Turbine Engine Oils - VPS Lubricants

Turbine Engine Oils - VPS Lubricants Turbine Engine Oils - VPS Lubricants

NOTES108Turbine Engine OilsTable continuedPROPERTIES MIL-PRF-23699F TYPICALGrade STDCorrosion & Oxidation Stability72 hrs @ 175°C Must pass Passes72 hrs @ 204°C Must pass Passes72 hrs @ 218°C Must pass PassesRyder Gear Test, Relative RatingHercolube A % 102 123.7Bearing Test RigType 1 1 ⁄2 conditions– Overall deposit demerit rating 80.0 max 32.2– viscosity change @ 40°C % –5 to +30 +13.3– Total Acid Number changemgKOH/g 2 max 1.04– filter deposits g 3 max 0.235Sonic shear stability– viscosity change @ 40°C % 4 max 0.6Trace metal content Must pass PassSediment mg/l 10 max 0Ash mg/l 1 max 0Turbine Engine Oils109www.shell.com/aviationThe AeroShell BookEdition 18 2003

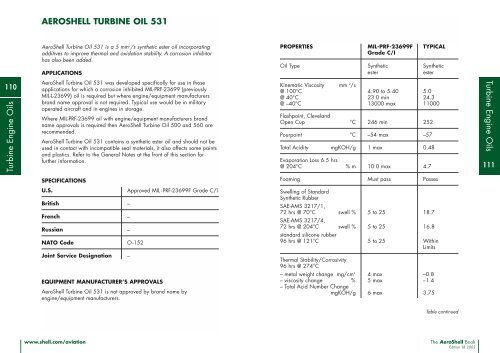

AEROSHELL TURBINE OIL 531AeroShell Turbine Oil 531 is a 5 mm 2 /s synthetic ester oil incorporatingadditives to improve thermal and oxidation stability. A corrosion inhibitorhas also been added.APPLICATIONSPROPERTIES MIL-PRF-23699F TYPICALGrade C/IOil Type Synthetic Syntheticesterester110Turbine Engine OilsAeroShell Turbine Oil 531 was developed specifically for use in thoseapplications for which a corrosion inhibited MIL-PRF-23699 (previouslyMIL-L-23699) oil is required but where engine/equipment manufacturersbrand name approval is not required. Typical use would be in militaryoperated aircraft and in engines in storage.Where MIL-PRF-23699 oil with engine/equipment manufacturers brandname approvals is required then AeroShell Turbine Oil 500 and 560 arerecommended.AeroShell Turbine Oil 531 contains a synthetic ester oil and should not beused in contact with incompatible seal materials, it also affects some paintsand plastics. Refer to the General Notes at the front of this section forfurther information.Kinematic Viscosity mm 2 /s@ 100°C 4.90 to 5.40 5.0@ 40°C 23.0 min 24.3@ –40°C 13000 max 11000Flashpoint, ClevelandOpen Cup °C 246 min 252Pourpoint °C –54 max –57Total Acidity mgKOH/g 1 max 0.48Evaporation Loss 6.5 hrs@ 204°C % m 10.0 max 4.7Turbine Engine Oils111SPECIFICATIONSFoaming Must pass PassesU.S.British –French –Russian –NATO Code O -152Approved MIL - PRF-23699F Grade C/ISwelling of StandardSynthetic RubberSAE-AMS 3217/1,72 hrs @ 70°C swell % 5 to 25 18.7SAE-AMS 3217/4,72 hrs @ 204°C swell % 5 to 25 16.8standard silicone rubber96 hrs @ 121°C 5 to 25 WithinLimitsJoint Service Designation –EQUIPMENT MANUFACTURER’S APPROVALSAeroShell Turbine Oil 531 is not approved by brand name byengine/equipment manufacturers.Thermal Stability/Corrosivity96 hrs @ 274°C– metal weight change mg/cm 2 4 max –0.8– viscosity change % 5 max –1.4– Total Acid Number ChangemgKOH/g 6 max 3.75Table continuedwww.shell.com/aviationThe AeroShell BookEdition 18 2003

- Page 1: AEROSHELL TURBINE OILS74Turbine Eng

- Page 5 and 6: Aluminium and steel and their alloy

- Page 7: AEROSHELL TURBINE OIL 286Turbine En

- Page 10 and 11: PROPERTIES OST 38.01163-78 TYPICALS

- Page 12 and 13: NOTES96Turbine Engine OilsTable con

- Page 14 and 15: NOTES100Turbine Engine OilsPROPERTI

- Page 16 and 17: PROPERTIES MIL-PRF-23699F TYPICALGr

- Page 20 and 21: NOTES112Turbine Engine OilsTable co

- Page 22 and 23: 116Turbine Engine OilsEQUIPMENT MAN

- Page 24 and 25: AEROSHELL TURBINE OIL 560AeroShell

- Page 26 and 27: NOTES124Turbine Engine OilsTable co

- Page 28 and 29: NOTES128Turbine Engine OilsTable co

- Page 30: Turbine Engine Oils132TYPICAL TEMPE

AEROSHELL TURBINE OIL 531AeroShell <strong>Turbine</strong> Oil 531 is a 5 mm 2 /s synthetic ester oil incorporatingadditives to improve thermal and oxidation stability. A corrosion inhibitorhas also been added.APPLICATIONSPROPERTIES MIL-PRF-23699F TYPICALGrade C/IOil Type Synthetic Syntheticesterester110<strong>Turbine</strong> <strong>Engine</strong> <strong>Oils</strong>AeroShell <strong>Turbine</strong> Oil 531 was developed specifically for use in thoseapplications for which a corrosion inhibited MIL-PRF-23699 (previouslyMIL-L-23699) oil is required but where engine/equipment manufacturersbrand name approval is not required. Typical use would be in militaryoperated aircraft and in engines in storage.Where MIL-PRF-23699 oil with engine/equipment manufacturers brandname approvals is required then AeroShell <strong>Turbine</strong> Oil 500 and 560 arerecommended.AeroShell <strong>Turbine</strong> Oil 531 contains a synthetic ester oil and should not beused in contact with incompatible seal materials, it also affects some paintsand plastics. Refer to the General Notes at the front of this section forfurther information.Kinematic Viscosity mm 2 /s@ 100°C 4.90 to 5.40 5.0@ 40°C 23.0 min 24.3@ –40°C 13000 max 11000Flashpoint, ClevelandOpen Cup °C 246 min 252Pourpoint °C –54 max –57Total Acidity mgKOH/g 1 max 0.48Evaporation Loss 6.5 hrs@ 204°C % m 10.0 max 4.7<strong>Turbine</strong> <strong>Engine</strong> <strong>Oils</strong>111SPECIFICATIONSFoaming Must pass PassesU.S.British –French –Russian –NATO Code O -152Approved MIL - PRF-23699F Grade C/ISwelling of StandardSynthetic RubberSAE-AMS 3217/1,72 hrs @ 70°C swell % 5 to 25 18.7SAE-AMS 3217/4,72 hrs @ 204°C swell % 5 to 25 16.8standard silicone rubber96 hrs @ 121°C 5 to 25 WithinLimitsJoint Service Designation –EQUIPMENT MANUFACTURER’S APPROVALSAeroShell <strong>Turbine</strong> Oil 531 is not approved by brand name byengine/equipment manufacturers.Thermal Stability/Corrosivity96 hrs @ 274°C– metal weight change mg/cm 2 4 max –0.8– viscosity change % 5 max –1.4– Total Acid Number ChangemgKOH/g 6 max 3.75Table continuedwww.shell.com/aviationThe AeroShell BookEdition 18 2003