PikQuik Jumbo Brochure - Steiner-Atlantic

PikQuik Jumbo Brochure - Steiner-Atlantic

PikQuik Jumbo Brochure - Steiner-Atlantic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

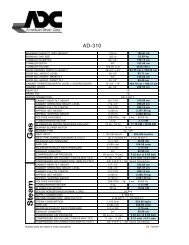

Pik-Quik JUMBODimensionsand UtilitiesCONNECTION(S)A Air ConnectionD Compressed Air DrainE Electrical ConnectionDIA.1/2”----SHIPPING WEIGHTDomestic, lb. [kg]3858 [1750]HEIGHT114” [2896]64” [1626]109” [2769]Top View69” [1740]D A67” [1689]47” [1181]E197” [5004]Front ViewSide ViewNOTE:1. Specifications subject to changewithout notice. Consult factory forcertified construction floor plan.2. Metric dimensions are in [ ].3. All dimensions are ± 1/2".4. Utility connections are located asshown.145” [3683]92” [2330]55” [1384]34” [870]Input(Hopper)Output27” [686]80” [2032]Why You NeedPik-Quik <strong>Jumbo</strong>Like the original Pik-Quik system, Pik-Quik <strong>Jumbo</strong> endsthe time consuming and physically stressful process ofunloading wet, tangled, heavy linen from cart systemsby hand. The addition of this piece of equipmentdramatically reduces the bending, twisting and liftingrequired of laundry employees who have to prepare thewet, heavy linen for feeding through flatwork ironers orfolders. By improving the ergonomic efficiency of theprocess and eliminating the job’s physically demandingstresses, Chicago has managed to unjam this costly andtime-consuming bottleneck to help your laundry facilityhandle a far greater output than ever, while streamlininglinen flow and improving working conditions.CAT AutomatedLoading SystemCAT (Cart Auto Tram) System receives tangled linendirectly from an overhead sling or conveyor drop into aspecially designed integral separating cart. The loadedcart then automatically moves across a built-in tracksystem into position under Pik-Quik’s picking head forlinen separation. Upon completion, the substantiallyemptied cart automatically returns to loading positionto receive the next batch of incoming linen. Working inconjunction with Pik-Quik <strong>Jumbo</strong>, the larger, updatedCAT system allows heavier linen volume to beprocessed, and can be configured to receive linen fromthe front, left or right side.A Complete Range ofSeparating, Feeding,Ironing, Folding andSorting OptionsBecause Chicago specializes only in flatwork finishingequipment, it can offer the world’s widest range ofhigh production separating, feeding, ironing, foldingand sorting equipment. Complete flatwork finishingsystems range from automated multi-roll systemsproducing over 2000 pounds per hour, to compactironers for small on-premise laundries.Chicago's performance record is unmatched inthousands of installations in commercial, hospitality,health care, textile rental, institutional and on-premiselaundries all over the world. An experienced Chicagoprofessional will be pleased to make an objectiveequipment recommendation based on your production,space, utility and budget requirements. Contact yourlocal Chicago distributor or the factory sales assistanceoffice for a no-obligation analysis of your needs.Chicago’s Customer Service department offers fulltechnical and service support by telephone and on ourwebsite. We also offer overnight service for quick partsavailability. Visit our website, www.chidry.com, tolearn more about our complete line of flatworkfinishing systems, including video of Chicago ®equipment in action.®CHICAGO DRYER COMPANY2200 North Pulaski RoadChicago, Illinois 60639-3737 USAPhone • 773.235.4430Fax • 773.235.4439Web • www.chidry.comEmail • chicago@chidry.com Bulletin #7545