7. operating the multipress - Grass

7. operating the multipress - Grass

7. operating the multipress - Grass

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

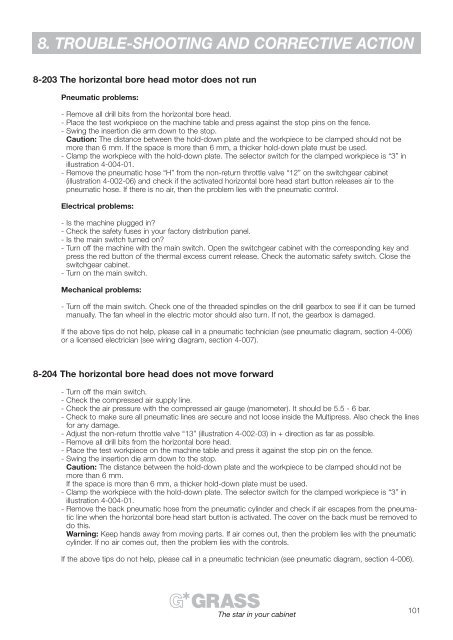

8. TROUBLE-SHOOTING AND CORRECTIVE ACTION8-203 The horizontal bore head motor does not runPneumatic problems:- Remove all drill bits from <strong>the</strong> horizontal bore head.- Place <strong>the</strong> test workpiece on <strong>the</strong> machine table and press against <strong>the</strong> stop pins on <strong>the</strong> fence.- Swing <strong>the</strong> insertion die arm down to <strong>the</strong> stop.Caution: The distance between <strong>the</strong> hold-down plate and <strong>the</strong> workpiece to be clamped should not bemore than 6 mm. If <strong>the</strong> space is more than 6 mm, a thicker hold-down plate must be used.- Clamp <strong>the</strong> workpiece with <strong>the</strong> hold-down plate. The selector switch for <strong>the</strong> clamped workpiece is “3” inillustration 4-004-01.- Remove <strong>the</strong> pneumatic hose “H” from <strong>the</strong> non-return throttle valve “12” on <strong>the</strong> switchgear cabinet(illustration 4-002-06) and check if <strong>the</strong> activated horizontal bore head start button releases air to <strong>the</strong>pneumatic hose. If <strong>the</strong>re is no air, <strong>the</strong>n <strong>the</strong> problem lies with <strong>the</strong> pneumatic control.Electrical problems:- Is <strong>the</strong> machine plugged in?- Check <strong>the</strong> safety fuses in your factory distribution panel.- Is <strong>the</strong> main switch turned on?- Turn off <strong>the</strong> machine with <strong>the</strong> main switch. Open <strong>the</strong> switchgear cabinet with <strong>the</strong> corresponding key andpress <strong>the</strong> red button of <strong>the</strong> <strong>the</strong>rmal excess current release. Check <strong>the</strong> automatic safety switch. Close <strong>the</strong>switchgear cabinet.- Turn on <strong>the</strong> main switch.Mechanical problems:- Turn off <strong>the</strong> main switch. Check one of <strong>the</strong> threaded spindles on <strong>the</strong> drill gearbox to see if it can be turnedmanually. The fan wheel in <strong>the</strong> electric motor should also turn. If not, <strong>the</strong> gearbox is damaged.If <strong>the</strong> above tips do not help, please call in a pneumatic technician (see pneumatic diagram, section 4-006)or a licensed electrician (see wiring diagram, section 4-007).8-204 The horizontal bore head does not move forward- Turn off <strong>the</strong> main switch.- Check <strong>the</strong> compressed air supply line.- Check <strong>the</strong> air pressure with <strong>the</strong> compressed air gauge (manometer). It should be 5.5 - 6 bar.- Check to make sure all pneumatic lines are secure and not loose inside <strong>the</strong> Multipress. Also check <strong>the</strong> linesfor any damage.- Adjust <strong>the</strong> non-return throttle valve “13” (illustration 4-002-03) in + direction as far as possible.- Remove all drill bits from <strong>the</strong> horizontal bore head.- Place <strong>the</strong> test workpiece on <strong>the</strong> machine table and press it against <strong>the</strong> stop pin on <strong>the</strong> fence.- Swing <strong>the</strong> insertion die arm down to <strong>the</strong> stop.Caution: The distance between <strong>the</strong> hold-down plate and <strong>the</strong> workpiece to be clamped should not bemore than 6 mm.If <strong>the</strong> space is more than 6 mm, a thicker hold-down plate must be used.- Clamp <strong>the</strong> workpiece with <strong>the</strong> hold-down plate. The selector switch for <strong>the</strong> clamped workpiece is “3” inillustration 4-004-01.- Remove <strong>the</strong> back pneumatic hose from <strong>the</strong> pneumatic cylinder and check if air escapes from <strong>the</strong> pneumaticline when <strong>the</strong> horizontal bore head start button is activated. The cover on <strong>the</strong> back must be removed todo this.Warning: Keep hands away from moving parts. If air comes out, <strong>the</strong>n <strong>the</strong> problem lies with <strong>the</strong> pneumaticcylinder. If no air comes out, <strong>the</strong>n <strong>the</strong> problem lies with <strong>the</strong> controls.If <strong>the</strong> above tips do not help, please call in a pneumatic technician (see pneumatic diagram, section 4-006).The star in your cabinet101