Proline Promass 83E/F/O Modbus RS485 Operating Instructions

Proline Promass 83E/F/O Modbus RS485 Operating Instructions

Proline Promass 83E/F/O Modbus RS485 Operating Instructions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

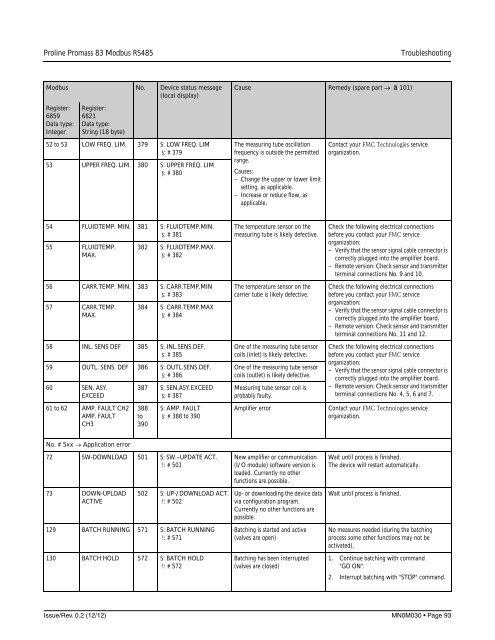

<strong>Proline</strong> <strong>Promass</strong> 83 <strong>Modbus</strong> <strong>RS485</strong>äTroubleshooting<strong>Modbus</strong> No. Device status message(local display)Cause Remedy (spare part ä 101)Register:6859Data type:IntegerRegister:6821Data type:String (18 byte)52 to 53 LOW FREQ. LIM. 379 S: LOW FREQ. LIM$: # 37953 UPPER FREQ. LIM. 380 S: UPPER FREQ. LIM$: # 380The measuring tube oscillationfrequency is outside the permittedrange.Causes:– Change the upper or lower limitsetting, as applicable.– Increase or reduce flow, asapplicable.Contact your serviceorganization.54 FLUIDTEMP. MIN. 381 S: FLUIDTEMP.MIN.$: # 38155 FLUIDTEMP.MAX.382 S: FLUIDTEMP.MAX.$: # 38256 CARR.TEMP. MIN. 383 S: CARR.TEMP.MIN$: # 38357 CARR.TEMP.MAX.384 S: CARR.TEMP.MAX$: # 38458 INL. SENS DEF 385 S: INL.SENS.DEF.$: # 38559 OUTL. SENS. DEF 386 S: OUTL.SENS.DEF.$: # 38660 SEN. ASY.EXCEED61 to 62 AMP. FAULT CH2AMP. FAULTCH3387 S: SEN.ASY.EXCEED$: # 387388to390S: AMP. FAULT$: # 388 to 390The temperature sensor on themeasuring tube is likely defective.The temperature sensor on thecarrier tube is likely defective.One of the measuring tube sensorcoils (inlet) is likely defective.One of the measuring tube sensorcoils (outlet) is likely defective.Measuring tube sensor coil isprobably faulty.Amplifier errorCheck the following electrical connectionsbefore you contact your serviceorganization:– Verify that the sensor signal cable connector iscorrectly plugged into the amplifier board.– Remote version: Check sensor and transmitterterminal connections No. 9 and 10.Check the following electrical connectionsbefore you contact your serviceorganization:– Verify that the sensor signal cable connector iscorrectly plugged into the amplifier board.– Remote version: Check sensor and transmitterterminal connections No. 11 and 12.Check the following electrical connectionsbefore you contact your serviceorganization:– Verify that the sensor signal cable connector iscorrectly plugged into the amplifier board.– Remote version: Check sensor and transmitterterminal connections No. 4, 5, 6 and 7.Contact your serviceorganization.No. # 5xx Application error72 SW-DOWNLOAD 501 S: SW.–UPDATE ACT.!: # 501New amplifier or communication(I/O module) software version isloaded. Currently no otherfunctions are possible.Wait until process is finished.The device will restart automatically.73 DOWN-UPLOADACTIVE502 S: UP-/DOWNLOAD ACT.!: # 502Up- or downloading the device datavia configuration program.Currently no other functions arepossible.Wait until process is finished.129 BATCH RUNNING 571 S: BATCH RUNNING!: # 571130 BATCH HOLD 572 S: BATCH HOLD!: # 572Batching is started and active(valves are open)Batching has been interrupted(valves are closed)No measures needed (during the batchingprocess some other functions may not beactivated).1. Continue batching with command"GO ON".2. Interrupt batching with "STOP" command. Issue/Rev. 0.2 (12/12) MN0M030 • Page 93