CNC Portal Milling Machine - F. Zimmermann GmbH

CNC Portal Milling Machine - F. Zimmermann GmbH

CNC Portal Milling Machine - F. Zimmermann GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

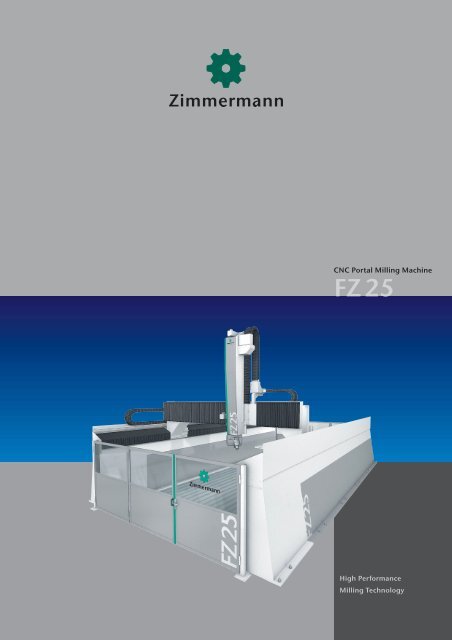

<strong>CNC</strong> <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong>FZ 25High Performance<strong>Milling</strong> Technology

FZ 25Maximum Work Rangesfor Large WorkpiecesWith the FZ 25, <strong>Zimmermann</strong>extends the wide range of highlyspecialised 5-axis portal millingmachines for simultaneous HSCmachining.They are ideally suited for drymachining of very large workpieces,with the main focus onlight composite materials such ascarbon and glass fibre reinforcedplastics, ureol, polyurethane,polystyrene, etc.The FZ 25 is specially designedfor two important fields ofapplication:■ Extremely large work rangesup to 5 000 mm in the Y-axis andup to 2 000 mm in the Z-axis.The machine is designed so thatthe rack-and-pinion drive in theX-axis can be extended to almostany length up to 40 000 mm ormore.■ Even higher accuracy andsurface finish.The machine is provided withcontinuous, structurally rigidside walls made of welded steelwhich are filled with a specialfibre-reinforced concrete (Demtec® ) for vibration absorptionand thermal stability as well asan overhead, relatively lightweightportal.Micro-dust bellows, particularly importantwith dust producing materials (carbonand glass fibre reinforced plastics).<strong>Portal</strong> with rack and pinion drive on bothsides; well away from the dirt zone.Clamping table with T-slots made of steel orcast iron, directly fixed to the foundation.Overhead, weight-optimised and structurallystiff portal for high dynamics andprecision.4-sided safety guarding through closedside walls, back panel and hinged frontdoor with large windows.2 <strong>CNC</strong> <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong> FZ 25

The combination of a robustdesign with very low movedmasses (structurally lightweightportal, Z-slide and milling head)enables a dynamic performancewhich is unique in its class.And despite accepting the largestworkpieces ever catered for bya <strong>Zimmermann</strong> machine and itsvery fast rate of machining, theaccuracy resulting means thereis little or no need for manualreworking of the already excellentsurface finish.Application fieldsThe FZ 25 is ideal for machiningof large workpieces to highaccuracy:■ In the aircraft industry,e.g. for milling of panels,other large components or partswith extreme contours.■ In ship and boat buildingwhere large dimensions arerequired in all three axes becausethe parts to be machined oftenhave long drawn shapes.■ In the design studios wherelarge, voluminous models even in1:1 scale are to be produced.■ In general, the FZ 25 is particularlysuitable for machiningvery large, curved parts (e.g.rotation moulds for tanks, pools,etc.).Weight-optimised vertical slide with highbending stiffness for large Z-axis travel.Dynamic and weight-optimised 2-axisVH 1 milling head with harmonic drive.Grouted trapezoidal sidewalls withenlarged base3

FZ 25<strong>Milling</strong> HeadVH 1The VH 1 milling head especiallydeveloped for lightweightmaterials is the most compactmilling head in the <strong>Zimmermann</strong>range and offers several advantages.Thus, on the one hand,a very fast dynamic performanceand consequently high chipremoval rate can be achievedduring HSC milling; on the otherhand, thanks to its lightweightconstruction, the portal of themilling machine is less susceptibleby torsion and bendingforces.This results in a high qualitysurface finish.The VH 1 milling head is ideallysuited to the dimensions of theFZ 25 and thus permits the layoutof large work ranges in all axes.To take full advantage of thesefeatures the VH 1 has beendesigned as a true minimalist.The straightforward designgoes without all unnecessaryballast, concentrating on thefactors affecting performanceand accuracy. The harmonicdrive system conforms exactlyto this philosophy. It is dynamicand lightweight with a gentle,dampening characteristics andachieves with ease the highaccuracy required for this typeof application.Features VH 1HARMONICDRIVEHarmonic drive systemWeight only 140 kgStandard spindle with15 kW / 12 Nm and 22.000 rpm5

FZ 25Technical Data<strong>Machine</strong> FZ 25Working rangesX-axis 4 000 – 10 000 mm 1Y-axis 2 500 – 5 000 mm 1Z-axis 1 000 – 2 000 mm 1Worktable sizeLength4 000 – 10 000 mmWidth2 500 – 5 000 mmHeight220 mmMax. worktable load max. 5 000 kg/m 2T-slots (longitudinal) 18 H12 (optional 18 H8 )Distance T-slots250 mmFeed drivesFeed drive X- and Y-axesup to 50 000 mm/min.Feed drive Z-axisup to 30 000 mm/min.Acceleration of linear axes up to 5 m/s 2Accuracy 2Positioning accuracy X-axisPositioning accuracy Y-, Z-axesRepeatability X-axisRepeatability Y-, Z-axes0,050 mm0,030 mm0,020 mm0,015 mmMiling head VH 1Swivel rangesA-axis ±115°C-axis ±213°PerformanceTorque A-axis300 NmTorque C-axis300 NmAcceleration A-axis 120°/s 2Acceleration C-axis 150°/s 2Feed rates A-, C-axis50°/sAccuracy 2Positioning accuracy A-, C-axis 56“ = 0,015°Repeatability A-, C-axis 12“=0,0033°Axes clampingClamping A-axisClamping C-axis<strong>Milling</strong> spindle■ hydraulic■ hydraulicUniversal spindlePower S1 max. (100 % ED) 15 kWTorque S1 max. (100 % ED) 12 NmMax. torque22 000 min -1 22 000 min -1Constant power range 12 000 min -1 up to 15 000 min -1Tool holderDistance swivel axis – spindle noseTool clampingTool unclampingLubricationHSK 63 F262 mmspring clamppneumaticpermanent grease1Other dimensions on request.2According to VDI / DGQ 3441.6 <strong>CNC</strong> <strong>Portal</strong> <strong>Milling</strong> <strong>Machine</strong> FZ 25

VH 1 <strong>Milling</strong> spindle performance diagramUniversal spindle 15 kWTorque Md Power PMd [Nm]P [kW]1007060755040503015 kW2512 Nm151200 5000 1200015000 22000 2400030000 35000n [min -1 ]DimensionsHeight approx. 4 780 – 5 780 mmX-axis approx. ca. 4 000 – 10 000 mmZ-axis 1 000 – 2 000 mmY-axis approx. 2 500 – 5 000 mmWorktable width2 500 – 5 000 mmWorktable length 4 000 – 10 000 mmWidth 5 625 – 8 125 mmOptions FZ 25Minimum quantity lubrication■Air-conditioned control cabinet ■Safety guarding■Tool changer■15, 30 positions or moreTouch probe■Tool measuring■Simultaneous A-axis■Simultaneous C-axis■Special voltage■Special painting■Chip conveyor■Extraction systems■Fixturing systems■Clamping table alternatives■■ Standard■ OptionLength approx. ca. 6 600 – 12 600 mmAll dimensions shown are examples of the FZ 25 in the minimumor maximum configurations. Special variations within this rangeare also possible.7

High Performance<strong>Milling</strong> TechnologyStyrofoam<strong>Milling</strong> TechnologyFZ 50FZ 20FZ 42FZ 15FZ 38FZ 37<strong>Zimmermann</strong> is synonymouswith <strong>CNC</strong> portal milling machineson a big scale. Specialisation andour high rate of innovation hasput our technology out in frontworldwide.A uniquely wide and finely tunedprogramme, including a largenumber of different machinesand milling heads, enables you tochoose the perfect machine forevery application, thus offeringyou the ideal solution with regardto quality and cost-effectiveness.FZ 35FZ 32FZ 30FZ 25BK 4 · 3·2F. <strong>Zimmermann</strong> <strong>GmbH</strong>Goethestraße 23 – 27D-73770 Denkendorf, GermanyPhone +49 (7 11) 93 49 35 - 0Fax +49 (7 11) 934935-300info@f-zimmermann.comwww.f-zimmermann.comMember of theDMTGDalian <strong>Machine</strong> Tool Group Corp.38 Anshan RoadDalian 116022PRCwww.dmtg.comApollo 11 06.07