Accelerated Solvent Extraction (ASE) and Productivity ... - Dionex

Accelerated Solvent Extraction (ASE) and Productivity ... - Dionex

Accelerated Solvent Extraction (ASE) and Productivity ... - Dionex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Accelerated</strong> <strong>Solvent</strong> <strong>Extraction</strong> (<strong>ASE</strong>) <strong>and</strong><br />

<strong>Productivity</strong> Gains in Environmental Analyses<br />

Bruce Richter1 , Sheldon Henderson1 , Eric Francis1 , Richard Carlson1 , Brett Murphy1 ,<br />

Brian Dorich1 , Jennifer Peterson1 , Kannan Srinivasan2 , <strong>and</strong> Rahmat Ullah2 Bruce Richter<br />

1<strong>Dionex</strong> Corporation, Salt Lake City Technical Center, Salt Lake City, Utah<br />

2<strong>Dionex</strong> Corporation, Sunnyvale, CA USA<br />

1 , Sheldon Henderson1 , Eric Francis1 , Richard Carlson1 , Brett Murphy1 ,<br />

Brian Dorich1 , Jennifer Peterson1 , Kannan Srinivasan2 , <strong>and</strong> Rahmat Ullah2 1<strong>Dionex</strong> Corporation, Salt Lake City Technical Center, Salt Lake City, Utah<br />

2<strong>Dionex</strong> Corporation, Sunnyvale, CA USA<br />

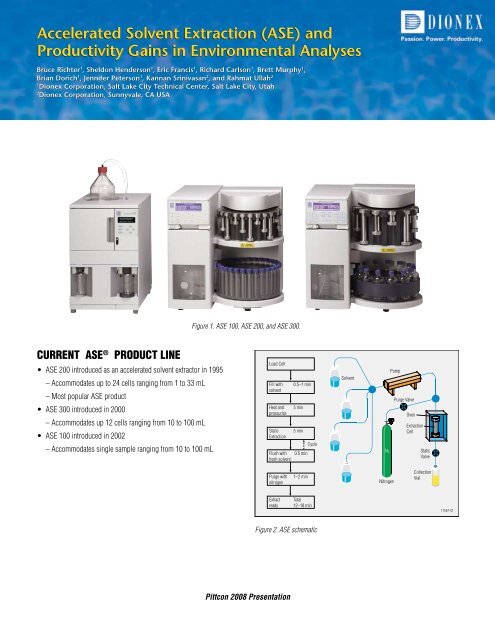

Current ASe ® ProduCt Line<br />

• <strong>ASE</strong> 200 introduced as an accelerated solvent extractor in 1995<br />

– Accommodates up to 24 cells ranging from 1 to 33 mL<br />

– Most popular <strong>ASE</strong> product<br />

• <strong>ASE</strong> 300 introduced in 2000<br />

– Accommodates up 12 cells ranging from 10 to 100 mL<br />

• <strong>ASE</strong> 100 introduced in 2002<br />

– Accommodates single sample ranging from 10 to 100 mL<br />

Figure 1. <strong>ASE</strong> 100, <strong>ASE</strong> 200, <strong>and</strong> <strong>ASE</strong> 300.<br />

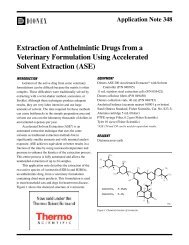

Load Cell<br />

Fill with 0.5–1 min<br />

solvent<br />

Heat <strong>and</strong> 5 min<br />

pressurize<br />

Static 5 min<br />

<strong>Extraction</strong><br />

Flush with 0.5 min<br />

fresh solvent<br />

Purge with 1–2 min<br />

nitrogen<br />

Figure 2. <strong>ASE</strong> schematic<br />

Pittcon 2008 Presentation<br />

Cycle<br />

Extract Total<br />

ready 12–18 min<br />

<strong>Solvent</strong><br />

N2<br />

Nitrogen<br />

Pump<br />

Purge Valve<br />

Oven<br />

<strong>Extraction</strong><br />

Cell<br />

Static<br />

Valve<br />

Collection<br />

Vial<br />

17567-01<br />

Pittcon 2008 Presentation 1

ASe teChnoLogy<br />

• Patented flow-thru design that allows solvent control separately for<br />

each sample<br />

– In-line filtration<br />

– In-cell cleanup<br />

– Fractionation or selectivity<br />

• Control of temperature <strong>and</strong> pressure for each individual sample:<br />

– Requires small quantities of solvent <strong>and</strong> short periods of time<br />

– 50 mL vs. hundreds of mL<br />

– 15 min vs. several hours<br />

• Multiple cell sizes that support a wide range of sample sizes<br />

(1–100 g)<br />

• Platform for automation<br />

• Used by government agencies <strong>and</strong> laboratories worldwide<br />

ASe StAndArd MethodS uPdAte<br />

• US EPA Method 3545A<br />

– OCP, OPP, BNA, TPH, PCDD, herbicides <strong>and</strong> semivolatiles<br />

– No other vendor has submitted data demonstrating validity<br />

• Accepted under CLP SOW OLM04.2 (Contract Laboratory Program<br />

Statement of Work)<br />

• Chinese Method GB/T 19649–2005 for 405 pesticides in grains <strong>and</strong><br />

grain products<br />

• German Method L00.00–34 for pesticides in foodstuffs<br />

• ASTM St<strong>and</strong>ard Practice D 7210 for additives in polymers<br />

• Other methods in various stages of approval globally<br />

– 16 environmental methods in China<br />

APPLiCAtionS<br />

Environmental Applications<br />

• US EPA method 3545A<br />

– Pesticides <strong>and</strong> herbicides<br />

– PAHs <strong>and</strong> semi-volatiles<br />

– PCBs<br />

– Dioxins <strong>and</strong> furans<br />

– TPH (Total Petroleum<br />

Hydrocarbons)<br />

– Explosives<br />

• Air samples<br />

– PUF (polyurethane foam) cartridges<br />

– Quartz filters<br />

– XAD <strong>and</strong> charcoal<br />

• PBDEs in flora, fauna, sediments <strong>and</strong> soils<br />

• Method 6860<br />

– Perchlorate in soils, plants <strong>and</strong> animal tissues<br />

• Organo-mercury, arsenic, tin <strong>and</strong> selenium<br />

Figure 3. Schematic of selective extraction using <strong>ASE</strong>.<br />

2 <strong>Accelerated</strong> <strong>Solvent</strong> <strong>Extraction</strong> (<strong>ASE</strong>) <strong>and</strong> <strong>Productivity</strong> Gains in Environmental Analyses<br />

<strong>Extraction</strong><br />

Sample plus<br />

dispersant<br />

In cell absorbents to<br />

reduce interferences<br />

(alumina, silica, etc.)<br />

22854

PCBs in Animal Tissues<br />

One-Step Selective <strong>Extraction</strong><br />

• Egg, oyster, clam, fish, <strong>and</strong> mussel samples collected, freeze-dried,<br />

<strong>and</strong> ground<br />

• 2 g samples mixed with Florisil, placed on 6 g of Florisil in extraction<br />

cell (use of in-cell absorbents)<br />

• DCM/pentane (15:85, v/v) at 40 °C<br />

• 1500 psi (10.34 MPa)<br />

• 25-min extraction, 40 mL of solvent<br />

• GC with ECD for analysis<br />

Gomez-Ariza, J. L., et al., J. Chromatogr. A, 2002, 946, 209–219.<br />

PCBs in Animal Tissues: Selective <strong>Extraction</strong><br />

• Lipid content of samples ranged from 2.9 to 10.2% by weight<br />

• 85–120% recovery as compared to Soxhlet<br />

• Less than 0.1% of the lipids in<br />

sample were collected in vials<br />

because of selective extraction<br />

• MDLs of 0.001 to 0.004 ng/g<br />

• Less than 11% RSD<br />

Integrated Clean-Up: Salmon Extracts<br />

Figure 4. Extracts with <strong>and</strong> without in-cell clean-up<br />

of fish tissue using alumina, silica gel, <strong>and</strong> acidic<br />

silica gel (40% H 2 SO 4 ).<br />

Clx Clx<br />

• Analyzed by Agilent Tech., (GC) 6890N, with a GCMate II (MS), ionization<br />

mode, electron-capture negative ionization (ECNI), monitoring<br />

bromines (79 <strong>and</strong> 81 m/z).<br />

• DB5-HT column (30m)<br />

• Top chromatogram is calibration check<br />

• Second chromatogram is the salmon sample extract with in cell<br />

clean-up<br />

Data courtesy of Mark LaGuardia of VIMS<br />

Figure 5. <strong>ASE</strong> PBDE results.<br />

Pittcon 2008 Presentation 3

introduCing the new ASe 150 And 350<br />

<strong>ASE</strong> 150<br />

• Improved <strong>and</strong> repackaged <strong>ASE</strong> 100<br />

• Faster pump (70 mL/min vs. 35 mL/min)<br />

• Accepts both sizes of collection bottles (60- <strong>and</strong> 250-mL)<br />

• New pneumatics use less compressed gas<br />

• New oven block design for improved heating<br />

• pH hardened pathway with Dionium components<br />

– Optional Dionium cells<br />

– Adsorbent or resin mixed with samples to<br />

neutralize acid<br />

• Accommodates all cell sizes (1, 5, 10, 22, 34, 66, <strong>and</strong> 100 mL)<br />

• New industrial design: new colors <strong>and</strong> outside design; safety shields<br />

Figure 6. <strong>ASE</strong> 150.<br />

4 <strong>Accelerated</strong> <strong>Solvent</strong> <strong>Extraction</strong> (<strong>ASE</strong>) <strong>and</strong> <strong>Productivity</strong> Gains in Environmental Analyses<br />

<strong>ASE</strong> 350: the New St<strong>and</strong>ard<br />

• New pump, oven block, pneumatics, safety shield, etc.<br />

• Combination of <strong>ASE</strong> 200 <strong>and</strong> 300 capabilities<br />

– 24 smaller cells (1, 5, 10, 22, or 34 mL)<br />

– 19 larger cells (66 or 100 mL)<br />

– 19 smaller cells <strong>and</strong> 5 larger cells<br />

– 60- or 250-mL collection bottles (up to 28 small <strong>and</strong> 5 large)<br />

• New colors <strong>and</strong> industrial design<br />

• pH hardened pathway with Dionium components<br />

– Optional Dionium cells<br />

– Adsorbent or resin mixed with samples to neutralize acid<br />

• Integrated <strong>Solvent</strong> Controller<br />

• New mode of operation—<strong>Solvent</strong> Saver Mode<br />

• USB port for firmware update <strong>and</strong> computer connection<br />

– Chromeleon ® control not available at introduction<br />

Figure 7. <strong>ASE</strong> 350.

Figure 8. <strong>ASE</strong> 350 (blue) <strong>and</strong> <strong>ASE</strong> 300 with solvent controller (orange). Smaller<br />

overall footprint; less total bench space required<br />

innovAtion in teChnoLogy<br />

pH-Hardened pathway<br />

• Resistant to acids <strong>and</strong> bases<br />

– 0.1 M HCl, H SO , NaOH, KOH<br />

2 4<br />

– Cannot pump strong acids or bases<br />

– Can perform acidic or alkaline<br />

pretreatments<br />

• Inert cells with Dionium<br />

– Stainless steel st<strong>and</strong>ard<br />

• Acidic adsorbents can be better utilized for<br />

selective extractions<br />

<strong>Solvent</strong><br />

Pretreated<br />

Matrix<br />

In-cell<br />

Clean-up<br />

Relief Valve<br />

<strong>Solvent</strong> <strong>Solvent</strong><br />

Mixing Valve<br />

Figure 9. 66-mL<br />

Dionium cell body.<br />

Figure 10. New <strong>ASE</strong> Schematic. Inherently the same <strong>ASE</strong>, accepted under st<strong>and</strong>ard<br />

methods, but you can do more!<br />

Pump<br />

N 2<br />

Chemistry<br />

<strong>Solvent</strong> extraction<br />

Static Valve<br />

Collection Bottle<br />

new APPLiCAtionS with new<br />

ASe ProduCtS<br />

• Environmental<br />

– Acid pretreatment for improved recoveries of phenols,<br />

herbicides, etc.<br />

– Improved in cell clean-up for dioxins, PCBs, etc.<br />

– Oil <strong>and</strong> grease after acidification<br />

– High pH extraction of Cr (VI)<br />

• Bio/Pharma<br />

– Drugs <strong>and</strong> metabolites from animal tissue after pH adjustment<br />

– Pretreatment of capsules or tablets for potency testing<br />

– Natural products after pH adjustment<br />

• Food <strong>and</strong> Beverage<br />

– Lipid content after acid hydrolysis or base saponification<br />

• Chem/Petrochem<br />

– Biomass after acidic treatments—ethanol production<br />

– Lipid content in bio-diesel processes<br />

SuMMAry<br />

New <strong>ASE</strong> 150 <strong>and</strong> 350<br />

Same Advantages as with Current <strong>ASE</strong><br />

• Save Time<br />

– Fast extraction <strong>and</strong> walk-away automation provides greater<br />

throughput than other techniques<br />

• Save <strong>Solvent</strong>s<br />

– Reduced solvent consumption using st<strong>and</strong>ard <strong>ASE</strong> operation or<br />

<strong>Solvent</strong> Saver Mode<br />

• Save Labor<br />

– Integrated steps save chemists <strong>and</strong> technicians sample<br />

h<strong>and</strong>ling time<br />

Additional Advantages of New <strong>ASE</strong> 150 <strong>and</strong> 350<br />

• Increased Capability<br />

– pH hardened flow path allows for extraction of acidic or<br />

basic matrices for new applications<br />

• Increased <strong>Productivity</strong><br />

– Combining pretreatment, extraction <strong>and</strong> cleanup all in one step<br />

• Increased Flexibility<br />

– New modes of operation<br />

– New absorbent<br />

• Increased Value<br />

– Built-in <strong>Solvent</strong> Controller<br />

– Different sample sizes on same instrument<br />

Pittcon 2008 Presentation 5

Passion. Power. <strong>Productivity</strong>.<br />

dionex Corporation<br />

1228 Titan Way<br />

P.O. Box 3603<br />

Sunnyvale, CA<br />

94088-3603<br />

(408) 737-0700<br />

north America<br />

U.S. (847) 295-7500<br />

Canada (905) 844-9650<br />

South America<br />

Brazil (55) 11 3731 5140<br />

europe<br />

Austria (43) 1 616 51 25 Benelux (31) 20 683 9768; (32) 3 353 4294<br />

Denmark (45) 36 36 90 90 France (33) 1 39 30 01 10 Germany (49) 6126 991 0<br />

Irel<strong>and</strong> (353) 1 644 0064 Italy (39) 02 51 62 1267 Switzerl<strong>and</strong> (41) 62 205 9966<br />

United Kingdom (44) 1276 691722<br />

Dionium is a trademark <strong>and</strong> <strong>ASE</strong> <strong>and</strong> Chromeleon are registered trademarks of <strong>Dionex</strong> Corporation.<br />

Asia Pacific<br />

Australia (61) 2 9420 5233 China (852) 2428 3282 India (91) 22 2764 2735<br />

Japan (81) 6 6885 1213 Korea (82) 2 2653 2580 Singapore (65) 6289 1190<br />

Taiwan (886) 2 8751 6655<br />

www.dionex.com<br />

LPN 2018-01 3/08<br />

©2008 <strong>Dionex</strong> Corporation