Table of Contents◗APPLICATION ENGINEERING DATA“Air Champ” ®◗ CLUTCH AND BRAKE SELECTIONClutch and brake selection is rathersimple when the functions of themachine are clearly defined. Make surethat the location, shaft size, heatdissipation capacity and speed specificationsare compatible with the clutchor brake selected. Match the machinerequirements to a clutch or brake that islarge enough to handle the load.First, classify the application.Occasional start or stop:Applications where a clutch disconnectsthe prime mover (usually an electricmotor) from the machine at cycle ratesof less than four or five times a minute..Torque and transmitted horsepower areimportant considerations ofapplications of this type.Cyclic start and stop:Applications where the clutch or brakecycles more than five per minute, fallinto this classification. Inertia, torque,energy per cycle, heat sink capacity andresponse time all may requireevaluation.High inertia start or stop:Applications of this type are identifiedby a requirement to start or stop heavyrotating rolls or flywheels in a specificlength of time. Start or stop periods ofmore than 1.0 second are typical of thisapplication type. Thermalcharacteristics and torque are veryimportant considerations when highinertia loads are present.Continuous slip or constanttensioning:Applications of this type appearfrequently in the paper or textileindustries where material is pulled froma roll. A clutch or brake is connected tothe shaft supporting the rolls toprovided tension in the material. Heatdissipation is the primary concern forthe clutch or brake.Many clutch and brake selectionsare successfully made on thebasis of transmitted horsepowerand speed only.For these applications it is a simplematter of solving the basic torqueformulas and selecting a unit from thetorque vs. air pressure graphs in the AirChamp catalog or various other productbrochures.Nexen also provides selection chartsthat suggest specific models at varioustransmitted horsepower and speeds.These charts include an appropriateservice factor for the selected model.Motor frame charts showing modelswhich fit the motor shaft and/or NEMA“C” flanges are provided for somemodels. A general rule-of-thumb formotor mounted applications is: if theunit fits the motor, it will do the job.Nexen units have adequate torque tohandle what the motors deliver.Applications where the clutch or brakedo not fit the motor require anevaluation of inertia, torque and thermalcharacteristics. Thermal characteristicsare very important for high inertia orhigh cyclic applications. Do not select aunit from the catalog selection charts ifhigh inertia loads are present.Location is one of the most importantthings to consider when making aclutch or brake selection. Since torque(in. lbs) equals 63000 x HP , theRPMclutch or brake should be located on thehighest speed shaft in the drive train.An ideal location is directly on themotor shaft. Mounting is easier andmore convenient. Lower torque requirementsmean smaller diameter units,which result in considerable cost savings.Because “Air Champ” Clutches andBrakes are rugged and designed withhigh thermal horsepower ratings, wecan use the following rule-of-thumb forselecting the proper size unit for yourapplication:Ninety percent of the time you canmake your clutch/brake selectionbased on the torque requirementalone. It’s that simple. Sure it’simportant to use a service factor, butfor the most part the torquerequirement is your prime considerationwhen choosing which size clutch to use.For severe applications with high inertialoads and high cycle rates, you alsoneed to consider the thermalhorsepower requirement.◗ CLUTCH & BRAKE SERVICE FACTORA service factor of 1.2 to 2 shouldalways be used when operating at anyair pressure. The service factor isdependent on the severity of theapplication. It is not recommended thata clutch or brake be used in an applicationat its maximum designed torque.360

Table of Contents“Air Champ” ®APPLICATION ENGINEERING DATA◗ INERTIA VALUES OF VARIOUS COMPONENTSAll values unless specified are in Lb In 2 . To convert to Lb Ft 2 use the following formula:Friction ClutchesROTATES ROTATESMODEL COMPONENTS WITH SHAFT WITH DRIVEMulti-Disc ClutchesLB IN 2 = LB FT 2144ROTATES ROTATESMODEL COMPONENTS WITH SHAFT WITH DRIVEM, Micro Housing, Facing, Bearing ---- 0.050Friction Disc, Hub 0.193 ----BW,Bantam WeightPilot Mount w/Bearing2.750 Sheave w/Bearing--------0.8540.854Friction Disc, Hub 0.979 ----F-450 / FW Pilot Mount w/Bearing & Lining ---- 4.7003.350 Sheave w/Bearing & Lining ---- 5.404Friction Disc, Hub 4.787 ----L-600 / LW Pilot Mount w/Bearing & Lining ---- 27.4704.500 Sheave w/Bearing & Lining ---- 27.8305.300 Sheave w/Bearing & Lining ---- 36.740Friction Disc, Hub 16.126 ----M-800 / MW Pilot Mount w/Bearing & Lining ---- 127.3005.300 Sheave w/Bearing & Lining ---- 127.830Friction Disc, Hub 63.273 ----H-1000 / HW Pilot Mount w/Bearing & Lining ---- 428.7707.100 Sheave w/Bearing & Lining ---- 504.350Friction Disc, Hub 180.440 ----XHW Pilot Mount w/Bearing & Lining ---- 1263.0408.000 Sheave w/Bearing & Lining ---- 966.520Friction Disc, Hub 272.980 ----Tooth ClutchesROTATES ROTATESMODEL COMPONENTS WITH DRIVE WITH SHAFT5H30 Ring, Plate, Hub, Flange 6.000 1.2605H35 Ring, Plate, Hub, Flange 10.680 2.7105H40 Ring, Plate, Hub, Flange 16.860 3.7605H45 Ring, Plate, Hub, Flange 26.090 8.3505H50 Ring, Plate, Hub, Flange 41.780 11.4805H60 Ring, Plate, Hub, Flange 92.660 25.8005H70 Ring, Plate, Hub, Flange 176.060 50.4605H20P Ring, Plate, Hub, Flange 2.160 0.3505H30P Ring, Plate, Hub, Flange 5.140 1.3105H35P Ring, Plate, Hub, Flange 11.280 2.8805H40P Ring, Plate, Hub, Flange 15.770 3.9005H45P Ring, Plate, Hub, Flange 25.970 8.9205H50P Ring, Plate, Hub, Flange 42.830 12.1905H60P Ring, Plate, Hub, Flange 94.400 27.3705H70P Ring, Plate, Hub, Flange 186.030 52.8505H80P Ring, Plate, Hub, Flange 347.600 73.4505H100P Ring, Plate, Hub, Flange 1241.080 372.9705H30P-E Ring, Plate, Hub, Flange 6.990 1.5105H35P-E Ring, Plate, Hub, Flange 12.700 3.2005H40P-E Ring, Plate, Hub, Flange 14.890 4.8905H45P-E Ring, Plate, Hub, Flange 29.030 10.0105H50P-E Ring, Plate, Hub, Flange 55.660 13.7005H60P-E Ring, Plate, Hub, Flange 100.940 30.5505H30P-SP Ring, Plate, Hub, Flange, Ball Carrier 8.380 2.1205H35P-SP Ring, Plate, Hub, Flange, Ball Carrier 16.030 4.3405H40P-SP Ring, Plate, Hub, Flange, Ball Carrier 22.630 6.0805H45P-SP Ring, Plate, Hub, Flange, Ball Carrier 35.590 12.4305H50P-SP Ring, Plate, Hub, Flange, Ball Carrier 55.160 16.6205H60P-SP Ring, Plate, Hub, Flange, Ball Carrier 115.880 36.6205H70P-SP Ring, Plate, Hub, Flange, Ball Carrier 231.640 48.1005H80P-SP Ring, Plate, Hub, Flange, Ball Carrier 394.010 73.4505H30PSP-E Ring, Plate, Hub, Flange, Ball Carrier 10.560 2.2205H35PSP-E Ring, Plate, Hub, Flange, Ball Carrier 18.110 4.6005H40PSP-E Ring, Plate, Hub, Flange, Ball Carrier 22.710 7.1605H45PSP-E Ring, Plate, Hub, Flange, Ball Carrier 39.860 13.4005H50PSP-E Ring, Plate, Hub, Flange, Ball Carrier 69.710 18.0205H60PSP-E Ring, Plate, Hub, Flange, Ball Carrier 125.150 39.3904H30P Thrust Plate, Inner Plates, Flange, Hub 1.610 ----Outer Plates, Driving Shell ---- 8.0704H35P Thrust Plate, Inner Plates, Flange, Hub 3.490 ----Outer Plates, Driving Shell ---- 13.3404H40P Thrust Plate, Inner Plates, Flange, Hub 4.870 ----Outer Plates, Driving Shell ---- 14.4604H45P Thrust Plate, Inner Plates, Flange, Hub 10.740 ----Outer Plates, Driving Shell ---- 36.7004H50P Thrust Plate, Inner Plates, Flange, Hub 17.590 ----Outer Plates, Driving Shell ---- 60.4004H60P Thrust Plate, Inner Plates, Flange, Hub 42.480 ----Outer Plates, Driving Shell ---- 115.7004H70P Thrust Plate, Inner Plates, Flange, Hub 70.370 ----Outer Plates, Driving Shell ---- 211.100Dual Plate ClutchesROTATES ROTATESMODEL COMPONENTS WITH SHAFT WITH DRIVEDPC-9T Cylinder, Piston, Facing, Hub 460.800 ----Friction Discs, Housings, Pilot ---- 460.8008.000 Sheave ---- 161.3009.000 Sheave ---- 270.700DPC-11T Cylinder, Piston, Facing, Hub 907.200 ----Friction Discs, Housings, Pilot ---- 1022.400Sheave ---- 440.600DPC-13T Cylinder, Piston, Facing, Hub 2001.600 ----Friction Discs, Housings, Pilot ---- 2635.2008.000 Sheave ---- 2757.600DPC-15T Cylinder, Piston, Facing, Hub 3470.400 ----Friction Discs, Housings, Pilot ---- 4176.0008.000 Sheave ---- 5781.600High Capacity ClutchesROTATES ROTATESMODEL COMPONENTS WITH SHAFT WITH DRIVEDFE 1150-S or H Disc 403.200 ----Housing ---- 3283.200DFE 1650-S or H Disc 2001.600 ----Housing ---- 10900.600DFE 2200-S or H Disc 6494.400 ----Housing ---- 31536.000DFE 2500-S or H Disc 10080.000 ----Housing ---- 50299.200QFE 1150-S or H Disc 806.400 ----Housing ---- 3902.400QFE 1650-S or H Disc 3542.400 ----Housing ---- 13032.000QFE 2200-S or H Disc 12960.000 ----Housing ---- 38044.600QFE 2500-S or H Disc 20059.200 ----Housing ---- 60393.600361

- Page 1:

Table of ContentsPRODUCTCAT ALOG10-

- Page 4 and 5:

Table of Contents◗PRODUCT NUMBER

- Page 6 and 7:

Table of Contents◗PRODUCT NUMBER

- Page 8:

Table of Contents◗PRODUCT NUMBER

- Page 12 and 13:

Table of Contents◗FAMILY OF PRODU

- Page 16:

Table of Contents◗FAMILY OF PRODU

- Page 19:

Table of Contents“Air Champ” ®

- Page 24:

Table of Contents◗APPLICATION GUI

- Page 27 and 28:

Table of ContentsWeb ProductsGUIDE

- Page 29 and 30:

Table of Contents“Air Champ” ®

- Page 31 and 32:

Table of Contents◗ MICRO FRICTION

- Page 33 and 34:

Table of Contents“Air Champ” ®

- Page 35 and 36:

Table of Contents“Air Champ” ®

- Page 37 and 38:

Table of Contents“Air Champ” ®

- Page 39 and 40:

Table of Contents“Air Champ” ®

- Page 41 and 42:

Table of Contents“Air Champ” ®

- Page 43 and 44:

Table of Contents“Air Champ” ®

- Page 45 and 46:

Table of Contents“Air Champ” ®

- Page 47 and 48:

Table of Contents“Air Champ” ®

- Page 49 and 50:

Table of Contents“Air Champ” ®

- Page 51 and 52:

Table of Contents“Air Champ” ®

- Page 53 and 54:

Table of Contents“Air Champ” ®

- Page 55 and 56:

Table of Contents“Air Champ” ®

- Page 57 and 58:

Table of Contents◗“Air Champ”

- Page 59 and 60:

Table of Contents“Air Champ” ®

- Page 61 and 62:

Table of Contents“Air Champ” ®

- Page 63 and 64:

Table of Contents“Air Champ” ®

- Page 65 and 66:

Table of Contents“Air Champ” ®

- Page 67 and 68:

Table of Contents“Air Champ” ®

- Page 69 and 70:

Table of ContentsWeb ProductsIn acc

- Page 71 and 72:

Table of ContentsWeb ProductsTENSIO

- Page 73 and 74:

Table of ContentsWeb ProductsHousin

- Page 75 and 76:

Table of ContentsWeb ProductsTENSIO

- Page 77 and 78:

Table of ContentsWeb ProductsTENSIO

- Page 79 and 80:

Table of Contents“Air Champ” ®

- Page 81 and 82:

Table of Contents“Air Champ” ®

- Page 83 and 84:

Table of Contents“Air Champ” ®

- Page 85 and 86:

Table of Contents“Air Champ” ®

- Page 87 and 88:

Table of Contents“Air Champ” ®

- Page 89 and 90:

Table of Contents“Air Champ” ®

- Page 91 and 92:

Table of Contents“Air Champ” ®

- Page 93 and 94:

Table of Contents“Air Champ” ®

- Page 95 and 96:

Table of Contents“Air Champ” ®

- Page 97 and 98:

Table of Contents“Air Champ” ®

- Page 99 and 100:

Table of Contents“Air Champ” ®

- Page 103 and 104:

Table of Contents“Air Champ” ®

- Page 105 and 106:

Table of Contents“Air Champ” ®

- Page 107 and 108:

Table of Contents“Air Champ” ®

- Page 109 and 110:

Table of Contents“Air Champ” ®

- Page 111 and 112:

Table of Contents◗ AIR PRESSURE C

- Page 113 and 114:

Table of Contents“Air Champ” ®

- Page 115 and 116:

Table of Contents“Air Champ” ®

- Page 117 and 118:

Table of Contents“Air Champ” ®

- Page 119 and 120:

Table of Contents“Air Champ” ®

- Page 121 and 122:

Table of Contents“Air Champ” ®

- Page 123 and 124:

Table of Contents“Air Champ” ®

- Page 125 and 126:

Table of Contents“Air Champ” ®

- Page 127 and 128:

Table of ContentsEclipse SERVOMOTOR

- Page 129 and 130:

Table of ContentsEclipse SERVOMOTOR

- Page 131 and 132:

Table of ContentsEclipse LINEAR MOT

- Page 133 and 134:

Table of ContentsEclipse NEMA AC MO

- Page 135 and 136:

Table of ContentsEclipse METRIC AC

- Page 137 and 138:

Table of Contents◗ BW MODEL BRAKE

- Page 139 and 140:

Table of Contents“Air Champ” ®

- Page 141 and 142:

Table of Contents“Air Champ” ®

- Page 143 and 144:

Table of Contents“Air Champ” ®

- Page 145 and 146:

Table of Contents“Air Champ” ®

- Page 147 and 148:

Table of Contents“Air Champ” ®

- Page 149 and 150:

Table of Contents“Air Champ” ®

- Page 151 and 152:

Table of Contents“Air Champ” ®

- Page 153 and 154:

Table of Contents“Air Champ” ®

- Page 155 and 156:

Table of Contents“Air Champ” ®

- Page 157 and 158:

Table of Contents“Air Champ” ®

- Page 160 and 161:

Table of Contents◗CALIPER BRAKES

- Page 162 and 163:

Table of Contents◗CALIPER BRAKES

- Page 164 and 165:

Table of Contents◗CALIPER BRAKES

- Page 166 and 167:

Table of Contents◗CALIPER BRAKES

- Page 168 and 169:

Table of Contents◗CALIPER BRAKES

- Page 170 and 171:

Table of Contents◗CALIPER BRAKESS

- Page 172 and 173:

Table of Contents◗CALIPER BRAKES

- Page 174 and 175:

Table of Contents◗CALIPER BRAKES

- Page 176 and 177:

Table of Contents◗DRUM BRAKES“A

- Page 178 and 179:

Table of ContentsDRUM BRAKES “Air

- Page 180 and 181:

Table of ContentsDRUM BRAKES “Air

- Page 182 and 183:

Table of Contents◗HEAVY DUTY BRAK

- Page 184 and 185:

Table of Contents◗HEAVY DUTY BRAK

- Page 186 and 187:

Table of Contents◗HEAVY DUTY BRAK

- Page 188 and 189:

Table of Contents◗HEAVY DUTY BRAK

- Page 190 and 191:

Table of Contents◗HEAVY DUTY BRAK

- Page 192 and 193:

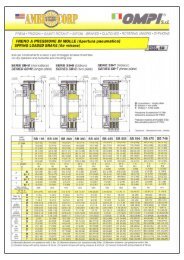

Table of Contents◗METRIC BRAKES

- Page 194 and 195:

Table of Contents◗METRIC BRAKES

- Page 196 and 197:

Table of Contents◗METRIC BRAKES

- Page 198 and 199:

Table of Contents◗BRAKESWeb Produ

- Page 200 and 201:

Table of Contents◗TENSION CONTROL

- Page 202 and 203:

Table of Contents◗TENSION CONTROL

- Page 204 and 205:

Table of Contents◗TENSION CONTROL

- Page 206 and 207:

Table of Contents◗TENSION CONTROL

- Page 208 and 209:

Table of Contents◗TENSION CONTROL

- Page 210 and 211:

Table of Contents◗TENSION CONTROL

- Page 212 and 213:

Table of Contents◗TENSION CONTROL

- Page 214 and 215:

Table of Contents◗TENSION CONTROL

- Page 216 and 217:

Table of Contents◗TENSION CONTROL

- Page 218 and 219:

Table of Contents◗TENSION CONTROL

- Page 220 and 221:

Table of Contents◗TENSION CONTROL

- Page 222 and 223:

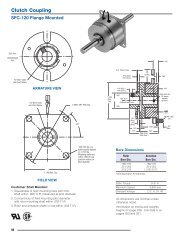

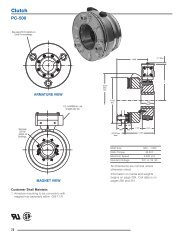

Table of Contents◗CLUTCH/BRAKES

- Page 224 and 225:

Table of Contents◗CLUTCH/BRAKES

- Page 226 and 227:

Table of Contents◗CLUTCH/BRAKES

- Page 228 and 229:

Table of Contents◗CLUTCH/BRAKESFM

- Page 230 and 231:

Table of Contents◗CLUTCH/BRAKES

- Page 232 and 233:

Table of Contents◗CLUTCH/BRAKESFM

- Page 234 and 235:

Table of Contents◗CLUTCH/BRAKESFM

- Page 236 and 237:

Table of Contents◗CLUTCH/BRAKES

- Page 238 and 239:

Table of Contents◗CLUTCH/BRAKES

- Page 240 and 241:

Table of Contents◗CLUTCH/BRAKES

- Page 242 and 243:

Table of Contents◗CLUTCH/BRAKES

- Page 244 and 245:

Table of Contents◗CLUTCH/BRAKES

- Page 246 and 247:

Table of Contents◗CLUTCH/BRAKES

- Page 248 and 249:

Table of Contents◗CLUTCH/BRAKES

- Page 250 and 251:

Table of Contents◗CLUTCH/BRAKES

- Page 252 and 253:

Table of Contents◗CLUTCH/BRAKESA

- Page 254 and 255:

Table of Contents◗CLUTCH/BRAKES

- Page 256 and 257:

Table of Contents◗CLUTCH/BRAKES

- Page 258 and 259:

Table of Contents◗CLUTCH/BRAKES

- Page 260 and 261:

Table of Contents◗CLUTCH/BRAKES

- Page 262 and 263:

Table of Contents◗CLUTCH/BRAKES

- Page 264 and 265:

Table of ContentsCLUTCH/BRAKES “A

- Page 266 and 267:

Table of ContentsCLUTCH/BRAKES “A

- Page 268 and 269:

Table of ContentsCLUTCH/BRAKES “A

- Page 270 and 271:

Table of Contents◗CLUTCH/BRAKES

- Page 272 and 273:

Table of Contents◗METRIC CLUTCH/B

- Page 274 and 275:

Table of Contents◗METRIC CLUTCH/B

- Page 276 and 277:

Table of Contents◗METRIC CLUTCH/B

- Page 278 and 279:

Table of Contents◗METRIC CLUTCH/B

- Page 280 and 281:

Table of Contents◗METRIC CLUTCH/B

- Page 282 and 283:

Table of Contents◗METRIC CLUTCH/B

- Page 284 and 285:

Table of Contents◗METRIC CLUTCH/B

- Page 286 and 287:

Table of Contents◗METRIC CLUTCH/B

- Page 288 and 289:

Table of Contents◗METRIC CLUTCH/B

- Page 290 and 291:

Table of Contents◗METRIC CLUTCH/B

- Page 292 and 293:

Table of Contents◗TENSION CONTROL

- Page 294 and 295:

Table of Contents◗TENSION CONTROL

- Page 296 and 297:

Table of Contents◗TENSION CONTROL

- Page 298 and 299:

Table of Contents◗TENSION CONTROL

- Page 300 and 301:

Table of Contents◗TENSION CONTROL

- Page 302 and 303:

Table of Contents◗TENSION CONTROL

- Page 304 and 305:

Table of Contents◗TENSION CONTROL

- Page 306 and 307:

Table of Contents◗TENSION CONTROL

- Page 308 and 309:

Table of Contents◗TENSION CONTROL

- Page 310 and 311: Table of Contents◗TENSION CONTROL

- Page 312 and 313: Table of Contents◗TENSION CONTROL

- Page 314 and 315: Table of Contents◗TENSION CONTROL

- Page 316 and 317: Table of Contents◗TENSION CONTROL

- Page 318 and 319: Table of Contents318

- Page 320 and 321: Table of Contents◗WEB GUIDING CON

- Page 322 and 323: Table of Contents◗WEB GUIDING CON

- Page 324 and 325: Table of Contents◗WEB GUIDING CON

- Page 326 and 327: Table of Contents◗WEB GUIDING CON

- Page 328 and 329: Table of Contents◗WEB GUIDING CON

- Page 330 and 331: Table of Contents◗WEB GUIDING CON

- Page 332 and 333: Table of Contents◗WEB GUIDING CON

- Page 334 and 335: Table of Contents◗WEB GUIDING CON

- Page 336 and 337: Table of Contents◗WEB AUXILLARY C

- Page 338 and 339: Table of Contents◗WEB AUXILLARY C

- Page 340 and 341: Table of Contents◗WEB AUXILLARY C

- Page 342 and 343: Table of Contents◗CONTROLS“Air

- Page 344 and 345: Table of Contents◗CONTROLS“Air

- Page 346 and 347: Table of Contents◗CONTROLS“Air

- Page 348 and 349: Table of Contents◗CONTROLS“Air

- Page 350 and 351: Table of Contents◗CONTROLS“Air

- Page 352 and 353: Table of Contents◗REPAIR KITS“A

- Page 354 and 355: Table of Contents◗REPAIR KITS“A

- Page 356 and 357: Table of Contents◗REPAIR KITS“A

- Page 358 and 359: Table of Contents◗REPAIR KITS“A

- Page 362 and 363: Table of Contents◗APPLICATION ENG

- Page 364 and 365: Table of Contents◗APPLICATION ENG

- Page 366 and 367: Table of Contents◗APPLICATION ENG

- Page 368 and 369: Table of Contents◗APPLICATION ENG

- Page 370 and 371: Table of Contents◗APPLICATION ENG

- Page 372 and 373: Table of Contents◗FUNCTION EXAMPL

- Page 374 and 375: Table of Contents◗FUNCTION EXAMPL

- Page 376 and 377: Table of Contents◗FUNCTION EXAMPL

- Page 378 and 379: Table of Contents◗FUNCTION EXAMPL

- Page 380 and 381: Table of Contents◗FUNCTION EXAMPL

- Page 382 and 383: Table of Contents◗FUNCTION EXAMPL

- Page 384 and 385: Table of Contents◗FUNCTION EXAMPL

- Page 386: Table of Contents◗FAMILY OF PRODU