You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SLICINGAERATORSAssembly/Operator's/& Parts ManualFor PA & PAR SERIESMarch 2008Form: <strong>Aerator</strong>.indd

TABLE OF CONTENTSSECTIONDESCRIPTIONPAGE1 Introduction .............................................................. 11.1 Serial Number Location .......................................... 12 Safety ............................................................................ 22.1 General Safety ......................................................... 32.2 Equipment Safety Guidelines ................................. 42.3 Safety Training ........................................................ 52.4 Safety Signs ............................................................. 52.5 Preparation .............................................................. 62.6 Operating Safety ...................................................... 72.7 Transport Safety ...................................................... 82.8 Storage Safety .......................................................... 82.9 Maintenance Safety ................................................. 83 Safety Sign Decals ..............................................9 - 104 Operation .................................................................. 104.1 To the New Operator or Owner ............................ 104.2 Machine Break-In .................................................. 114.3 Pre-Operation Checklist ........................................ 114.4 Field Operation ...................................................... 124.5 Transporting .......................................................... 134.6 Storage ................................................................... 135 General Maintenance ............................................. 145.1 Tines ....................................................................... 145.2 Tines Replacement ................................................ 145.3 Bearing Maintenance ............................................ 145.4 Torque Specifications ............................................. 156 Assembly .................................................................... 166.1 <strong>Aerator</strong> Assembly .................................................. 166.2 Pull Kit Assembly .................................................. 166.3 Roll Hitch Assembly .............................................. 176.4 3-Point Hitch Assembly ......................................... 177 Replacement Parts .................................................. 187.1 Parts Lists - Tines .................................................. 187.2 Parts Lists - Axle ................................................... 197.3 Parts Lists - Frame ................................................ 207.4 Parts Lists - Pull Hitch .......................................... 218 Limited Warranty .................................................... 22

1 INTRODUCTIONCongratulations on your choice of a <strong>Gearmore</strong> Slicing <strong>Aerator</strong>. This equipment has been designed and manufacturedto meet the needs of a discriminating buyer for the efficient aeration of land.Safe, efficient and trouble free operation of your <strong>Aerator</strong> requires that you and anyone else whowill be operating or maintaining the machine, read and understand the Safety, Operation, Maintenanceand Troubleshooting information contained within the Operator's Manual.This manual covers the PA and PAR Series of slicing aerators. Use the Table of Contents as a guide to locaterequired information.Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your <strong>Gearmore</strong>dealer or distributor if you need assistance, information or additional copies of the manuals.OPERATOR ORIENTATION - The directions left, right, front and rear, as mentioned throughout this manual,are as seen from the driver's seat and facing in the direction of travel.1.1 SERIAL NUMBER LOCATIONAlways give your dealer the serial number of your <strong>Aerator</strong> when ordering parts or requesting service orother information.The serial number plate is located where indicated. Please mark the number in the space provided for easyreference.Serial Number PlateDATE OF PURCHASE: ___________________________MODEL NUMBER: ______________________________SERIAL NUMBER: ______________________________1

2 SAFETYSAFETY ALERT SYMBOLThis Safety Alert symbol meansATTENTION! BECOMEALERT! YOUR SAFETY IS IN-VOLVED!The Safety Alert symbol identifiesimportant safety messages on the<strong>Aerator</strong> and in the manual. Whenyou see this symbol, be alert to thepossibility of personal injury ordeath. Follow the instructions inthe safety message.Why is SAFETY important to you?3 Big ReasonsAccidents Disable and KillAccidents CostAccidents Can Be AvoidedSIGNAL WORDS:Note the use of the signal words DANGER,WARNING and CAUTION with the safetymessages. The appropriate signal word foreach message has been selected using thefollowing guide-lines:SI NO LEE INGLES, PIDA AYUDAA AIGUIEN QUE SI LO LEA PARAQUE LE TRADUZCA LASMIDIDAS DE SEGURIDAD.DANGER - Indicates an imminently hazardoussituation that, if not avoided, will resultin death or serious injury. This signalword is to be limited to the mostextreme situations typically formachine components which, forfunctional purposes, cannot be guarded.WARNING - Indicates a potentially hazardoussituation that, if not avoided, couldresult in death or serious injury, andincludes hazards that are exposedwhen guards are removed. It mayalso be used to alert against unsafepractices.CAUTION - Indicates a potentially hazardoussituation that, if not avoided, mayresult in minor or moderate injury.It may also be used to alert againstunsafe practices.If you have any questions not answered in this manual or require additional copies or the manual isdamaged, please contact your dealer.2

2.1 GENERAL SAFETYYOU are responsible for the SAFE operation andmaintenance of your <strong>Aerator</strong>. YOU must ensure thatyou and anyone else who is going to operate, maintainor work around the <strong>Aerator</strong> be familiar with theoperating and maintenance procedures and relatedSAFETY information contained in this manual. Thismanual will take you step-by-step through your workingday and alerts you to all good safety practices thatshould be adhered to while operating the <strong>Aerator</strong>.Remember, YOU are the key to safety. Good safetypractices not only protect you, but also the peoplearound you. Make these practices a working part ofyour safety program. Be certain that EVERYONEoperating this equipment is familiar with the recommendedoperating and maintenance procedures andfollows all the safety precautions. Most accidents canbe prevented. Do not risk injury or death by ignoringgood safety practices.• <strong>Aerator</strong> owners must give operatinginstructions to operators or employeesbefore allowing them to operate themachine, and at least annually thereafter per OSHA (Occupational Safety andHealth Administration) regulation1928.57.• The most important safety feature onthis equipment is a SAFE operator. It isthe operator's responsibility to read andunderstand ALL Safety and Operatinginstructions in the manual and to followthese. Most accidents can be avoided.• A person who has not read and understoodall operating and safety instructionsis not qualified to operate the machine.An untrained operator exposes himselfand bystanders to possible serious injuryor death.• DO NOT modify the equipment in anyway. Unauthorized modification may impairthe function and/or safety and couldaffect the life of the equipment.• Think SAFETY! Work SAFELY!1. Read and understand theOperator's Manual and allsafety signs before operating,maintaining adjusting or unplugging the <strong>Aerator</strong>.2. Have a first-aid kit availablefor use should the need ariseand know how to use it.3. Have a fire extinguisheravailable for use shouldthe need arise and knowhow to use it.4. Wear appropriate protectivegear. This list includes but isnot limited to:- A hard hat- Protective shoeswith slip resistantsoles- Protective goggles,glasses or faceshield- Heavy gloves- Protective clothing5. Install and secure all guardsbefore starting.6. DO NOT allow riders.7. Wear suitable ear protectionfor prolonged exposure to excessivenoise.8. Place all controls in neutral, stop tractorengine, set park brake, remove ignitionkey and wait for all moving parts to stopbefore servicing, adjusting, repairing, orunplugging.9. Clear the area of people, especially smallchildren, before starting.10. Review safety related items annuallywith all personnel who will be operatingor maintaining the <strong>Aerator</strong>.3

2.2 EQUIPMENT SAFETY GUIDELINESSafety of the operator and bystanders is one of themain concerns in designing and developing a machine.However, every year many accidents occurwhich could have been avoided by a few seconds ofthought and a more careful approach to handlingequipment. You, the operator, can avoid manyaccidents by observing the following precautionsin this section. To avoid personal injury or death,study the following precautions and insist thoseworking with you, or for you, follow them.• In order to provide a better view, certainphotographs or illustrations in this manualmay show an assembly with a safety shieldremoved. However, equipment should neverbe operated in this condition. Keep all shieldsin place. If shield removal becomes necessaryfor repairs, replace the shield prior to use.• Replace any safety sign or instruction signthat is not readable or is missing. Location ofsuch safety signs is indicated in this manual.• NEVER use alcoholic beverages or drugswhich can hinder alertness or coordinationwhile operating this equipment. Consult yourdoctor about operating this machine whiletaking prescription medications.• Under no circumstances should youngchildren be allowed to work with thisequipment. Do not allow persons tooperate or assemble this unit until theyhave read this manual and have developeda thorough understanding of thesafety precautions and of how it works.Review the safety instructions with all usersannually.WARNINGBefore operating your machine,stop and read this owners manual.Do not attempt to operate the unituntil you fully understand the materialcovered in thismanual. Withoutthe knowledge contained in thismanual, injury or death can result.• This equipment is dangerous to children andpersons unfamiliar with its operation. The operatorshould be a responsible, properly trainedand physically able person familiar with farmmachinery and trained in this equipment'soperations. If the elderly are assisting withfarm work, their physical limitations need to berecognized and accommodated.• Use a tractor equipped with a Roll Over ProtectiveStructure (ROPS) and a seat belt.• NEVER exceed the limits of a piece of machinery.If its ability to do a job, or to do so safely, isin question - DON'T TRY IT.• Do not modify the equipment in any way. Unauthorizedmodification may impair the functionand/or safety and could affect the life of theequipment.In addition to the design and configuration of thisimplement, including Safety Signs and Safety Equipment,hazard control and accident prevention aredependent upon the awareness, concern, prudenceand proper training of personnel involved in the operation,transport, maintenance and storage of themachine. Refer also to Safety Messages and operationinstruction in each of the appropriate sections of thetractor and machine manuals. Pay close attentionto the Safety Signs affixed to the tractor and themachine.Think SAFETY! Work SAFELY!WARNING:Turning with tines in the groundwill cause bearing failure andpossible tine damage and thusvoids the warranty.4

2.3 SAFETY TRAINING2.4 SAFETY SIGNSSafety is a primary concern in the design and manufactureof our products. Unfortunately, our efforts toprovide safe equipment can be wiped out by a singlecareless act of an operator or bystander.In addition to the design and configuration of equipment,hazard control and accident prevention aredependent upon the awareness, concern, prudenceand proper training of personnel involved in theoperation, transport, maintenance and storage ofthis equipment.It has been said, "The best safety feature is aninformed, careful operator." We ask you to bethat kind of an operator. It isthe operator's responsibility toread and understand ALLSafety and Operating instructionsin the manual and to follow these. Accidents can beavoided.Working with unfamiliar equipment can lead tocareless injuries. Read this manual, and the manualfor your tractor, before assembly or operating, to acquaintyourself with the machines. If this machine isused by any person other than yourself, or is loanedor rented, it is the machine owner's responsibility tomake certain that the operator, prior to operating:a. Reads and understands the operator'smanuals.b. Is instructed in safe and proper use.Should ownership of the equipment be transferred,thismanual must also be transferred.Know your controls and how to stop tractor, engineand machine quickly in an emergency. Read thismanual and the one provided with your tractor.Train all new personnel and review instructionsfrequently with existing workers. Be certain onlya properly trained and physically able person willoperate the machinery. A person who has not readand understood all operating and safety instructionsis not qualified to operate the machine. An untrainedoperator exposes himself and bystanders to possibleserious injury or death. If the elderly are assistingwith farm work, their physical limitations need tobe recognized and accommodated.1. Safety decals and this manual must beconsidered a permanent part of yourequipment.2. Keep safety signs clean and legible at all times.3. Replace safety signs that are missing or havebecome illegible.4. Replaced parts that displayed a safety signshould also display the current sign.5. Safety signs are available from your authorizeddealer or from <strong>Gearmore</strong>.How To Install Safety Signs:• Be sure that the installation area is cleanand dry.• Be sure temperature is above 50º F (10º C).• Determine exact position before you removethe backing paper. (See Section 3)• Remove the smallest portion of the splitbacking paper.• Align the sign over the specified area andcarefully press the small portion with theexposed sticky backing in place.• Slowly peel back the remaining paper andcarefully smooth the remaining portion of thesign in place.• Small air pockets can be pierced with a pinand smoothed out using the piece of signbacking paper.For any part of this manual that you do not understand,contact your dealer or <strong>Gearmore</strong>, <strong>Inc</strong>.5

2.5 PREPARATION1. Never operate the tractor and machine untilyou have read and completely understandthis manual, the Tractor Operator's Manualand each of the Safety Messages found onthe safety signs on the tractor and machine.2. Personalprotectionequipment,including hardhat, safetyglasses, safetyshoes and glovesare recommendedduring assembly,installation, operation, adjustment,maintaining, repairing, removal or movingthe implement. DO NOT allow long hair,loose fitting clothing or jewelry to be aroundequipment.3. PROLONGED EXPOSURETO LOUD NOISE MAYCAUSE PERMANENTHEARING LOSS!Tractors with or withoutequipment attached canoften be noisy enough to cause permanent,partial hearing loss. We recommend thatyou wear hearing protection on a full-timebasis if the noise in the Operator's positionexceeds 80db. Noise over 85db on a longtermbasis can cause severe hearing loss.Noise over 90db adjacent to the Operatorover a long-term basis may cause permanent,total hearing loss.4. Operate the machine onlywith a tractor equippedwith an approved Roll-OverProtective Structure (ROPS).Always wear your seat belt.Serious injury or even deathcould result from falling offthe tractor --- particularly during a turnoverwhen the operator could be pinnedunder the ROPS or the tractor.5. Clear working area of stones, branchesor hidden obstacles that might be hookedor snagged, causing injury or damage.6. Operate only in daylight or good artificiallight.7. Be sure machine is properly mounted,adjusted and in good operating condition.8. Ensure that all safety shielding andsafety signs are properly installed and ingood condition.NOTE: Hearing loss from loud noise (fromtractors, chain saws, radios, and other suchsources close to the ear) is cumulativeover a lifetime without hope of naturalrecovery.6

2.6 OPERATING SAFETYPlease remember it is important that you read andheed the safety signs on the <strong>Aerator</strong>. Clean or replaceall safety signs if they cannot be clearly read andunderstood. They are there for your safety, as wellas the safety of others. The safe use of this machineis strictly up to you, the operator.All things with moving parts are potentially hazardous.There is no substitute for a cautious, safemindedoperator who recognizes potential hazardsand follows reasonable safety practices. The manufacturerhas designed this <strong>Aerator</strong> to be used with allits safety equipment properly attached to minimizethe chance of accidents. Study this manual to makesure you have all safety equipment attached.If a safety shield or guard is removed for any reason,it must be replaced before the machine is againoperated.When the use of hand tools is required to performany part of assembly, installation, adjustment,maintaining, repairing, removal, or moving, be surethe tools used are designed and recommended by thetool manufacturer for that specific task.Personal protection equipment including hard hat,safety glasses, safety shoes, and gloves are recommendedduring assembly, installation, operation,adjustment, maintaining, repairing, removal, ormoving. Do not allow long hair, loose fitting clothing,or jewelry to be around moving parts.Always use two people to handle heavy, unwieldycomponents during assembly, installation, removal,or moving.Never place any part of your body where it would bein danger if movement should occur during assembly,installation, operation, maintaining, repairing,removal, or moving.A heavy load can cause instability of the tractor. Useextreme care during travel. Slow down on turns andwatch out for bumps. The tractor may need frontcounterweights to counterbalance the weight of themachine.Never use alcoholic beverages or drugs, which canhinder alertness or coordination, while operatingthis equipment. Consult your doctor about operatingthis machine while taking prescription medications.Do not allow riders on the machine or tractor at anytime. There is no safe place for any riders.Before you operate the machine, check over all pins,bolts and connections to be sure all are securely inplace. Replace any damaged or worn parts immediately.Do not allow anyone who is not familiar with thesafety rules and operation instructions to use thismachine.Never allow children to operate or be around thismachine.Use stabilizer bars, adjustable sway chains, or swayblocks on the tractor lift arms to keep the machinefrom swinging side to side. Adjust as tightly as practicalfor best performance.Clear the work area of objects which might be pickedup and snagged or entangled in the machine.Keep hands, feet, hair, jewelry, and clothing awayfrom all moving and/or rotating parts.Unauthorized modifications to the equipment arenot recommended. This could impair the function,safety, and life of the machine.Never place yourself between the tractor and machinewhile implement is in operation.Do not walk or work under a raised machine or attachmentunless it is securely blocked or held in position.Do not depend on the tractor hydraulic systemto hold the machine or attachment in place.7

2.7 TRANSPORT SAFETY1. Comply with state and local laws governinghighway safety and movement of farmmachinery on public roads.2. The use of flashing amber lights isacceptable in most localities. However,some localities prohibit their use. Locallaws should be checked for all highwaylighting and marking requirements.3. At all times, when driving the tractor andequipment on the road or highway under20 mph (32 kph) use flashing amberwarning lights and a slow moving vehicle(SMV) identification emblem. Do not exceed20 mph (32 kph). Reduce speed on roughroads and surfaces.4. Plan your route to avoid heavy traffic.5. Always install transport locks, pins, orbrackets before transporting.6. Do not drink and drive.7. Be a safe and courteous driver. Always yieldto oncoming traffic in all situations,including narrow bridges, intersections, etc.Watch for traffic when operating near orcrossing roadways.8. Turn into curves or go up or down hills onlyat a low speed and at a gradual steeringangle. Make certain that at least 20% of thetractor's weight is on the front wheels tomaintain safe steerage. Slow down on roughor uneven surfaces.9. Never allow riders on either tractor ormachine.2.8 STORAGE SAFETY1. Store the unit in an area away from humanactivity.2. Do not permit children to play on or aroundthe stored machine.3. Store the unit in a dry, level area. Supportthe frame with planks if required.2.9 MAINTENANCE SAFETY1. Good maintenance is your responsibility.Poor maintenance is an invitation totrouble.2. Follow good shop practices.- Keep servicearea cleanand dry.- Be sure electricaloutlets and toolsare properlygrounded.- Use adequate lightfor the job at hand.3. Make sure there is plenty of ventilation.Never operate the engine in a closedbuilding. The exhaust fumes may causeasphyxiation.4. Before working on this machine, shutoff the engine, set the brakes, and removethe ignition key.5. Never work under equipment unless it isblocked securely.6. Use personal protection devices such as eye,hand, and hearing protectors, whenperforming any service or maintenancework.7. Where replacement parts are necessary forperiodic maintenance and servicing,genuine factory replacement parts must beused to restore your equipment to originalspecifications. The manufacturer will not beresponsible for injuries or damages causedby use of unapproved parts and/oraccessories.8. A fire extinguisherand first aid kitshould be keptreadily accessiblewhile performingmaintenance onthis equipment9. Periodically tighten all bolts, nuts andscrews and check that all cotter pins areproperly installed to ensure unit is in a safecondition.10. When completing a maintenance or servicefunction, make sure all safety shields anddevices are installed before placing unit inservice.8

4.2 MACHINE BREAK-IN 4.3 PRE-OPERATION CHECKLISTAlthough there are no operational restrictions onthe <strong>Aerator</strong> when used for the first time, it is recommendedthat the following mechanical itemsbe checked:A. After Operating The First Day:1. Check all nuts, bolts and other fasteners.Tighten to their specified torque level.2. Check that the tines are in goodcondition.Efficient and safe operation of the <strong>Aerator</strong>requires that each operator reads and understandsthe operating procedures and all relatedsafety precautions outlined in this section. A preoperationchecklist is provided for the operator.It is important for both the personal safety andmaintaining the good mechanical condition ofthe <strong>Aerator</strong> that this checklist is followed.Before operating the machine and each timethereafter, the following areas should be checkedoff:√ Use only a tractor of the correcthorsepower rating on the machine.√√√√Check that the machine is properlyattached to the tractor. Be sure retainersare used on the mounting pins.Be sure extra weights are mounted on thefront of the tractor if required.Check the tines. Be sure they are notdamaged or broken and are not badlyworn. Repair or replace as required.Check for entangled material. Remove thismaterial.11

4.4 FIELD OPERATIONOPERATING SAFETY1. Read and understand the Operator's Manualand all safety signs before operating, servicing,adjusting, repairing, or unplugging.2. Do not allow riders.3. Install and secure all guards and shieldsbefore starting or operating.4. Keep hands, feet, hair, and clothing awayfrom moving parts.5. Place all controls in neutral, stop tractorengine, set park brake, remove ignition keyand wait for all moving parts to stop beforeservicing, adjusting, repairing, or unplugging.6. Place all tractor and machine controls inneutral before starting.7. Never start or operate machine unless sittingon tractor seat.8. Clear the area of bystanders, especiallysmall chilren, before starting.9. Clean refl ectors, SMV and lights beforetransporting.10. Use hazard fl ashers on tractor when transporting.11. Do not put hands or feet under machinewhile tractor engine is running.Each operator should review this section of themanual at the start of the season and as often asrequired to be familiar with the machine. Whenusing, follow this procedure:1. Review and follow the Pre-OperationChecklist.2. Attach the tractor to the machine.CAUTION:DO NOT make turns with the tines in theground. Your <strong>Aerator</strong> must be lifted out of theground when making turns to prevent nonwarrantee damage to the <strong>Aerator</strong>.DANGER:Excessive tractor speed or radical operation whenturning can endanger tractor and operators safety.OPERATING INSTRUCTIONS:1. Lower the tractor 3-point hitch to obtain thedepth required, which is usually maximumtine depth to obtain the most effective results.If you can not obtain maximum depth,additional weight may be required.2. It is usually best to start at (zero) straight tinerotors. If large aerated openings are required,angle the tine rotors to the degrees that bestfit your requirements. If the soil is severelycompacted, it may be necessary to aerateseveral times.3. Travel at a speed which is safe, keeping inmind tractor stability, steering ability, soiland weather conditions, and operator comfort.4. DO NOT make sharp turns with the tinedroller in the ground. The <strong>Aerator</strong> roller mustbe lifted out of the ground when makingsharp turns.5. Severely compacted soil and high trafficareas may need to be aerated several times.6. For greater cultivation on quick adjustmodelspull the adjusting pins and move the swingarms toward the rear of the implement. Thereare various positions to choose from, startingat 0° and going to 10° at 2.5° increments.7. When disconnecting your <strong>Aerator</strong> from thetractor, remove the jack pin and extend thelegs to the maximum length. Then re-insertthe jack pin and its hair pin clip, making surethat all 4 legs are on solid level ground. Alwaysuse the extended jacklegs for the safe storageof the <strong>Aerator</strong>.12

4.5 TRANSPORTINGTRANSPORT SAFETY1. Make sure you are in compliance with alllocal regulations regarding transportingequipment on public roads and highways.2. Make sure the SMV (Slow Moving Vehicle)emblem and all the lights and refl ectors thatare required by the local highway and transportauthorities are in place, are clean andcan be seen clearly by all overtaking andoncoming traffi c.3. Do not allow anyone to ride on the <strong>Aerator</strong>or tractor during transport.4. Do not exceed 20 mph (32 kph). Reducespeed on rough roads and surfaces.5. Use retainers on the mounting pins whenattaching.6. Always use hazard fl ashers on the tractorwhen transporting unless prohibited by law.When transporting the machine, review and followthese instructions:1. Be sure all bystanders are clear of the machine.2. Be sure that the machine is securely attached tothe tractor and all retainer pins are installed.3. Be sure you have installed extra weights on thefront of the tractor if required.4. Clean the SMV emblem, lights and reflectorsand be sure they are working.5. Be sure you are in compliance with all applicablelighting and marking regulations when transporting.Check with your local authorities.6. Be sure your machine can clearly be seen byovertaking and oncoming traffic.7. Keep to the right and yield the right-of-way toallow faster traffic to pass. Drive on the roadshoulder if permitted by law.8. Do not allow riders.4.6 STORAGESTORAGE SAFETY1. Store the unit in an area away from humanactivity.2. Do not permit children to play on or aroundthe stored machine.3. Store the unit in a dry, level area. Supportthe frame with planks if required.After the season's use, the machine should bethoroughly inspected and prepared for storage.Repair or replace any worn or damaged componentsto prevent any unnecessary down time atthe start of next season. To insure a long, troublefree life, this procedure should be followedwhen preparing the unit for storage:1. Clear the area of bystanders, especiallysmall children.2. Thoroughly wash the machine using a pressurewasher to remove all dirt, mud, debrisand residue.3. Inspect the implement for damage or entangledmaterial. Repair or replace damagedparts. Remove all entangled material.4. Touch up all paint nicks and scratches toprevent rusting.5. Move to storage area.6. Select an area that is dry, level and free ofdebris.7. Unhook from tractor.8. If the machine cannot be placed inside,cover with a waterproof tarpaulin and tiesecurely in place.9. Store the machine in an area away from humanactivity.10. Do not allow children to play on or aroundthe stored machine.9. Always use hazard flashers on the tractor whentransporting unless prohibited by law.13

5 GENERAL MAINTENANCE5.1 TINES1. Inspect tines for signs of excessive wear or breakage before operating the<strong>Aerator</strong>.2. Re-torque tine bolts to (120 ft./lbs) after first day of use.3. After first week of use, re-check torque to make sure the tines are lockedtightly in place.5.2 TINES REPLACEMENT:If tines are badly worn or broken, replace them right away to ensure effective useof your <strong>Aerator</strong>. The stamped number 225-0003LF is the left hand tines. Standingbehind the aerator use these tines on the left hand side. The right side tines arestamped number 225-0004RF and should be mounted on the right side.5.3 BEARING MAINTENANCE AND LUBRICATION:Lubricate bearings daily with water resistant, lithium based, EP 2 grease orequal. Use enough grease to purge contaminates out of the bearings. To improve theeffectiveness of the lubrication process, rotate the rotors by hand to ensure thatthe fresh grease is evenly distributed throughout the bearing and purge outcontaminated grease. Continue until the fresh grease is visible.CAUTION:Be careful not to allow hands and clothes to becomeentangled in the sharp rotating tines.14

5.4 BOLT TORQUECHECKING BOLT TORQUEThe tables shown below give correct torque values for various bolts and capscrews. Tighten all boltsto the torques specified in chart unless otherwise noted. Check tightness of bolts periodically, usingbolt torque chart as a guide. Replace hardware with the same strength bolt.ENGLISH TORQUE SPECIFICATIONSBoltDiameter SAE 2"A" N.m (lb-ft)1/ 4"5/ 16"3/ 8"7/ 16"1/ 2"9/ 16"5/ 8"3/ 4"7/ 8"1"81327416195128225230345(6)(10)(20)(30)(45)(70)(95)(165)(170)(225)Bolt Torque *SAE 5N.m (lb-ft)12254572110155215390570850(9)(19)(33)(53)(80)(115)(160)(290)(420)(630)SAE 8N.m (lb-ft)1736631001552203055408801320(12)(27)(45)(75)(115)(165)(220)(400)(650)(970)Torque figures indicated above are valid for non-greased or non-oiled threads and heads unless otherwisespecified. Therefore, do not grease or oil bolts or capscrews unless otherwise specified in thismanual. When using locking elements, increase torque values by 5%.* Torque value for bolts and capscrews are identified by their head markings.15

6 ASSEMBLY6.1 AERATOR ASSEMBLYYour <strong>Aerator</strong> comes fully assembled except the light kit and SMV placard that must be installed beforeoperation begins.STEP 1:Mount your light kit into the mounting holes on the outsiderear corners of your <strong>Aerator</strong>. Route the wiring harnessthrough the frames so that your weights or weight boxes willnot make contact or rub the wiring. Use the provided wiringclips to secure the wiring onto the frame. The female plugon the end of the wiring has a storage mount for when notin use. It is located on the center bracket of the 3-point hitch.This storage bracket requires a 1/4 twist to hold the plug intothe storage bracket.STEP 2:Mount your SMV placard into the bracketon the rear of the <strong>Aerator</strong>.6.2 PULL KIT ASSEMBLYSTEP 1:Mount tires and wheels onto hubs of transport dolly.STEP 2:Align transport dolly with the mounting brackets on the back of <strong>Aerator</strong> frame, when mountingpoints are aligned install pins into the brackets. Make sure the flat sides align with the stopswelded to the outside of one mounting bracket. Drive roll pins into pins to secure pins into frame.STEP 3:Mount hydraulic cylinder on upper cylinder mount on rear offrame and onto the transport dolly, using mounting pins onhydraulic cylinder. Connect hydraulic hoses onto cylinder androute hoses through U-bolt brackets welded onto frame andsecure with straps and nuts.16

6.3 ROLL HITCH ASSEMBLYSTEP 1:Mount tongue into the front 3-point hitchusing the Cat. 2 hitch pins. Mount tonguebrace into top link positions and tongue heightbracket on tongue assembly. This adjustableheight bracket will need to be adjusted tomatch your tractor's drawbar height, allowingthe tongue to stay in a level position duringoperation.STEP 2:Mount tongue jack onto pivot tube welded to tongue.Continue to route hydraulic hoses down the tongueand secure through welded U-bolt mounts and straps.6.4 3-POINT HITCH ASSEMBLYSTEP 1:Before attaching to tractor, make sure the<strong>Aerator</strong> is in a solid, level position.STEP 2:Back the tractor to the <strong>Aerator</strong> until thelower 3-point hitch arms are inside the unitslower clevis hitch points.STEP 3:Install the lower hitch pins and lock in place.STEP 4:Install the tractor turnbuckle to the <strong>Aerator</strong>top link.STEP 5:Adjust the lateral limiters to remove excessivesway from the lower link arms.STEP 6:Hydraulically lift the <strong>Aerator</strong> and retract the 4parking legs. Then lower the unit to the ground.STEP 7:From the rear of the <strong>Aerator</strong>, add the ballastrequired for maximum penetration. Maximumballast weight is 200 lbs. per foot of the <strong>Aerator</strong>width.CAUTION:If the weight of the ballasted <strong>Aerator</strong> exceedsthe lift capacity of the tractor 3-point hitch,then order the pull hitch assembly. The pullhitch bolts directly to the <strong>Aerator</strong> with nomodifications.CAUTION:If the weight of the ballasted <strong>Aerator</strong> resultsin the loss of tractor stability in steering, tractorfront mount weights must be added beforeuse.17

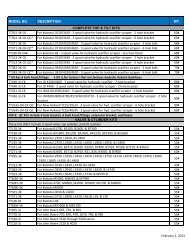

7 REPLACEMENT PARTS - PA SERIES ONLY7.1 PARTS LIST - TINESREF # PART NO. DESCRIPTION1 225-0008 Spool, 7.25", "Disregard Number in Casting"2 225-0002 Spool, End3 255-0011 Nut, Tine, bolt, ½ x 20 FLG, Stover4 255-0010 Bolt, Tine, ½ - 20 x 2 ¾ Flanged5 225-0003LF Tine, Left Hand5 225-0004RF Tine, Right Hand225-0123 Tine, Set of 12 of #225-0003225-0124 Tine, Set of 12 of #225-00046 225-0058 Safety Chain Assembly7 700-225-0010 C-Flex Shank Bracket8 225-0063 C-Flex Spring Shim9 225-0069 Bracket, 4-Hole Flange Bearing10 HC812F136Z Bolt, ¾ - 16 x 8 ½", Gr. 811 NNE834FZ Nut, Nylon Lock, ¾ - 16, Gr. 812 225-0005 C-Flex Shank Spring, RH225-0006 C-Flex Shank Spring, LH13 NSB50CZ Nut, Stover Lock ½ - 1314 HC58C24Z Bolt ½ - 13 x 1 ½"15 Eccentric Lock Collar (comes with bearing)16 225-0066 Bearing, 4-Hole Flange, 1 ½"17 NNE834FZ Nut, Nylon Lock, ¾ - 16, Gr. 818 HC812F56Z Bolt, ¾ - 16 x 3 ½, Gr. 819 225-0056 Block, Stop, C-Flex Spring, LH225-0057 Block, Stop, C-Flex Spring, RH18

7.2 PARTS LIST - AXLEREF # PART NO. DESCRIPTION20 225-0036 Axle Weldment, 8'225-0037 Axle Weldment, 10'225-0038 Axle Weldment, 12'225-0039 Axle Weldment, 15'21 255-0006 Nut, Slotted, 1 ½" - 1221A TC-135 Cotter Pin, 3⁄16 x 3"22 700-225-0075 Axle Spacer23 255-0007 Flat Washer, 1 ½", Gr. 824 225-0014 Dust Cap25 TC-109 Outer Bearing26 225-0010 Hub Assembly, Complete27 225-0013 Inner Bearing28 225-0015 Seal29 225-0059 Spindle, With Nut & Pin30 225-0028 Gang Arm, 8'225-0029 Gang Arm, 10'225-0030 Gang Arm, 12'225-0031 Gang Arm, 15'31 225-0040 Pivot Pin, Gang Arm32 PRO38S32Z Roll Pin ⅜ x 2"19

7.3 PARTS LIST - FRAMEREF # PART NO. DESCRIPTION46 225-0020 Frame - 8'225-0021 Frame - 10'225-0022 Frame - 12'225-0023 Frame - 15'47 TC-126 Cat. 2 Lift Pin48 TC-126A 7⁄16" Lynch Pin49 500-22 Cat. 2 Top Link Pin50 MH-01 Manual Holder51 UT-207A Pin w/Hair Clip52 225-0064 Clevis Pin, ½" x 3"53 225-0065 Hair Clip Pin54 225-0044 Stand55 225-0047 Weight Container225-0050 Light Kit - 8' (not shown)225-0051 Light Kit - 10' (not shown)225-0052 Light Kit - 12' (not shown)225-0053 Light Kit - 15' (not shown)225-0054 SMV Placard (not shown)225-0055 SMV Placard Bracket (not shown)225-0008 Wiring Harness Clip (not shown)20

7.4 PARTS LIST - PULL HITCHREF # PART NO. DESCRIPTION33 225-0024 Hydraulic Cylinder, 3" x 12"225-0025 Hydraulic Cylinder, 4" x 12"34 225-0026 Hydraulic Hose35 225-0046 Jack36 225-0016 Tire & Wheel37 225-0041 Pivot Pin38 PRO38S32Z Roll Pin ⅜" x 2"39 225-0032 2 Spindle Carrier225-0033 4 Spindle Carrier40 500-22 Pin41 TC-126A Pin42 225-0048 Tongue43 UR-207A Pin with Hair Clip44 225-0049 Tongue Brace45 225-0068 Hydraulic Hose Strap225-0009 Stop, Cylinder, <strong>Aerator</strong> Pull Kit (not shown)225-0017 Bolt, Lug 9⁄16 - 18 x 1 ⅜ (not shown)225-0027 Chain, Safety, <strong>Aerator</strong> Pull Kit (not shown)21

8 LIMITED WARRANTYGEARMORE, INC., warrants each new <strong>Gearmore</strong> product to be free from defects in material and workmanshipfor a period of twelve (12) months from date of purchase to the original purchaser. This warrantyshall not apply to implements or parts that have been subject to misuse, negligence, accident, or that havebeen altered in any way.Our obligation shall be limited to repairing or replacement of any part, provided that such part is returnedwithin thirty (30) days from date of failure to <strong>Gearmore</strong> through the dealer from whom the purchase wasmade, transportation charges prepaid.This warranty shall not be interpreted to render us liable for injury or damages of any kind or nature, direct,consequential or contingent, to person or property. This warranty does not extend to loss of crops, lossbecause of delay in harvesting or any other expenses, for any other reasons.<strong>Gearmore</strong> in no way warranties engines, tires, or other trade accessories, since these items are warrantedseparately by these respective manufacturers.<strong>Gearmore</strong> reserves the right to make improvements in design or changes in specifi cation at any time,without incurring any obligations to owners or units previously sold.Please be advised that all warranty work done by your dealer must be approved by <strong>Gearmore</strong> before workbegins.Always refer to and heed machine operating warning decals on machine.GEARMORE, INC.13477 Benson Ave.Chino, CA 91710To insure warranty, please fi ll out the enclosed warranty formand return to <strong>Gearmore</strong> via mail.22