J2000 Series from Technical data - REO-PACK

J2000 Series from Technical data - REO-PACK

J2000 Series from Technical data - REO-PACK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2741<br />

3381<br />

Kongsdal Havn 4<br />

DK-9550 Mariager<br />

Tlf. +45 9858 4100<br />

Fax.+45 9858 4188<br />

E-mail: mail@reo-pack.com<br />

www.reo-pack.com<br />

www.cth.dk | 021257<br />

1940<br />

1940<br />

900<br />

A-A<br />

1100<br />

<strong>J2000</strong><br />

ÿ2050<br />

500<br />

<strong>J2000</strong>ISS<br />

Ø2050<br />

500<br />

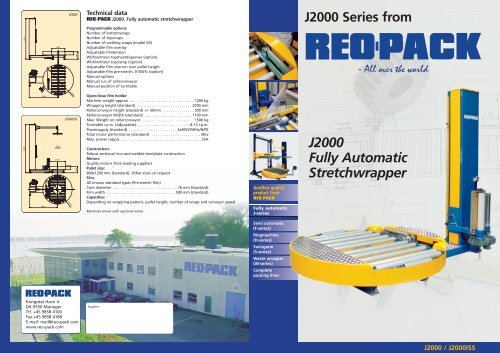

<strong>Technical</strong> <strong>data</strong><br />

<strong>REO</strong>-<strong>PACK</strong> <strong>J2000</strong>. Fully automatic stretchwrapper<br />

Programmable options:<br />

Number of bottomwraps<br />

Number of topwraps<br />

Number of welding wraps (model ISS)<br />

Adjustable film overlay<br />

Adjustable filmtension<br />

With/without topsheetdispenser (option)<br />

With/without topclamp (option)<br />

Adjustable film overrun over pallet height<br />

Adjustable film pre-strecth, 0-350% (option)<br />

Manual options<br />

Manual run of rollerconveyor<br />

Manual position of turntable<br />

Open/close film holder:<br />

Machine weight approx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200 kg<br />

Wrapping height (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . 2200 mm<br />

Rollerconveyor height (standard) +/- 50mm . . . . . . . . . . . . . . . 500 mm<br />

Rollerconveyor Width (standard) . . . . . . . . . . . . . . . . . . . . . . 1100 mm<br />

Max. Weight on rollerconveyor . . . . . . . . . . . . . . . . . . . . . . . . . 1500 kg<br />

Turntable r.p.m. (Adjustable) . . . . . . . . . . . . . . . . . . . . . . . . . 8-15 r.p.m.<br />

Powersupply (standard) . . . . . . . . . . . . . . . . . . . . . . . 3x400V/50Hz/N/PE<br />

Total motor performance (standard) . . . . . . . . . . . . . . . . . . . . . . . 3Kw<br />

Max. power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25A<br />

Construction:<br />

Robust sectional iron and welded steelplate construction<br />

Motors:<br />

Quality motors <strong>from</strong> leading suppliers<br />

Pallet size:<br />

800x1200 mm (standard). Other sizes on request<br />

Film:<br />

All known standard types (Pre-stretch film)<br />

Core diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 mm (standard)<br />

Film width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mm (standard)<br />

Capacities:<br />

Depending on wrapping pattern, pallet height, number of wraps and conveyor speed<br />

Machines shows with optional extras<br />

Supplier:<br />

Another quality<br />

product <strong>from</strong><br />

<strong>REO</strong>-<strong>PACK</strong><br />

Fully automatic<br />

J-series<br />

Semi automatic<br />

(F-series)<br />

Ringmachine<br />

(H-series)<br />

Swingarm<br />

(S-series)<br />

Waste wrapper<br />

(W-series)<br />

Complete<br />

packing lines<br />

<strong>J2000</strong> <strong>Series</strong> <strong>from</strong><br />

- All over the world<br />

<strong>J2000</strong><br />

Fully Automatic<br />

Stretchwrapper<br />

<strong>J2000</strong> / <strong>J2000</strong>ISS

<strong>J2000</strong><br />

Advantages with <strong>J2000</strong> series<br />

● High Capacity<br />

● Minimal space requirements<br />

● Simple and robust construction<br />

● Fully covered turntable<br />

● Easy service access<br />

● Inverter controlled turntable with a max. load<br />

of 1500kg.<br />

● Stepless adjustment of film tension<br />

● Stepless adjustment of film overlay<br />

● Runs all standard types of film<br />

● Siemens S7 300 PLC is standard, other types on<br />

request.<br />

● All motors can be operated manually<br />

● Safe signal exchange with other controlunits<br />

Options:<br />

● Double motorised pre-strecth system 0-350%<br />

● Electric topclamp with full stroke<br />

● Turntable can be designed to take most pallet<br />

sizes<br />

● Turntable can be supplied with chain, slat, belt<br />

or roller conveyor<br />

● Control of existing conveyors<br />

● Customised wrapping programmes<br />

● Can be supplied in painted, electroplated or<br />

stainless finish performance on request<br />

● Extra wrapping height above 2200mm<br />

● Load on turntable upto 4.500 kg.<br />

● <strong>J2000</strong> can be supplied with topsheet dispenser<br />

R2000 for dust- or water- proof wrapping<br />

▲ <strong>J2000</strong> + R2000 topsheetdispenser<br />

with 90 degree delivery.<br />

▲<br />

Controller<br />

with standard<br />

Siemens S7 PLC.<br />

▲<br />

Siemens OP17<br />

<strong>J2000</strong> with<br />

integrated chainlift.<br />

▲<br />

▲ Stainless steel <strong>J2000</strong> with<br />

chainconveyor for the fishindustry.<br />

<strong>J2000</strong> an investment<br />

for the future<br />

If stability and speed are required, the <strong>REO</strong>-<strong>PACK</strong> <strong>J2000</strong> fullyautomatic<br />

stretchwrapper is the optimal answer. <strong>J2000</strong> is a turntablewrapper, which<br />

can be designed for numerous tasks. There are over 600 <strong>J2000</strong> wrapppers<br />

operating all over the world. <strong>J2000</strong> has since 1982 proved its strengths by<br />

faultless wrapping of millions of pallets.<br />

The <strong>J2000</strong> is built of standard components <strong>from</strong> global suppliers witch gives<br />

a unique security of supply for many years to come.Targeted product<br />

developments through the years have made the <strong>J2000</strong> a more obvious<br />

choice than ever.<br />

The controls in the <strong>J2000</strong> are a PLC, which guarantees stability and large<br />

flexibility within wrapping programmes.<br />

Film pre-stretch<br />

<strong>J2000</strong> can be supplied with a double motorised pre-strecth. Frequency<br />

inverters control two direct driven motors which pre-stretch the film <strong>from</strong><br />

0-350%. The simple construction makes the system service free. An electronic<br />

sensor controls the pre-stretch and ensures economical film usage.<br />

Special wrappers<br />

<strong>REO</strong>-<strong>PACK</strong> designs and builds <strong>J2000</strong> wrappers to customer specification.<br />

<strong>J2000</strong> designed for 2800 x 1500 mm pallets for the furniture sector.<br />

Electroplated/stainless machines for the food industry and the chemical<br />

industry.<br />

▲ <strong>J2000</strong> with chain and rollerstrip.<br />

▲ Gearmotor driving directly into the<br />

Ø1050 toothedballbearing. The<br />

combination of fibre gearwheel and<br />

the steel bearing makes the drive<br />

maintenance free.<br />

Stepless adjustable<br />

doublemotorised prestretch<br />

system, 0-350%.<br />

Electronic control.<br />

▲<br />

- All over the world<br />

<strong>J2000</strong>ISS<br />

Advantages for the <strong>J2000</strong>ISS are the same<br />

as for the <strong>J2000</strong>, in addition the <strong>J2000</strong>ISS<br />

offers the following possibilities:<br />

● Uniqe filmclamp and seaming mechanism<br />

● Perfect for contour control<br />

● Very short seaming ”tail”<br />

● Seaming the film against a blade, not the<br />

product<br />

● Seaming the whole film width<br />

▲ Top: Welding blade in inserted position.<br />

Here is an optional number of wraps around<br />

the blade and pallet.<br />

Bottom: Cutting/welding mechanism in welding<br />

position.<br />

www.reo-pack.com <strong>J2000</strong> / <strong>J2000</strong>ISS