>Linear</strong> speed, maximum [m/s] 2,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximum [N] 5000Dynamic load (Fy), maximum [N] 6000 1 / 55090 2Dynamic load (Fz), maximum [N] 6000 1 / 55090 2Dynamic load torque (Mx), maximum [Nm] 400 1 / 2890 2Dynamic load torque (My), maximum [Nm] 460 1 / 4490 2Dynamic load torque (Mz), maximum [Nm] 460 1 / 4490 2Drive shaft force (Frd), maximum [N] 350Drive shaft torque (Mta), maximum [Nm] 60Ball screw diameter (d0) [mm] 25Ball screw lead (p) [mm] 5, 10, 20, 50Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]14,401,655,7038 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>MLSM60DBall Screw Drive, Ball GuideA1: depth 10A2: socket cap screw ISO4762-M6×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 750 (0 - 580) 90 45 435 (605)751 - 1220 (581 - 1050) 105 90 495 (665)1221 - 1980 (1051 - 1810) 125 110 535 (705)1981 - 2730 (1811 - 2560) 150 135 585 (765)Values between brackets = for units with long carriageA4: tapered lubricating nipple to DIN71412 AM6 on fixed-bearing side as standard featureA5: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]2731 - 3490 (2561 - 3320) 170 155 625 (795)3491 - 4240 (3321 - 4070) 195 180 675 (845)4241 - 5000 (4071 - 4830) 215 200 715 (885)5001 - 5500 (4831 - 5330) 235 220 755 (925)Long CarriageParameterMLSM60DCarriage length [mm] 450Dynamic load torque (My), maximum [Nm] 940Dynamic load torque (Mz), maximum [Nm] 940Weight [kg] 6,5A1: depth 10Double CarriagesParameterMLSM60DMinimum distance between carriages (L A) [mm] 320Dynamic load (Fy), maximum [N] 12000Dynamic load (Fz), maximum [N] 12000Dynamic load torque (My), maximum [Nm] L A 1 × 6Dynamic load torque (Mz), maximum [Nm] L A 1 × 6Force required to move second carriage [N] 270Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com39

MLSM80DBall Screw Drive, Ball Guide» Ordering key - see page 204» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterMLSM80DProfile size (w × h) [mm] 240 × 85Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 20 p = 40Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutsplastic cover bandincluded in all units that requirescrew supportscentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 1,6 2,2 2,5 2,81500 2,7 3,2 3,4 4,03000 3,2 4,0 4,2 4,5M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterMLSM80DStroke length (S max), maximum [mm] 5200<strong>Linear</strong> speed, maximum [m/s] 2,0Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,01Input speed, maximum [rpm] 3000A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Definition of ForcesOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximumscrew lead 5, 10, 20 mmscrew lead 40 mm[N]120008000Dynamic load (Fy), maximum [N] 8000 1 / 71860 2Dynamic load (Fz), maximum [N] 8000 1 / 71860 2Dynamic load torque (Mx), maximum [Nm] 780 1 / 5890 2Dynamic load torque (My), maximum [Nm] 900 1 / 6640 2Dynamic load torque (Mz), maximum [Nm] 900 1 / 6640 2Drive shaft force (Frd), maximum [N] 700Drive shaft torque (Mta), maximum [Nm] 85Ball screw diameter (d0) [mm] 32Ball screw lead (p) [mm] 5, 10, 20, 40Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]29,52,711,540 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>MLSM80DBall Screw Drive, Ball GuideA1: depth 15A2: socket cap screw ISO4762-M8×20 8.8A3: ENF inductive sensor rail option kit (optional)Stroke length (S max) [mm] A [mm] B [mm] C [mm]0 - 750 (0 - 570) 100 90 530 (710)751 - 1140 (571 - 960) 130 120 590 (770)1141 - 1880 (961 - 1700) 160 150 650 (830)1881 - 2620 (1701 - 2440) 190 180 710 (890)Values between brackets = for units with long carriageA4: tapered lubricating nipple to DIN71412 M8×1 on fixed-bearing side as standard featureA5: can be changed over to one of the three alternative lubricating points by the customerStroke length (S max) [mm] A [mm] B [mm] C [mm]2621 - 3360 (2441 - 3180) 220 210 770 (950)3361 - 4100 (3181 - 3920) 250 240 830 (1010)4101 - 4840 (3921 - 4660) 280 270 890 (1070)4841 - 5000 (4661 - 4820) 310 300 950 (1130)Long CarriageParameterMLSM80DCarriage length [mm] 500Dynamic load torque (My), maximum [Nm] 1750Dynamic load torque (Mz), maximum [Nm] 1750Weight [kg] 16A1: depth 15Double CarriagesParameterMLSM80DMinimum distance between carriages (L A) [mm] 400Dynamic load (Fy), maximum [N] 16000Dynamic load (Fz), maximum [N] 16000Dynamic load torque (My), maximum [Nm] L A 1 × 8Dynamic load torque (Mz), maximum [Nm] L A 1 ×8Force required to move second carriage [N] 350Total length (L tot) [mm] S max + C + L A1Value in mmwww.danahermotion.com41

2HBE10Ball Screw Drive, Ball GuideGeneral Specifications» Ordering key - see page 205» Accessories - see page 137» Additional data - see page 191Carriage Idle Torque (M idle) [Nm]Parameter2HBE10Profile size (w × h) [mm] 100 × 33,5Input speed [rpm]Screw lead [mm]p = 5 p = 10Type of screwCarriage sealing systemball screw with double nutnone150 0,1 0,11500 0,1 0,1Screw supportsLubricationnonelubrication ofscrew and guides3000 0,1 0,1M idle = the input torque needed to move the carriage with no load on it.Included accessories noneDeflection of the ProfilePerformance SpecificationsParameter2HBE10Stroke length (S max), maximum [mm] 850<strong>Linear</strong> speed, maximum [m/s] 0,5Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,005Input speed, maximum [rpm] 3000The unit must be continiously supported by a machined surface under its entire length.Definition of ForcesOperation temperature limits [°C] -20 – 70Dynamic load (Fx), maximum [N] 2500Dynamic load (Fy), maximum [N] 2065 1 / 8250 2Dynamic load (Fz), maximum [N] 2065 1 / 8250 2Dynamic load torque (Mx), maximum [Nm] 290 1 / 395 2Dynamic load torque (My), maximum [Nm] 225 1 / 305 2Dynamic load torque (Mz), maximum [Nm] 225 1 / 305 2Drive shaft force (Frd), maximum [N] 0Drive shaft torque (Mta), maximum [Nm] 4,4Ball screw diameter (d0) [mm] 16Ball screw lead (p) [mm] 5, 10Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]2,590,690,8242 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>2HBE10Ball Screw Drive, Ball GuideA1: depth 10A2: depth 10 Heli coilA3: lubrication nipple (using the unit with the nipple mounted makes stroke 10 mm shorter)Double CarriagesParameter2HBE10Minimum distance between carriages (Lc) [mm] 112Dynamic load (Fy), maximum [N] 4130Dynamic load (Fz), maximum [N] 4130Dynamic load torque (My), maximum [Nm] Lc 1 × 8,25Dynamic load torque (Mz), maximum [Nm] Lc 1 × 8,25Force required to move second carriage [N] 12Ordering length (L order) [mm] S max + Lc + 125Total length (L tot] [mm] L order + 96,5Weightof unit with zero strokeof carriages1Value in mm[kg]4,31,6www.danahermotion.com43

2HBE20Ball Screw Drive, Ball Guide» Ordering key - see page 205» Accessories - see page 137» Additional data - see page 191General SpecificationsCarriage Idle Torque (M idle) [Nm]Parameter2HBE20Profile size (w × h) [mm] 200 × 44Input speed [rpm]Screw lead [mm]p = 5 p = 10 p = 25Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball screw with double nutnonenonelubrication ofscrew and guidesnone150 0,15 0,20 0,351500 0,16 0,21 0,383000 0,17 0,25 0,47M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameter2HBE20Stroke length (S max), maximum [mm] 2800<strong>Linear</strong> speed, maximum [m/s] 1,3Acceleration, maximum [m/s 2 ] 20Repeatability [± mm] 0,005Input speed, maximum [rpm] 3000The unit must be continiously supported by a machined surface under its entire length.Definition of ForcesOperation temperature limits [°C] -20 – 70Dynamic load (Fx), maximum [N] 5000Dynamic load (Fy), maximum [N] 9515 1 / 38000 2Dynamic load (Fz), maximum [N] 9515 1 / 38000 2Dynamic load torque (Mx), maximum [Nm] 2760 1 / 3770 2Dynamic load torque (My), maximum [Nm] 2130 1 / 2910 2Dynamic load torque (Mz), maximum [Nm] 2130 1 / 2910 2Drive shaft force (Frd), maximum [N] 0Drive shaft torque (Mta), maximum [Nm] 22Ball screw diameter (d0) [mm] 25Ball screw lead (p) [mm] 5, 10, 25Weightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit2Value for the ball guide only[kg]13,321,704,4744 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>2HBE20Ball Screw Drive, Ball GuideA1: depth 12A2: depth 15 Heli coilA3: lubrication nipple (using the unit with the nipple mounted makes stroke 10 mm shorter)Double CarriagesParameter2HBE20Minimum distance between carriages (Lc) [mm] 210Dynamic load (Fy), maximum [N] 19030Dynamic load (Fz), maximum [N] 19030Dynamic load torque (My), maximum [Nm] Lc 1 × 38Dynamic load torque (Mz), maximum [Nm] Lc 1 × 38Force required to move second carriage [N] 17Ordering length (L order) [mm] S max + Lc + 240Total length (L tot] [mm] L order + 145Weightof unit with zero strokeof carriages1Value in mm[kg]21,59,0www.danahermotion.com45

46 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong><strong>Linear</strong> <strong>Units</strong> with Ball Screw Drive and Slide GuideBaseLine, MovopartVelocityNoiseAccelerationMaintenanceRepeatabilityCostForceGuide RobustnessLoad TorqueStiffnessTypical ApplicationsTypical applications are where low to medium loads needs to be moved at low tomedium speed. These units are also suited for harsh environments. Typical examplesare all types of machines in the food, chemical, paper and wood working industry.Materials handling is another area where these units are ideal.www.danahermotion.com47

BaseLine WBWB40Features• Can be installed in all directions• Plastic cover band• Robust external slide guides• Ball screw or lead screw driveParameter WB40 WB60Profile size (width × height) [mm] 40 × 37 60 × 59Stroke length (S max), maximum [mm] 1000 5200<strong>Linear</strong> speed, maximum [m/s] 0,25 1,0Dynamic carriage load (Fz), maximum [N] 250 650Remarks Ball screw or lead screw drive Ball screw or lead screw drivePage 50 52Movopart MM75Features• Can be installed in all directions• Self-adjusting stainless steel cover band• Patented internal self-adjusting prism slide guides• Wash down protected versions availableParameter M55 M75 M100Profile size (width × height) [mm] 58 × 55 86 × 75 108 × 100Stroke length (S max), maximum [mm] 3000 4000 6000<strong>Linear</strong> speed, maximum [m/s] 1,0 1,6 1,6Dynamic carriage load (Fz), maximum [N] 400 1485 3005Remarkssingle ball nut orcomposite nutsingle ball nut orcomposite nutsingle ball nut orcomposite nutPage 54 56 5848 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>Movopart MDM100DFeatures• Can be installed in all directions• Self-adjusting stainless steel cover band• Patented intenal self-adjusting prism slide guides• Wash down protected versions availableParameter M75D M100DProfile size (width × height) [mm] 86 × 75 108 × 100Stroke length (S max), maximum [mm] 3550 6000<strong>Linear</strong> speed, maximum [m/s] 1,6 1,6Dynamic carriage load (Fz), maximum [N] 1485 3005Remarks double ball nuts double ball nutsPage 60 62WB-Series Technical PresentationCover bandThe durable plastic cover bandprotect the interior of the unitfrom the penetration of dirt, dustand liquids.Central lubricationOne central lubrication point onthe carriage services the entireunit resulting in a minimummaintenace required.Slide guidesThe robust and accurate slideguides can be easily replacedby the user whenever needed.DriveSelect between the fast highprecision ball screw or the robustlead screw with composite nut.Screw supportThe screw support system reducenoise and vibrations and permitshigh speed at long stroke lengths.www.danahermotion.com49

WB40Ball Screw or Lead Screw Drive, Slide Guide» Ordering key - see page 206» Accessories - see page 137» Additional data - see page 192General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWB40Profile size (w × h) [mm] 40 × 37Input speed [rpm]Screw lead [mm]p = 4 p = 5 p = 8Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball or lead screw with single nutplastic cover bandnonecentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 - 0,02 -1500 - 0,35 -3000 - 0,50 -M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWB40Stroke length (S max), maximum [mm] 1000<strong>Linear</strong> speed, maximum [m/s] 0,25Acceleration, maximum [m/s 2 ] 5Repeatability [± mm] 0,05Input speed, maximumBall screw unitsLead screw units with composite nut[rpm]30001500A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Critical SpeedOperation temperature limits [°C] 0 – 80Dynamic load (Fx), maximumball screw units / lead screw units[N]200 / 500Dynamic load (Fy), maximum [N] 200 1Dynamic load (Fz), maximum [N] 250 1Dynamic load torque (Mx), maximum [Nm] 6 1Dynamic load torque (My), maximum [Nm] 15 1Dynamic load torque (Mz), maximum [Nm] 10 1Drive shaft force (Frd), maximum [N] 80Drive shaft torque (Mta), maximum [Nm] 11: For lead screw units2: For ball screw unitsDefinition of ForcesScrew diameter (d0) [mm] 12Screw lead (p)ball screw units / lead screw unitsWeightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit[mm][kg]5 / 4, 81,070,300,4550 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WB40Ball Screw or Lead Screw Drive, Slide GuideA1: depth 10A2: lubricating nipple DIN3405 D 1/AA3: socket cap screw ISO4762-M5×20 8.8A4: ENF inductive sensor rail option kit (optional)www.danahermotion.com51

WB60Ball Screw or Lead Screw Drive, Slide Guide» Ordering key - see page 206» Accessories - see page 137» Additional data - see page 192General SpecificationsCarriage Idle Torque (M idle) [Nm]ParameterWB60Profile size (w × h) [mm] 60 × 59Input speed [rpm]Screw lead [mm]p = 5 p = 8 p = 20Type of screwCarriage sealing systemScrew supportsLubricationIncluded accessoriesball or lead screw with single nutplastic cover bandnumber of screw supports to bespecified by customer at ordercentral lubrication of all parts thatrequire lubrication4 × mounting clamps150 0,5 - 0,71500 1,0 - 1,353000 1,5 - 1,8M idle = the input torque needed to move the carriage with no load on it.Deflection of the ProfilePerformance SpecificationsParameterWB60Stroke length (S max), maximum [mm] 5200<strong>Linear</strong> speed, maximum [m/s] 1,0Acceleration, maximum [m/s 2 ] 5Repeatability [± mm] 0,05A mounting clamp must be installed at least at every 750 mm to be able to operate themaximum load. Less clamps may be required if less load is being operated, see the additionaltechnical data for more information.Critical SpeedInput speed, maximumBall screw unitsLead screw units with composite nut[rpm]30001500Operation temperature limits [°C] 0 – 80Dynamic load (Fx), maximumball screw units / lead screw units[N]2500 / 2500Dynamic load (Fy), maximum [N] 500 1Dynamic load (Fz), maximum [N] 650 1Dynamic load torque (Mx), maximum [Nm] 30 1Dynamic load torque (My), maximum [Nm] 70 1Dynamic load torque (Mz), maximum [Nm] 50 11: Max. input speed for ball screw units2: Max. input speed for lead screw units3: No screw supports required4: One pair of screw supports required5: Two pairs of screw supports required6: Three pairs of screw supports requiredDrive shaft force (Frd), maximum [N] 150Drive shaft torque (Mta), maximum [Nm] 17Definition of ForcesScrew diameter (d0) [mm] 20Screw lead (p)ball screw units / lead screw unitsWeightof unit with zero strokeof every 100 mm of strokeof each carriage1Value for the complete unit[mm][kg]5, 20 / 83,630,721,1752 www.danahermotion.com

<strong>Linear</strong> <strong>Units</strong>WB60Ball Screw or Lead Screw Drive, Slide GuideA1: depth 12A2: lubricating nipple DIN3405 D 1/AA3: socket cap screw ISO4762-M6×20 8.8A4: depth 10A5: ENF inductive sensor rail option kit (optional)www.danahermotion.com53