Model Super Cut 315CE - Dake

Model Super Cut 315CE - Dake

Model Super Cut 315CE - Dake

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

USE AND MAINTENANCE MANUAL275 SUPER CUT300 SUPER CUT315 SUPER CUTTHOMASTHOMAS S.p.A. - Via Pasubio, 32 - 36033 Isola Vicentina (VI) - Telephone 0444 / 97.61.05 - Fax 0444 / 97.69.34Registro Imprese 4272//VI 116 REA n. 93906/Vicenza

SUPER CUTContentsContents ........................................................................ " 2Ordering spare parts .................................................... " 2Guarantee ...................................................................... " 2Machine certification and identification marking ....... " 3CHAPTER 1Reference to accident-prevention regulations ........... " 41.1 - Advice for the operator ............................................ " 41.2 - Location of shields against accidental contact withthe tool .................................................................... " 41.3 - Electrical equipment according to EuropeanStandard "CENELEC EN 60 204-1" (1992) ............ " 41.4 - Emergencies according to European Standard"CENELEC EN 60 204-1" (1992) ........................... " 4CHAPTER 2Recommendations and advice for use ....................... " 42.1 - Recommendations and advice for using the machine .. " 4CHAPTER 3Technical characteristics ............................................. " 53.1 - Table of cutting capacity and technical details ........ " 5CHAPTER 4Machine dimensions - Transport - InstallationDismantling ................................................................... " 64.1 - Machine dimensions ............................................... " 64.2 - Transport and handling of the machine .................. " 64.3 - Minimum requirements for the premiseshousing the machine .............................................. " 64.4 - Anchoring the machine ........................................... " 74.5 - Instructions for electrical connection ...................... " 74.6 - Instructions for assembly of the loose parts andaccessories ............................................................. " 74.7 - Disactivating the machine....................................... " 74.8 - Dismantling ............................................................. " 7CHAPTER 5Machine functional parts ............................................. " 75.1 - Operating head ....................................................... " 75.2 - Vice ......................................................................... " 75.3 - Bed .......................................................................... " 8CHAPTER 6Description of the operating cycle ............................. " 86.1 - Starting up and cutting cycle .................................. " 8CHAPTER 7Regulating the machine ............................................... " 8Ordering spare parts- When ordering spare parts you must state:MACHINE MODELSERIAL NUMBERPART REFERENCE NUMBERWithout these references WE WILL NOT SUPPLY the spares. See point 10.1 - list spare parts -.Guarantee7.1 - Disk head ................................................................ " 87.2 - Vice ......................................................................... " 87.3 - <strong>Cut</strong>ting angle adjustment ........................................ " 97.4 - Changing the disk ................................................... " 97.5 - Changing the lubricating coolant pump .................. " 9CHAPTER 8Routine and special maintenance .............................. " 98.1 - Daily maintenance .................................................. " 98.2 - Weekly maintenance .............................................. " 98.3 - Monthly maintenance ............................................. " 98.4 - Six-monthly maintenance ....................................... " 98.5 - Oils for lubricating coolant ...................................... " 98.6 - Oil disposal ............................................................. " 108.7 - Special maintenance .............................................. " 10CHAPTER 9Material classification and choice of tool.................. " 109.1 - Definition of materials ............................................. " 109.2 - Choosing the disk ................................................... " 109.3 - Teeth pitch .............................................................. " 119.4 - <strong>Cut</strong>ting and advance speed .................................... " 119.5 - Running in the disk ................................................. " 119.6 - Disk structure .......................................................... " 119.7 - Type of disks ........................................................... " 11Tooth shape ........................................................... " 11Tooth cutting angle ................................................ " 119.7.1 - Table of recommended cutting parameters ................. " 129.7.2 - Table of cutting speed according to disk diameter ....... " 12CHAPTER 10Machine components ................................................... " 1310.1- List of spare parts .................................................. " 13CHAPTER 11Wiring diagrams ........................................................... " 17CHAPTER 12Troubleshooting ............................................................ " 1912.1- Blade and cutting diagnosis.................................... " 1912.2- Electrical components diagnosis ............................ " 21CHAPTER 13Noise tests ..................................................................... " 21CHAPTER 14Optional ......................................................................... " 2214.1 - Pneumatic vice ...................................................... " 2214.2 - Connection to the pneumatic system ................... " 22Plates and labels .......................................................... " 22Notes .............................................................................. " 23- The Company guarantees that the machine to which this manual refers has been designed and built to comply with safety regulationsand that it has been tested for functionality in the factory.- The machine is guaranteed for 12 months: the guarantee does not cover the electric motors, electric components, pneumaticcomponents or any damage due to dropping or to bad machine management, the failure to observe maintenance standards or badhandling by the operator.- The buyer has only the right to replacement of the faulty parts, while transport and packing costs are at his expense.- The serial number on the machine is a primary reference for the guarantee, for after-sales assistance and for identifying the machinefor any necessity.2

SUPER CUTMachine certification and identification markingMACHINE LABELvia Pasubio, 32MODEL36033 ISOLA VIC. - ITALIASUPER CUTTYPSERIAL NUMBERYEAR OF MANUFACTURE(Space reserved for the NAME and STAMP of the DEALER and/or IMPORTER)3

SUPER CUT1REFERENCE TO ACCIDENT-PREVENTION REGULATIONSThis machine has been built to comply with the national andcommunity accident-prevention regulations in force.Improper use and/or tampering with the safety devices willrelieve the manufacturer of all responsibility.1.1 - Advice for the operator- Check that the voltage indicated on the plate, normally fixedto the machine motor, is the same as the line voltage.- Check the efficiency of your electric supply and earthing system;connect the power cable of the machine to the socket and theearth lead (yellow-green in colour) to the earthing system.- When the tool head is in rest position (raised), the tootheddisk must be stationary.- It is forbidden to work on the machine without its shields (theseare all white, grey or blue in colour).- Always disconnect the machine from the power socket beforechanging the disk or carrying out any maintenance job, evenin the case of abnormal machine operation.- It is forbidden to disconnect the “man present” device, knownmore correctly in the EEC as the “safety switch with holddownaction”.- Always wear suitable eye protection.- Never put your hands or arms into the cutting area while themachine is operating.- Do not shift the machine while it is cutting.- Do not wear loose clothing with sleeves that are too long,gloves that are too big, bracelets, chains or any other objectthat could get caught in the machine during operation; tie backlong hair.- Keep the area free of equipment, tools or any other object.- Perform only one operation at a time and never have severalobjects in your hands at the same time. Keep your hands asclean as possible.- All internal and/or internal operations, maintenance or repairs,must be performed in a well-lit area or where there is sufficientlight from extra sources so as to avoid the risk of even slightaccidents.dust.- Protection of the system against short circuits is ensured bymeans of rapid fuses and earthing; in the event of motoroverload, protection is provided by a thermal probe.- In the event of a power cut, the specific start-up button mustbe reset.- The machine has been tested in conformity with point 20 ofEN 60204.1.4 - Emergencies according to EuropeanStandard "CENELEC EN 60 204-1"- In the event of incorrect operation or of danger conditions, themachine may be stopped immediately by pressing the redmushroom button.NOTE: Resetting of machine operation after each emergencystop is achieved by reactivating the specific restartbutton.2RECOMMENDATIONS ANDADVICE FOR USE2.1 - Recommendations and advice for using themachine- The machine has been designed to cut metal buildingmaterials, with different shapes and profiles, used inworkshops, turner’s shops and general mechanical structuralwork.- Only one operator is needed to use the machine.1.2 - Location of shields against accidentalcontact with the tool- Green metal shield screwed onto the disk head.- Self-regulating mobile blue plastic shield, fitted coaxially withthe fixed shield.1.3 - Electrical equipment according to EuropeanStandard"CENELEC EN 60 204-1" which assimilates,with some integrating modifications,the publication "IEC 204-1"- The electrical equipment ensures protection against electricshock as a result of direct or indirect contact. The active partsof this equipment are housed in a box to which access is limitedby screws that can only be removed with a special tool; theparts are fed with alternating current at low voltage (24 V).The equipment is protected against splashes of water and- To obtain good running-in of the machine it is advisable tostart using it at intervals of about half an hour. This operationshould be repeated two or three times, after which the machinemay be used continuously.- Before starting each cutting operation, ensure that the part isfirmly gripped in the vice and that the end is suitably supported.- Do not use disks of a different size from those stated in themachine specifications.- If the disk gets stuck in the cut, release the running buttonimmediately, switch off the machine, open the vice slowly,remove the part and check that the disk or its teeth are notbroken. If they are broken, change the tool.- Before carrying out any repairs on the machine, consult thedealer or apply to THOMAS.4

SUPER CUT3TECHNICALCHARACTERISTICS3.1 - Table of cutting capacity and technical details275 SUPER CUT 300 SUPER CUT0° 85 70 95 x 600° 90 75 100 x 6545° DX - SX 72 65 75 x 6045° DX - SX 80 70 80 x 602-speed three-phase electric motor KW 1,1 ÷ 1,52-speed three-phase electric motor KW 1,2 ÷ 1,61-speed single-phase electric motor KW 1,51-speed single-phase electric motor KW 1,5Max. electric absorption KW 1,55Max. electric absorption KW 1,55Oil-bath reduction unit i 34 : 1Oil-bath reduction unit i 34 : 1Max. blade diameter mm 275Max. blade diameter mm 300Min. blade diameter mm 250Min. blade diameter mm 250Blade rotation speed rpm 41 ÷ 82Blade rotation speed rpm 41 ÷ 82Vice opening mm 120Vice opening mm 120Machine Weight KG 123Machine Weight KG 125Coolant liquid L 5Coolant liquid L 5Working table height with base mm 980Working table height with base mm 98010501800 CON PIEDISTALLO10801800 CON PIEDISTALLO1100 170 520 31010001100170520 31010005

4SUPER CUTMACHINE DIMENSIONSTRANSPORTINSTALLATIONDISMANTLING315 SUPER CUT4.1 - Transport and handling of the machineIf the machine has to be shifted in its own packing, use a forklifttruck or sling it with straps as illustrated.0° 95 82 110 x 7045° DX - SX 90 80 85 x 702-speed three-phase electric motor KW 1,3 ÷ 1,91-speed single-phase electric motor KW 1,5Max. electric absorption KW 1,95Oil-bath reduction unit i 34 : 1Max. blade diameter mm 315Min. blade diameter mm 250Blade rotation speed rpm 41 ÷ 82Vice opening mm 120Machine Weight KG 128Coolant liquid L 5Working table height with base mm 9804.2 - Minimum requirements for the premiseshousing the machine- Mains voltage and frequency complying with the machine motorcharacteristics.- Environment temperature from -10 °C to +50 °C.- Relative humidity not over 90%.4.3 - Anchoring the machine6907055070108011001800 CON PIEDISTALLO170520 3101000630445 185AAM812SEC. A - APEDESTAL PROFILE- Position the machine on a firm cement floor maintaining, atthe rear, a minimum distance of 800 mm from the wall; anchorit to the ground as shown in the diagram, using screws andexpansion plugs or tie rods sunk in cement, ensuring that it issitting level.6

SUPER CUT4.4 - Instructions for electrical connection- The machine is not provided with an electric plug, so thecustomer must fit a suitable one for his own working conditions:1 - WIRING DIAGRAM FOR THREE-PHASE MACHINE -SOCKET FOR A 16A PLUGR = L1S = L2T = L3PE = GND2 - WIRING DIAGRAM FOR THE SINGLE-PHASE SYSTEMSOCKET FOR A 16A PLUG= L1= L2= PE4.5 - Instructions for assembly of the loose partsand accessories1) Cast iron or ferrous materials, composed of metal alone,are secondary raw materials, so they may be taken to aniron foundry for re-smelting after having removed the contents(classified in point 3);2) electrical components, including the cable and electronic material(magnetic cards, etc.), fall within the category of materialclassified as being assimilable to urban waste accordingto the laws of the European community, so they may be setaside for collection by the public waste disposal service;3) old mineral and synthetic and/or mixed oils, emulsified oilsand greases are special refuse, so they must be collected,transported and subsequently disposed of by the old oildisposal service.NOTE: since standards and legislation concerning refuse ingeneral is in a state of continuous evolution and thereforesubject to changes and variations, the user must keepinformed of the regulations in force at the time ofdisposing of the machine tool, as these may differ fromthose described above, which are to be considered asa general guide line.5MACHINE FUNCTIONALPARTS5.1 - Operating head- Machine part composed of the parts that transmit movement(motor, reduction unit), the lubricating coolant pump and theelectrical components.Fit the components supplied as indicated in the photo:- part. 1 Screw the lever onto the head and fix it- part. 2 Fit the bar holding rod- part. 3 Fix the pedestal firmly onto the base ( optional )- part. 4 Fit and align the roller carrying arm on the countervicebench.4.6 - Disactivating the machine- If the sawing machine is to be out of use for a long period, it isadvisable to proceed as follows:1) detach the plug from the electric supply panel2) release the head return spring3) empty the coolant tank4) carefully clean and grease the machine5) if necessary, cover the machine.5.2 - Vice- System for gripping material during the cutting operation,operated with handwheel and fast manual blocking lever.It is provided with an anti-burr device for blocking the part thatis to be cut.4.7 - Dismantling(because of deterioration and/or obsolescence)General rulesIf the machine is to be permanently demolished and/or scrapped,divide the material to be disposed of according to type andcomposition, as follows:7

SUPER CUT5.3 - Bed- Support structure for the OPERATING HEAD (rotating armfor gradual cutting, with respective blocking system), the VICE,the BAR STOP, the material support ROLLER and the housingfor the cutting coolant TANK.64576DESCRIPTION OF THEOPERATING CYCLEBefore operating, all the main organs of the machine mustbe set in optimum conditions (see the chapter on“Regulating the machine”).6.1 - Starting up and cutting cycle2and that sufficient coolant is coming out.The cropper is now ready to start work, bearing in mind that theCUTTING SPEED and the TYPE of DISC - combined with asuitable descent of the head - are of decisive importance forcutting quality and for machine performance (for further detailson this topic, see below in the chapter on “Materialclassification and choice of disks”).- When starting to cut with a new disk, in order to safeguardits life and efficiency, the first two or three cuts must bemade while exerting a slight pressure on the part, so thatthe time taken to cut is about double the normal time (seebelow in the chapter on “Material classification and choiceof disks” in the section on Running in the disk).- Press the red emergency button ( 1 ) when there are conditionsof danger or malfunctions in general, so as to stop machineoperation immediately.317REGULATINGTHEMACHINE- Ensure that the machine is not in emergency stop condition;if it is, release the red mushroom button ( 1 ).- Select the cutting speed on the switch ( 3 ):position 1 = 41 rpm.position 2 = 82 rpm.- Press the start/reset button ( 2 ): its green light will go on.- Place material to be cut in the vice ( 4 ). Close jaws againstpiece, keeping a distance of approx. 3 - 4 mm then clampwith lever.- Grip the handle ( 6 ) of the HEAD control arm and press thebutton, checking that the disk is turning in the directionindicated (if not, invert the two phase leads):7.1 - Disk head- If excessive axial play is found on the hinge, it will be sufficientto tighten the screws ( 7 ), paying attention not to make thejoint too tight.7.2 - Vice- The device does not require any particular adjustment.8

SUPER CUT7.3 - <strong>Cut</strong>ting angle adjustment- Release lever ( 1 ), rotate the cutting head and make surethat the wanted cutting angle perfectly meets with the referenceindex before locking with the lever ( 1 ).8 ROUTINEAND SPECIALMAINTENANCETHE MAINTENANCE JOBS ARE LISTED BELOW, DIVIDEDINTO DAILY, WEEKLY, MONTHLY AND SIX-MONTHLYINTERVALS. IF THE FOLLOWING OPERATIONS ARENEGLECTED, THE RESULT WILL BE PREMATURE WEAROF THE MACHINE AND POOR PERFORMANCE.8.1 - Daily maintenanceBEFORE PERFORMING THE FOLLOWING OPERATIONS,THE ELECTRIC POWER SUPPLY AND THE POWER CABLEMUST BE COMPLETELY DISCONNECTED.7.4 - Changing the diskTo change the disk:- Release the mobile yellow, white or orange guard and turn it back.- Block a piece of wood in the vice and lean the disk on it.- Insert the special spanner provided and remove the screw( 1 ), slackening it in a clockwise direction because it has aleft-handed thread, then slip off the flange that holds the disk.- Fit the new disk, checking the cutting direction of the teeth,then replace the flange, the screw and the mobile white, yellowor orange guard.1- General cleaning of the machine to remove accumulatedshavings.- Top up the level of lubricating coolant.- Check the disk for wear.- Lift the head into a high position to avoid yield stress on thereturn spring.- Check functionality of the shields and emergency stops.8.2 - Weekly maintenance- More accurate general cleaning of the machine to removeshavings, especially from the lubricant fluid tank.- Clean the filter of the pump suction head and the suctionarea.- Clean and grease the screw and the sliding guide of the vice.- Clean the disk housing.- Sharpen the disk teeth.8.3 - Monthly maintenance- Check tightness of the screws on the motor, the pump, thejaws and shields.- Check that the shields are unbroken.- Grease the head hinge pin.8.4 - Six-monthly maintenance7.5 - Changing the lubricating coolant pump1- Change the oil in the reduction unit using oil type GEARCO85W-140 by NATIONAL CHEMSERACH or MOBIL GLYCOLE30 or KLUBER SINTHESO 460 EP or an equivalent oil,proceeding as follows:- Remove the connecting plugfrom the electric box and unscrewthe head movinglever.- Drain off the old oil from thecap at the side ( 1 ).- Pour in new oil up to themark ( 2 ), through the leverfixing hole, keeping the headin a horizontal position.- Reassemble all the parts.1- Check continuity of the equipotential protection circuit8.5 - Oils for lubricating coolant2- Takes the pipes of the lubricating-refrigerating system off.- Remove the fastening screws and replace the little pump, beingcareful to keep the driving stem centred on the drive shaftbearing.Considering the vast range of products on the market, the usercan choose the one most suited to his own requirements, usingas reference the type SHELL LUTEM OIL ECO.THE MINIMUM PERCENTAGE OF OIL DILUTED IN WATERIS 8 - 10 %.9

SUPER CUT8.6 - Oil disposalThe disposal of these products is controlled by strict regulations.Please see the Chapter on “Machine dimensions - Transport- Installation” in the section on Dismantling.8.7 - Special maintenanceSpecial maintenance operations must be carried out by skilledpersonnel. However, we advise contacting THOMAS or theirdealer and/or importer. The term special maintenance alsocovers the resetting of protection and safety equipment anddevices.9MATERIALCLASSIFICATION ANDCHOICE OF TOOLTYPES OF STEELSince the aim is to obtain excellent cutting quality, the variousparameters such as hardness of the material, shape andthickness, transverse cutting section of the part to becut, choice of the type of cutting disk, cutting speed andcon-trol of head descent, must be suitably combined.Thesespe-cifications must therefore be harmoniously combinedin a single operating condition according to practical considera-tionsand common sense, so as to achieve an optimumcondi-tion that does not require countless operations toprepare the machine when there are many variations in thejob to be performed.The various problems that crop up fromtime to ti-me will be solved more easily if the operator has agood know-ledge of these specifications.WE THEREFORE ADVISE YOU ALWAYS TO CHOOSEORIGINAL SPARE DISKS THAT GUARANTEE SUPERIORQUALITY AND PERFORMANCE.9.1 - Definition of materialsThe table at the foot of the page lists the characteristics of thematerials to be cut, so as to choose the right tool to use.9.2 - Choosing the diskFirst of all the pitch of the teeth must be chosen, suitable for thematerial to be cut, according to these criteria:- parts with a thin and/or variable section such as profiles, pipesand plate, need close toothing, so that the number of teethused simultaneously in cutting is from 3 to 6;- parts with large transverse sections and solid sections needwidely spaced toothing to allow for the greater volume of theshavings and better tooth penetration;- parts made of soft material or plastic (light alloys, mild bronze,teflon, wood, etc.) also require widely spaced toothing.CHARACTERISTICS10USEConstructionsteelsCarbonsteelsSpring steelsAlloyed steels forhardening andtempering and fornitridingAlloyedcasehardeningsteelsSteel forbearingsTool steelStainlesssteelCopper alloysSpecial brassBronzeCast ironIUNIFe360Fe430Fe510C20C40C50C6050CrV460SiCr835CrMo439NiCrMo441CrAlMo718NiCrMo720NiCrMo2DDINSt37St44St52CK20CK40CK50CK6050CrV460SiCr734CrMo436CrNiMo441CrAlMo7----21NiCrMo2FAF NORE24E28E36XC20XC42H1----XC5550CV4----35CD439NCD440CADG1220NCD720NCD2GBSB----4350060 A 20060 A 40----060 A 62735 A 50----708 A 37----905 M 39En 325805 H 20USAAISI-SAE------------10201040105010606150926241359840----43204315HardnessBRINELLHB116148180198198202202207224220228232232224HardnessROCKWELLHRB678088939394949598989910010098R=N/mm2360÷480430÷560510÷660540÷690700÷840760÷900830÷9801140÷13301220÷1400780÷930880÷1080930÷1130760÷1030690÷980100Cr6 100Cr6 100C6 534 A 99 52100 207 95 690÷98052NiCrMoKUC100KUX210Cr13KU58SiMo8KUX12Cr13X5CrNi1810X8CrNi191056NiCrMoV7C100W1X210Cr12----40014301----4401--------Z200C12Y60SC7----Z5CN18.09----Z6CDN17.12----BS 1BD2 - BD3--------304 C 12----X8CrNiMo1713316 S 16Aluminium copper alloy G-CuAl11Fe4Ni4 UNI 5275Special manganese/silicon brass G-CuZn36Si1Pb1 UNI5038Manganese bronze SAE43 - SAE430Phosphor bronze G-CuSn12 UNI 7013/2aGray pig ironG25Spheroidal graphite cast iron GS600Malleable cast iron W40-05----S-1D6 - D3S5410304----316244212252244202202202202220140120100212232222102961031029494949498776956,59610098800÷1030710÷980820÷1060800÷1030670÷885590÷685540÷685490÷685620÷685375÷440320÷410265÷314245600420

SUPER CUT9.3 - Teeth pitchAs already stated, this depends on the following factors:- hardness of the material- dimensions of the section- thickness of the wall.SSSS (MM) PICTH SHAPE SPEEDup to 2 4 - 6Bshaped22 ÷ 5 8Csolid25 ÷ 10 8Csolid1over 10 8Csolid1up to 20 8Csolid120 ÷ 50 10Csolid1Tooth shapeThe profile of the toothing depends on the size, shape andthickness of the section to be cut, either straight or at an angle.It may also vary according to the pitch, but not so distinctly asto make this an element for classification.- Fine toothing is to be chosen for cutting small sections with aprofiled shape and tubular sections with thin walls (2-5 mmdepending on the material).- Large toothing is suitable for cutting medium and large solidsections or fairly thick profiled or tubular sections (over 5 mm)."A" toothing:normal fine toothing"B" toothing:normal large toothing with orwithout shaving breaking incision"AW" toothing:fine toothing with alternate siderake"BW" toothing:large toothing with alternateside rake9.4 - <strong>Cut</strong>ting and advance speedThe cutting speed (m/min) and the advance speed (cm 2 /min =area travelled by the disk teeth when removing shavings) arelimited by the development of heat close to the tips of the teeth.- The cutting speed is subordinate to the resistance of thematerial (R = N/mm 2 ), to its hardness (HRC) and to thedimensions of the widest section.- Too high an advance speed (= disk descent) tends to causethe disk to deviate from the ideal cutting path, producing nonrectilinear cuts on both the vertical and the horizontal plane.9.5 - Running in the disk“C (HZ)” toothing:large toothing with roughingtooth with rake on both sides,alternating with a finishingtooth without rake. The roughingtooth is 0.15-0.30 mmhigherAdded toothing:disks made in this way areused for cutting non-ferrousmetals, such as light alloys,and plastics, and above all inwood-working. The teeth arehard metal (HM) plates brazedonto the body of the disk; thereare various types and shapesand, considering the vastnessof the field, the topic is notdeveloped further here.When cutting for the first time, it is good practice to run inthe tool making a series of cuts at a low advance speed(= 30-35 cm 2 /min on material of average dimensions with respectto the cutting capacity and solid section of normal steel withR = 410-510 N/mm 2 ), generously spraying the cutting areawith lubricating coolant.9.6 - Disk structureThe most commonly used disks are made of extra high speedsteel (HHS) of normal quality (HHS/DMo5) or superior quality(HHS/Mo5 + Co5) with a treated tooth, which differentiates themfrom the former on account of the high value of structuralresistance, greater resistance to seizing, absence of stress inthe mass and a better holding of lubricating coolant during work.9.7 - Type of disksThe disks differ essentially in their constructive characteristics,such as:- Tooth shape- Tooth cutting angleTooth cutting angleEach tooth has two cutting angles:- α : front rake angle- γ : rear rake angleSHARPENING CIRCULAR SAWSγαT 3 4 5 6 7 8 9 10 12 14 16p 1,3 1,6 2,1 2,5 2,9 3,4 3,8 4,2 5,1 5,9 7,2d 1,5 2 2,5 3 3,5 4 4,5 5 6 7 8h = 0,2 mmh = 0,3 mmThe rake varies especially according to the type of materialto be cut.11

SUPER CUT9.7.1 - RECOMMENDED CUTTING PARAMETERSMild steelR = 350-500 N/mm 2Semi-hard steelR = 500-700 N/mm 2Hard steelR = 750-950 N/mm 2Extra-hard steelR = 950-1000 N/mm 2Heat-treated steelR = 950-1300 N/mm 2Austentic stainlesssteelR = 500-800 N/mm 2Martensitic stainlesssteelR = 500-800 N/mm 2Grey cast ironAluminium and alloysR = 200-400 N/mm 2Aluminium and alloysR = 300-300 N/mm 2CopperR = 200-350 N/mm 2Phosphor bronzeR = 400-600 N/mm 2Hard bronzeR = 600-900 N/mm 2BrassR = 200-400 N/mm 2Alloyed brassR = 400-700 N/mm 2Titanium and alloysR = 300-800 N/mm 2Tubes and beams0,05. DR = 300-600 N/mm 2Tubes and beams0,025. DR = 300-600 N/mm 2CUTTING ANGLESSECTION TO BE CUT (IN MM)*T mmVt m/1'Av mm/1'*T mmVt m/1'Av mm/1'*T mmVt m/1'Av mm/1'*T mmVt m/1'Av mm/1'*T mmVt m/1'Av mm/1'*T mmVt m/1'Av mm/1'*T mmVt m/1'Av mm/1'RECOMMENDED LUBRIFICANTS Emulsion - <strong>Cut</strong>ting oil DryKeroseneDry Emulsion <strong>Cut</strong>ting oil Emulsion9.7.2 - DIAGRAM OF CUTTING SPEEDS ACCORDING TO DISK DIAMETERVt m/minn = g/minKEYTAv mm/minVt m/minAzNg/minZpTooth pitch in millimetresAdvance in millimetres per minute<strong>Cut</strong>ting speed in metres per minuteTooth advanceNumber of revs per minuteNumber of teeth on the diskTooth depthdhγαN/mma-fØDiameter of the tooth fillet cone distanceTooth protrusionFront rakeRear rakeUltimate tensile stressFlat parts of the cutting edgeTube diameter or profile width12

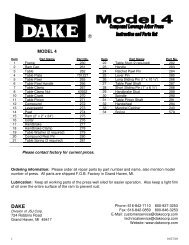

SUPER CUT10 MACHINE COMPONENTS10.1 - List of spare partsREFERENCE N° DESCRIPTION REFERENCE N° DESCRIPTION1 Machine bed2 Revolving arm3 Revolving arm locking pin4 Revolving arm locking bush5 Revolving arm locking lever6 Screw M87 Countervice8 Pin9 Countervice jaws10 Burr-free jaws11 Countervice fixing pin12 Roller arm13 Roller14 Washer M1015 Vite M101617 Vice18 Vice jaws19 Vice jaws washer20 Screw M1221 Vice jaws washer22 Screw M1223 Grain M824 Lever bush25 Quick lock vice lever26 Thrust bearing AX 3047+ CP 304727 Quick lock vice lever washer28 Vice closing handwheel Ø 1829 Elastic pin Ø 530 Washer31 Screw M832333435 Vice thread36 Lock vice spring37 Burr-free transverse plate38 Burr-free plate39 Grain M840 Screw M841 Tank filter42 Screw M643 Bar stop rod444546 Bar stop48 Screw M849 Support tank cover50 Ring seeger Ø 42 I51 Tank cover filter52 Tank cover filter53 Tank cover54 Washer55 1/4" gas tap56 Coolant tube57 Oiler Ø 858 Return spring connection59 Head return spring60 Nut M1261 Screw M1262 Head63 plug64 Oil level plug65 Oil drain plug66 Screw M1067 Hinge pin68 Hinge pin washer69 Hinge pin bush70 Grain M871 Nut M872 Nut M1673 Head lever74 Head lever handgrip75 GUK ring nut M25x1,576 Worm wheel13

SUPER CUTN° REFERENCE RIFERIMENTO N° DESCRIPTIONDENOMINAZIONEN° REFERENCE RIFERIMENTO N° DESCRIPTIONDENOMINAZIONEREFERENCE N°REFERENCE N°DESCRIPTIONDESCRIPTION77 Ring SM 35-47-778 Blade shaft79 Pin80 Blade81 Shaft flange stakes82 Screw M1283 Fixed blade guard848586 Coolant distributor87 Coolant tube88 Grain M689 Mobile blade guard90 Ring seeger Ø 60E919293 Tir rod support94 Washer95 Screw M896 Mobile guard rod97 Screw M898 Washer99 Bearing 6301100 GUK ring nut M17x1101 Worm screw102 Spacer103 Spacer Ø 47104 Bearing 3204105 Ring DPSM 25-40-7106 Head gasket107 Front motor flange108 Motor shaft (rotor)109 Key110 Washer111 Stud bolt112 Nut113 Motor and stator casing114115116 Rear motor flange118119 Bearing 6205 2Z120 Ring seeger Ø 25E121 Fan122 Screw M4123 Fan cover124 Bearing 609125 Pump connection box126127 Screw M5128 Coolant pump129 Washer130 Screw M611714

SUPER CUT15

SUPER CUTLEGENDA140 Auxiliary relay141 Remore control switch142 Fuse carrier143 Transformer144 Socket connector145 Plug connector142140141144143145146147149LEGENDA146 Speed switch147 Reset button148 Emergency push button149 Electric components box14816

11WIRING DIAGRAMSSUPER CUTV 230/50 HzCODE DESCRIPTIONM1 Disk motorXP SocketXS PlugQS Isolating switchC CondenserFU1 Fuse cartridgeFU2 Fuse cartridgeTC1 TransformerCODE DESCRIPTIONSQ1 MicroswitchSB1 Mushroom buttonSB2 Luminous buttonHL Pilot lampKA Auxiliary relayKM Remote-control switchST1 Thermal probeCIRCUIT DIAGRAM SINGLE-PHASE17

SUPER CUTV 400 / 50 HzSIGLA DESCRIZIONEM1 Motore discoXP PresaXS SpinaSA CommutatoreFU1 Cartuccia fusibileFU2 Cartuccia fusibileTC1 TrasformatoreSIGLA DESCRIZIONESQ1 MicrointerruttoreSB1 Pulsante a fungoSB2 Pulsante luminosoHL Lampada spiaKA Relè ausiliarioKM TeleruttoreST1 Sonda termicaCIRCUIT DIAGRAM THREE-PHASES18

12TROUBLESHOOTINGSUPER CUTThis chapter lists the probable faults and malfunctions that could occur while the machine is being used and suggests possibleremedies for solving them.The first paragraph provides diagnosis for TOOLS and CUTS, the second for ELECTRICAL COMPONENTS.12.1 - Blade and cut diagnosisFAULT PROBABLE CAUSE REMEDYTOOTH BREAKAGEToo fast advanceWrong cutting speedWrong tooth pitchLow quality diskIneffective gripping of the part in thevice.Previously broken tooth left in the cut<strong>Cut</strong>ting resumed on a groove madepreviously.Insufficient lubricating refrigerant orwrong emulsionSticky accumulation of material onthe disk.Decrease advance, exerting less cuttingpressureChange disk speed and/or diameter.See Chapter “ Material classificationand choice of disks” and the Table ofcutting speeds according to disk diameter.Choose a suitable disk.See Chapter “Material classificationand choice of disks”.Use a better quality disk.Check the gripping of the part.Accurately remove all the parts left in.Make the cut elsewhere, turning the part.Check the level of the liquid in the tank.Increase the flow of lubricating refrigerant,checking that the hole and the liquid outletpipe are not blocked.Check the blend of lubricating coolant andchoose a better quality disk.PREMATURE DISK WEARCHIPPED DISKWrong running in of the diskWrong cutting speedUnsuitable tooth profileWrong tooth pitchLow quality diskInsufficient lubricating refrigerantHardness, shape or flaws in the material(oxides, inclusions, lack of homogeneity,etc..)Wrong cutting speedWrong tooth pitchVibrationsDisk incorrectly sharpenedLow quality diskSee Chapter “Material classificationand choice of disks” in the paragraphon Running in the disk.Change disk speed and/or diameter.See Chapter “Material classificationand choice of disks” and the Table ofcutting speeds according to disk diameter.Choose a suitable disk. See Chapter“Material classification and choice ofdisks” in the paragraph on Type of disks.Choose a suitable disk.See Chapter “Material classificationand choice of disks”.Use a better quality disk.Check the level of the liquid in the tank.Increase the flow of lubricating refrigerant,checking that the hole and the liquid outletpipe are not blocked.Reduce the cutting pressure and/or theadvance.Change disk speed and/or diameter. SeeChapter “Material classification andchoice of disks” and the Table ofcutting speeds according to diskdiameter.Choose a suitable disk.See Chapter “Material classificationand choice of disks”.Check gripping of the part.Replace the disk with one that is moresuitable and correctly sharpened.Use a better quality disk.19

SUPER CUTFAULT PROBABLE CAUSE REMEDYDISK VIBRATIONRIDGES ON THE CUTTING SURFACECUTS OFF THE STRAIGHTIncorrect emulsion of the lubricatingrefrigerantWrong tooth pitchUnsuitable tooth profileIneffective gripping of the part in thevice.Dimensions of the solid section toolarge with respect to the maximumadmissible cutting dimensionsDisk diameter incorrect and/or toolargeDisk diameter incorrect and/or toolargeIneffective gripping of the part in thevice.Too fast advanceDisk teeth are wornInsufficient lubricating refrigerantToothing does not unload shavingswellToo fast advanceIneffective gripping of the part in theviceDisk head off the straightDisk sides differently sharpened.Disk thinner than the commercialstandard.Dirt on the gripping deviceCheck the percentage of water and oil inthe emulsion.Choose a suitable disk.See Chapter “Material classificationand choice of disks” .Choose a suitable disk.See Chapter “Material classificationand choice of disks” in the paragraphon Type of disks.Check the gripping of the part.Abide by the instructions.Decrease the disk diameter, adapting itto the dimensions of the part to be cut;the cutting part of the disk must not betoo large for the shape of the part to becut.Decrease the disk diameter, adapting itto the dimensions of the part to be cut;the cutting part of the disk must not betoo large for the shape of the part to becut.Check the gripping of the part.Decrease advance, exerting less cuttingpressure.Sharpen the tool.Check the level of the liquid in the tank.Increase the flow of lubricating refrigerant,checking that the hole and the liquid outletpipe are not blocked.Choose a blade with a larger tooth pitchthat allows better unloading of shavingsand that holds more lubricating refrigerant.Decrease advance, exerting less cuttingpressure.Check the gripping of the part which maybe moving sideways.Adjust the head.Choose tool quality carefully in every detailas regards type and construction characteristics.Carefully clean the laying and contactsurfaces.BLADE STICKS IN THE CUTToo fast advanceLow cutting speedWrong tooth pitchSticky accumulation of material onthe disk.Insufficient lubricating refrigerantDecrease advance, exerting less cuttingpressure.Increase speed.Choose a suitable disk.See Chapter “Material classificationand choice of disks” .Check the blend of lubricating coolant andchoose a better quality disk.Check the level of the liquid in the tank.Increase the flow of lubricating refrigerant,checking that the hole and the liquid outletpipe are not blocked.20

SUPER CUT12.2 - Electrical components diagnosisFAULT PROBABLE CAUSE REMEDYTHE GREEN PILOT LIGHT“HL” DOES NOT LIGHT UPFused lampPower supplyFuses “FU 1”Short circuitsSpeed switch “SA” in position “0”Emergency button “SB 1” onCycle reset or line button “SB 2”Thermal probe built into the statorwinding has tripped due to motoroverheatingTransformer “TC 1”Fuse “FU 2”Auxiliary relay “KA”Change it.Check: - phases- cables- socket- plugVoltage must arrive upstream from thefuses.Check for efficiency.Identify and eliminate.It must be turned to position 1 or 2.Ensure that it is off and that its contactsare unbroken.Check mechanical efficiency.Check current continuity on the two wiresin the prone after letting the motor coolfor about 10-15 minutes. If after this timethere is no current continuity in the twowires, the motor must be changed orrewound.Check that the supply voltage is the sameas the line voltage and that it gives a valueof 24 V at output.Check fuse efficiency and ensure thereare no short circuits causing the protectionto trip.Check that 24 V reach the coil terminalswhen the button “SB 2” is pressed; if thishappens and the relay is not self-fed, itmust be changed.MOTOR STOPPED WITH PILOTLIGHT “HL” LITSocket and plug connecting theelectric box/ microswitch in the handleMicroswitch “SQ 1” in the handleRemote-control switch “KM”Motor “M 1”Check that the plug is correctly insertedand look for any bad connections insidethe box.Check operation and/or efficiency; replaceif broken.Check that phases are present at bothinput and output; ensure that it is notblocked, that it closes when fed, that itdoes not cause short circuits; otherwisechange it.Check that it is not burnt and that it turnsfreely.It may be rewound or changed.13NOISE TESTSIn accordance with point 1.7.4.f of the Machines Directive EEC 89/392SOUND LEVEL CALIBRATOR MOD. BRUEL & KIAER 22602 measurements with the machine.- The microphone was been located close to the operator's head, at medium height.- The weighted equivalent continuous acoustic pressure level was 71,6 dB (A).- The maximum level of the WEIGHTED instantaneous acoustic pressure C was always less than 130 dB.NOTE: with the machine operating, the noise level will vary according to the different materials being processed. The user mustthere-fore assess the intensity and if necessary provide the operators with the necessary personal protection, as required by Law277/1991.21

SUPER CUT14 OPTIONAL14.1 - Pneumatic vice- System for clamping material during the cutting operations,with an automated pneumatic device.It is provided with an anti-burr device for blocking the part ofthe piece that has been cut off.21114.2 - Connection to the pneumatic system- Connect the tube of the pneumatic system to the filter unitpart ( 1 ) and check that the pressure gauge part ( 2 ) showsa pressure of 6 - 7 BAR, sufficient to ensure optimumfunctioning of the device.- The vice opening mechanism is controlled by the valve part( 1 ) operated only if the head is completely lifted.- Leave a play of 3 - 4 mm between the jaws and the piece tobe clamped, then lower the head to block the piece.PLATES AND LABELS22

SUPER CUTNOTES: _________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________23

SUPER CUT24THOMAS S.p.A. - Via Pasubio, 32 - 36033 Isola Vicentina (VI) - Telephone 0444 / 97.61.05 - Fax 0444 / 97.69.34