New Researches in Biotechnology - Facultatea de Biotehnologii ...

New Researches in Biotechnology - Facultatea de Biotehnologii ... New Researches in Biotechnology - Facultatea de Biotehnologii ...

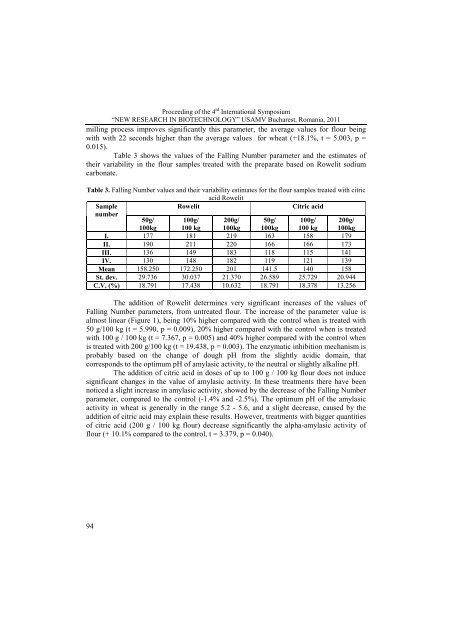

Proceeding of the 4 rd International Symposium“NEW RESEARCH IN BIOTECHNOLOGY” USAMV Bucharest, Romania, 2011milling process improves significantly this parameter, the average values for flour beingwith with 22 seconds higher than the average values for wheat (+18.1%, t = 5.003, p =0.015).Table 3 shows the values of the Falling Number parameter and the estimates oftheir variability in the flour samples treated with the preparate based on Rowelit sodiumcarbonate.Table 3. Falling Number values and their variability estimates for the flour samples treated with citricacid RowelitSampleRowelitCitric acidnumber50g/100kg100g/100 kg200g/100kg50g/100kg100g/100 kg200g/100kgI. 177 181 219 163 158 179II. 190 211 220 166 166 173III. 136 149 183 118 115 141IV. 130 148 182 119 121 139Mean 158.250 172.250 201 141.5 140 158St. dev. 29.736 30.037 21.370 26.589 25.729 20.944C.V. (%) 18.791 17.438 10.632 18.791 18.378 13.256The addition of Rowelit determines very significant increases of the values ofFalling Number parameters, from untreated flour. The increase of the parameter value isalmost linear (Figure 1), being 10% higher compared with the control when is treated with50 g/100 kg (t = 5.990, p = 0.009), 20% higher compared with the control when is treatedwith 100 g / 100 kg (t = 7.367, p = 0.005) and 40% higher compared with the control whenis treated with 200 g/100 kg (t = 19.438, p = 0.003). The enzymatic inhibition mechanism isprobably based on the change of dough pH from the slightly acidic domain, thatcorresponds to the optimum pH of amylasic activity, to the neutral or slightly alkaline pH.The addition of citric acid in doses of up to 100 g / 100 kg flour does not inducesignificant changes in the value of amylasic activity. In these treatments there have beennoticed a slight increase in amylasic activity, showed by the decrease of the Falling Numberparameter, compared to the control (-1.4% and -2.5%). The optimum pH of the amylasicactivity in wheat is generally in the range 5.2 - 5.6, and a slight decrease, caused by theaddition of citric acid may explain these results. However, treatments with bigger quantitiesof citric acid (200 g / 100 kg flour) decrease significantly the alpha-amylasic activity offlour (+ 10.1% compared to the control, t = 3.379, p = 0.040).94

Proceeding of the 4 rd International Symposium“NEW RESEARCH IN BIOTECHNOLOGY” USAMV Bucharest, Romania, 2011250200150100Row elitCitric Acid500Control 50 g/100 kg 100 g/100 kg 200 g/100 kgFigure 1. The evolution of the Falling Number parameter in case oftreatments with Rowelit and citric acidSince in bakeries using a wide range of acidifiers (acetic acid, lactic acid, citricacid etc), the use of sodium carbonate can be a problem, due to its reactivity. Table 4contains the results obtained by the treatment of the flour samples with differentcombinations of the two preparates, namely Rowelit and citric acid.Table 4. Falling Number values and their variability estimates for the flour samples treated withRowelit and citric acidRowelit + Citric acidSamplenumber25 + 25g/100kg50 + 50g/100 kg100 + 100g/100kg25 +100g/100kg100 + 25g/100kgI. 158 165 166 175 195II. 173 185 189 175 189III. 123 125 121 120 139IV. 116 120 118 121 138Mean 142.500 148.750 148.500 147.750 165.250St. dev. 27.404 31.456 34.799 31.468 30.988C.V. (%) 19.231 21.148 23.434 21.298 18.752From Table 4 we notice that the use of equal quantities of the two preparates didnot alter significantly the value of the Falling Number parameter. Also, the combination of25 g/100 kg Rowelit and 100 g/100 kg citric acid does not significantly influence theamylasic activity of flours. Instead, the combination of 100 g/100 kg Rowelit and 25 g/100kg citric acid causes a significant increase of the Falling Number parameter (+ 15.16%compared to the control, t = 4.207, p = 0.024). This fact suggests that the use of averagedoses of sodium carbonate can be considered for reducing the amylasic activity in flourswith defects, while the technological processes use relatively small quantities of acidifiers.However, the degree of inhibition of amylasic activity is not big enough to allow thecorrection of some flours having initially large amylasic activity. In the context of thisresearch, we consider that the potential of reducing the amylasic activity by using sodium95

- Page 43 and 44: Proceeding of the 4 rd Internationa

- Page 45 and 46: Proceeding of the 4 rd Internationa

- Page 47 and 48: Proceeding of the 4 rd Internationa

- Page 49 and 50: Proceeding of the 4 rd Internationa

- Page 51 and 52: Proceeding of the 4 rd Internationa

- Page 53 and 54: Proceeding of the 4 rd Internationa

- Page 55 and 56: Proceeding of the 4 rd Internationa

- Page 57 and 58: Proceeding of the 4 rd Internationa

- Page 59 and 60: Proceeding of the 4 rd Internationa

- Page 61 and 62: Proceeding of the 4 rd Internationa

- Page 63 and 64: Proceeding of the 4 rd Internationa

- Page 65 and 66: Proceeding of the 4 rd Internationa

- Page 67 and 68: Proceeding of the 4 rd Internationa

- Page 69 and 70: Proceeding of the 4 rd Internationa

- Page 71 and 72: Proceeding of the 4 rd Internationa

- Page 73 and 74: Proceeding of the 4 rd Internationa

- Page 75 and 76: Proceeding of the 4 rd Internationa

- Page 77 and 78: Proceeding of the 4 rd Internationa

- Page 79 and 80: Proceeding of the 4 rd Internationa

- Page 81 and 82: Proceeding of the 4 rd Internationa

- Page 83 and 84: Proceeding of the 4 rd Internationa

- Page 85 and 86: Proceeding of the 4 rd Internationa

- Page 87 and 88: Proceeding of the 4 rd Internationa

- Page 89 and 90: Proceeding of the 4 rd Internationa

- Page 91 and 92: Proceeding of the 4 rd Internationa

- Page 93: Proceeding of the 4 rd Internationa

- Page 97 and 98: Proceeding of the 4 rd Internationa

- Page 99 and 100: Proceeding of the 4 rd Internationa

- Page 101 and 102: Proceeding of the 4 rd Internationa

- Page 103 and 104: Proceeding of the 4 rd Internationa

- Page 105 and 106: Proceeding of the 4 rd Internationa

- Page 107 and 108: Proceeding of the 4 rd Internationa

- Page 109 and 110: Proceeding of the 4 rd Internationa

- Page 111 and 112: Proceeding of the 4 rd Internationa

- Page 113 and 114: Proceeding of the 4 rd Internationa

- Page 115 and 116: Proceeding of the 4 rd Internationa

- Page 117 and 118: Proceeding of the 4 rd Internationa

- Page 119 and 120: Proceeding of the 4 rd Internationa

- Page 121 and 122: Proceeding of the 4 rd Internationa

- Page 123 and 124: Proceeding of the 4 rd Internationa

- Page 125 and 126: Proceeding of the 4 rd Internationa

- Page 127 and 128: Proceeding of the 4 rd Internationa

- Page 129 and 130: Proceeding of the 4 rd Internationa

- Page 131 and 132: Proceeding of the 4 rd Internationa

- Page 133 and 134: Proceeding of the 4 rd Internationa

- Page 135 and 136: Proceeding of the 4 rd Internationa

- Page 137 and 138: Proceeding of the 4 rd Internationa

- Page 139 and 140: Proceeding of the 4 rd Internationa

- Page 141 and 142: Proceeding of the 4 rd Internationa

- Page 143 and 144: Proceeding of the 4 rd Internationa

Proceed<strong>in</strong>g of the 4 rd International Symposium“NEW RESEARCH IN BIOTECHNOLOGY” USAMV Bucharest, Romania, 2011mill<strong>in</strong>g process improves significantly this parameter, the average values for flour be<strong>in</strong>gwith with 22 seconds higher than the average values for wheat (+18.1%, t = 5.003, p =0.015).Table 3 shows the values of the Fall<strong>in</strong>g Number parameter and the estimates oftheir variability <strong>in</strong> the flour samples treated with the preparate based on Rowelit sodiumcarbonate.Table 3. Fall<strong>in</strong>g Number values and their variability estimates for the flour samples treated with citricacid RowelitSampleRowelitCitric acidnumber50g/100kg100g/100 kg200g/100kg50g/100kg100g/100 kg200g/100kgI. 177 181 219 163 158 179II. 190 211 220 166 166 173III. 136 149 183 118 115 141IV. 130 148 182 119 121 139Mean 158.250 172.250 201 141.5 140 158St. <strong>de</strong>v. 29.736 30.037 21.370 26.589 25.729 20.944C.V. (%) 18.791 17.438 10.632 18.791 18.378 13.256The addition of Rowelit <strong>de</strong>term<strong>in</strong>es very significant <strong>in</strong>creases of the values ofFall<strong>in</strong>g Number parameters, from untreated flour. The <strong>in</strong>crease of the parameter value isalmost l<strong>in</strong>ear (Figure 1), be<strong>in</strong>g 10% higher compared with the control when is treated with50 g/100 kg (t = 5.990, p = 0.009), 20% higher compared with the control when is treatedwith 100 g / 100 kg (t = 7.367, p = 0.005) and 40% higher compared with the control whenis treated with 200 g/100 kg (t = 19.438, p = 0.003). The enzymatic <strong>in</strong>hibition mechanism isprobably based on the change of dough pH from the slightly acidic doma<strong>in</strong>, thatcorresponds to the optimum pH of amylasic activity, to the neutral or slightly alkal<strong>in</strong>e pH.The addition of citric acid <strong>in</strong> doses of up to 100 g / 100 kg flour does not <strong>in</strong>ducesignificant changes <strong>in</strong> the value of amylasic activity. In these treatments there have beennoticed a slight <strong>in</strong>crease <strong>in</strong> amylasic activity, showed by the <strong>de</strong>crease of the Fall<strong>in</strong>g Numberparameter, compared to the control (-1.4% and -2.5%). The optimum pH of the amylasicactivity <strong>in</strong> wheat is generally <strong>in</strong> the range 5.2 - 5.6, and a slight <strong>de</strong>crease, caused by theaddition of citric acid may expla<strong>in</strong> these results. However, treatments with bigger quantitiesof citric acid (200 g / 100 kg flour) <strong>de</strong>crease significantly the alpha-amylasic activity offlour (+ 10.1% compared to the control, t = 3.379, p = 0.040).94