VESTAMID HTplus M3033black

VESTAMID HTplus M3033black

VESTAMID HTplus M3033black

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Product Information<strong>VESTAMID</strong>® <strong>HTplus</strong> M3033Polyphthalamide based on PA10T<strong>VESTAMID</strong> <strong>HTplus</strong> M3033 is a PA 10T-based,black colored, glass-fiber reinforced (30%),heat-stabilized copolyamide. PA 10T is apoly-condensation product of 1,10-decamethylene diamine (10) and terephthalicacid (T). As 1,10-decamethylene diamine isderived from castor oil plants, <strong>VESTAMID</strong><strong>HTplus</strong> M3033 is partially natural resourcedand thus bio-based.This resin is especially suited formanufacturing parts subjected to hightemperature.<strong>VESTAMID</strong> <strong>HTplus</strong> M3033 is supplied asspherical pellets in polyethylene packaging.Drying at 120°C for at least 4 hours beforeprocessing is recommended.Compared to PA 6T-based resins <strong>VESTAMID</strong><strong>HTplus</strong> M3033 has a broader processingwindow as well as a reduced tendency toabsorb water. Therefore the material exhibitsless variation in mechanical properties anddimensional changes with humidity.Our technical experts would appreciate togive support regarding the specialrequirements for the processing of<strong>VESTAMID</strong> <strong>HTplus</strong> M3033.For further information, please contact our experts in the department Market Developmentof the High Performance Polymers Business Line.<strong>VESTAMID</strong>® = registered trademark of the Evonik Degussa GmbH July 2010

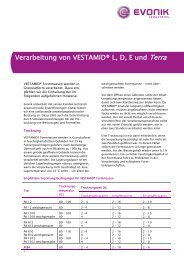

PropertyTest methodinternationalnationalUnit<strong>VESTAMID</strong><strong>HTplus</strong>M3033Density 23°C ISO 1183 DIN EN ISO 1183 g/cm 3 1.36Tensile testISO 527-1DIN EN ISO 527-1Stress at breakISO 527-2DIN EN ISO 527-2MPa169Strain at break%2.4Tensile modulus ISO 527-1ISO 527-2DIN EN ISO 527-1DIN EN ISO 527-2MPa 9400CHARPY impact strengthISO 179/1eUDIN EN ISO 179/1eU23°C-40°CkJ/m 2kJ/m 256 C 1)52 C 1)CHARPY notched impact strengthISO 179/1eADIN EN ISO 179/1eA23°C-40°CkJ/m²kJ/m²8.6 C 1)7.5 C 1)Temperature of deflectionunder loadISO 75-1ISO 75-2DIN EN ISO 75-1DIN EN ISO 75-2Method A 1.8 MPaMethod B0.45 MPa°C°C263284Melting pointISO 11357DSC2 nd heating°C approx. 285Pigmentation may affect values.1) C = Complete break, incl. hinge break HThe results shown have been generated from a low number of production lots. Therefore, they are preliminary and not yet the result of astatistical evaluation. Therefore they must not be used to establish specifications.® = registered trademarkThis information and all technical and other advice are based on Evonik’s present knowledge and experience. However, Evonik assumes noliability for such information or advice, including the extent to which such information or advice may relate to third party intellectualproperty rights. Evonik reserves the right to make any changes to information or advice at any time, without prior or subsequent notice.Evonik disclaims all representations and warranties, whether express or implied, and shall have no liability for, merchantability of theproduct or its fitness for a particular purpose (even if Evonik is aware of such purpose), or otherwise. Evonik shall not be responsible forconsequential, indirect or incidental damages (including loss of profits) of any kind. It is the customer’s sole responsibility to arrange forinspection and testing of all products by qualified experts. Reference to trade names used by other companies is neither arecommendation, nor an endorsement of the corresponding product, and does not imply that similar products could not be used.Evonik Degussa GmbH High Performance Polymers 45764 Marl GermanyPhone +49 2365 49-9878 E-mail evonik-hp@evonik.comwww.vestamid.com