friction clutches - Arten Freios e Embreagens Industriais

friction clutches - Arten Freios e Embreagens Industriais

friction clutches - Arten Freios e Embreagens Industriais

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

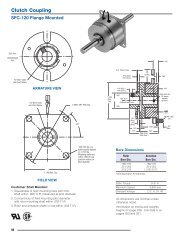

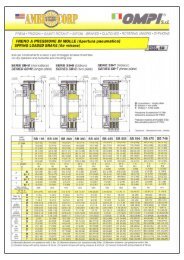

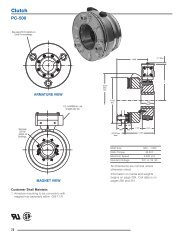

Table of Contents◗TENSION CONTROL CLUTCHESTCC 7, TCC 10,TCC 14 & TCC 20For nearly 50 years, Nexen hasbeen providing tensioncontrol equipment for the paper,printing and converting industries;building <strong>clutches</strong>, brakesand controls for operationsthat manufacture and/or handlepaper, foil, film, rubber, plasticsand fabrics.In fact, Nexen's very firstpneumatic <strong>clutches</strong> were designedfor the paper manufacturingindustry in North America, toprovide tension control forrewind and unwind stands.Since then, Nexen has becomea major supplier of all kinds of<strong>clutches</strong> to industry (and theworld) at large. But our rootsare still firmly anchored in thefield of tension control.Modular ConstructionNexen's innovative line ofModular Tension ControlClutches are designed to be themost flexible, maintenance-freepneumatic units available forcontinuous winding operations.Ruggedly built to endure thecontinuous drag and high heatload that tension control demands,yet extremely sensitive andresponsive to a wide range oftorque requirements.70Tailor-made designat off-rack prices..Today's tension controloperations may have standardhorsepower requirements, buttorque output needs that vary agreat deal. For example, a webprinting press may use a differentgrade and weight paper foreach printing job–and the tensionrequirements for each roll ofpaper can vary considerably.The ideal tension control clutchis capable of handling all thesechanges. And, the ideal clutch isthe Nexen Clutch.FeaturesThe Modular construction ofNexen TC Clutches lets acustomer custom design aclutch that satisfies a variety ofspecific needs:• A broad range of thermalhorsepower and torquecapacities.• A full selection of HousingAssemblies with variouscaliper positions.• Separate CaliperAssemblies.• .20, .35 and .45 CoefficientRated Friction Facings.• Rotary Air Unions.Web ProductsNexen Tension Control Clutches, The Ideal Selection.Design VersatilitySprockets or pulleys areattached to the TCC Clutchhousing pilot diameter. Torqueoutput is varied by selecting ahousing with the number ofcaliper positions that match thetorque requirements to aparticular rewind application.Three <strong>friction</strong> coefficients areavailable in facings to furtherfine tune the performancecharacteristics of a TC Clutch.The housing assembly and rotorassembly of the clutch bothrotate. Calipers are attached tothe clutch housing in equallyspaced positions to maintainproper clutch balance.Clutch housing productnumbers are set up with thecorrect number of caliperpositions for balance purposes.The rotary air union, with dualoutput ports, is attached to theshaft for connecting the airsupply to the calipers.Torque ranges from a minimumof 8 inch pounds ( 0.90 NewtonMeters) at 1 psi (7 kPa) percaliper set to a maximum of10,400 inch pounds (1160 NewtonMeters) at 80 psi. (550 kPa).It can stand the heat...The Nexen TC Units haveexcellent thermal capacity(required because of the constantdrag on the <strong>friction</strong> facings).Capacities of maximum heatdissipation range from 4.5 to16.5 thermal horsepower (3.4to 12.3 Kilowatts). Since theclutch is air operated and aircooled, it does not require anexpensive water cooling system.It's practicallycare-free...Only two parts of the TCClutch will ever need replacing;the diaphragm in the caliperassemblies (virtually never) andthe <strong>friction</strong> facing.The diaphragms will lastpractically forever. However, the<strong>friction</strong> facings need replacingbecause of wear and the desireto change the coefficient of<strong>friction</strong>. All it takes is a wrenchand screwdriver to remove fourcap screws and two machinescrews. The whole operationtakes about 2 minutes per facing.(Incidentally, Nexen’s facingshave been free of asbestos forover 20 years.)Sensitive, accurateair control...Each caliper assembly isconstructed with a diaphragminstead of a piston/O-ringassembly. This provides asmoother, more sensitiveresponse to the air pressureapplied in response to signalsfrom the control panel.Internal springs return thepiston to the disengagedposition to guarantee clearancebetween the <strong>friction</strong> facing andthe rotor when no air pressureis applied.Air is supplied to the TC clutchcalipers through a dual outputrotary air union which isattached to the shaft.