- Page 3: GENERAL INFORMATIONChapterDescripti

- Page 6: 2.0 - GENERAL LAYOUTshaftapplicabil

- Page 9: Icon symbolises the weight.Columns

- Page 12 and 13: 7.0 - EFFICIENCYThe parameter is de

- Page 14 and 15: 11.0 - SELECTING THE PRODUCTThe key

- Page 16 and 17: d) Once « T c2 » and « i » are

- Page 20 and 21: - Use bolts of grade 8.8 or greater

- Page 22 and 23: 3 L3 R18.0 - PRODUCT DESIGNATION3 1

- Page 24 and 25: 3/V L3/V 05 L 3 623 NPCOUTPUT VERSI

- Page 26 and 27: 3/A L3/A 06 L 2 69.9 NPCOUTPUT VERS

- Page 28 and 29: 3 L19.0 - MOUNTING POSITIONMounting

- Page 30 and 31: 3/V L(A12)AA-AE-AF-ADEA-EE-EF-EDTA-

- Page 32 and 33: 20.0 - LUBRICATION (prior to start-

- Page 34 and 35: 3 L3 R(A16)P0-P1-P2-P3 R0-R1-R2-R3

- Page 36 and 37: 3/A L(A21)ALL GEARBOXES(planetary s

- Page 38 and 39: 3/V L3/A ROil quantity [ liters ] -

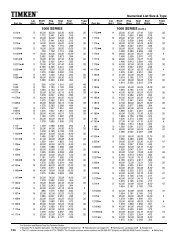

- Page 40 and 41: 3 L300 L8,850 in•lbsn 1 i n 2 Tn

- Page 42 and 43: 3 L300 L8,850 in•lbsn 1 i n 2 Tn

- Page 44 and 45: 3 L301 L 17,700 in•lbsn 1 i n 2 T

- Page 46 and 47: 3 L301 L17,700 in•lbsn 1 i n 2 Tn

- Page 48 and 49: 3 L303 L25,000 in•lbsn 1 i n 2 Tn

- Page 50 and 51: 3 L303 L25,000 in•lbsn 1 i n 2 Tn

- Page 52 and 53: 3 L305 L49,000 in•lbsn 1 i n 2 Tn

- Page 54 and 55: 3 L305 L49,000 in•lbsn 1 i n 2 Tn

- Page 56 and 57: 3 L306 L84,000 in•lbsn 1 i n 2 Tn

- Page 58 and 59: 3 L306 L84,000 in•lbsn 1 i n 2 Tn

- Page 60 and 61: 3 L307 L125,000 in•lbsn 1 i n 2 T

- Page 62 and 63: 3 L307 L125,000 in•lbsn 1 i n 2 T

- Page 64 and 65: 3 L309 L180,000 in•lbsn 1 i n 2 T

- Page 66 and 67: 3 L310 L250,000 in•lbsn 1 i n 2 T

- Page 68 and 69:

3 L310 L250,000 in•lbsn 1 i n 2 T

- Page 70 and 71:

3 L311 L400,000 in•lbsn 1 i n 2 T

- Page 72 and 73:

3 L311 L400,000 in•lbsn 1 i n 2 T

- Page 74 and 75:

3 L313 L485,000 in•lbsn 1 i n 2 T

- Page 76 and 77:

3 L315 L900,000 in•lbsn 1 i n 2 T

- Page 78 and 79:

3 L316 L1,100,000 in•lbsn 1 i n 2

- Page 80 and 81:

3 L317 L1,500,000 in•lbsn 1 i n 2

- Page 82 and 83:

3 L318 L2,200,000 in•lbsn 1 i n 2

- Page 84 and 85:

3 L319 L3,000,000 in•lbsn 1 i n 2

- Page 86 and 87:

84This page intentionally left blan

- Page 88 and 89:

3 R300 R8,850 in•lbsn 1 i n 2 Tn

- Page 90 and 91:

3 R300 R8,850 in•lbsn 1 i n 2 Tn

- Page 92 and 93:

3 R301 R17,000 in•lbsn 1 i n 2 Tn

- Page 94 and 95:

3 R303 R23,000 in•lbsn 1 i n 2 Tn

- Page 96 and 97:

3 R305 R47,000 in•lbsn 1 i n 2 Tn

- Page 98 and 99:

3 R306 R83,000 in•lbsn 1 i n 2 Tn

- Page 100 and 101:

3 R306 R83,000 in•lbsn 1 i n 2 Tn

- Page 102 and 103:

3 R307 R115,000 in•lbsn 1 i n 2 T

- Page 104 and 105:

3 R309 R170,000 in•lbsn 1 i n 2 T

- Page 106 and 107:

3 R310 R265,000 in•lbsn 1 i n 2 T

- Page 108 and 109:

3 R311 R398,000 in•lbsn 1 i n 2 T

- Page 110 and 111:

3 R313 R485,000 in•lbsn 1 i n 2 T

- Page 112 and 113:

3 R313 R485,000 in•lbsn 1 i n 2 T

- Page 114 and 115:

3 R315 R900,000 in•lbsn 1 i n 2 T

- Page 116 and 117:

3 R317 R1,500,000 in•lbsn 1 i n 2

- Page 118 and 119:

3 R318 R2,200,000 in•lbsn 1 i n 2

- Page 120 and 121:

3 R319 R3,000,000 in·lbsn 1 i n 2

- Page 122 and 123:

120This page intentionally left bla

- Page 124 and 125:

3/V L3/V 00 L38,200 in•lbsn 1 i n

- Page 126 and 127:

3/V L3/V 06 L375,000 in•lbsn 1 i

- Page 128 and 129:

3/V L3/V 10 L4246,000 in•lbsn 1 i

- Page 130 and 131:

3/V Ln 1 i n 2 Tn 2 Pn 1 Rn 2 [lbs]

- Page 132 and 133:

3/V Ln 1 i n 2 Tn 2 Pn 1 Rn 2 [lbs]

- Page 134 and 135:

3/A L3/A 00 L25,500 in•lbsn 1 i n

- Page 136 and 137:

3/A Ln 1 i n 2 Tn 2 Pn 1 Rn 2 [lbs]

- Page 138 and 139:

3/A Ln 1 i n 2 Tn 2 Pn 1 Rn 2 [lbs]

- Page 140 and 141:

30025.0 - INSTALLATION DRAWINGSNEMA

- Page 142 and 143:

300NHCHZNEMA inputSolid input shaft

- Page 144 and 145:

300FPFZNEMA inputSolid input shaftT

- Page 146 and 147:

300Flange60°0.41 (x6)0.832.170.20A

- Page 148 and 149:

301NPCPZNEMA inputSolid input shaft

- Page 150 and 151:

301NHCHZNEMA inputSolid input shaft

- Page 152 and 153:

301FPFZNEMA inputSolid input shaftT

- Page 154 and 155:

301Flange60°0.41 (x6)0.832.170.20A

- Page 156 and 157:

303NPCPZNEMA inputSolid input shaft

- Page 158 and 159:

303NHCHZNEMA inputSolid input shaft

- Page 160 and 161:

303FPFZNEMA inputSolid input shaftT

- Page 162 and 163:

303Flange0.49 (x12)0.942.680.35A58x

- Page 164 and 165:

305NPCPZNEMA inputSolid input shaft

- Page 166 and 167:

305NHCHZNEMA inputSolid input shaft

- Page 168 and 169:

305FPFZNEMA inputSolid input shaftT

- Page 170 and 171:

305Flange0.49 (x12)0.942.680.35A58x

- Page 172 and 173:

306NPCPZNEMA inputSolid input shaft

- Page 174 and 175:

306NHCHZNEMA inputSolid input shaft

- Page 176 and 177:

306FPFZNEMA inputSolid input shaftT

- Page 178 and 179:

306Flange0.75 (x12)1.103.540.39A70x

- Page 180 and 181:

307NPCPZNEMA inputSolid input shaft

- Page 182 and 183:

307NHCHZNEMA inputSolid input shaft

- Page 184 and 185:

307FPFZNEMA inputSolid input shaftT

- Page 186 and 187:

307Flange0.75 (x12)1.183.540.43A80x

- Page 188 and 189:

309NPCPZNEMA inputSolid input shaft

- Page 190 and 191:

309NHCHZNEMA inputSolid input shaft

- Page 192 and 193:

309 FPNEMA inputSolid input shaftT2

- Page 194 and 195:

FZNEMA inputSolid input shaftT2ETVT

- Page 196 and 197:

309Flange0.75 (x12)1.183.540.43A80x

- Page 198 and 199:

310NPCPZNEMA inputSolid input shaft

- Page 200 and 201:

310NHCHZNEMA inputSolid input shaft

- Page 202 and 203:

310FPFZNEMA inputSolid input shaftT

- Page 204 and 205:

310Flange0.83 (x12)1.464.330.47A100

- Page 206 and 207:

311NPCPZNEMA inputSolid input shaft

- Page 208 and 209:

311NHCHZNEMA inputSolid input shaft

- Page 210 and 211:

311FPFZNEMA inputSolid input shaftT

- Page 212 and 213:

311Flange0.83 (x12)1.464.330.47A100

- Page 214 and 215:

313NPCPZNEMA inputSolid input shaft

- Page 216 and 217:

313NHCHZNEMA inputSolid input shaft

- Page 218 and 219:

313FPFZNEMA inputSolid input shaftT

- Page 220 and 221:

313Flange0.98 (x12)1.305.120.43N120

- Page 222 and 223:

315NPCPZNEMA inputSolid input shaft

- Page 224 and 225:

315 NHC HZNEMA inputSolid input sha

- Page 226 and 227:

315 FP FZNEMA inputSolid input shaf

- Page 228 and 229:

315Flange1.26 (x12)1.225.910.47N150

- Page 230 and 231:

316PCPZNEMA inputSolid input shaftT

- Page 232 and 233:

316 HC HZNEMA inputSolid input shaf

- Page 234 and 235:

316 FP FZNEMA inputSolid input shaf

- Page 236 and 237:

316Flange20°1.576.500.63N170x5x32D

- Page 238 and 239:

317PCPZNEMA inputSolid input shaftT

- Page 240 and 241:

317 HC HZNEMA inputSolid input shaf

- Page 242 and 243:

317 FP FZNEMA inputSolid input shaf

- Page 244 and 245:

317Flange0.79(x10)36°9° 18°2.057

- Page 246 and 247:

318PCPZNEMA inputSolid input shaftT

- Page 248 and 249:

318 HC HZNEMA inputSolid input shaf

- Page 250 and 251:

318 FP FZNEMA inputSolid input shaf

- Page 252 and 253:

318Flange15°1.978.270.83N220x5x42D

- Page 254 and 255:

319PCPZNEMA inputSolid input shaftT

- Page 256 and 257:

319 HC HZNEMA inputSolid input shaf

- Page 258 and 259:

319 FP FZNEMA inputSolid input shaf

- Page 260 and 261:

319Flange12°2.3610.243.94N260x5DIN

- Page 262 and 263:

321PCPZNEMA inputSolid input shaftT

- Page 264 and 265:

321 HC HZNEMA inputSolid input shaf

- Page 266 and 267:

321 FP FZNEMA inputSolid input shaf

- Page 268 and 269:

321Flange10°3.1511.814.33 N 300x8D

- Page 270 and 271:

3/V3/A(A)L7UNI 6604DIN 8885(B)L73/V

- Page 272 and 273:

Selection criteriaIf the mechanical

- Page 274 and 275:

R2This publication supersedes any p