Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Evaluation and Repair of Wrought Iron and - Purdue e-Pubs ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

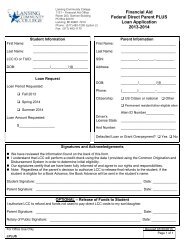

xFigurePageFigure 3.3 Donated Eyebars 4 <strong>and</strong> 5 Along With a Similar Eyebar that Was Straightened<strong>and</strong> Used in the Reconstruction <strong>of</strong> the Bell Ford Bridge.......................................... 60Figure 3.4 Round Diagonal Tensile Rods........................................................................ 60Figure 3.5 Micrograph <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong> (100 x magnification) ...................................... 61Figure 3.6 Hardness Values for One Sample <strong>of</strong> <strong>Wrought</strong> <strong>Iron</strong>........................................ 61Figure 3.7 Heated Areas in Blue on Eyebar 2 ................................................................. 62Figure 3.8 Piece <strong>of</strong> Historic <strong>Wrought</strong> <strong>Iron</strong> From Eyebar 3 Heated Till it is Cherry Red InColor ......................................................................................................................... 62Figure 3.9 Tensile Coupon Dimensions per ASTM 370 ................................................. 63Figure 3.10 Method used to Mechanically Straighten a Bar ........................................... 63Figure 3.11 Detail Used in Groove Weld Test Specimens ............................................... 64Figure 3.12 Weld Detail after Initial Root Pass on Testing Specimen ............................. 64Figure 3.13 Round Tensile Testing Specimen................................................................. 65Figure 3.14 Specimen in Testing Machine Ready to be tested........................................ 65Figure 3.15 Typical Plot <strong>of</strong> Stress vs. Strain from Elastic Test....................................... 66Figure 3.16 Typical Plot <strong>of</strong> Stress vs. Strain from Test to Full Failure........................... 66Figure 3.17 Orientation <strong>of</strong> Different Charpy Specimens................................................. 67Figure 3.18 Dimensions <strong>of</strong> Charpy Specimens per ASTM E23...................................... 67Figure 3.19 Charpy Impact Testing Machine ................................................................... 68Figure 3.20 Liquid Bath Setup used for Cooling Charpy Specimens.............................. 68Figure 3.21 Placement <strong>of</strong> Strain Gages on Eyebar Connections ..................................... 69Figure 3.22 Eyebar Connection After Strain Gages were Applied.................................. 69Figure 3.23 Eyebar Connection in MTS Machine with Added Setup before Testing..... 70Figure 3.24 Plot <strong>of</strong> Linear Strain Readings from Strain Gages on Eye Connection ........ 70Figure 3.25 Eyebar Connection A After Material Was Removed to Simulate Corrosion 71Figure 3.26 Initial Filler Weld Pass on Eyebar Connection A ........................................ 71Figure 3.27 Eyebar A After Filler Weld was Completed <strong>and</strong> Before Surface Grinding. 72Figure 3.28 Eyebar B After Material Was Removed to Simulate Worst Case Corrosion72Figure 3.29 Initial Filler Weld Passes on Eyebar Connection B ..................................... 73