Turbine Engine Oils - VPS Lubricants

Turbine Engine Oils - VPS Lubricants Turbine Engine Oils - VPS Lubricants

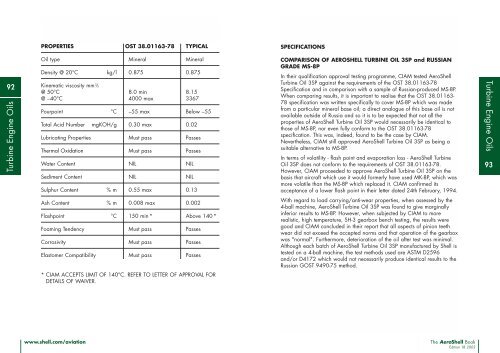

PROPERTIES OST 38.01163-78 TYPICALSPECIFICATIONS92Turbine Engine OilsOil type Mineral MineralDensity @ 20°C kg/l 0.875 0.875Kinematic viscosity mm 2 ⁄S@ 50°C 8.0 min 8.15@ −40°C 4000 max 3367Pourpoint °C −55 max Below −55Total Acid Number mgKOH/g 0.30 max 0.02Lubricating Properties Must pass PassesThermal Oxidation Must pass PassesWater Content NIL NILSediment Content NIL NILSulphur Content % m 0.55 max 0.13COMPARISON OF AEROSHELL TURBINE OIL 3SP and RUSSIANGRADE MS-8PIn their qualification approval testing programme, CIAM tested AeroShellTurbine Oil 3SP against the requirements of the OST 38.01163-78Specification and in comparison with a sample of Russian-produced MS-8P.When comparing results, it is important to realise that the OST 38.01163-78 specification was written specifically to cover MS-8P which was madefrom a particular mineral base oil; a direct analogue of this base oil is notavailable outside of Russia and so it is to be expected that not all theproperties of AeroShell Turbine Oil 3SP would necessarily be identical tothose of MS-8P, nor even fully conform to the OST 38.01163-78specification. This was, indeed, found to be the case by CIAM.Nevertheless, CIAM still approved AeroShell Turbine Oil 3SP as being asuitable alternative to MS-8P.In terms of volatility - flash point and evaporation loss - AeroShell TurbineOil 3SP does not conform to the requirements of OST 38.01163-78.However, CIAM proceeded to approve AeroShell Turbine Oil 3SP on thebasis that aircraft which use it would formerly have used MK-8P, which wasmore volatile than the MS-8P which replaced it. CIAM confirmed itsacceptance of a lower flash point in their letter dated 24th February, 1994.With regard to load carrying/anti-wear properties, when assessed by the4-ball machine, AeroShell Turbine Oil 3SP was found to give marginallyinferior results to MS-8P. However, when subjected by CIAM to morerealistic, high temperature, SH-3 gearbox bench testing, the results weregood and CIAM concluded in their report that all aspects of pinion teethwear did not exceed the accepted norms and that operation of the gearboxwas "normal". Furthermore, deterioration of the oil after test was minimal.Although each batch of AeroShell Turbine Oil 3SP manufactured by Shell istested on a 4-ball machine, the test methods used are ASTM D2596and/or D4172 which would not necessarily produce identical results to theRussian GOST 9490-75 method.Turbine Engine Oils93Ash Content % m 0.008 max 0.002Flashpoint °C 150 min * Above 140 *Foaming Tendency Must pass PassesCorrosivity Must pass PassesElastomer Compatibility Must pass Passes* CIAM ACCEPTS LIMIT OF 140°C. REFER TO LETTER OF APPROVAL FORDETAILS OF WAIVER.www.shell.com/aviationThe AeroShell BookEdition 18 2003

AEROSHELL TURBINE OIL 308AeroShell Turbine Oil 308 is a 3 mm 2 /s synthetic ester oil incorporatingadditives to improve resistance to oxidation and corrosion and to minimisewear.APPLICATIONSPROPERTIES MIL-PRF-7808L TYPICALGrade 3Oil type Synthetic ester Syntheticester94Turbine Engine OilsAeroShell Turbine Oil 308 was developed specifically for use in particularmodels of aircraft turbo-prop and turbo-jet engines for which a MIL-PRF-7808 (formerly MIL-L-7808) oil is required.AeroShell Turbine Oil 308 contains a synthetic ester oil and should not beused in contact with incompatible seal materials and it also affects somepaints and plastics. Refer to the General Notes at the front of this sectionfor further information.SPECIFICATIONSU.S. Approved MIL - PRF - 7808L Grade 3British –Density @ 15°C kg/l - 0.956Kinematic viscosity mm 2 ⁄S@ 100°C 3.0 min 3.1@ 40°C 11.5 min 12.0@ –40°C – 2400@ –51°C 17000 max 12000Viscosity stability Must pass PassesPourpoint °C – Below −62Flashpoint, ClevelandOpen Cup °C 210 min 235Turbine Engine Oils95French –Total Acidity mgKOH/g 0.3 max 0.15Russian –Trace metal content Must pass PassesNATO Code O -148Evaporation 6.5 hrs @ 205°C % m 30 max 20Joint Service Designation OX - 9Silver – bronze corrosion @ 232°C– silver gm/m 2 ± 4.5 max 0.01– bronze gm/m 2 ± 4.5 max 0.05Deposit Test– deposit rating 1.5 max 0.8– neutralization number change % 20 max 2.0– viscosity change @ 40°C % 100 max 12.0Storage stability Must pass PassesCompatibility Must pass PassesTable continuedwww.shell.com/aviationThe AeroShell BookEdition 18 2003

- Page 1: AEROSHELL TURBINE OILS74Turbine Eng

- Page 5 and 6: Aluminium and steel and their alloy

- Page 7: AEROSHELL TURBINE OIL 286Turbine En

- Page 12 and 13: NOTES96Turbine Engine OilsTable con

- Page 14 and 15: NOTES100Turbine Engine OilsPROPERTI

- Page 16 and 17: PROPERTIES MIL-PRF-23699F TYPICALGr

- Page 18 and 19: NOTES108Turbine Engine OilsTable co

- Page 20 and 21: NOTES112Turbine Engine OilsTable co

- Page 22 and 23: 116Turbine Engine OilsEQUIPMENT MAN

- Page 24 and 25: AEROSHELL TURBINE OIL 560AeroShell

- Page 26 and 27: NOTES124Turbine Engine OilsTable co

- Page 28 and 29: NOTES128Turbine Engine OilsTable co

- Page 30: Turbine Engine Oils132TYPICAL TEMPE

PROPERTIES OST 38.01163-78 TYPICALSPECIFICATIONS92<strong>Turbine</strong> <strong>Engine</strong> <strong>Oils</strong>Oil type Mineral MineralDensity @ 20°C kg/l 0.875 0.875Kinematic viscosity mm 2 ⁄S@ 50°C 8.0 min 8.15@ −40°C 4000 max 3367Pourpoint °C −55 max Below −55Total Acid Number mgKOH/g 0.30 max 0.02Lubricating Properties Must pass PassesThermal Oxidation Must pass PassesWater Content NIL NILSediment Content NIL NILSulphur Content % m 0.55 max 0.13COMPARISON OF AEROSHELL TURBINE OIL 3SP and RUSSIANGRADE MS-8PIn their qualification approval testing programme, CIAM tested AeroShell<strong>Turbine</strong> Oil 3SP against the requirements of the OST 38.01163-78Specification and in comparison with a sample of Russian-produced MS-8P.When comparing results, it is important to realise that the OST 38.01163-78 specification was written specifically to cover MS-8P which was madefrom a particular mineral base oil; a direct analogue of this base oil is notavailable outside of Russia and so it is to be expected that not all theproperties of AeroShell <strong>Turbine</strong> Oil 3SP would necessarily be identical tothose of MS-8P, nor even fully conform to the OST 38.01163-78specification. This was, indeed, found to be the case by CIAM.Nevertheless, CIAM still approved AeroShell <strong>Turbine</strong> Oil 3SP as being asuitable alternative to MS-8P.In terms of volatility - flash point and evaporation loss - AeroShell <strong>Turbine</strong>Oil 3SP does not conform to the requirements of OST 38.01163-78.However, CIAM proceeded to approve AeroShell <strong>Turbine</strong> Oil 3SP on thebasis that aircraft which use it would formerly have used MK-8P, which wasmore volatile than the MS-8P which replaced it. CIAM confirmed itsacceptance of a lower flash point in their letter dated 24th February, 1994.With regard to load carrying/anti-wear properties, when assessed by the4-ball machine, AeroShell <strong>Turbine</strong> Oil 3SP was found to give marginallyinferior results to MS-8P. However, when subjected by CIAM to morerealistic, high temperature, SH-3 gearbox bench testing, the results weregood and CIAM concluded in their report that all aspects of pinion teethwear did not exceed the accepted norms and that operation of the gearboxwas "normal". Furthermore, deterioration of the oil after test was minimal.Although each batch of AeroShell <strong>Turbine</strong> Oil 3SP manufactured by Shell istested on a 4-ball machine, the test methods used are ASTM D2596and/or D4172 which would not necessarily produce identical results to theRussian GOST 9490-75 method.<strong>Turbine</strong> <strong>Engine</strong> <strong>Oils</strong>93Ash Content % m 0.008 max 0.002Flashpoint °C 150 min * Above 140 *Foaming Tendency Must pass PassesCorrosivity Must pass PassesElastomer Compatibility Must pass Passes* CIAM ACCEPTS LIMIT OF 140°C. REFER TO LETTER OF APPROVAL FORDETAILS OF WAIVER.www.shell.com/aviationThe AeroShell BookEdition 18 2003