Connector Tooling Guide - AeroElectric Connection

Connector Tooling Guide - AeroElectric Connection

Connector Tooling Guide - AeroElectric Connection

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

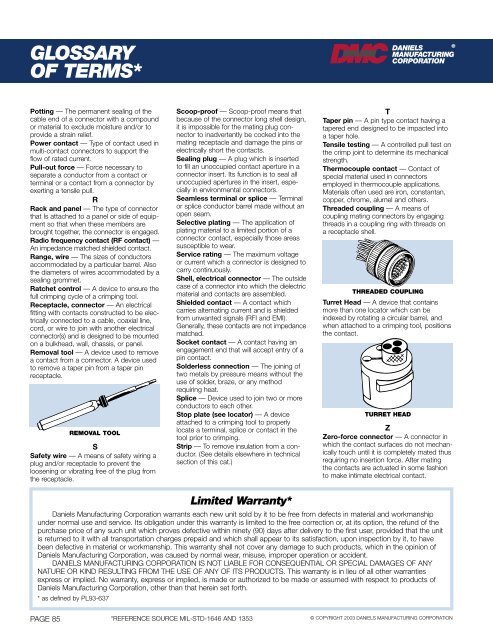

GLOSSARYOF TERMS*®DANIELSMANUFACTURINGCORPORATION®Potting — The permanent sealing of thecable end of a connector with a compoundor material to exclude moisture and/or toprovide a strain relief.Power contact — Type of contact used inmulti-contact connectors to support theflow of rated current.Pull-out force — Force necessary toseparate a conductor from a contact orterminal or a contact from a connector byexerting a tensile pull.RRack and panel — The type of connectorthat Is attached to a panel or side of equipmentso that when these members arebrought together, the connector is engaged.Radio frequency contact (RF contact) —An impedance matched shielded contact.Range, wire — The sizes of conductorsaccommodated by a particular barrel. Alsothe diameters of wires accommodated by asealing grommet.Ratchet control — A device to ensure thefull crimping cycle of a crimping tool.Receptacle, connector — An electricalfitting with contacts constructed to be electricallyconnected to a cable, coaxial line,cord, or wire to join with another electricalconnector(s) and is designed to be mountedon a bulkhead, wall, chassis, or panel.Removal tool — A device used to removea contact from a connector. A device usedto remove a taper pin from a taper pinreceptacle.REMOVAL TOOLSSafety wire — A means of safety wiring aplug and/or receptacle to prevent theloosening or vibrating free of the plug fromthe receptacle.Scoop-proof — Scoop-proof means thatbecause of the connector long shell design,it is impossible for the mating plug connectorto inadvertently be cocked into themating receptacle and damage the pins orelectrically short the contacts.Sealing plug — A plug which is insertedto fill an unoccupied contact aperture in aconnector insert. Its function is to seal allunoccupied apertures in the insert, especiallyin environmental connectors.Seamless terminal or splice — Terminalor splice conductor barrel made without anopen seam.Selective plating — The application ofplating material to a limited portion of aconnector contact, especially those areassusceptible to wear.Service rating — The maximum voltageor current which a connector is designed tocarry continuously.Shell, electrical connector — The outsidecase of a connector into which the dielectricmaterial and contacts are assembled.Shielded contact — A contact whichcarries alternating current and is shieldedfrom unwanted signals (RFI and EMI).Generally, these contacts are not impedancematched.Socket contact — A contact having anengagement end that will accept entry of apin contact.Solderless connection — The joining oftwo metals by pressure means without theuse of solder, braze, or any methodrequiring heat.Splice — Device used to join two or moreconductors to each other.Stop plate (see locator) — A deviceattached to a crimping tool to properlylocate a terminal, splice or contact in thetool prior to crimping.Strip — To remove insulation from a conductor.(See details elsewhere in technicalsection of this cat.)TTaper pin — A pin type contact having atapered end designed to be impacted intoa taper hole.Tensile testing — A controlled pull test onthe crimp joint to determine its mechanicalstrength.Thermocouple contact — Contact ofspecial material used in connectorsemployed in thermocouple applications.Materials often used are iron, constantan,copper, chrome, alumel and others.Threaded coupling — A means ofcoupling mating connectors by engagingthreads in a coupling ring with threads ona receptacle shell.THREADED COUPLINGTurret Head — A device that containsmore than one locator which can beindexed by rotating a circular barrel, andwhen attached to a crimping tool, positionsthe contact.TURRET HEADZZero-force connector — A connector inwhich the contact surfaces do not mechanicallytouch until it is completely mated thusrequiring no insertion force. After matingthe contacts are actuated in some fashionto make intimate electrical contact.Limited Warranty*Daniels Manufacturing Corporation warrants each new unit sold by it to be free from defects in material and workmanshipunder normal use and service. Its obligation under this warranty is limited to the free correction or, at its option, the refund of thepurchase price of any such unit which proves defective within ninety (90) days after delivery to the first user, provided that the unitis returned to it with all transportation charges prepaid and which shall appear to its satisfaction, upon inspection by it, to havebeen defective in material or workmanship. This warranty shall not cover any damage to such products, which in the opinion ofDaniels Manufacturing Corporation, was caused by normal wear, misuse, improper operation or accident.DANIELS MANUFACTURING CORPORATION IS NOT LIABLE FOR CONSEQUENTIAL OR SPECIAL DAMAGES OF ANYNATURE OR KIND RESULTING FROM THE USE OF ANY OF ITS PRODUCTS. This warranty is in lieu of all other warrantiesexpress or implied. No warranty, express or implied, is made or authorized to be made or assumed with respect to products ofDaniels Manufacturing Corporation, other than that herein set forth.* as defined by PL93-637PAGE 85*REFERENCE SOURCE MIL-STD-1646 AND 1353© COPYRIGHT 2003 DANIELS MANUFACTURING CORPORATION

![G-Series-Ext [pdf] - Carling Technologies](https://img.yumpu.com/50918301/1/190x245/g-series-ext-pdf-carling-technologies.jpg?quality=85)