- Page 1 and 2: Filling Machines | Sampling | Plast

- Page 3: Table of contents Pumps10 - 16 Cont

- Page 7 and 8: Gas-tight bottlingWith volatile med

- Page 9 and 10: 8 www.buerkle.de | info@buerkle.de

- Page 11 and 12: OTAL hand pumps | to fit most comme

- Page 13 and 14: OTAL foot pumps | high performance,

- Page 15 and 16: Pump-it ® container pumpAdapter se

- Page 17 and 18: Dosing pumps Dosi-Pump21 mm 28,5 mm

- Page 19 and 20: PP barrel pumps | robust industrial

- Page 21 and 22: Stainless Steel Barrel Pump | for f

- Page 23 and 24: Solvent pump foot operatedSolvent p

- Page 25 and 26: Anti-static set | prevents electros

- Page 27 and 28: Thread adapters PP1 2 3 4 567891011

- Page 29 and 30: Gas-tight barrel pump PP | odor-fre

- Page 31 and 32: Compact lever pumpLever pumpPiston

- Page 33 and 34: AccuOne / EnergyOne | Flexible - re

- Page 35 and 36: AccuOne/EnergyOne | accessoriesLabo

- Page 37 and 38: Drum pump for acids and alkalisDrum

- Page 39 and 40: Flow metersOil-free double-diaphrag

- Page 41 and 42: Siphon with stopcock | for occasion

- Page 43 and 44: Stopcocks | completely water-tight,

- Page 45 and 46: Compact stop cockThe spigot Compact

- Page 47 and 48: StopCock PA, electroconductiveSpigo

- Page 49 and 50: Spigot Jumbo, whiteSpigot Jumbo, wi

- Page 51 and 52: LiquoFill filler for fluidsMetering

- Page 53 and 54: LiquoFill filler for fluidsLiquoFil

- Page 55 and 56:

Wall-mounted dosing machine | preci

- Page 57 and 58:

Rubiflex glovesNitrile glovesPlasti

- Page 59 and 60:

Eye protection / safety gogglesUltr

- Page 61 and 62:

Disposal containersDisposal contain

- Page 63 and 64:

Table of contentsSamplers & sample

- Page 65 and 66:

Take samples - but do it right!Taki

- Page 67 and 68:

Sampling techniquestoo, you must pa

- Page 69 and 70:

Repro sample divider | high-precisi

- Page 71 and 72:

Zone samplers | for all kinds of bu

- Page 73 and 74:

Zone samplers | for all kinds of bu

- Page 75 and 76:

All-layer drillFlorian Bippus, Sale

- Page 77 and 78:

PowderProof ® | mobile powder samp

- Page 79 and 80:

SiloDrill | for sampling from silo

- Page 81 and 82:

Silo sampler SiloPickerUnit-Dose-Sa

- Page 83 and 84:

MicroSampler | useful for taking sm

- Page 85 and 86:

PharmaSpoon | for ultrapure samplin

- Page 87 and 88:

QuickPicker | collects samples quic

- Page 89 and 90:

close-it control seal | essential f

- Page 91 and 92:

Control seal close-itfoodHeidi Nön

- Page 93 and 94:

close-it | with individual customer

- Page 95 and 96:

Tamper proof labels safe-it and sec

- Page 97 and 98:

Pigment lanceValve lancePigment lan

- Page 99 and 100:

SpatulaUniversal instrument for col

- Page 101 and 102:

ViscoSampler | sample collector for

- Page 103 and 104:

Dip Sampler, plunging siphonUseAll-

- Page 105 and 106:

Chemistry scoopStainless steel scoo

- Page 107 and 108:

TeleScoop | for industry and water

- Page 109 and 110:

Sampler Liquid CupSamplerIt is poss

- Page 111 and 112:

MiniSampler | taking samples - comf

- Page 113 and 114:

ProfiSampler | vacuum-operated samp

- Page 115 and 116:

Liqui zone samplersUp to three poin

- Page 117 and 118:

UniSampler with suction lanceUse1.

- Page 119 and 120:

Dipping bottlesDipping bottleDippin

- Page 121 and 122:

Dipping vesselDipping vessel for ta

- Page 123 and 124:

Manually-operated reelsLowering cab

- Page 125 and 126:

LiquiDispoDispoPipetteViscoDispoDis

- Page 127 and 128:

SteriPlastSteriPlast sampling spade

- Page 129 and 130:

Sampling bag SteriBag | the sterili

- Page 131 and 132:

SteriPlast sampling tubeSteriPlast

- Page 133 and 134:

Scoop AISI 304EasyScoop Stainless s

- Page 135 and 136:

PharmaSpoon | for ultrapure samplin

- Page 137 and 138:

Plastic scoops and scrapersIron sco

- Page 139 and 140:

BeefSteaker | as per HACCPIceSample

- Page 141 and 142:

Soil sampler GeoSampler | soil samp

- Page 143 and 144:

MiniThermSnowPack dry ice machineTh

- Page 145 and 146:

Tubes with screw capSample beaker w

- Page 147 and 148:

Table of contents Containers148 - 1

- Page 149 and 150:

Narrow-necked bottles for universal

- Page 151 and 152:

Narrow-necked square bottleNarrow-n

- Page 153 and 154:

Narrow-neck reagent bottleWide-neck

- Page 155 and 156:

Wide-necked square bottleMulti-Bott

- Page 157 and 158:

Bottle with child safety lockSpray

- Page 159 and 160:

Pressure atomizerWash bottleRobust

- Page 161 and 162:

Dropping bottles | for controlled d

- Page 163 and 164:

Aluminum bottle | light, unbreakabl

- Page 165 and 166:

Tubes with screw capWide-necked box

- Page 167 and 168:

All-purpose tubes, screw capAll-pur

- Page 169 and 170:

Sample tubes aseptic, with sealSamp

- Page 171 and 172:

Flachmann - the compact jerrycan |

- Page 173 and 174:

JerrycansCanister for storage or tr

- Page 175 and 176:

Storage bottles, with/without threa

- Page 177 and 178:

Sealable wide-mouth containersWide-

- Page 179 and 180:

Packaging containers with UN approv

- Page 181 and 182:

Containers, rectangular and round s

- Page 183 and 184:

Safety jerrycans stainless steelSaf

- Page 185 and 186:

Packaging bucketPackaging bags with

- Page 187 and 188:

Table of contentsLaboratory & indus

- Page 189 and 190:

All-purpose trays | hygienic, easy

- Page 191 and 192:

Photographic trays | in a variety o

- Page 193 and 194:

Instrument traysInstrument serversT

- Page 195 and 196:

Laboratory bucketIndustrial bucket

- Page 197 and 198:

Draining rack, wallmount | practica

- Page 199 and 200:

Titrating burette automaticBurette

- Page 201 and 202:

Funnels | transparent, available in

- Page 203 and 204:

Buechner funnel PPSedimentation fun

- Page 205 and 206:

Laboratory beakers/Griffin beakers,

- Page 207 and 208:

Graduated cylinders, tall formGradu

- Page 209 and 210:

Measuring jugs industrialLight and

- Page 211 and 212:

Volumetric flasks PPVolumetric flas

- Page 213 and 214:

Pi-Pump | safety pipette controller

- Page 215 and 216:

PVC industrial tubingPVC pressure t

- Page 217 and 218:

Silicone tubingHose cutterVery flex

- Page 219 and 220:

Flow indicatorsFlow indicators give

- Page 221 and 222:

T-connectorsY-connectorsAngled conn

- Page 223 and 224:

Universal hose tubing connectors Re

- Page 225 and 226:

stop-it hose clampsUtilitymodelThe

- Page 227 and 228:

Hose clamp Squeeze-FixHose clips PO

- Page 229 and 230:

Valves made of PTFE, two-way/three

- Page 231 and 232:

Rapid couplingsFast and safe connec

- Page 233 and 234:

Rapid couplings, nw 3.2 mm, female

- Page 235 and 236:

Rapid couplings, nw 6.4 mm, female

- Page 237 and 238:

Threaded fittingsPPHose nozzle with

- Page 239 and 240:

Threaded fittingsSocket with inner

- Page 241 and 242:

VacuMan vacuum pumpVacuMan vacuum o

- Page 243 and 244:

DesiccatorMercury collectorDesiccat

- Page 245 and 246:

HotGripRubiflex protective glovesHa

- Page 247 and 248:

Standard bungs siliconeStandard bun

- Page 249 and 250:

Magnetic stirring barsBaffle clipsC

- Page 251 and 252:

Chemical resistance of plasticsChem

- Page 253 and 254:

Suitable thread adapters | for many

- Page 255 and 256:

Jerrycan pumps 23Jerrycans 172Jerry

- Page 257:

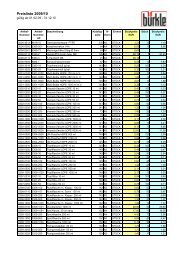

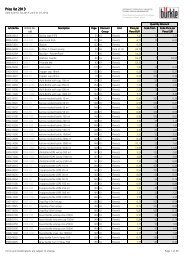

Contents | by item no.Item no. Page