View - METZNER Maschinenbau GmbH

View - METZNER Maschinenbau GmbH

View - METZNER Maschinenbau GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

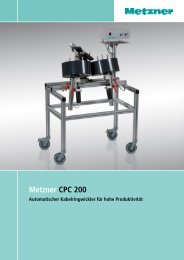

Metzner customer-specific processing line• Integration of a »Metzner Variocut« cut-to-length machine• Fully automatic cut-to-length of thin wires• Integration of a wire straightener for twist-free feeding• Wire printing »on the fly« with an ink jet printer• PC-controlled production• Coiling of the cut wires with a Metzner CPC 200Metzner customer-specific processing line• Integration of a »Metzner AM 5300 HD«• Metzner DR 12.1000 with accumulator arm for cable feeding• Fully automatic cut-to-length and stripping of cables up to 240mm²• Integration of a heavy-duty wire straightener for twist-free feeding• PC-controlled production• Cable coiling with a Metzner CRC 750• Marking with separate label printerMetzner customer-specific processing line• Integration of a »Metzner AM 5350« with rotary cut• Fully automatic cut-to-length and stripping of cables up to 185mm²• Metzner PF 235.30 feeding unit with dancer arm• Printing »on the fly« with two ink jet printers and without any losttime• PC-controlled productionMetzner customer-specific processing line• Integration of a »Metzner CT 4200« corrugated tube processing machinefor processing a corrugated tubes with a glass-fibre reinforcedsilicon covering• With an application specific sensor systems, the cut is still alwaysguaranteed to take place on the crest of the corrugation• Metzner DRS 3 unwind unit• Metzner PF 235.30 feed unit with loop control24