Technology Today Research Issue 2_2010 - Raytheon

Technology Today Research Issue 2_2010 - Raytheon

Technology Today Research Issue 2_2010 - Raytheon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technology</strong><br />

<strong>Today</strong><br />

HigHligHting RaytHeon’s tecHnology<br />

<strong>Raytheon</strong> <strong>Research</strong><br />

Maintaining our technology edge<br />

<strong>2010</strong> ISSUE 2

A Message From Mark E. Russell<br />

Do you have an idea for an article?<br />

We are always looking for ways to connect<br />

with you — our Engineering, <strong>Technology</strong> and<br />

Mission Assurance professionals. If you have an<br />

article or an idea for an article regarding<br />

technical achievements, customer solutions,<br />

relationships, Mission Assurance, etc., send it<br />

along. If your topic aligns with a future issue of<br />

<strong>Technology</strong> <strong>Today</strong> or is appropriate for an online<br />

article, we will be happy to consider it and will<br />

contact you for more information.<br />

Send your article ideas to techtodayeditor@<br />

raytheon.com.<br />

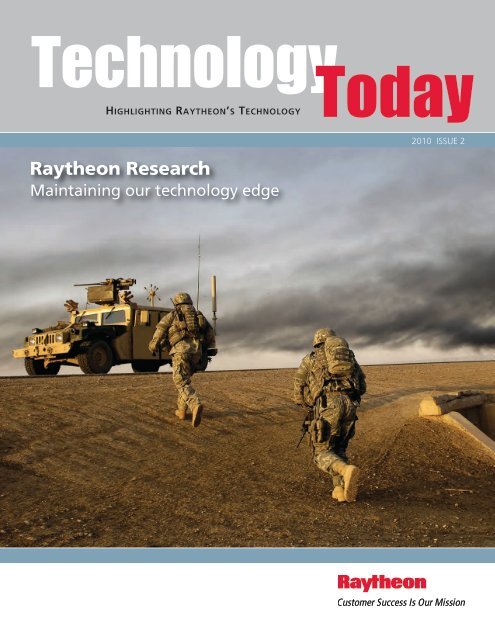

On the cover: <strong>Raytheon</strong> BBN Boomerang<br />

shooter detection system. Photo courtesy<br />

of Air Force Master Sgt. Andy Dunaway.<br />

2 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

Vice President of Engineering, <strong>Technology</strong> and Mission Assurance<br />

Fifty years ago, the world changed forever with a research breakthrough leading to the<br />

first operating laser — a moment in <strong>Raytheon</strong>’s rich research heritage that transformed<br />

modern life with countless applications from DVDs to supercomputing.<br />

<strong>Today</strong>, research is as vital as ever to delivering new technologies and capabilities to<br />

our customers. At <strong>Raytheon</strong>, research begins with a customer focus. What current and<br />

emerging capabilities do our customers need? Where do technology gaps lie? Then we<br />

focus our research and technology road maps to address these capabilities needs.<br />

<strong>Raytheon</strong> funds and supports research at many different levels. We leverage the domain<br />

knowledge of <strong>Raytheon</strong>’s world-class people with investments through program funding,<br />

contracted research and development, independent research and development, and<br />

enterprise campaigns. In addition, we tap new external ideas and approaches through<br />

partnerships, alliances, mergers and acquisitions.<br />

This <strong>Research</strong> issue of <strong>Technology</strong> <strong>Today</strong> shows how <strong>Raytheon</strong> is investing at all levels<br />

of research to provide customers with mission critical capabilities. Articles discuss the<br />

development of the once theoretical wide bandgap semiconductor gallium nitride, and<br />

the Morphable Networked Micro-Architecture as the most adaptable processor ever<br />

built for the U.S. Department of Defense. You will also learn about a new radiation<br />

detection system for the U.S. Department of Homeland Security, and how we are using<br />

virtual-reality technology for battlefield simulation training.<br />

In this issue’s Leaders Corner, Bill Kiczuk, vice president and chief technology officer,<br />

focuses on technology and innovation, two cornerstones for <strong>Raytheon</strong>’s success. Bill<br />

works with leaders across the businesses to ensure our technology efforts are coordinated<br />

and integrated for both near term needs as well as for long term capabilities.<br />

In the Events section we highlight our 2009 Excellence in Engineering and <strong>Technology</strong><br />

Award recipients, our <strong>Raytheon</strong> Six Sigma President’s Award winners and of those,<br />

the winners of the CEO Award, plus <strong>Raytheon</strong>’s 38 newest certified architects. Our<br />

<strong>Raytheon</strong> Certified Architect Program has garnered accreditation by the Open Group,<br />

an international vendor- and technology-neutral consortium. <strong>Raytheon</strong> is the first in<br />

the aerospace and defense industry to receive this recognition.<br />

Best regards,<br />

Mark E. Russell

View <strong>Technology</strong> <strong>Today</strong> online at:<br />

www.raytheon.com/technology_today/current INSIDE THIS ISSUE<br />

<strong>Technology</strong> <strong>Today</strong> is published<br />

by the Office of Engineering,<br />

<strong>Technology</strong> and Mission Assurance.<br />

Vice President<br />

Mark E. Russell<br />

Edition Editor<br />

John Zolper<br />

Managing Editor<br />

Lee Ann Sousa<br />

Senior Editors<br />

Donna Acott<br />

Tom Georgon<br />

Eve Hofert<br />

Art Director<br />

Debra Graham<br />

Photography<br />

Rob Carlson<br />

Dan Plumpton<br />

Website Design<br />

Joe Walch IV<br />

Publication Distribution<br />

Dolores Priest<br />

Contributors<br />

John Cacciatore<br />

Kate Emerson<br />

Feature: <strong>Raytheon</strong> <strong>Research</strong><br />

Overview: Maintaining Our <strong>Technology</strong> Edge 4<br />

COSMOS: Next Generation, High-Performance, Mixed Signal Circuits 7<br />

<strong>Raytheon</strong>'s Trimode Imager for Nuclear Detection 10<br />

Advances in Passive Short Wave Infrared Imaging 13<br />

Adaptive Flight Control Systems 16<br />

Computational Materials Engineering 18<br />

GaN Microwave Amplifiers Come of Age 21<br />

Monarch Meets Demanding, High-Stress Processing Requirements 24<br />

YAG Solid State Laser Ceramics Breakthroughs 26<br />

Partnering With Universities for Knowledge Technologies 29<br />

Small Business Innovation <strong>Research</strong> 32<br />

Virtual and Warfighter Training Counter IEDs 35<br />

<strong>Raytheon</strong> BBN Technologies 37<br />

<strong>Raytheon</strong> Joins DARPA's Focus Center <strong>Research</strong> Program 39<br />

Leaders Corner:<br />

Q&A With Bill Kiczuk 40<br />

EYE on <strong>Technology</strong><br />

Knowledge Exploitation: Enabling IO 42<br />

Next Generation RF Systems 43<br />

Events<br />

Excellence in Engineering and <strong>Technology</strong> Awards 46<br />

<strong>2010</strong> Mission Assurance Forum 48<br />

<strong>Raytheon</strong> Six Sigma Awards 49<br />

Excellence in Operations and Quality Awards 50<br />

People<br />

<strong>Raytheon</strong>’s Newest Certified Architects 51<br />

Special Interest<br />

Ultrathin Environmental and Electroactive Polymer Coatings 52<br />

Patents 53<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 3

Feature<br />

Photo courtesy of<br />

Air Force Master Sgt. Andy Dunaway.<br />

4 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

<strong>Raytheon</strong> <strong>Research</strong> Overview<br />

Maintaining Our <strong>Technology</strong> Edge<br />

<strong>Technology</strong> continues to be a key discriminator for <strong>Raytheon</strong> in delivering<br />

value to our customers. Our technology research is done in a highly<br />

collaborative environment, with ideas coming internally and from partners in<br />

academia, small businesses, large contractors and national laboratories. In today’s<br />

global economy, research is no longer solely an internally focused activity, but a<br />

highly dynamic, collaborative process where good ideas and novel solutions come<br />

from many sources. The research enables upgrades to existing products as well as<br />

the demonstration of completely new capabilities.<br />

<strong>Raytheon</strong> combines engineering and scientific research — systematic studies<br />

to generate new knowledge or insights — with an emphasis on innovation.<br />

Innovation can occur by applying existing knowledge in new ways to deliver novel<br />

products, methods or services that add value to our customers. Innovation is part<br />

of <strong>Raytheon</strong>’s culture of bringing forward new solutions that add value to all<br />

parts of our business, with research innovation primarily focusing on technology<br />

development.<br />

This issue of <strong>Technology</strong> <strong>Today</strong> highlights some of <strong>Raytheon</strong>’s ongoing research<br />

activities and demonstrates the breadth of our partnerships and research areas. The<br />

figure on the following page illustrates the sources of new technology ideas and<br />

technology funding that <strong>Raytheon</strong> brings to bear to solve customer problems and<br />

maintain our technology edge.<br />

Program-Funded <strong>Technology</strong> Development<br />

One path for technology funding comes within the context of ongoing acquisition<br />

programs, whereby our customer reaches out to <strong>Raytheon</strong> to help develop a key<br />

technology, often in partnership with subcontractors, to address a program need.<br />

An example is the work done under our radar, electronic warfare, communications<br />

and missile programs. We have successfully developed and delivered technologies<br />

such as advanced signal processing algorithms, new computing architectures, advanced<br />

monolithic microwave integrate circuits (MMICS), and new waveforms to<br />

meet the system specifications for the U.S. Missile Defense Agency, Army, Navy,<br />

Air Force and Intelligence community.<br />

Contracted <strong>Research</strong> and Development<br />

<strong>Technology</strong> research is also done under Contracted <strong>Research</strong> and Development<br />

(CRAD) programs, which align with our core and growth markets. In response to<br />

customer solicitations, <strong>Raytheon</strong> forms teams that maximize the value and impact<br />

of the proposed solution. Depending on the nature of the research, <strong>Raytheon</strong> may<br />

be the overall team leader or integrator, a primary subcontractor, or a mission transition<br />

partner. Often, over the course of a technology research program, the role<br />

<strong>Raytheon</strong> takes on evolves to ensure that the developed capability becomes available<br />

for the end user. Several examples of ongoing CRAD programs are discussed<br />

in this issue, including Standoff Radiation Detection System (SORDS), Compound<br />

Semiconductors on Silicon (COSMOS), and Photon Counting Arrays (PCAR).<br />

The SORDS program is developing a new concept based on a Trimode Imager (TMI)<br />

for nuclear material detection with a team that brings together a small-company<br />

expert in nuclear detection (Bubble Technologies, Inc.) with nuclear physicists from<br />

Los Alamos National Lab; academic experts in imaging and detection from the<br />

Massachusetts Institute of <strong>Technology</strong> and the University of Michigan; and the

High<br />

Degree of Customer Funding<br />

Low<br />

Sources of <strong>Technology</strong><br />

Program<br />

Funding<br />

Contracted <strong>Research</strong> &<br />

Development (CRAD)<br />

Internal <strong>Research</strong> &<br />

Development (IRAD)<br />

Partnerships &<br />

Alliances<br />

Mergers &<br />

Acquisitions<br />

systems engineering, design and testing expertise<br />

of <strong>Raytheon</strong>. The team is pioneering<br />

the trimodal imager approach that exploits<br />

two imaging technologies, along with<br />

spatial information, to achieve unsurpassed<br />

effectiveness in detecting nuclear and<br />

radiological threats while driving down false<br />

alarm rates. This program is funded by the<br />

Domestic Nuclear Detection Office of the<br />

U.S. Department of Homeland Security.<br />

The COSMOS program, funded by the<br />

Defense Advanced <strong>Research</strong> Projects<br />

Agency’s (DARPA) Microsystems <strong>Technology</strong><br />

Office, is changing the paradigm of how<br />

mixed signal circuits (combined analog and<br />

digital circuits such as analog-to-digital converts)<br />

are designed and built. The COSMOS<br />

program is enabling close integration of<br />

different semiconductor materials within<br />

the same circuit to allow the designer to<br />

pick the “best junction for the function,”<br />

thereby improving circuit dynamic range,<br />

bandwidth and power performance.<br />

<strong>Raytheon</strong> is leading a multidisciplinary<br />

team to demonstrate manufacturable highperformance,<br />

mixed-signal circuits.<br />

The DARPA-funded PCAR program extends<br />

the capability of infrared (IR) imagers for<br />

the warfighter by developing detectors<br />

able to measure single photons in the short<br />

wave IR (SWIR) band. The SWIR wavelength<br />

band, nominally from 1 to 3 microns, has<br />

gone largely unused because of inadequate<br />

detectors and a lack of understanding of<br />

the imaging phenomenology in this band.<br />

The <strong>Raytheon</strong> PCAR research team has developed<br />

high speed, high sensitivity SWIR<br />

sensors, along with low noise readout<br />

electronics and novel scene integration<br />

algorithms, to dramatically improve the<br />

image dynamic range, allowing low-light<br />

images to be resolved in the same scene as<br />

a bright object.<br />

Feature<br />

Internal <strong>Research</strong> and Development<br />

<strong>Raytheon</strong> maintains an Internal <strong>Research</strong><br />

and Development (IRAD) program that includes<br />

projects executed within individual<br />

businesses, as well as cross-company enterprise<br />

campaigns that are collaborations<br />

between several <strong>Raytheon</strong> businesses.<br />

The portfolio of IRAD projects addresses<br />

improvement of existing products, as well<br />

as disruptive new solutions, for our core<br />

and growth markets. These projects bring<br />

to bear the full capability of <strong>Raytheon</strong>’s<br />

technologies to address the most pressing<br />

customer needs. <strong>Raytheon</strong>’s IRAD investment<br />

is defined by developing technology<br />

road maps and quantifying the technology<br />

gaps that need to be addressed to deliver<br />

capabilities that meet customers’ needs.<br />

There are two articles in this issue covering<br />

research primarily funded by IRAD. The first,<br />

about computational materials, discusses<br />

leveraging advances in computational<br />

power and understanding of quantum<br />

physics to analyze potential replacement<br />

materials for lead (Pb) in lead/tin solder<br />

without compromising the electronic integrity<br />

of the solder. Taking this computational<br />

approach has allowed a more rapid analysis<br />

of material combinations than could be<br />

done experimentally.<br />

The second featured IRAD program<br />

describes how <strong>Raytheon</strong> is pulling from<br />

university research in adaptive control<br />

algorithms to develop robust, adaptive<br />

flight control algorithms that will enable<br />

higher performance missiles or UAVs.<br />

IRAD and CRAD Synergies for Longer-<br />

Term Initiatives<br />

While the above discussion suggests<br />

research is done solely under either CRAD<br />

or IRAD projects, many longer-term, highpayoff<br />

research efforts span many years and<br />

benefit from the contributions of multiple<br />

investments addressing specific aspects of a<br />

technology. A noteworthy example of this is<br />

presented in the article on the status of gallium<br />

nitride (GaN) microwave amplifiers.<br />

Continued on page 6<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 5

Feature<br />

Continued from page 5<br />

For more than 30 years, the wide bandgap<br />

semiconductor GaN has been theoretically<br />

identified as ideal for producing high-powered,<br />

high-frequency transistors. However,<br />

until the late 1990s, research on GaN was<br />

largely limited to a few university research<br />

groups and small companies, because the<br />

quality of the material was insufficient to<br />

support high-performance devices. The<br />

article presents an overview of the history<br />

of GaN electronics along with current work<br />

that is preparing to insert GaN MMICs into<br />

U.S. Department of Defense (DoD) systems.<br />

This research effort began at <strong>Raytheon</strong> in<br />

2000 and has benefited from funding from<br />

multiple agencies — including the Office of<br />

Naval <strong>Research</strong>, the Missile Defense Agency<br />

(formerly the Ballistic Missile Defense<br />

Organization) and DARPA — as well as significant<br />

IRAD investments from <strong>Raytheon</strong> to<br />

address various aspects of the development.<br />

Another example of a research effort that<br />

spanned more than 10 years and required<br />

several investments is presented in the article<br />

about the Monarch processor. This effort<br />

— initially funded under a DoD study for a<br />

high performance processing system, then<br />

continued under IRAD investment before<br />

winning support from DARPA under the<br />

Polymorphic Computing program — demonstrates<br />

new records for microprocessor<br />

performance and computational efficiency.<br />

As discussed in the article, the Monarch chip<br />

is now being leveraged for real-time data<br />

analysis in DARPA’s Seismic and Acoustic<br />

Vibration Imaging (SAVi) program.<br />

A third example of the payoff of long-term<br />

investment is presented in the article about<br />

recent work on nanoparticle ceramics to<br />

produce low-loss optical ceramic gain media<br />

for slab lasers. The current work leverages<br />

a long history of leading optical materials<br />

research by this group and will enable more<br />

efficient, high-power slab lasers.<br />

Beyond the topics covered in feature articles<br />

in this issue, <strong>Raytheon</strong> is also pursuing<br />

several other longer-term research investments<br />

in high-power laser technology and<br />

multifunction radio frequency (RF) systems.<br />

Under the DARPA-funded Adaptive<br />

Photonic Phase-Locked Elements (APPLE)<br />

program, <strong>Raytheon</strong> is leveraging a long-term<br />

6 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

investment in liquid crystal modulators to<br />

demonstrate an optical phased array to realize<br />

an electronically steered, high-power laser<br />

with adaptive optics for atmospheric correction.<br />

In the area of multifunction RF systems,<br />

<strong>Raytheon</strong> is leveraging long-term investments<br />

in beamsteering, laser-based frequency<br />

sources and high-speed sampling to develop<br />

ultra broadband systems that enable multifunction<br />

capabilities. This area is discussed<br />

in more detail in the Eye on <strong>Technology</strong><br />

article “Next-Generation RF Systems.”<br />

Partnerships and Alliances with<br />

Universities and Small Businesses<br />

In all of its research, <strong>Raytheon</strong> actively partners<br />

with leading technologists to bring the<br />

best minds to bear on problems. <strong>Raytheon</strong><br />

has active university research partnerships,<br />

both through directed research projects and<br />

through membership in university centers.<br />

An example of our university partnerships<br />

is presented in the article about <strong>Raytheon</strong>’s<br />

collaborative work in the area of knowledge<br />

technology, with the University of Texas<br />

at Dallas and Penn State. The field of data<br />

analysis has moved from searching data for<br />

key terms to focusing on approaches that<br />

extract knowledge — as opposed to data —<br />

from large, often unrelated databases.<br />

In this context, knowledge refers to the<br />

association of multiple elements of a data<br />

set to develop additional insights into meaning<br />

that could not be determined when the<br />

individual data is considered alone.<br />

<strong>Raytheon</strong> has also joined the DARPAsponsored<br />

Focused <strong>Research</strong> Center<br />

Program (FCRP), a consortium of six<br />

research centers and more than 40 universities<br />

formed to address critical challenges<br />

in microelectronic technology and applications.<br />

As a member of the FCRP, <strong>Raytheon</strong><br />

receives royalty-free rights to intellectual<br />

property generated under the program, gets<br />

access to top engineering students, and<br />

gains early insights into emerging research<br />

areas that impact <strong>Raytheon</strong> systems.<br />

Similar to universities, small businesses<br />

offer a wealth of novel technologies, and<br />

<strong>Raytheon</strong> proactively engages with the<br />

government’s Small Business Innovation<br />

<strong>Research</strong> (SBIR) program to find technologies<br />

that address our customers’ needs. The<br />

article on the DoD SBIR program highlights<br />

multiple SBIR success stories for <strong>Raytheon</strong>.<br />

<strong>Research</strong> Overview<br />

Another example of partnering with a<br />

small business is shown in the article<br />

“The Convergence of Virtual Reality and<br />

Warfighter Training to Counter Improvised<br />

Explosive Devices.” This article discusses<br />

research <strong>Raytheon</strong> has done with Motion<br />

Reality, Inc., and BreakAway, Ltd., to<br />

combine motion capture technology, simulation-based<br />

realism and battlefield domain<br />

expertise that puts warfighters into a fully<br />

immersive environment for training before<br />

they deploy into a war zone.<br />

Mergers and Acquisitions<br />

The final method of establishing technology<br />

capability is to acquire companies that<br />

are pioneering new fields important to<br />

<strong>Raytheon</strong>’s markets. <strong>Raytheon</strong> uses targeted<br />

acquisitions to expand our technology<br />

capabilities in our core and growth markets.<br />

Examples include acquisitions of several<br />

cyber technology companies and the recent<br />

acquisition of BBN Technologies. BBN’s<br />

diverse portfolio encompasses a range of<br />

technologies, including advanced networking,<br />

speech and language technologies,<br />

information technologies, sensor systems<br />

and cybersecurity. The history of innovation<br />

at BBN — from its start as a leader in<br />

acoustics to seminal work on the Internet<br />

and language translation — is discussed in<br />

the article “<strong>Raytheon</strong> BBN Technologies:<br />

Persistent Innovation.” A BBN accomplishment<br />

currently supporting warfighters in<br />

the field is the sniper detection system,<br />

Boomerang, shown mounted on the top of<br />

a vehicle on the cover of this issue. The ultrasensitive<br />

directional microphones detect the<br />

shock wave of a flying bullet, even when the<br />

vehicle is moving, and are used to identify and<br />

report the position of the shooter.<br />

Summary<br />

<strong>Raytheon</strong> continues to strengthen our<br />

technology portfolio through leading-edge<br />

research. The research leverages internal<br />

expertise and external partnerships with<br />

the best and brightest through multiple<br />

mechanisms to bring the finest technology<br />

forward for our customers. Using this broad<br />

research approach, <strong>Raytheon</strong> is maintaining<br />

its competitive edge as an innovative<br />

technology provider. •<br />

John Zolper

COSMOS: A Path to Next-Generation,<br />

High-Performance, Mixed Signal Circuits<br />

<strong>Raytheon</strong>’s research in Compound<br />

Semiconductor Materials on Silicon<br />

(COSMOS) will enable a new class of<br />

high-performance mixed-signal integrated<br />

circuits (ICs) that enhance the capabilities of<br />

U.S. Department of Defense (DoD) systems<br />

through direct monolithic integration of<br />

compound semiconductors — such as gallium<br />

arsenide (GaAs) and indium phosphide<br />

(InP) — and silicon (Si) CMOS on a common,<br />

low-cost silicon substrate. Using<br />

COSMOS technology, <strong>Raytheon</strong> is designing<br />

and fabricating high-speed, high dynamic<br />

range, low-power dissipation converter circuits<br />

(analog to digital converters, or ADCs,<br />

and digital to analog converters, or DACs)<br />

with performance that cannot be achieved<br />

with today’s technology.<br />

The future of integrated circuits will include<br />

the integration of high-performance III-V<br />

electronic and/or opto-electronic devices<br />

with standard Si CMOS. While traditional<br />

hybrid approaches — such as wire bonded<br />

or flip-chip multi-chip assemblies (see<br />

Figure 1) — may provide short-term solutions,<br />

the variability, losses and size of the<br />

interconnects and the limitation in the<br />

placement of III-V devices relative to CMOS<br />

transistors limit the performance, utility,<br />

size and cost benefits of these approaches.<br />

A more attractive approach is the direct<br />

integration of Si CMOS and III-V devices<br />

on a common silicon substrate (Figure 1,<br />

right). In this way, circuit performance can<br />

be optimized by the strategic placement of<br />

high-performance III-V devices adjacent to Si<br />

CMOS transistors and cells, and the devices<br />

and subcircuits can be interconnected using<br />

standard semiconductor on-wafer interconnect<br />

processes.<br />

Integrating III-V devices on silicon wafers<br />

is not new. For example, in the 1980s and<br />

1990s, there was considerable, although<br />

unsuccessful, effort to “grow” GaAs devices<br />

on silicon wafers. So what is new this time?<br />

TFN Si CMOS TFN III-V TFN<br />

Multilayer Substrate<br />

<strong>Today</strong>’s Hybrid <strong>Technology</strong><br />

“chip and wire” or flip chip<br />

with thin film networks (TFNs)<br />

Overcoming Technical Challenges<br />

Feature<br />

To address the many technical challenges<br />

associated with the direct integration of<br />

silicon CMOS and III-V devices on the same<br />

wafer, <strong>Raytheon</strong> assembled a team of internationally<br />

recognized experts in the fields<br />

of materials/substrate engineering and<br />

advanced semiconductor devices.<br />

The first challenge was the creation of<br />

a substrate that is compatible with both<br />

silicon and III-V device materials and fabrication<br />

processes. To address this challenge,<br />

<strong>Raytheon</strong> worked with Eugene Fitzgerald<br />

of the Materials Science Department of the<br />

Massachusetts Institute of <strong>Technology</strong> (MIT)<br />

Revolutionary<br />

developments<br />

enable system<br />

on a chip<br />

Continued on page 8<br />

Si Multilayer Interconnect<br />

Si CMOS III-V Si CMOS<br />

Si Substrate<br />

III-V CMOS Integration<br />

III-V devices embedded in a Si wafer<br />

using III-V templates and standard<br />

Si multilayer interconnects and processing<br />

Figure 1. Traditional hybrid assembly (left) and direct monolithic integration of III-V devices<br />

and silicon CMOS (right)<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 7

Feature COSMOS<br />

Continued from page 7<br />

and Paradigm <strong>Research</strong> LLC, a world-re-<br />

nowned expert in semiconductor substrate<br />

engineering. To facilitate integration of III-V<br />

devices with silicon CMOS, Fitzgerald devel-<br />

oped SOLES — silicon on lattice engineered<br />

substrates. SOLES wafers, a variation of sili-<br />

con on insulator (SOI) substrates commonly<br />

used for the fabrication of silicon ICs, allow<br />

for the fabrication of silicon devices on the<br />

silicon surfaces and the direct growth and<br />

fabrication of compound semiconductor<br />

material (GaAs, InP) devices (high electron<br />

mobility transistors, or HEMTs, and hetero-<br />

junction bipolar transistors, or HBTs) on a<br />

buried template layer (Figure 2). To a silicon<br />

wafer fab, SOLES look like a standard silicon<br />

or SOI wafer. The SOLES wafer technology<br />

was transitioned from MIT to production at<br />

Soitec in France, the world’s leading sup-<br />

plier of SOI wafers.<br />

Si nmos<br />

III-V Device<br />

Compound Semiconductor Template Layer<br />

The second challenge was demonstrating<br />

that the silicon CMOS fabricated on SOLES<br />

performed the same as silicon CMOS on<br />

native silicon substrates. For this task, the<br />

team selected <strong>Raytheon</strong>’s 100mm silicon<br />

fab at <strong>Raytheon</strong> Systems Limited (RSL)<br />

in Glenrothes, Scotland. RSL successfully<br />

modified its 1.2mm production silicon CMOS<br />

process for compatibility with SOLES with<br />

no discernable change in transistor proper-<br />

ties. To further drive cost and performance<br />

the process is being transitioned to 200mm<br />

diameter wafers and 180nm CMOS at SVTC<br />

in San Jose, Calif.<br />

Silicon<br />

Si pmos<br />

SOLES wafer<br />

Figure 2. Schematic cross section of<br />

COSMOS technology showing silicon CMOS<br />

and III-V transistors on a silicon template<br />

wafers (SOLES)<br />

8 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

Figure 3. SEM image of a completed InP HBT in close proximity to a Si CMOS transistor prior<br />

to heterogeneous interconnect formation.<br />

The third challenge was the selective growth<br />

of III-V devices on SOLES. <strong>Raytheon</strong>’s<br />

Advanced Semiconductor Material group,<br />

leaders in advanced III-V epitaxial growth,<br />

teamed with IQE in Bethlehem, Pa., the<br />

world’s leading supplier of III-V epitaxial<br />

material, to successfully demonstrate the<br />

growth of both InP HBT and GaAs pHEMT<br />

epitaxial material on SOLES. Key to this<br />

success was <strong>Raytheon</strong>’s and IQE’s pioneer-<br />

ing work in metamorphic buffer layer<br />

technology, which enables the growth of<br />

high-quality semiconductor materials on<br />

dissimilar substrates.<br />

The final challenge was the fabrication<br />

of high-performance compound semi-<br />

conductor devices on SOLES and the<br />

interconnection of these devices with the<br />

silicon CMOS transistors. Here the team<br />

has focused on two complementary device<br />

technologies — InP HBTs for mixed signal<br />

VDD<br />

VBP<br />

OUTN<br />

INP<br />

VBN<br />

VSS<br />

Silicon<br />

PMOS<br />

M1 M3<br />

InP<br />

HBT<br />

Silicon<br />

NMOS<br />

InP HBT BT<br />

Silicon CMOS<br />

OUTP<br />

INN<br />

HBT<br />

PMOS NMOS PMOS<br />

Silicon<br />

PMOS<br />

InP HBT<br />

Silicon CMOS<br />

applications and GaAs pHEMTs for<br />

RF applications.<br />

For the integration of InP HBTs, the team<br />

leveraged Teledyne Scientific’s (Thousand<br />

Oaks, Calif.) expertise in InP HBT transis-<br />

tors and circuits developed under DARPA’s<br />

TFAST program to fabricate InP directly<br />

adjacent to Si CMOS transistors (Figure<br />

3). The InP HBTs on SOLES exhibited per-<br />

formance that was comparable to InP<br />

HBTs fabricated on native InP substrates.<br />

Teledyne’s multilayer interconnect process,<br />

developed for InP mixed-signal circuits, was<br />

adapted for the creation of heterogeneous<br />

interconnects between InP HBTs and silicon<br />

CMOS with nearly 100 percent yield for<br />

InP HBT — silicon CMOS spacing as small<br />

as 2.5mm. The resulting device structure<br />

and fabrication process are analogous to<br />

5µm<br />

a SiGe BiCMOS process where SiGe HBTs<br />

are replaced with an InP HBTs, but with a<br />

Silicon<br />

NMOS<br />

Silicon<br />

PMOS<br />

InP HBT InP HBT<br />

Figure 4. Schematic (left), layout (center) and optical image (right) of differential amplifier<br />

with output buffer and bias circuit. The differential amplifier met all of the DARPA COSMOS<br />

Phase 1 Go/No-Go Metrics with first pass design success.

significant performance advantage due to<br />

the superior speed, gain and high-frequency<br />

performance, and higher operating voltage<br />

of InP HBTs.<br />

MODULATOR<br />

CALIBRATION DAC<br />

1MHz<br />

Digital<br />

Companion efforts underway at <strong>Raytheon</strong>’s<br />

MMIC foundry in Andover, Mass., have<br />

demonstrated GaAs pHEMTs on SOLES, with<br />

performance comparable to GaAs pHEMTs<br />

fabricated on native GaAs substrates.<br />

To demonstrate the viability of the COSMOS<br />

technology, the team successfully designed<br />

and fabricated a high-speed differential<br />

amplifier, which consisted of silicon CMOS<br />

current sources and an InP HBT differential<br />

pair (Figure 4). The complete circuit (differ-<br />

ential amplifier with bias circuit and output<br />

buffer) contained over 100 heterogeneously<br />

RZCK<br />

DIGITAL CLOCK<br />

DAC<br />

DECODE BUFFER<br />

DECODE FF/CLK<br />

DECODE MUX<br />

INPUT BUFFER<br />

Figure 5. Layout of a compact, low power dissipation (1.6W) high resolution (13 bit, > 78 dB<br />

spur free dynamic range digital-to-analog converter designed using COSMOS technology.<br />

The DAC contains on chip calibration circuitry and consists of > 1000 InP HBTs and >5,000<br />

silicon NMOS and PMOS transistors. Total chip areas is < 12mm 2 . The DAC is the DARPA<br />

COSMOS Phase 2 demonstration circuit and is currently being fabricated.<br />

integrated InP HBTs and silicon CMOS tran-<br />

sistors. The circuit met all of the DARPA<br />

COSMOS Phase 1 Go/No-Go Milestones<br />

with first pass design success. This circuit<br />

is a building block for a low power dissipa-<br />

tion (1.6W), high resolution (13 bit, greater<br />

than 78 dB spur free dynamic range digital-<br />

to-analog converter (DAC) currently being<br />

fabricated (Figure 5). The DAC, with its on-<br />

chip calibration circuitry contains over 6,000<br />

heterogeneously integrated InP HBT and<br />

silicon CMOS transistors.<br />

Addressing Next Steps<br />

The COSMOS Phase 2 DAC is a building<br />

block for other types of high-speed, high<br />

dynamic range, low power dissipation con-<br />

verter circuits, including ADCs and direct<br />

digital synthesizers (DDS). The next step is<br />

Feature<br />

to integrate these mixed-signal converter<br />

circuits with radio frequency transistors<br />

(HEMTs and HBTs) to enable single chip<br />

digital transceivers and dynamically recon-<br />

figurable circuits as well as compact circuit<br />

elements for low-cost panel arrays.<br />

The new class of high-performance mixed-<br />

signal circuits enabled by the COSMOS<br />

technology will provide unprecedented<br />

performance, and size advantage to current<br />

and future RF systems, including: compact,<br />

high dynamic range radars; broadband<br />

communication systems; multi-beam com-<br />

munications for comm-on-the-move;<br />

high-resolution synthetic aperture radars<br />

(SAR) and inverse SAR; data links; active<br />

missile seekers; active self-protect systems;<br />

and multifunction unmanned air vehicle<br />

sensors.<br />

While the circuit results presented here are<br />

for InP HBTs directly integrated onto the<br />

silicon substrate, the approach is equally<br />

applicable to other III-V electronic (e.g.,<br />

GaAs pHEMTs or MHEMTs, GaN HEMTs)<br />

and opto-electronic (e.g., photodiodes,<br />

lasers - VSCLS) devices and opens the door<br />

to a new class of highly integrated, high-<br />

performance, mixed-signal circuits. These<br />

circuits will enhance the capabilities of<br />

existing DoD systems, enable new system<br />

architectures, and facilitate proliferation of<br />

low-cost sensors and active electronically<br />

scanned arrays for a wide range of DoD<br />

and U.S. Department of Homeland<br />

Security applications. •<br />

Thomas E Kazior<br />

ACKNOWLEDGEMENT<br />

This work is supported in part by the DARPA<br />

COSMOS Program (Contract Number N00014-<br />

07-C-0629). The author would like to thank Mark<br />

Rosker (DARPA) and Harry Dietrich (ONR).<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 9

Feature<br />

<strong>Raytheon</strong>’s Trimode Imager for Nuclear Detection:<br />

Merging Technologies to Defeat Radiological Threats<br />

Nuclear or radiological terrorism is a<br />

growing concern for U.S. national<br />

security, driving a need for high<br />

performance (high probability of detection<br />

and low false alarm rate) standoff detectors<br />

for nuclear material. Under the Standoff<br />

Radiation Detection System (SORDS) program,<br />

<strong>Raytheon</strong> has developed a Trimode<br />

Imager (TMI) that employs three simultaneous<br />

modalities — Compton imaging (CI),<br />

code aperture (CA) imaging, and spatial<br />

information from a non-imaging shadow<br />

technology — in a wide field of view system<br />

to improve system performance, with<br />

an emphasis on driving down the false<br />

alarm rate. The research team included<br />

<strong>Raytheon</strong>, national labs, small businesses<br />

and universities. The system was designed<br />

to detect nuclear or radiological threats by<br />

enabling the rapid search of urban or suburban<br />

environments using a mobile threat<br />

imaging system with unique discrimination<br />

capabilities.<br />

Detecting gamma rays from strategic<br />

nuclear materials or radiological materials<br />

is very difficult in a complex urban environment<br />

because of the natural background<br />

and environmental sources of gamma<br />

rays. To detect a threat (a point source of<br />

radiation) in the presence of background<br />

(a distributed source of radiation) in a large<br />

field of view requires that the field of view<br />

10 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

be pixilated to achieve a detectable signal<br />

to noise. To identify a threat and eliminate<br />

natural sources of radiation requires very<br />

effective imaging for low and high energy<br />

gamma rays. The CA imaging capability of<br />

the TMI is very effective for lower energy<br />

gamma rays, and the CI capability is very<br />

effective for higher energy gamma rays.<br />

Two Technologies Merge for the First Time<br />

The <strong>Raytheon</strong> TMI for the first time merges<br />

these two imaging technologies to achieve<br />

an unsurpassed effectiveness in defeating<br />

nuclear and radiological threats. The nonimaging<br />

shadow technology utilizes the<br />

Coded Aperture<br />

Imager<br />

LANL/BTI<br />

Compton Imager<br />

LANL/BTI<br />

Shadow Imager<br />

BTI<br />

Modeling & Sim.<br />

LANL<br />

Technical and Program Management<br />

RTN<br />

Data<br />

Acquisition<br />

System<br />

BTI<br />

System Arch.<br />

RTN<br />

System Software<br />

RTN<br />

Figure 1. Trimode imager system and responsible organizations<br />

shielding of the detectors by the superstructure<br />

of the truck and mounting hardware to<br />

give the operator a rough idea of where in<br />

the search area an increase in radioactivity<br />

may be located.<br />

The development of the <strong>Raytheon</strong> TMI<br />

is the result of a collaboration composed<br />

of <strong>Raytheon</strong>, Los Alamos National<br />

Laboratory (LANL), Massachusetts Institute<br />

of <strong>Technology</strong>, University of Michigan, and<br />

Bubble Technologies Inc. (BTI). The major<br />

components of the TMI are shown with<br />

their responsible organizations in Figure 1.<br />

Navigation/Orientation System<br />

RTN<br />

Data<br />

Analysis<br />

System<br />

BTI/LANL/RTN<br />

Technical Advisory Committee<br />

MIT-UMICH<br />

Data Visualization<br />

Software<br />

RTN<br />

System Utilities<br />

RTN<br />

Digital Camera System<br />

RTN<br />

System Transp.<br />

RTN

The CA and CI designs are being headed<br />

by LANL and BTI, respectively; the Shadow<br />

imager is the responsibility of BTI. BTI is<br />

also leading the development of the data<br />

acquisition and data analysis systems. Data<br />

visualization design and development is<br />

headed by <strong>Raytheon</strong>. The digital camera system<br />

design and development is also headed<br />

by <strong>Raytheon</strong>. Modeling and simulation of<br />

the system is headed by LANL, which is also<br />

in charge of the development of all imaging<br />

and analysis algorithms and how they<br />

interact to yield a fused nuclear and visual<br />

image with alarm protocols suitable for<br />

display by the data visualization system. BTI<br />

contributes to this analysis system with the<br />

isotope identification algorithm. <strong>Raytheon</strong><br />

is responsible for overall system integration,<br />

with company directorates leading design,<br />

integration and test efforts associated with<br />

system architecture, system software, system<br />

utilities (power, HVAC, lighting, etc.),<br />

and vehicle transportation.<br />

How the TMI Works<br />

Figure 2 shows a rendition of an exploded<br />

view of the TMI, with the TMI instrument<br />

package mounted in a panel truck. The cutaway<br />

shows the two arrays that provide for<br />

the TMI’s imaging capability. The front array<br />

of square sodium iodide (NaI) detectors<br />

serves as the mask for CA imaging and as<br />

the first scattering center for the Compton<br />

imaging. The back array of rectangular NaI<br />

detectors is the location-sensitive plane<br />

for both the coded and Compton imaging<br />

modes. The location measurement is accomplished<br />

using the difference between<br />

the amplitudes of the signals in the photomultiplier<br />

tubes on each end of the NaI<br />

detectors. The energy measurement is accomplished<br />

from the sum.<br />

The signals from the photomultiplier tubes<br />

are collected by a data acquisition system in<br />

the truck and then time-stamped, digitized<br />

and labeled with additional orientation and<br />

position information. These preprocessed<br />

signals are fed into the data analysis system,<br />

where the algorithms for constructing the<br />

cabinet assembly and CI images operate,<br />

seeking a point source of radiation in the<br />

moving field of view (FOV) on an eventby-event<br />

basis. The isotope identification<br />

detector (ID) algorithms operate in conjunction<br />

with the imaging algorithms to<br />

determine if a point source in the FOV is a<br />

threat and is presented on a display in the<br />

cab of the truck.<br />

Feature<br />

An example of the data visualization system<br />

is shown in Figure 3 (next page). A<br />

Cobalt-60 (Co-60) source inside the building<br />

near the window is detected at 25 meters<br />

with the TMI traveling at 30 mph. The nuclear<br />

images from the CA and the CI, shown<br />

in the upper left of the figure, are fused<br />

using an algorithm developed specially by<br />

the <strong>Raytheon</strong> team to form a combined<br />

nuclear image shown to the right.<br />

Simultaneously, range data is used to determine<br />

that the point source is 25 meters<br />

from the TMI, which in this example is<br />

traveling at 30 mph. The combined nuclear<br />

image is used in the isotope ID algorithm,<br />

which in this case determines that the point<br />

source is Co-60. The isotope ID spectrum is<br />

shown in the figure, along with the color<br />

code options for display. Co-60 is considered<br />

a threat. The color-coded crosshair<br />

labeling this as a threat is overlaid on the<br />

appropriate digital camera image determined<br />

from the geolocation and orientation<br />

data and presented to the TMI operator.<br />

The TMI user interface adds confidence<br />

level, geolocation data, and alarm status<br />

along with system health data.<br />

Continued on page 12<br />

Figure 2. Artist rendition of TMI system. CA and CI are housed in the back of a panel truck, along with the data acquisition system (not shown).<br />

The detection image is color-coded to the nature of the threat, overlaid on a visual image, and presented on a display in the cab.<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 11

Feature Trimode Imager<br />

Continued from page 11<br />

Development of a Unique Algorithm<br />

The TMI team has developed a unique<br />

algorithm for fusing the two nuclear<br />

images. This fusion algorithm enables unexpected<br />

improvement in the performance<br />

of the TMI instrument for both lower and<br />

higher energy gammas.<br />

Conventional wisdom holds that CA imaging<br />

works well for low-energy gammas,<br />

whereas Compton imaging works well for<br />

high-energy gammas. In a conventional<br />

CA system, the mask elements eventually<br />

become transparent to higher and higher<br />

energy gammas, thus defeating the utility<br />

of the mask. In the TMI active mask system,<br />

the elements of the mask detect the gammas<br />

that strike them. If the gammas are of<br />

low energy, they are stopped in the mask<br />

element and their energy measured. If the<br />

gammas are of higher energy they will<br />

Compton scatter in the first array and be<br />

stopped in the back array. This enables the<br />

Compton scattering imager to operate.<br />

Analysis has revealed a far richer role of<br />

these two imaging modes, particularly when<br />

their images are fused to form a common<br />

nuclear image.<br />

Equipped with validated simulations of imaging<br />

in the presence of background, and a<br />

TMI system and an algorithm for fusing the<br />

two nuclear images, the receiver operation<br />

characteristics (ROC) for the active aperture<br />

system can be evaluated. To calculate the<br />

ROC, one takes a figure of merit (FOM)<br />

that reveals the performance of the system<br />

— the presence of a point source radiation<br />

peak in the field of view. The operational<br />

system will have further FOMs such as the<br />

shape of the peak. This peak finding FOM<br />

is a starting point. The ROC curves for three<br />

radiation sources at 100 meters, with the TMI<br />

moving at 30 mph, are shown in Figure 4.<br />

The left plot is for Cesium-137 (Cs-137), the<br />

center plot is for Co-60 and the right plot<br />

for the H(n,γ) line at 2.23 MeV. All sources<br />

are 1mCi in strength. For each ROC curve,<br />

many hundreds of test cases were run with<br />

backgrounds randomly varied. For each CA<br />

and CI image, a simple peak finding routine<br />

searched the FOV, resulting in true positives<br />

and false positives. The percentage<br />

12 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

Time Stamp [Gamma]<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

0<br />

CODED APERATURE IMAGE<br />

COMPTON IMAGE<br />

COMBINED NUCLEAR IMAGE<br />

Isotope Identity of Combined Image<br />

Isotope is Cobalt 60 with an assigned threat color of RED<br />

intrinsic<br />

background noise<br />

algorithmic<br />

extraction<br />

process<br />

(fingerprint)<br />

Co-60<br />

500 1000 1500 2000 2500 3000<br />

Energy [keV]<br />

Figure 3. Sample data images from the CA and CA for a Co-60 source located within a building.<br />

The spectra shows the isotope ID spectrum used to determine the source as Co-60. The<br />

color legend describes the represented radiation source overlaid on the image scene, as explained<br />

in Figure 2.<br />

of true positives is plotted vertically and<br />

the percentage of false positives is plotted<br />

horizontally.<br />

Results for the CI images are plotted in red,<br />

CA results are plotted in blue, and results<br />

for the fused image are plotted in green.<br />

A random peak finding result would be<br />

plotted as a diagonal line from the origin<br />

to the upper right-hand corner; an ideal<br />

result would be a step function rising from<br />

the origin to the upper left-hand corner. In<br />

the plot for Cs-137, the CI results shown in<br />

red almost mimic this random result. This<br />

behavior is not so surprising, given that CI<br />

is not expected to do very well at lower<br />

energies. The CA results shown in blue are<br />

clearly better. However, the surprising thing<br />

in the research is that even at these lower<br />

energies, the hybrid image results shown in<br />

green are better than either imaging mode<br />

taken alone.<br />

For higher energy gammas (Co-60), the CI<br />

and CA have traded roles as the preferred<br />

approach, as expected, and the hybrid<br />

image results are almost the ideal step function.<br />

Moving higher in energy, the results<br />

for H(n,γ) show the CA performance is<br />

falling still further behind the CI, while the<br />

hybrid image results are nearly ideal. These<br />

results demonstrate analytically, for the first<br />

time, the superiority of the TMI aperture system<br />

over CA or CI imaging systems alone.<br />

This instrument is being developed for<br />

the Standoff Radiation Detection System<br />

(SORDS) program being conducted by<br />

Domestic Nuclear Detection Office (DNDO)<br />

of the Department of Homeland<br />

Security (DHS) under contract HSHQDC-<br />

08-C-00001. •<br />

Color Codes:<br />

Threat – Red<br />

Suspect – Yellow<br />

Medical – Blue<br />

Industrial – Purple<br />

NORM – Green<br />

OVERLAY TARGET IDENTIFIED<br />

RANGE DATA = 25m<br />

Michael Hynes<br />

Figure 4. Receiver operating curves showing improved system performance when combining<br />

the two signals

ENGINEERING PROFILE<br />

Hector Reyes<br />

Network Centric<br />

Systems<br />

NCS Texas<br />

Chief Technologist<br />

Hector Reyes currently<br />

serves as the<br />

technical director<br />

of Engineering and<br />

chief technologist<br />

for Network<br />

Centric Systems<br />

(NCS) in Texas.<br />

His primary responsibility is to provide technical<br />

insight and guidance to the programs in the<br />

region. As chief technologist, Reyes manages the<br />

regional technology portfolio and works with<br />

product line teams to develop integrated technology<br />

solutions.<br />

Specifically, Reyes works with NCS product<br />

lines to develop innovative concepts for sensor<br />

technologies (including active/passive electrooptical,<br />

infrared and laser); networked sensors;<br />

and border and warfighter sighting systems. He<br />

leads the engineering organization in developing<br />

a technical vision, product road maps, and<br />

a plan to transition to an integrated networked<br />

sensors systems provider for the military and<br />

civil customers.<br />

Reyes began his career in a co-op scholarship<br />

program at Southern Methodist University.<br />

His first job was weighing parts for the forward<br />

looking infrared (FLIR) targeting system<br />

for the F-18 Hornet. “I’ve been working on<br />

electro-optic systems in roles of increasing<br />

responsibility ever since,” he said.<br />

<strong>Today</strong>, Reyes is convinced he has found his<br />

ideal position. “Over my career, I’ve been in the<br />

cockpit of fighters and gunships and in the turret<br />

of armored vehicles and tanks,” said Reyes.<br />

“I’ve fired the gun on the Abrams Tank and<br />

flown anti-tank missiles down range. <strong>Today</strong>, I<br />

ensure our warfighter’s needs are being met by<br />

working to advance our technology. I have my<br />

dream job.”<br />

When he’s not working as a leader and mentor<br />

within <strong>Raytheon</strong> and the academic community,<br />

Reyes keeps busy at home where he enjoys<br />

photography and spending time with his family.<br />

Short Wave Infrared (SWIR) — the<br />

spectrum from nominally 1 to 3<br />

microns in wavelength — has gone<br />

largely unexploited due to a lack of suitable<br />

detectors and limited understanding<br />

of the image phenomenology in this band.<br />

Due to its shorter wavelength, SWIR offers<br />

the advantage of higher resolution and<br />

smaller optical systems than mid-wave and<br />

long-wave (LW) infrared systems, making<br />

it attractive for tactical applications. To enable<br />

the exploitation of the SWIR band,<br />

<strong>Raytheon</strong> has been leading in the development<br />

of new detectors and cameras, as well<br />

as studying the imaging phenomenology.<br />

<strong>Raytheon</strong> has made exciting advances in<br />

single-photon short-wave infrared detectors<br />

and imagers that open the door to new<br />

applications and operational advantages to<br />

the United States. New systems will leverage<br />

the key strengths that SWIR sensors<br />

provide, including:<br />

• True low-light imaging capability — turns<br />

night into day<br />

• Penetration of haze better than visible<br />

cameras<br />

Feature<br />

Counting Photons:<br />

Advances in Passive Short Wave Infrared Imaging<br />

• Sharper images than conventional LW<br />

thermal imagers<br />

• Observation of covert lasers and beacons<br />

• Uncooled technology for size, weight and<br />

power advantages over cryo-cooled systems<br />

• Spectral phenomenologies that enable<br />

camouflage exposure, human-flesh detection,<br />

and the ability to see through<br />

glass<br />

• High resolution iris and 3D facial image<br />

capture for standoff biometrics<br />

<strong>Raytheon</strong> continues to be the industry<br />

leader in delivering technologies to operate<br />

in new optical wavelength ranges such<br />

as SWIR; achieving even higher sensitivities<br />

(down to single photon detection); and<br />

improving the size, weight and power of<br />

infrared imagers. <strong>Raytheon</strong>’s collaboration<br />

with the Defense Advanced <strong>Research</strong><br />

Projects Agency (DARPA) and U.S. Army<br />

Night Vision and Electronic Sensors (NVESD)<br />

researchers has advanced the state of the<br />

art of SWIR imaging. <strong>Research</strong> has focused<br />

on developing SWIR imagers that exploit<br />

both urban light sources and natural<br />

Continued on page 14<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 13

ENGINEERING PROFILE<br />

Jeff Hoffner<br />

Space and Airborne<br />

Systems<br />

Principal<br />

Engineering Fellow<br />

During 37 years with<br />

<strong>Raytheon</strong> and its<br />

legacy companies, Jeff<br />

Hoffner developed<br />

extensive experience<br />

in airborne radar system<br />

design, analysis,<br />

and engineering and<br />

program management.<br />

He currently works on the Space and<br />

Airborne Systems Engineering Technical Staff in<br />

El Segundo, Calif.<br />

He is responsible for overseeing development of<br />

advanced air-to-ground radar technology with<br />

a focus on radar automatic target recognition<br />

(ATR) discrimination and electronic protection<br />

and fusion. From 2007 through 2009, he was<br />

co-lead of the Corporate Enterprise Campaign<br />

for ATR, which advanced fusion, feature-aided<br />

track, move-stop-move track, synthetic aperture<br />

radar ATR, and ground moving target ATR<br />

technologies. He is also program manager for a<br />

classified technology program, technical director<br />

for the <strong>Raytheon</strong>–Air Force <strong>Research</strong> Laboratory<br />

Radar Vision Target Identification program,<br />

and a <strong>Raytheon</strong> representative to the Military<br />

Sensing Symposia Tri-Service Radar Symposium<br />

steering committee.<br />

After many years in a leadership role for the<br />

continued development of air-to-ground radar<br />

system capability, Hoffner became involved<br />

in research and development around ATR. In<br />

1999 he became manager of the AGRI program,<br />

a radar-based stationary ground target ATR.<br />

“ATR became one of my key technical interests,”<br />

he said. “It was natural to join with my<br />

<strong>Raytheon</strong> colleague Al Coit in proposing and<br />

then co-leading the <strong>Raytheon</strong> ATR Enterprise<br />

Campaign which has focused on making<br />

<strong>Raytheon</strong>’s radar ATR the best in the industry.”<br />

He said he remains excited about his work<br />

because, “I am working with the best and the<br />

brightest from across <strong>Raytheon</strong> on technologies<br />

such as ATR and electronic protection —<br />

very challenging problems that are<br />

becoming increasingly more critical to our<br />

customer community.”<br />

14 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

Feature SWIR<br />

Continued from page 13<br />

Figure 1. SWIR tactical integrated vacuum packaged assembly, electronics core and field camera<br />

nightglow. Significant advances have been<br />

made with higher sensitivities, smaller pixels,<br />

larger imaging array sizes, and higher<br />

dynamic range. These advances will deliver<br />

new capabilities to the warfighter and are<br />

attracting interest for application to iris<br />

and 3D facial image capture for standoff<br />

biometrics.<br />

SWIR Passive Imagers With Near Single<br />

Photon Sensitivity<br />

Working with DARPA and NVESD researchers<br />

during the last decade, <strong>Raytheon</strong> has<br />

played a key role in developing imaging<br />

technology in the SWIR with near singlephoton<br />

uncooled imaging capability (see<br />

Figure 1). This challenges near-infrared image<br />

intensifiers in night-vision applications.<br />

Sky nightglow comes from natural chemical<br />

reactions with oxygen–hydrogen molecules<br />

in the Earth’s mesosphere (50 to 80 km altitudes)<br />

resulting in the release of energy in<br />

the form of photons in the SWIR band. This<br />

always-present light source is invisible to the<br />

SWIR sensor with standard dynamic range<br />

and high-sensitivity<br />

human eye, yet provides 13 times the light<br />

available from visible light on a moonless<br />

night and comes from nearly the entire sky.<br />

Exploiting nightglow with advanced sensors<br />

can provide superior range for target identification<br />

compared to conventional sensors.<br />

SWIR cameras can also see all common<br />

laser wavelengths (e.g., laser designators)<br />

in use today. Adoption of SWIR cameras<br />

and sensors into fielded systems will enable<br />

more systems to transition to eye-safe<br />

lasers. Active and range-gated SWIR sensors<br />

that take advantage of materials reflectivity<br />

and contrast provide additional application<br />

opportunities. Under DARPA’s sponsorship<br />

of the Multi-spectral Adaptive Networked<br />

Tactical Imaging System (MANTIS) and<br />

Photon Counting Arrays (PCAR) programs,<br />

<strong>Raytheon</strong> has developed multiple generations<br />

of SWIR cameras with dramatic<br />

improvements in sensitivity, resolution, and<br />

dynamic range — making <strong>Raytheon</strong> the<br />

current market leader in large-format and<br />

high-sensitivity uncooled SWIR focal planes.<br />

Figure 2. High Medium<br />

SWIR sensor with standard dynamic range<br />

and medium-sensitivity

<strong>Technology</strong> Leadership<br />

Combining ultra-low dark-current indium<br />

gallium arsenide detectors and ultrasensitive<br />

readout integrated indium gallium<br />

arsenide (InGaAs) circuits, <strong>Raytheon</strong> has<br />

maintained its uncooled (no cryogenic<br />

cooler) -SWIR technology leadership since<br />

2004, when the company demonstrated the<br />

first megapixel (1280x1024) SWIR camera.<br />

In tests by NVESD and others, <strong>Raytheon</strong><br />

SWIR outperforms third-generation image<br />

intensifiers and other competition with respect<br />

to sensitivity and resolution, providing<br />

superior night vision capability.<br />

More recently under DARPA’s PCAR program,<br />

<strong>Raytheon</strong> invented and demonstrated<br />

an advanced SWIR sensor design. A remarkable<br />

feature of this sensor is the inclusion of<br />

novel high dynamic range circuitry in small<br />

15×15 µm pixel. The result is a large-format,<br />

high-density 1280×1024 SWIR focal plane<br />

array. Dynamic range exceeding 16 bits<br />

(80,000:1) with less than five electrons read<br />

noise has been demonstrated with detector<br />

operation at or near ambient temperatures.<br />

High dynamic range performance is shown<br />

in Figure 2 in three representations obtained<br />

within one frame time and showing the<br />

resulting instanteous dynamic range image.<br />

With post processing, these 16-bit total<br />

dynamic ranges can be directly fed into an<br />

automated target recognition system, or<br />

individually contrast-adjusted and mapped<br />

into a typical 8-bit display.<br />

SWIR sensor with standard dynamic range<br />

and low-sensitivity<br />

Low Combined<br />

Feature<br />

These sensors’ extremely low noise and high<br />

dynamic range allow recognition of lowcontrast<br />

targets, without saturation from<br />

bright sources within the same frame of<br />

information. This enables operation in both<br />

urban and rural environments with imaging<br />

under low levels of ambient illumination,<br />

while simultaneously seeing around bright<br />

sources that would otherwise saturate conventional<br />

high-sensitivity sensors.<br />

<strong>Raytheon</strong>’s family of uncooled tactical SWIR<br />

focal planes and SWIR sensor technologies<br />

that were developed and matured through<br />

five years of DARPA programs is now ready<br />

for transition to production and integration<br />

into a wide range of applications, including:<br />

rifle sights, handheld targeting units,<br />

marine/ship-board surveillance cameras,<br />

port security systems, unmanned aerial<br />

vehicles, manned air vehicles, and longrange<br />

observation and targeting platforms.<br />

<strong>Raytheon</strong>’s innovative technology developed<br />

with support from DARPA has resulted in<br />

performance superior to conventional night<br />

vision systems. This has resulted in a compact,<br />

small-pixel, large-format SWIR camera<br />

which, within one scene, can operate over<br />

six orders of magnitude illumination, covering<br />

conditions ranging from extremely low<br />

light to full daylight. •<br />

David Acton<br />

PCAR SWIR sensor simultaneously imaging<br />

at high instantaneous dynamic range with<br />

low noise<br />

ENGINEERING PROFILE<br />

Al Coit<br />

Missile Systems<br />

Lead, ATR Enterprise<br />

Campaign<br />

Director, Mission<br />

Systems Solutions<br />

Al Coit has more than<br />

20 years experience<br />

in weapon system<br />

development, scientific<br />

research and program<br />

management. His<br />

technical background<br />

includes automatic target<br />

recognition (ATR) and tracking algorithms,<br />

infrared systems and laser systems. He led the<br />

ATR Enterprise Campaign (EC), and is the director<br />

of Mission System Solutions. Previously, Coit<br />

served as director of the Signal Processing Center<br />

in the Engineering functional organization.<br />

ATR consists of complex signal processing on<br />

sensors, ground stations and weapons, coupled<br />

with advanced algorithms to find and track<br />

objects of interest, and determine if friend,<br />

neutral or combatant. According to Coit, current<br />

in-theater experience shows that significant<br />

challenges remain in this area. “It’s still difficult<br />

to strike targets that are hiding or using evasive<br />

tactics. The problem is compounded by adverse<br />

weather, complex terrain and urban battlefields,<br />

and asymmetric threats.<br />

“Developing and demonstrating the next<br />

generation intelligence, surveillance and reconnaissance,<br />

targeting and weapon delivery<br />

algorithms is critical to growing <strong>Raytheon</strong>’s market<br />

share in sensing and effects, and continued<br />

recognition as a Mission Systems Integrator,”<br />

Coit noted. “<strong>Raytheon</strong> has much of the enabling<br />

technology and domain knowledge to address<br />

this critical issue for the warfighter. The ATR<br />

EC leverages expertise from across <strong>Raytheon</strong><br />

to develop near-term technology enablers and<br />

mid-term disruptive innovations to address the<br />

difficult challenges of assured identification and<br />

persistent tracking.”<br />

In addition to developing next-generation algorithms,<br />

the ATR EC eliminated duplicate efforts,<br />

catalogued best practices, conducted progressive<br />

capability demonstrations, and developed<br />

cross-domain dominance technologies. The team<br />

supported a wide range of pursuits and played a<br />

key role in several critical program wins.<br />

<strong>Raytheon</strong> employees can find additional information<br />

on the ATR EC on <strong>Raytheon</strong>’s internal<br />

wiki pages.<br />

RAYTHEON TECHNOLOGY TODAY <strong>2010</strong> ISSUE 2 15

Feature<br />

Adaptive Flight<br />

Control Systems<br />

Delivering more<br />

robust performance<br />

The ability of a missile or an unmanned<br />

aerial vehicle (UAV) to<br />

complete its mission depends heavily<br />

on the quality of its flight control system.<br />

The quality of a traditional flight control<br />

system is rooted in the validity of the<br />

mathematical models used in its design,<br />

the fidelity of the information it receives in<br />

flight, and the health of its actuation devices.<br />

When the models are a good match<br />

to reality and the sensors and actuators are<br />

functioning as expected, uncertainty in the<br />

system is low and the vehicle behaves as designed<br />

and predicted. However, air vehicles<br />

do not always perform as their models<br />

would predict — due to battle damage,<br />

system faults, or aerodynamic uncertainties<br />

in the design models themselves — and as<br />

a result system performance degrades and<br />

mission effectiveness is reduced. However,<br />

by employing adaptive control algorithms<br />

that dynamically adjust to the changing<br />

conditions, performance can be maintained<br />

in the face of uncertainty. <strong>Raytheon</strong> has<br />

integrated adaptive algorithms into our<br />

missile and UAV flight control systems to<br />

deliver more robust performance.<br />

While adaptive flight control has been an<br />

area of high interest in the controls community,<br />

it had not previously been applied to<br />

high performance missile systems or UAVs.<br />

<strong>Raytheon</strong>’s Adaptive Air Vehicle <strong>Technology</strong><br />

16 <strong>2010</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

(AAVT) strategic internal research and<br />

development effort has, for the first time,<br />

developed methods to utilize adaptive control<br />

techniques in <strong>Raytheon</strong> missile and UAV<br />

autopilots. By partnering with academic<br />

researchers to investigate and refine various<br />

adaptive control methods, the AAVT research<br />

has been able to develop promising<br />

algorithms for real-world applications.<br />

Consistent Performance for Uncertain<br />

or Degraded Systems<br />

An adaptive flight control system uses one<br />

of two methods to maintain a consistent<br />

level of system performance in the presence<br />

of uncertainty and faults with minimal degradation.<br />

In the first, called indirect adaptive<br />

control, the adaptive controller monitors the<br />

difference between the measured system<br />

behavior and the expected system behavior<br />

in real time, estimates why those differences<br />

exist, and adjusts key control design parameters<br />

based on those estimates to regain<br />

system performance.<br />

The second method is direct adaptive<br />

control where the controller uses the perceived<br />

differences to compute an input<br />

control signal that directly drives those<br />

errors to zero without concern of<br />

why the differences exist. Whichever<br />

method is employed, the ability of an<br />

adaptive autopilot to provide consistent<br />

performance for uncertain or degraded<br />

systems reduces the need for high fidelity<br />

models and subsystem performance that<br />

is normally required for high-performance,<br />

robust autopilot design. By reducing the<br />

initial modeling effort and essentially doing<br />

more with less, adaptive control technology<br />

allows <strong>Raytheon</strong> to rapidly develop and<br />

deploy reliable flight control systems for advanced<br />

missiles or UAVs at reduced cost.<br />

Where a traditional flight control system<br />

would show degraded performance, the<br />

adaptive flight control systems developed<br />

maintain an expected level of system performance,<br />

as measured against a reference<br />

(nominal behavior) model. Many adaptive<br />

systems either do not use a reference<br />

model, or use a simple reference model that<br />

is not consistent with the system dynamics.<br />

By adapting to the error between the desired<br />

response and the measured response of the<br />

vehicle in real time, the <strong>Raytheon</strong> adaptive

controller creates an additional<br />

control signal that is used to<br />

augment that of a traditional<br />

robust autopilot. If the system<br />

dynamics match the representative<br />

reference model, the<br />

contribution from the adaptive<br />

controller will be zero. If,<br />

however, they do not match,<br />

the adaptive control signal will<br />

correct any differences and the<br />

combined control signal retains<br />

the desired performance.<br />

Guidance<br />

Command<br />

Taking Algorithms from<br />

Academia to Missiles and UAVs<br />

Throughout the lifespan of <strong>Raytheon</strong>’s<br />

AAVT research, various adaptive control<br />

techniques have been investigated. These<br />

include the neural network-based adaptive<br />

control developed at the Georgia Institute of<br />

<strong>Technology</strong>, L1 adaptive control developed<br />

at Virginia Polytechnic Institute and State<br />

University, the Retrospective Correction<br />