Chei dinamometrice

Chei dinamometrice

Chei dinamometrice

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Overview of GEDORE torque tools260Series/TypePrecisionDriveRatchetScaleMech. torque wrench0,2 - 3.000 N·m+ / - 9269DREMOMETER MINI 3 %b264 - 265 DREMOMETER AM - F 3 %b -> g264 - 265 DREMOMETER BCK 3 %d270DREMOMETER Z 3 %j k Y271DREMOMETER SE 3 %} ~269DREMOMETER FS 6 %b276DREMASTER DMK 3 %d -> e276DREMASTER DMUK 3 %d278DREMASTER DMZ 3 %j k279DREMASTER DMSE 3 %} ~281TORCOFIX K 3 %b -> c283TORCOFIX K US 3 %b -> e284TORCOFIX Z 3 %j285TOROFIX SE 3 %}285TORCOFIX FS 3 %} ~295TSN SLIPPER 4 %b -> b299TBN KNICKER 4 %6 %j }300ATB 4 %j }296TSP SLIPPER 6 %b -> d297TSC SLIPPER 6 %b301Typ 83 4 %b -> f300Typ 88 4 %e kTorque screwdriver0,02 - 13,6 N·m292Typ 755 FS 6 %i291Typ 756 S 6 %i290Typ 757 S 6 %i293Typ 758 SP 6 %iElectr. torque wrench2 - 1.000 N·m287TORCOTRONIC III 1 %d286E-TORC II 1 %bTorque testers0,5 - 3.150 N·m` ^ \(760-00/01)302Dremotest E 1 %b -> g303E-TP 1 %b -> gOperation lengthindependentRelease types111111111111111233223222

Different Torque Tool MechanismsRange N·m5 10 15 20 40 60 80 100 150 200 300 400 500 750 1000 1500 2000Mech. torque wrench2 - 12 N·m6 - 3000 N·m40 - 200 N·m8 - 1000 N·m8 - 400 N·m1-14 N·m20 - 850 N·m20 - 850 N·mClick Tools(Overtightening Possible)1TorquePreset TorqueValueapprox. 3° movementApplied ForceOvertighteningPossibleWhen the preset torque value is reached theoperator will hear a click, feel an impulseand there will be approximately 3° of toolmovement. Resetting takes place when thehand pressure is released.Work can then immediately continue.These tools are generally length dependent(exception DREMOMETER models AM - F),the position of the hand on the tool altersthe torque produced.Continued application of force after the 3°of movement will cause the torque appliedto increase above the required preset limit.20 - 400 N·m20 - 300 N·m1 - 50 N·m10 lbf·in - 600 lbf·ft2 -50 N·m2 -50 N·m2 - 200 N·m3 - 125 N·m0,2 - 135 N·mSlipping Tools(Overtightening Impossible)TorquePresetTorque ValueWhen the preset torque value isreached, a mechanism in the tool causesthe application of torque to cease andthe tool slips free for a short time untilresetting occurs.Even if the application of force isrepeated, the preset torque value willnot be exceeded, therefore making itimpossible to overtighten a fastener.These tools are not length dependent.1 - 10 N·m5 - 100 N·m2Applied ForceOvertighteningImpossible1 - 10 N·m0,8 - 2000 N·m100 - 1500 N·mBreaking Tools(Overtightening Unlikely)Torque screwdriver0,02 -13,6 N·m0,05 -9 N·m0,2 -9 N·m10 - 500 cN·m/ 14 ozf.in - 40 lbf.inElectr. torque wrenchTorque testers10 - 350 N·m2 - 1000 N·m3TorquePreset TorqueValueOvertighteningUnlikelyapprox. 20°movementApplied ForceWhen the preset torque value is reached,these tools break at a specific point along thetool’s length - usually at a pivot point nearthe tool’s head.In most cases the movement isapproximately 20°.The tool is automatically reset by allowingthe handle to return to its in line position.These tools are length dependent, theposition of the hand on the tool alters thetorque produced.Continued application of force after 20° oftool movement will increase the torqueapplied above the preset limit but withthe greater angle of tool movement this isless likely.0,2 - 3150 N·m0,5 - 3150 N·m261

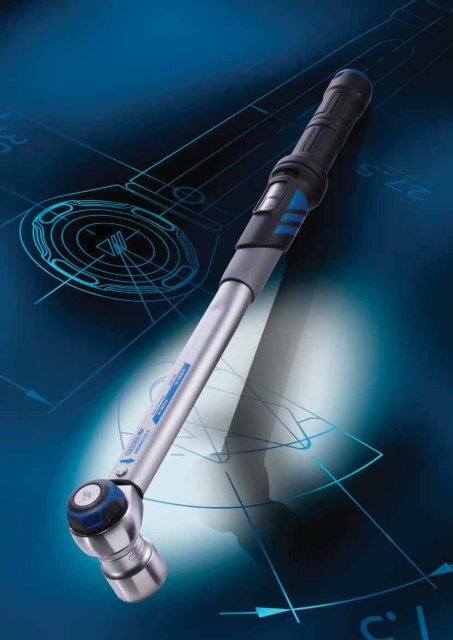

DREMOMETER - permanent precisionTorque wrench made of high-strength aluminium alloyDrive in accordance with application: DREMOMETERSare available for a large variety of applicationsin controlled screw tightening. The single squaredrive for controlled clockwise tightening or thedouble square drive (L) for controlled bi-directionaltightening. Special utilisation areas for DREMOMETERwith spigot end (Z) and rectangular cavity (SE)particularly for hard-to-access locations and wherespace is tight. Almost all DREMOMETER models haveseparate ratchet heads, and there are good reasons forthat: It is possible to work with or without the ratchethead function as desired.Robust and unsusceptible: The full-metalconstruction of the DREMOMETER makesit particularly unsusceptible to grime andrough handling on construction sites, inworkshops and in industry.Automatic resetting: The DREMOMETER givesoperator an audible signal and tactile impulseand is back in operation in an instant.ß¿Serial number on the wrench and onthe certificate for unambiguous productidentification, traceable to national standards.&Classified to DIN EN ISO 6789:2003 Type IIClass A, with a factory certificate allowing foroperations to be traced back. Calibrated to apermitted +/- 3 % deviation and better.The specifications of the standard (+/- 4 %)are exceeded.s b - g6-3000 N·mt L b - f6-2000 N·mZ ¡ ¢ Y8-1000 N·mSE } ~8-400 N·mWorking principleThe quality lever chain produced in the company's own drop forge reduces the strain on themechanics to a minimum. The proportioning of the individual levers, which are optimallyattuned to each other, gives the DREMOMETER its unique precision and its long tool life.1Technology223112Position of the lever chain without impactof force (in starting position).Position of the lever chain with impact of force before the set torqueis achieved. The force is transferred from the primary lever to theintermediary and final lever until the final lever slips past the socalledrelease lever through the sliding back of the angle-lever body.3T Setting of the torque value to N·m or alternatively tolbf·in / lbf·ft by the non-losable hexagon key in thehandgrip.T The smooth-running mechanism enables the settingto be made quickly without significant force needingto be applied.3Position of the lever chain when the force impacts after the torquesetting is achieved. Immediate position after the clear tactile impulseand audible signal "click". On relief, the lever chain moves back intothe starting position (1).A+ST All DREMOMETERS are also availablewith locking and safely device (A+S).262

cdefg8560-03 A266753269&ß¿97548568-35268266lw a b c d e f Tube /207 30 15.0 268 – – – – 580207 30 15.0 268 – – – – 580263 30 17.5 338 – – – – 1000263 30 17.5 338 – – – – 1000374 30 17.5 462 – – – – 1500374 30 17.5 462 – – – – 1500463 30 17.5 551 – – – – 1400463 30 17.5 551 – – – – 1300463 35 20.0 554 – – – – 1400529 30 17.5 617 – – – – 2000529 30 17.5 617 – – – – 2000624 30 22.5 717 – – – – 2400624 30 22.5 717 – – – – 2400719 35 22.5 812 – – – – 2900719 35 22.5 812 – – – – 2900719 35 22.5 812 – – – – 3200719 35 22.5 812 – – – – 32001297 35 22.5 812 1413 762 – 8571-80 50001297 35 22.5 812 1413 762 – 8571-80 50001297 35 22.5 812 1413 762 – 8571-80 56001297 35 22.5 812 1413 762 – 8571-80 56001473 40 30.0 932 1608 925 – 8564-92 108001473 40 30.0 932 1608 925 – 8564-92 108002218 40 30.0 932 2353 925 745 8564-92 / 8572-74 116002218 40 30.0 932 2353 925 745 8564-92 / 8572-74 116002313 40 35.0 1025 2453 925 745 8564-92 / 8572-74 13200Quantities in packs may vary.Technical informationT All DREMOMETERs of the types AM to E are alsoavailable with double square drive, ideal forcontrolled bi-directional tightening.T After being used, torque wrenches should wherepossible be turned back to the minimum scale value.T This helps to preserve the springs and ensures alonger product life cycle with high precision.265

753-12 - 8572-02DREMOMETERb cd ef gCode No. Type a " a N·m Inclusion 01957708 753-12 MINI 1/4 6.3 2-12 ' in plastic cassette 0.67674090 8554-02 s AM 1/4 6.3 6-30 ' in plastic cassette 0.97673790 8559-02 t AML 1/4 6.3 6-30 ' in plastic cassette 0.97682270 8560-02 s A 3/8 10.0 8-40 " in a sheet-metal case 2.27682350 8565-02 t AL 3/8 10.0 8-40 " in a sheet-metal case 2.27683830 8561-02 s B 1/2 12.5 20-120 " in a sheet-metal case 2.87684130 8566-02 t BL 1/2 12.5 20-120 " in a sheet-metal case 2.87683590 8573-02 s BC 1/2 12.5 40-200 " in a sheet-metal case 3.57683750 8578-02 t BCL 1/2 12.5 40-200 " in a sheet-metal case 3.57686340 8562-20 s C 1/2 12.5 50-300 " in a sheet-metal case 3.67686690 8567-20 t CL 1/2 12.5 50-300 " in a sheet-metal case 3.67689280 8570-20 s CD 3/4 20.0 80-360 " in a sheet-metal case 6.27689520 8575-20 t CDL 3/4 20.0 80-360 " in a sheet-metal case 6.21436112 8574-20 s DS 3/4 20.0 110-550 " in a sheet-metal case 6.71436120 8579-20 t DSL 3/4 20.0 110-550 " in a sheet-metal case 6.7Code No. Type a " a N·m Inclusion 07692070 8563-20 s D 3/4 20.0 140-760 " in a sheet-metal case 7.77692310 8568-20 t DL 3/4 20.0 140-760 " in a sheet-metal case 7.77670260 8563-02 s DR 3/4 20.0 140-760 " in a sheet-metal case 8.8with extension tube7670690 8568-02 t DRL 3/4 20.0 140-760 " in a sheet-metal case 8.8with extension tube7694520 8571-02 s DX 3/4 20.0 520-1000 " in a sheet-metal case 10.0with extension tube7694600 8576-02 t DXL 3/4 20.0 520-1000 " in a sheet-metal case 10.0with extension tube2311275 8581-02 s EK 1 25.0 600-1500 " in sheet-metal case 24.3with 1 extension tube2311305 8586-02 t EKL 1 25.0 600-1500 " in sheet-metal case 24.3with 1 extension tube7695680 8564-02 s E 1 25.0 750-2000 " in sheet-metal case 24.3with 2 extension tubes7695840 8569-02 t EL 1 25.0 750-2000 " in sheet-metal case 24.3with 2 extension tubes7717240 8572-02 s F 1.1/2 40.0 1500-3000 " in sheet-metal casewith 2 extension tubes24.0753-13 - 8572-03DREMOMETER SETS MMCode No. Type a " a N·m Inclusion 01957724 753-13 MINI 1/4 6.3 2-12 ( Set mm1.01 4 5 5,5 6 7 8 9 10; 1 2 3 ? 4 5.5 6.5 5 3 4 5 67 T20 T27 T30& 754-00 ' 55 + 97 mm20987674170 8554-03 s AM 1/4 6.3 6-30 # Set mm1.31 8 9 10 11 12 13 14; 3 ? 5.5 5 4 5 6 87 T20 T27 T30& 754-00 ' 55 + 97 mm7675060 8559-03 t AML 1/4 6.3 6-30 # Set mm1.31 8 9 10 11 12 13 14; 3 ? 5.5 5 4 5 6 87 T20 T27 T30& 754-00 ' 55 + 97 mm7682430 8560-03 s A 3/8 10.0 8-40 # Set mm3.11 8 10 11 13 14 15 17 195 4 5 6 8& 754-01 ' 125 + 250 mm7682940 8565-03 t AL 3/8 10.0 8-40 # Set mm3.11 8 10 11 13 14 15 17 195 4 5 6 8& 754-01 ' 125 + 250 mm7684480 8561-03 s B 1/2 12.5 20-120 # Set mm4.71 11 13 14 17 19 22 245 6 8 10 12& 754-02 ' 76 + 125 +250 mm7684640 8566-03 t BL 1/2 12.5 20-120 # Set mm4.71 11 13 14 17 19 22 245 6 8 10 12& 754-02 ' 76 + 125 +250 mm7683910 8573-03 s BC 1/2 12.5 40-200 # Set mm5.11 11 13 14 17 19 21 22 24 275 6 8 10 12& 754-02 ' 125 + 250 mm7684050 8578-03 t BCL 1/2 12.5 40-200 # Set mm5.11 11 13 14 17 19 21 22 24 275 6 8 10 12& 754-02 ' 125 + 250 mm7687070 8562-30 s C 1/2 12.5 50-300 # Set mm1 17 19 22 24 27 30 325 8 10 12 14& 754-02 ' 76 + 125 +250 mm6.0266b cd ef!Code No. Type a " a N·m Inclusion 07687310 8567-30 t CL 1/2 12.5 50-300 # Set mm6.01 17 19 22 24 27 30 325 8 10 12 14& 754-02 ' 76 + 125 +250 mm7689950 8570-30 s CD 3/4 20.0 80-360 # Set mm11.01 19 22 24 27 30 32& 754-04 ' 200 + 400 mm7690290 8575-30 t CDL 3/4 20.0 80-360 # Set mm11.01 19 22 24 27 30 32& 754-04 ' 200 + 400 mm7692660 8563-30 s D 3/4 20.0 140-760 # Set mm13.61 22 24 27 30 32 36 41 46& 754-04 ' 200 + 400 mm7692900 8568-30 t DL 3/4 20.0 140-760 # Set mm13.61 22 24 27 30 32 36 41 46& 754-04 ' 200 + 400 mm7670340 8563-03 s DR 3/4 20.0 140-760 # Set mm14.41 22 24 27 30 32 36 41 46& 754-04 ' 200 + 400 mm7670770 8568-03 t DRL 3/4 20.0 140-760 # Set mm14.41 22 24 27 30 32 36 41 46& 754-04 ' 200 + 400 mm7670930 8568-35 t DR-LKW3/4 20.0 140-760 # Set mm1 27 30 32& 754-04 ' 400 mm12.37694870 8571-03 s DX 3/4 20.0 520-10007694950 8576-03 t DXL 3/4 20.0 520-10002311283 8581-03 s EK 1 25.0 600-15002311313 8586-03 t EKL 1 25.0 600-15007696060 8564-03 s E 1 25.0 750-20007696140 8569-03 t EL 1 25.0 750-2000# Set mm1 30 32 36 41 46 50& 754-04 ' 200 + 400mmm# Set mm1 30 32 36 41 46 50& 754-04 ' 200 + 400 mm# Set mm2 36 41 46 50 55 60 65 70& 754-06 ' 200 + 400 mm# Set mm2 36 41 46 50 55 60 65 70& 754-06 ' 200 + 400 mm# Set mm2 36 41 46 50 55 60 65 70& 754-06 ' 200 + 400 mm# Set mm2 36 41 46 50 55 60 65 70& 754-06 ' 200 + 400 mm16.816.842.442.442.442.4Quantities in packs may vary.

753-14 - 8572-04DREMOMETER SETS INCHb cd e"Code No. Type a " a N·m Inclusion 01957732 753-14 MINI 1/4 6.3 2-12 ( Set INCH1.01 3/16 7/32 1/4 9/32 5/1611/32 3/8 7/16"; 1 2 3 ? 4 5.5 6.55 3 4 5 6 7 T20 T27 T30& 754-00 ' 55 + 97 mm20987674410 8554-04 s AM 1/4 6.3 6-30 # Set INCH1.31 9/32 5/16 11/32 3/8 7/161/2 9/16 ; 3 ? 5.55 4 5 6 8 7 T20 T27 T30& 754-00 ' 55 + 97 mm7675140 8559-04 t AML 1/4 6.3 6-30 # Set INCH1.31 9/32 5/16 11/32 3/8 7/161/2 9/16; 3 ? 5.5 5 4 5 6 87 T20 T27 T30& 754-00 ' 55 + 97 mm7683160 8560-04 s A 3/8 10.0 8-40 # Set INCH3.02 3/8 7/16 1/2 9/16 19/325/8 11/165 1/4 5/16 3/8& 754-01 ' 125 +250 mm7683240 8565-04 t AL 3/8 10.0 8-40 # Set INCH3.02 3/8 7/16 1/2 9/16 19/325/8 11/165 1/4 5/16 3/8& 754-01 ' 125 +250 mm7684990 8561-04 s B 1/2 12.5 20-120 # Set INCH5.32 7/16 1/2 9/16 19/32 5/811/163/4 25/32 13/16 7/815/16 1"5 5/16 3/8 1/2"& 754-02 ' 76 + 125 +250 mm7685100 8566-04 t BL 1/2 12.5 20-120 # Set INCH5.32 7/16 1/2 9/16 19/32 5/811/163/4 25/32 13/16 7/815/16 1"5 5/16 3/8 1/2"& 754-02 ' 76 + 125 +250 mm7684720 8573-04 s BC 1/2 12.5 40-200 # Set INCH4.92 1/2 9/16 5/8 11/16 3/413/16 7/8"5 5/16 3/8 1/2 9/16"& 754-02 ' 125 +250 mm7684210 8578-04 t BCL 1/2 12.5 40-200 # Set INCH2 1/2 9/16 5/8 11/16 3/413/16 7/8"5 5/16 3/8 1/2 9/16"& 754-02 ' 125 +250 mm4.9Code No. Type a " a N·m Inclusion 07687820 8562-40 s C 1/2 12.5 50-300 # Set INCH6.22 3/4 25/32 13/16 7/815/16 1" 1.1/16 1.1/8 1.1/4"5 3/8 1/2 9/16 5/8"& 754-02 ' 76 + 125+ 250 mm7688120 8567-40 t CL 1/2 12.5 50-300 # Set INCH6.22 3/4 25/32 13/16 7/815/16 1" 1.1/16 1.1/8 1.1/4"5 3/8 1/2 9/16 5/8"& 754-02 ' 76 + 125+ 250 mm7690530 8570-40 s CD 3/4 20.0 80-360 # Set INCH11.32 7/8 15/16 1" 1.1/8 1.1/41.3/8 1.1/2 1.5/8"& 754-04 ' 200 +400 mm7691180 8575-40 t CDL 3/4 20.0 80-360 # Set INCH11.32 7/8 15/16 1" 1.1/8 1.1/41.3/8 1.1/2 1.5/8"& 754-04 ' 200 +400 mm7693200 8563-40 s D 3/4 20.0 140-760 # Set INCH13.32 1" 1.1/8 1.1/4 1.5/161.3/8 1.7/16 1.1/2 1.5/81.3/4 1.13/16 1.7/8 2"& 754-04 ' 200 +400 mm7693550 8568-40 t DL 3/4 20.0 140-760 # Set INCH13.32 1" 1.1/8 1.1/4 1.5/161.3/8 1.7/16 1.1/2 1.5/81.3/4 1.13/16 1.7/8 2"& 754-04 ' 200 +400 mm7670420 8563-04 s DR 3/4 20.0 140-760 # Set INCH16.72 1" 1.1/8 1.1/4 1.5/161.3/8 1.7/16 1.1/2 1.5/81.3/4 1.13/16 1.7/8 2"& 754-04 ' 200 +400 mm7670850 8568-04 t DRL 3/4 20.0 140-760 # Set INCH16.72 1" 1.1/8 1.1/4 1.5/161.3/8 1.7/161.1/2 1.5/8 1.3/4 1.13/161.7/8 2"& 754-04 ' 200 +400 mm7695170 8571-04 s DX 3/4 20.0 520-1000# Set INCH2 1.1/8 1.1/4 1.3/8 1.1/21.3/4 1.7/8"& 754-04 ' 200 +400 mm16.07695330 8576-04 t DXL 3/4 20.0 520-1000# Set INCH2 1.1/8 1.1/4 1.3/8 1.1/21.3/4 1.7/8"& 754-04 ' 200 +400 mm16.0DVV-40ZRS329Quantities in packs may vary.267

ACCESSORIES DREMOMETER754RATCHET HEAD DREMOMETERUse:T Enables controlled torque tightening in combination with a DREMOMETERtorque wrench (Type MINI - E)Features:T Fine-pitched, sturdy ratchet headT With 1/4", 3/8", 1/2", 3/4" or 1" output square driveT Clockwise models (no. 754-00 to -06)T Counter-clockwise models (no. 754-11 to -16)T Made of chrome-vanadium steelScope of delivery:T Ratchet headT Single packed in poly-bagbcdefCode No. Q " a " H , A° Use Execution /7680490 754-00 1/4 1/4 21 24 18,0 MINI, AM clockwise 547680570 754-01 3/8 3/8 28 35 20,0 A clockwise 1507680650 754-02 1/2 1/2 35 46 7,5 B, BC, C clockwise 3507680730 754-04 3/4 3/4 53 65 10,0 CD, DS, D, clockwise 1000DR, DX7680810 754-06 1 1 63 73 10,0 E / EK clockwise 25007686770 754-11 3/8 3/8 28 35 20,0 AL counterclockwise1507686850 754-12 1/2 1/2 35 46 7,5 BL, BCL, CL counterclockwise3507686930 754-14 3/4 3/4 53 65 10,0 CDL, DSL, DL, counterclockwise1000DRL, DXL7687150 754-16 1 1 63 73 10,0 EL / EKL counterclockwise1800EXTENSION TUBES FOR DREMOMETER DR - F + WUse:T Spare extension tube for torque wrench series DREMOMETER DR - F and DXZT To enable high torque values by means of extending the lever armFeatures:T Guarantees proof connection to the DREMOMETERT Ideal for extending the lever armT Extension tubes 8572-74 / 8564-92 / 8564-40 made from high-grade, galvanised steelT Extension tube 8571-80 made from high-grade aluminium with anodised locknuts -extremely lightweightScope of delivery:T Extension tubeT Single packed in poly-bagRatchet heads DREMOMETER 754T Ratchet head no. 754 can only be used in combinationwith the DREMOMETER (*). Please note the right directionof rotation by the ratchet head when ordering. There areseparate models for clockwise or counter-clockwise rotation.Ratchet head nos. 754-11 to 754-16 (counter-clockwise) canonly be used with the DREMOMETER with double square drive.(*) not applicable to DREMOMETER 8573-10 BCK withintegrated ratchet8564-4030 D 301928571-80Code No. Description y 07621640 8564-40 Extension tube for DREMOMETER E 400 2.37622020 8572-74 Extension tube for DREMOMETER E/F 745 3.61686313 8571-80 Extension tube ALU for DREMOMETER DX/DR 762 0.87621720 8564-92 Extension tube for DREMOMETER E/EK/F 925 3.4268Quantities in packs may vary.

DREMOMETER MINI / T-FS753TORQUE WRENCH DREMOMETER MINI 2-12 N·m / 18-106 lbf·inUse:T Controlled screw tightening in the range 2 - 12 N·mT For use in almost all industrial manufacturing areasFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Working accuracy:+/- 3% tolerance of scale set torque. The specification of the standard (+/- 4%) is exceeded.T Torque wrench with 1/4" square drive with ball locking device DIN 3120 - A 6.3, similar toISO 1174, for controlled clockwise tighteningT Automatic short-path actuation with tactile impulse and audible signalT Lightweight plastic casing, made from high-grade, glass-fibre reinforced polyamide,with soft-grip handleT Dual scale with a scale graduation of 0.5 N·m and 5 lbf·inT Additional micrometer scale for setting interim values with N·m, graduations of 0.05 N·mT Window with a magnifying-glass effectT Locking button enables reliable locking of the torque settingScope of delivery:T Torque wrench type MINIT With certificate acc. to DIN EN ISO 6789:2003, traceable via in-house DKD laboratoryto national standardsb&ß¿Code No. Type a " a N·m lbf·in 9 lw a b c /1957694 753-11 MINI 1/4 6.3 2-12 18-106 0,5 N·m / 5 lbf·in + 0,05 N·m 130 28 14 211 320763TORQUE WRENCH DREMOMETER T-FS pre-set, 1-14 N·mUse:T Power-saving application for torques which are usually in the range of torque screwdriversT E.g. securing modules on solar power systems, tool supports etc.; wherever the torquesare too large for classic torque screwdriversFeatures:T Torque wrench series with 14 pre-set models for serial productionT For controlled clockwise tighteningT Working accuracy in accordance with DIN EN ISO 6789:2003 Type II Class E (+/- 6 %)T Lightweight and robust - housing made of a high-quality aluminium alloyT With certificate acc. to DIN EN ISO 6789:2003, traceable via in-houseDKD laboratory to national standardsbT Special ranges are available on request&ß¿Code No. a " a pre-set value /1947907 763-01 1/4 6.3 1 N·m 2411947915 763-02 1/4 6.3 2 N·m 2411947923 763-03 1/4 6.3 3 N·m 2411947931 763-04 1/4 6.3 4 N·m 2411947958 763-05 1/4 6.3 5 N·m 2411947966 763-06 1/4 6.3 6 N·m 2411947974 763-07 1/4 6.3 7 N·m 241Quantities in packs may vary.Code No. a " a pre-set value /1947990 763-08 1/4 6.3 8 N·m 2411948008 763-09 1/4 6.3 9 N·m 2411948016 763-10 1/4 6.3 10 N·m 2411948024 763-11 1/4 6.3 11 N·m 2411948032 763-12 1/4 6.3 12 N·m 2411948040 763-13 1/4 6.3 13 N·m 2411948059 763-14 1/4 6.3 14 N·m 241269

DREMOMETER Z8460 Z - 8471 ZTORQUE WRENCH DREMOMETER Z WITH QUICK-FITTING CHANGE 8-1000 N·m / 70 lbf·in - 730 lbf·ftT Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Working accuracy: +/- 3 % tolerance of scale set torque.The specification of the standard (+/- 4 %) is exceeded.T Lightweight yet robust (as the housing is made of an aluminium alloy) and resilient, very workshop-friendlyT Depending on the application, access is possible from the front (e.g. open-end fitting) or side (e.g. reversible ratchet and socket)T Force to be applied in the middle of the handgrip only - do not use an extension tube as otherwise, inaccuracies can evolve(except for model DXZ where the DREMOMETER has been calibrated and adjusted using the extension tube)T Operation only with end fittings with standardised depth gauges, otherise inaccuracies can arise. Keep the depth gauges onthe certificate in mind. Only use original GEDORE accessories.T Large drive cross-section transfers maximum torquesT Extremely low wear attributable to reduced forces in the lever mechanismT Forged lever chain from our own quality forgeT Maximum precision even when subjected to extreme continuous useT Long life cycles and tool livesT Easy operation - fast and safe torque tighteningT Easy adjustment thanks to attractive adjusting button secured against loss at the end of the handleT With certificate acc. to DIN EN ISO 6789, traceable via in-house DKD laboratory to national standardsjkY&ß¿9Code No. Type Ø N·m lbf·in lbf·ft 9 lwZ lcZ a b c d /7703610 8460-01 AZ 16 8-40 70-350 – 5 N·m / 50 lbf·in 301 32 35 38 17 366 10007704260 8461-01 BZ 16 20-120 – 15-90 5 N·m / 5 lbf·ft 412 32 35 38 17 490 14507704340 8462-01 CZ 16 50-400 – 35-300 5 N·m / 5 lbf·ft 567 32 35 38 17 645 20007703020 8463-10 DZ 22 140-620 – 105-450 10 N·m / 10 lbf·ft 768 56 45 49 18 846 30001251341 8471-01 DXZ 28 520-1000 – 380-730 10 N·m / 10 lbf·ft 1231 75 45 57 18 1329 5500Technical information ZT The large cross-section of the spigot end transfers a maximum torque. "Quick-fittingchange-system"with a locking pin mechanism guarantees that work takes place flexiblyand rapidly.T Ideal for bolted connections in cramped and hard-to-access locations. Depending on howthe torque wrench Z is used, it is possible to work both in the forward direction and alsoto the side. For anti-clockwise tightening, simply turn the torque wrench through 180°OUR SERVICE -qualified and customisedDKD312 -3197460 - 74712738791 - 8798jkY304 -307A+S270Quantities in packs may vary.

DREMOMETER SE8480 SE - 8482 SETORQUE WRENCH DREMOMETER SE WITH QUICK-FITTING CHANGE 8-400 N·m / 70 lbf·in - 300 lbf·ftT Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Working accuracy: +/- 3% tolerance of scale set torque.The specification of the standard (+/- 4%) is exceeded.T Lightweight yet robust (as the housing is made of an aluminium alloy) and resilient, very workshop-friendlyT Drive offers extensive range of accessoriesT Depending on the application, access is possible from the front (e.g. rectangular open-end fitting) or side (e.g. reversible ratchet and socket)T Force to be applied in the middle of the handgrip only - do not use an extension tube as otherwise, inaccuracies can ariseT Operation only with end fittings otherwise inaccuracies can arise. Keep the depth gauges on the certificate in mind. Only use original GEDORE accessories.T Extremely low wear attributable to reduced forces in the lever mechanismT Forged lever chain from our own quality forgeT Maximum precision even when subjected to extreme continuous useT Long life cycles and tool livesT Easy operation - fast and safe torque tighteningT Easy adjustment thanks to attractive adjusting button secured against loss at the end of the handleT With certificate acc. to DIN EN ISO 6789, traceable via in-house DKD laboratory to national standards}~&ß¿9Code No. Type : N·m lbf·in lbf·ft 9 lwSE lcSE a b c d /7714060 8480-01 A-SE 9 x 12 8-40 70-350 – 5 N·m / 50 lbf·in 303 17.5 35 40 17 361 9507714140 8481-01 B-SE 9 x 12 20-120 – 15-90 5 N·m / 5 lbf·ft 414 17.5 35 40 17 485 12507714220 8482-01 C-SE 14 x 18 50-400 – 35-300 5 N·m / 5 lbf·ft 582 25.0 35 53 17 653 1700Technical information - Quick-fitting changeQuick-fitting tool change system with pin locking guarantees flexibleand swift working methods. Ideal for installations in confined andpoorly accessible spaces. Depending on the application for theDREMOMETER SE, access is possible from the front and side.T On request, all torque wrenches can be factory pre-set.T When ordering, please specify the N·m value.T Pre-setting net P.O.A.7480 - 74827112 - 7918273308 -309A+SQuantities in packs may vary.271

DREMOMETER A+S7554 AM - 7572 FTORQUE WRENCH DREMOMETER A+S with pre-set value locking and safety deviceTechnical advantage/function:T Pre-set value locking and safety device (A+S) eliminates the possibility of unintentional or manipulated adjustment,thereby representing more process reliability of the userT Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Working accuracy: +/- 3 % tolerance of scale set torque.The specification of the standard (+/- 4 %) is exceeded.T Lightweight and robust (as housing is made of an aluminium alloy), very workshop-friendlyT No inaccuracies whether used with both hands or held away from the handle (as for standard torque wrenches) Both the square driveand fulcrum are on an axis which ensures a high degree of user safety; can be extended to reduce the user's working load.T Extremely low wear attributable to reduced forces in a unique lever mechanismT Forged lever chain from our own quality forgeT Maximum precision even when subjected to extreme continuous useT Long life cycles and tool livesT Easy operation - fast and safe torque tighteningT Single- and double-square drive for controlled bi-directional tighteningUse:T Controlled screw tightening in the range 6 - 3000 N·mT For use in almost all industrial manufacturing areasFeatures:T With certificate acc. to DIN EN ISO 6789, traceable via in-house DKD laboratory to national standardsT Automatic short-path actuation with tactile impulse and audible signalT Dual scale with corresponding scale graduation (see table)T Type B, BC, C with push-button releasebcdefgPre-set DREMOMETER forserial production wherever thesame value always needs to beappliedA+S&ß¿9Type B/BCCode No. Type a " a N·m lbf·in lbf·ft 9 lw a b c d e f /1210891 7554-01 s AM A+S 1/4 6.3 6-30 50-270 – 1 N·m / 10 lbf·in 207 30 15.0 268 – – – 5801210904 7559-01 t AML A+S 1/4 6.3 6-30 50-270 – 1 N·m / 10 lbf·in 207 30 15.0 268 – – – 5807708920 7560-01 s A A+S 3/8 10.0 8-40 70-350 – 5 N·m / 50 lbf·in 263 30 17.5 338 – – – 10001210939 7565-01 t AL A+S 3/8 10.0 8-40 70-350 – 5 N·m / 50 lbf·in 263 30 17.5 338 – – – 10007709060 7561-01 s B A+S 1/2 12.5 20-120 – 15-90 5 N·m / 5 lbf·ft 374 30 17.5 462 – – – 15001210947 7566-01 t BL A+S 1/2 12.5 20-120 – 15-90 5 N·m / 5 lbf·ft 374 30 17.5 462 – – – 15001211013 7573-00 s BC A+S 1/2 12.5 40-200 – 30-150 5 N·m / 5 lbf·ft 463 30 17.5 551 – – – 14001427113 7578-00 t BCL A+S 1/2 12.5 40-200 – 30-150 5 N·m / 5 lbf·ft 463 30 17.5 551 – – – 13007709650 7562-10 s C A+S 1/2 12.5 50-300 – 35-220 5 N·m / 5 lbf·ft 529 30 17.5 617 – – – 20001210955 7567-10 t CL A+S 1/2 12.5 50-300 – 35-220 5 N·m / 5 lbf·ft 529 30 17.5 617 – – – 20001210998 7570-10 s CD A+S 3/4 20.0 80-360 – 60-260 5 N·m / 5 lbf·ft 624 30 22.5 717 – – – 24001211021 7575-10 t CDL A+S 3/4 20.0 80-360 – 60-260 5 N·m / 5 lbf·ft 624 30 22.5 717 – – – 24001427164 7574-10 s DS A+S 3/4 20.0 110-550 – 80-400 10 N·m / 10 lbf·ft 719 35 22.5 812 – – – 29001427148 7579-10 t DSL A+S 3/4 20.0 110-550 – 80-400 10 N·m / 10 lbf·ft 719 35 22.5 812 – – – 29001210921 7563-10 s D A+S 3/4 20.0 140-760 – 100-560 10 N·m / 10 lbf·ft 719 35 22.5 812 – – – 32001210971 7568-10 t DL A+S 3/4 20.0 140-760 – 100-560 10 N·m / 10 lbf·ft 719 35 22.5 812 – – – 32001210912 7563-01 s DR A+S 3/4 20.0 140-760 – 100-560 10 N·m / 10 lbf·ft 1297 35 22.5 812 1413 762 – 50001210963 7568-01 t DRL A+S 3/4 20.0 140-760 – 100-560 10 N·m / 10 lbf·ft 1297 35 22.5 812 1413 762 – 50001211005 7571-01 s DX A+S 3/4 20.0 520-1000 – 380-730 10 N·m / 10 lbf·ft 1297 35 22.5 812 1413 762 – 56001211048 7576-01 t DXL A+S 3/4 20.0 520-1000 – 380-730 10 N·m / 10 lbf·ft 1297 35 22.5 812 1413 762 – 56002311321 7581-01 s EK A+S 1 25.0 600-1500 – – 25 N·m 1473 40 30.0 932 1608 925 – 108002311348 7586-01 t EKL A+S 1 25.0 600-1500 – – 25 N·m 1473 40 30.0 932 1608 925 – 108001547232 7564-01 s E A+S 1 25.0 750-2000 – – 50 N·m 2218 40 30.0 932 2353 925 745 116001547240 7569-01 t EL A+S 1 25.0 750-2000 – – 50 N·m 2218 40 30.0 932 2353 925 745 116001547259 7572-01 s F A+S 1.1/2 40.0 1500-3000 – – 50 N·m 2313 40 35.0 1025 2453 925 745 13200272Quantities in packs may vary.

7460 Z - 7471 ZTORQUE WRENCH DREMOMETER Z A+SPre-set DREMOMETER forserial production whereverthe same value always needsto be appliedA+SjkY&ß¿9Code No. Type Ø N·m lbf·in lbf·ft 9 lwZ lcZ a b c d /1427067 7460-01 AZ A+S 16 8-40 70-350 – 5 N·m / 50 lbf·in 301 32 35 38 17 355 10001427075 7461-01 BZ A+S 16 20-120 – 15-90 5 N·m / 5 lbf·ft 412 32 35 38 17 479 14501225669 7462-01 CZ A+S 16 50-400 – 35-300 5 N·m / 5 lbf·ft 567 32 35 38 17 634 20001427083 7463-10 DZ A+S 22 140-620 – 105-450 10 N·m / 10 lbf·ft 768 56 45 49 18 835 30001521977 7471-01 DXZ A+S 28 520-1000 – 380-730 10 N·m / 10 lbf·ft 1231 75 45 57 18 1329 55007480 SE - 7482 SETORQUE WRENCH DREMOMETER SE A+SPre-set DREMOMETER forserial production whereverthe same value always needsto be appliedA+S}~&ß¿9Code No. Type : N·m lbf·in lbf·ft 9 lwSE lcSE a b c d /1427059 7480-01 A-SE A+S 9 x 12 8-40 70-350 – 5 N·m / 50 lbf·in 303 17.5 35 40 17 350 9501427091 7481-01 B-SE A+S 9 x 12 20-120 – 15-90 5 N·m / 5 lbf·ft 414 17.5 35 40 17 474 12501427105 7482-01 C-SE A+S 14 x 18 50-400 – 35-300 5 N·m / 5 lbf·ft 582 25.0 35 53 17 641 17008791 - 8798jkY304 -3077112 - 7918308 -309Quantities in packs may vary.273

DREMASTER DMKRobust torque wrench with square drive and integrated ratchet-headfunction for controlled bi-directional tightening and interchangeablemushroom head with push-button release9Chrome-plated ratchet head: All 1/2" squaredrives of the DREMASTER DMK-series havea black plastic cap - also referred to as amushroom head. This mushroom headprevents an unintentional pulling out of thewhole square drive when changing the nutsocket.&Classified to DIN EN ISO 6789:2003 Type II Class A,with a factory certificate allowing for operationsto be traced back. Calibrated to a permitted +/- 3% deviation and better. The specifications of thestandard (+/- 4 %) are exceeded.Robust steel tube: With highcorrosion protection, chromeplated,silk-metal.ß¿Automatic actuation: TheDREMASTER DMK actuates with aclear tactile impulse and audiblesignal and is immediately ready foroperation again.Features Anti-loss attachmentFunctionIn order to change the turningdirection of the DREMASTER DMK:T Press on the push-button withyour thumb and take out themushroom head, turn the wrenchand re-insert the square drive.All the benefits at a single glanceT Additional protection of the serial numberT Concealed setting drill holeT Engaging adjusting button with locking reference(lock symbol)T Rapid adjustment provision using a separate hexagon allen keyT Mushroom head with release button and soft componentT Plastic grip with soft componentT Dual scale (main unit with vernier)T At all times only one unit in the viewing area (N·m or lbf·ft)T Change-over switch for selecting the unitT Controlled safety via in-house DKD-/DAkkS test laboratory274

Nonius: Model-dependent intervals of1 or 0.5 N·m allow very accurate settings.Additional protection of the serial number. Concealedsetting drill hole = secured adjusting/setting systemSerial number on the wrench and on the certificate forunambiguous product identification, traceable via inhouseDKD-/DAkkS laboratory to national standardsHandgrip with a user aid: Grey plastichandgrip, new ergonomically enhancedshape, with an indentation in themiddle of the handgrip.User aid and reference points forcalibration.9Dual scale with main and alternativeunit (N·m/Ibf·ft).Main unit N·m with vernier.At all times only one unit in the viewingarea = avoids any reading errors.Change-over switch next to the scale forstraightforward unit selection.Ligthweight and reliable: Lockingbutton enables reliable locking of thetorque setting."Torque adjustable" reference bymeans of opened lock symbol.Provision for rapid setting from theseparate hexagon allen key fixture.DREMASTER DMUKTorque wrench with square drive and integrated ratchet-function for controlledclockwise tighteningFeaturesWith 1/2" square drive andintegrated lever-change reversibleratchet function for controlledclockwise tightening2Robust tubular steel: with highcorrosion protection, satin chromeplated,chrome-plated ratchetOperationFor the DREMASTER DMUK:Switch the lever of the reversibleratchet to correspond with thedesired direction, clockwise orcounter-clockwise.281DMK d - e20-850 N·mDMUK d20-300 N·mDMZ j k20-850 N·mDMSE } ~20-400 N·mTORCOFIX b - c1 - 50 N·m275

DMK - DMUKTORQUE WRENCH DREMASTER K / UK 20-850 N·m / 15 - 630 lbf·ftUse:T Controlled screw tightening in the most common range of 20 - 850 N·m / 15 - 630 lbf·ft (guide for screws M7-10.9 to M24-8.8, M30-5.6)T Adjustable, releasing and sturdy tubular torque wrench with integrated ratchet and with square drive for industry and the tradesFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate allowing for operations to be traced back.Calibrated to a permitted +/- 3 % deviation and better. The specifications of the standard (+/- 4 %) are exceeded.T For controlled bi-directional tightening DMUK only for controlled clockwise-tighteningT Models DMK: 1/2" mushroom head interchangeable square with push-button releasing and a ball-locking mechanism.From Model No. DMK 400 with 3/4" push-through square and a pin-locking mechanismT Models DMUK: With 1/2" reversible ratchetT Sturdy, satin chrome-plated tubular steel construction, with chrome-plated ratchet head and top-grade plastic partsT Ergonomically shaped, 2-component plastic grip with calibration aidT Change-over between N·m main scale and lbf·ft ancillary scale to avoid reading errors when setting the torque wantedT With micrometre scale for main N·m scale for setting interim valuesT Release system triggers a tactile and audible signalT Ergonomic system for torque adjustment with reference symbolT Fast adjustment provisionT Secured adjusting/setting systemTPatent applieddeDMK 200&ß¿9Code No. a " a N·m lbf·ft 9 scale ring L lw c h b /2641232 DMK 100 1/2 12.5 20-100 15-75 5 N·m 0,5 N·m 423.5 329.2 35 38.4 44 11002641240 DMK 200 1/2 12.5 40-200 30-150 10 N·m 1 N·m 514.5 420.2 35 38.4 44 13002641259 DMK 300 1/2 12.5 60-300 45-220 10 N·m 1 N·m 606.5 511.2 35 38.4 46 15002641267 DMK 400 3/4 20.0 80-400 60-300 10 N·m 1 N·m 715.5 609.2 46 31.0 67 24002641275 DMK 550 3/4 20.0 110-550 80-405 10 N·m 1 N·m 953.5 846.7 52 31.0 69 38002641283 DMK 750 3/4 20.0 150-750 110-550 10 N·m 1 N·m 1,228.5 1,121.7 327 31.0 69 49002641291 DMK 850 3/4 20.0 250-850 185-630 10 N·m 1 N·m 1,375.5 1,268.7 474 31.0 69 5200dDMUK 200hbclwl&ß¿Code No. a " a N·m lbf·ft 9 scale ring L lw c h b /2641305 DMUK 100 1/2 12.5 20-100 15-75 5 N·m 0,5 N·m 438.0 344.2 50 22.0 43 12002641313 DMUK 200 1/2 12.5 40-200 30-150 10 N·m 1 N·m 529.0 435.2 50 22.0 43 14002641348 DMUK 300 1/2 12.5 60-300 45-220 10 N·m 1 N·m 620.0 526.2 50 22.0 43 1600276Quantities in packs may vary.

GDMKTORQUE WRENCH SET DREMASTER KT The DREMASTER DMK as a practical tool setT Most-widely-used tools in a robust sheet-metal caseT Clearly organised - everything always ready to handT With foam-material inlay modules (on request, these can be customised or extended individually)deCode No. a " a N·m lbf·ft Contents 02641593 GDMK 100 1/2 12.5 20-100 15-75 " No. DMK 100 in sheet-metal case4.51 10 13 17 19 24 ' 125 mm and 1/2" square drive2641607 GDMK 200 1/2 12.5 40-200 30-150 " No. DMK 200 in sheet-metal case5.71 10 13 17 19 24 ' 125 mm and 1/2" square drive2641615 GDMK 300 1/2 12.5 60-300 45-220 " No. DMK 300 in sheet-metal case5.81 17 19 24 27 ' 125 mm and 1/2" square drive2641623 GDMK 400 3/4 20.0 80-400 60-300 " No. DMK 400 in sheet-metal case1 18 19 24 27 ' 200 mm and 3/4" square drive6.5&ß¿9DMKPKMUSHROOM HEAD / SQUARE DRIVEdeCode No. Description Q " Q a " a /2551829 DMKPK 7 Mushroom head 1/2" 1/2 12.5 1/2 12.56279090 3294 Coupler 3/4" 3/4 20.0 3/4 20.0 1339204549541c281bQuantities in packs may vary.277

DMZTORQUE WRENCH DREMASTER Z 20-850 N·m / 15-630 lbf·ftUse:T Controlled screw tightening in the most common range of 20 - 850 N·m / 15 - 630 lbf·ft (guide for screws M7-10.9 to M24-8.8, M30-5.6)T Adjustable, releasing and sturdy tubular torque wrench with spigot end for industry and the tradesFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate allowing for operations to be traced back.Calibrated to a permitted +/- 3 % deviation and better. The specifications of the standard (+/- 4 %) are exceeded.T For controlled bi-directional tighteningT Sturdy, satin chrome-plated tubular steel construction, with phosphated spigot end (16 mm or 22 mm) and high-grade plastic partsT Ergonomically shaped, 2-component plastic grip with calibration aidT Change-over between N·m main scale and lbf·ft ancillary scale to avoid reading errors when setting the torque wanted.T With micrometre scale for main N·m scale for setting interim valuesT Release system triggers a tactile and audible signalT Ergonomic system for torque adjustment with reference symbolT Fast adjustment provisionT Secured adjusting/setting systemT Factory depth gauge: 32 mm (16 mm) or 56 mm (22 mm)T Operation only with end fittings with standardised depth gauge - otherwise inaccuracies may arise.T Depending on the application, access is possible from the front (e.g. open-end fitting) or side (e.g. reversible ratchet and socket)TPatent appliedjk&ß¿9Code No. Ø N·m lbf·ft 9 scale ring L lwZ lcZ b c /2641518 DMZ 100 16 20-100 15-75 5 N·m 0,5 N·m 405.5 326.2 32 27.5 32 9002641526 DMZ 200 16 40-200 30-150 10 N·m 1 N·m 496.5 417.2 32 27.5 32 11002641534 DMZ 300 16 60-300 45-220 10 N·m 1 N·m 587.5 508.2 32 27.5 32 13002641542 DMZ 400 16 80-400 60-300 10 N·m 1 N·m 677.5 598.2 32 33.0 32 22002641550 DMZ 550 22 110-550 80-405 10 N·m 1 N·m 913.0 840.7 56 36.5 37 36002641569 DMZ 750 22 150-750 110-550 10 N·m 1 N·m 1,194.0 1,121.7 56 38.5 318 47002641577 DMZ 850 22 250-850 185-630 10 N·m 1 N·m 1,341.0 1,268.7 56 38.5 465 5000GDMZTORQUE WRENCH SET DREMASTER ZT The DREMASTER DMZ as a practical tool setT Most-widely-used tools in a robust sheet-metal caseT Clearly organised - everything always ready to handT With foam-material inlay modules (on request, these can be customised or extended individually)jk& ß¿ 9Code No. Ø N·m lbf·ft Contents 02641704 GDMZ 100 16 20-100 15-75 " No. DMZ 100 in sheet-metal case4.51 17 19 24 4 17 19 24 and 1/2" ratchet head2641712 GDMZ 200 16 40-200 30-150 " No. DMZ 200 in sheet-metal case5.81 17 19 24 4 17 19 24 and 1/2" ratchet head2641720 GDMZ 300 16 60-300 45-220 " No. DMZ 300 in sheet-metal case6.51 24 27 30 32 4 24 27 and 1/2" ratchet head2641739 GDMZ 400 16 80-400 60-300 " No. DMZ 400 in sheet-metal case7.41 24 27 30 32 4 24 27 and 1/2" ratchet head278Quantities in packs may vary.

DMSETorque wrench DREMASTER SE 20-400 N·m / 15-300 lbf·ftUse:TTControlled screw tightening in the most common range of 20 - 400 N·m / 15 - 300 lbf·ft (guide for screws M7-10.9 to M20-6.9)TTAdjustable, releasing and sturdy tubular torque wrench with rectangular cavity for industry and the tradesFeatures:TTClassified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate allowing for operations to be traced back.Calibrated to a permitted +/- 3 % deviation and better. The specifications of the standard (+/- 4 %) are exceeded.TTFor controlled bi-directional tighteningTTSturdy, satin chrome-plated tubular steel construction, with chrome-plated rectangular cavity (9x12 mm or 14x18mm)and high-grade plastic partsTTErgonomically shaped, 2-component plastic grip with calibration aidTTChange-over between N·m main scale and lbf·ft ancillary scale to avoid reading errors when setting the torque wanted.TTWith micrometre scale for main N·m scale for setting interim valuesTTRelease system triggers a tactile and audible signalTTErgonomic system for torque adjustment with reference symbolTTFast adjustment provisionTTSecured adjusting/setting systemTTFactory depth gauge: 17.5 mm (9x12 mm) or 25 mm (14x18 mm)TTOperation only with end fittings with standardised depth gauges, otherwise inaccuracies can ariseTTDepending on the application, access is possible from the front (e.g. open-end fitting) or side (e.g. reversible ratchet and socket).TTPatent applied}~&ß¿9Code No. : N·m lbf·ft 9 scale ring L lwSE lcSE b c /2641445 DMSE 100 9 x 12 20-100 15-75 5 N·m 0,5 N·m 398.5 326.2 17.5 27.5 32 8002641453 DMSE 150 9 x 12 30-150 22-110 10 N·m 1 N·m 489.5 417.2 17.5 27.5 32 10002641461 DMSE 200 14 x 18 40-200 30-150 10 N·m 1 N·m 499.5 427.2 25.0 27.5 42 11002641488 DMSE 300 14 x 18 60-300 45-220 10 N·m 1 N·m 590.5 518.2 25.0 27.5 42 13002641496 DMSE 400 14 x 18 80-400 60-300 10 N·m 1 N·m 677.5 605.2 25.0 33.0 42 2000GDMSETorque wrench set DREMASTER SETTThe DREMASTER DMSE as a practical tool setTTMost-widely-used tools in a robust sheet-metal caseTTClearly organised - everything always ready to handTTWith foam-material inlay modules (on request, these can becustomised or extended individually)}~& ß¿ 9Code No. : N·m lbf·ft Contents 02641658 GDMSE 100 9 x 12 20-100 15-75 " No. DMSE 100 in sheet-metal case3.91 13 17 19 4 13 17 19 and 1/2" ratchet head2643731 GDMSE 150 9 x 12 30-150 22-110 " No. DMSE 150 in sheet-metal case5.61 13 17 19 4 13 17 19 and 1/2" ratchet head2641666 GDMSE 200 14 x 18 40-200 30-150 " No. DMSE 200 in sheet-metal case6.31 17 19 24 4 17 19 24 and 1/2" ratchet head2641674 GDMSE 300 14 x 18 60-300 45-220 " No. DMSE 300 in sheet-metal case6.51 24 30 32 4 24 30 32 36 and 1/2" ratchet head2641690 GDMSE 400 14 x 18 80-400 60-300 " No. DMSE 400 in sheet-metal case7.01 24 30 32 4 24 30 32 36 and 1/2" ratchet headQuantities in packs may vary.279

TORCOFIX K / K USRobust torque wrench with square drive and integrated ratchet-headfunction for controlled bi-directional tightening.Micrometer scale: Optimised shape,stable scale frame with red-shadedmicrometer scale ring.Model-dependent intervals of 0.25; 0.1 or0.025 N·m allow very accurate settings.&9Working accuracy: +/- 3 % tolerance of scale Scale: Easily readable dual scale (N·m / lbf·in /set torque. Includes test certificate according lbf·ft) well protected under a window withto DIN EN ISO 6789.a magnifying-glass effect.Serial number on the wrench and onThe torque setting is readable on the scale or,the certificate for unambiguous productmore particularly, on the scale in combinationidentification, traceable to nationalwith the scale ring.standards.Ligthweight and reliable: Lockingbutton enables reliable locking of thetorque setting.9Chrome-plated ratchet head: All 1/4" -3/8" square drives of the TOROFIX K-serieshave a black plastic cap - also referred toas a mushroom head.This mushroom head prevents anunintentional pulling out of the wholesquare drive when changing the nutsocket.ß¿Automatic actuation: TheTORCOFIX actuates with a cleartactile impulse and audiblesignal and is immediately readyfor operation again.Robust steel tube: Withhigh corrosion protection,chrome-plated, silk-metal.Handgrip with a user aid:Black plastic handgrip, newergonomically enhanced shape,with an indentation in the middleof the handgrip.User aid and reference points forcalibration.K b - c1 - 50 N·m280K US b - e10 Ibf·in - 600 Ibf·ftZ j2 - 50 N·mSE }2 - 50 N·m

TORCOFIX K4549TORQUE WRENCH TORCOFIX K 1-50 N·m / 0.75-37 lbf·ftUse:T Controlled screw tightening in the most widely used range of 1 - 50 N·m / 0.75 - 37 lbf·ftT For use in almost all industrial manufacturing areasFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Working accuracy: +/- 3 % tolerance ofscale set torque. The specification of the standard (+/- 4 %) is exceeded.T Adjustable torque wrench with square drive and integrated ratchet function for controlled bi-directional tighteningT 1/4", 3/8" interchangeable mushroom head with ball locking device as per DIN 3120 - A 6.3 or A 10, similar toISO 1174T With certificate acc. to DIN EN ISO 6789, traceable via in-house DKD laboratory to national standardsT Release system triggers a tactile and audible signalT Sturdy, satin chrome-plated tubular steel design, with chrome-plated ratchet head and high-quality plastic partsT Dual scale N·m and lbf·ft below a window with a magnifying glass effectT Magnifying glass with marking for minimum paralaxe errors allows a high degree of safety when setting therequisite torque valueT Additional micrometre scale for setting interim valuesT Ergonomically shaped, convenient black plastic handgrip, with an indentation in the middle as a calibration aidbc&ß¿9Code No. a " a N·m lbf·ft 9 scale ring lw a b c d /2201429 4549-00 1/4 6.3 1-5 0,75-3,7 0,25 N·m 0,025 N·m 146.0 25.3 35 26 224.0 3231545132 4549-02 1/4 6.3 2-25 1,5-18 1 N·m 0,1 N·m 206.5 24.0 35 26 284.5 4501545140 4549-05 3/8 10.0 5-50 3,5-37 2,5 N·m 0,25 N·m 256.5 24.0 35 26 334.5 5404549-GTORQUE WRENCH SET TORCOFIX K 1-50 N·m / 0.75-37 lbf·ftT The TORCOFIX K as a practical tool setT Most-widely-used tools in a robust sheet-metal caseT Clearly organised - everything always ready to handT With foam-material inlay modules (on request, these can be customised or extended individually)bc&¿ß9Code No. a " a Contents N·m lbf·ft 9 02312646 4549-G00 1/4 6.3 " No. 4549-00 - in sheet-metal case1-5 0,75-3,7 0,25 N·m 3.01 7 8 10 13 ' 55 mmand 1/4" square drive1547003 4549-G02 1/4 6.3 " No. 4549-02 - in sheet-metal case2-25 1,5-18 1 N·m 3.21 7 8 10 13 ' 55 mmand 1/4" square drive1547011 4549-G05 3/8 10.0 " No. 4549-05 - in sheet-metal case1 8 10 13 17 ' 125 mmand 3/8" square drive5-50 3,5-37 2,5 N·m 3.5Quantities in packs may vary.281

45504549QUICK-TURN WITH T-GRIP DREH-FIXUse:T Enables controlled torque tightening in combination with a DREMASTER DMK,TORCOFIX K and K UST Very quick pre-tightening, following the torque wrench makes the final workFeatures:T Made of chrome-vanadium steelT With T-grip made of polypropylene (PPN)T Scarred gripT With 3/8" or 1/2" square drive with ball locking deviceT Max. continuous load of coupler according to DIN EN ISO 6789:2003;T 4550-80 1/2" = 340 N·mT 4550-81 3/8" = 135 N·mScope of delivery:T DREH-FIXT Single packed in poly-bagcdMUSHROOM HEAD / SQUARE DRIVE TORCOFIX KUse:T Interchangeable square drive (mushroom head) for TORCOFIX K and K USFeatures:T Made of chrome-vanadium steel, zinc-platedT With black mushroom head made of polypropylene (PPN)T With 1/4" or 3/8" output square drive with ball locking devicebcCode No. Q " Q a " a , /1545167 4549-87S 3/8 10 1/4 6.3 35 211566385 4549-88S 3/8 10 3/8 10.0 35 22Code No. a " a Q " Q /7604470 4550-81 3/8 10.0 1/2 12.5 1007604390 4550-80 1/2 12.5 1/2 12.5 100MechanicsFeaturesRatchet head drive with push-through,reversible or interchangeable square drivePull out the locking button at the end of the handgrip and turn the handgripin the clockwise or counter-clockwise direction in order to make the desiredtorque setting. Lock the locking button again. Finished!2Lever1233456Final leverSpringScale (N·m, lbf·in, lbf·ft) + scale ring (N·m)HandgripFunctionIn order to change theturning direction of theTORCOFIX K:T Press on the protrudingsquare drive with yourthumb and take out themushroom head, turn thewrench and re-insert thesquare drive.1327Locking button180282Quantities in packs may vary.

TORCOFIX K US6550 - 6551TORCOFIX K US 10 lbf·in - 600 lbf·ft / 1.1 - 810 N·mUse:T Controlled screw tightening in the most widely used range of 10 lbf·in - 600 lbf·ftT For use in almost all areas of industrial manufacturingFeatures:TAnglo-American unitT Adjustable torque wrench with square drive and integrated ratchet functionT For controlled bi-directional tighteningT 1/4", 3/8", 1/2" interchangeable mushroom head-square drive with ball locking device as per DIN 3120 - A 6.3, A 10 or A 12.5, ISO 1174T With 3/4" push through square drive with pin-locking mechanism DIN 3120 - B 20, ISO 1174 (no. 6551-120)T With test certificate acc. to DIN EN ISO 6789, traceable to national standardsT Lever-breaking mechanism with a castor guarantee tactile-impulse and audible actuation signalsT Working accuracy: +/- 3 % tolerance of scale set torqueT Robust, silk-matt chrome-plated steel tube construction, with chrome-plated ratchet head and high-quality plastic partsT Dual scale in lbf·in resp. lbf·ft and N·m underneath a window with a magnifying-glass effectT Additional micrometer scale with lbf·in / lbf·ft graduation (see table)T Ergonomically shaped convenient black plastic handgrip with blue adjusting knobT With an indentation in the middle of the handgrip as a calibration aidT 9 models in the range 10 lbf·in - 600 lbf·ftScope of delivery:T Torque wrench type TORCOFIX K UST Test certificate acc. to DIN EN ISO 6789 Type II class ATOperating instructionsT The individual wrench is delivered in a transparent plastic box with a practical suspension mounting or in sturdy cardboard packaging (no. 6551-60/-120)bcde3/4"6551-120&ß¿96551-306550-156550-01USCode No. a " a N·m lbf·in lbf·ft 9 scale ring lw a b c y /1956744 6550-01 1/4 6.3 1,1-5,6 10-50 2,5 lbf·in 0,25 lbf·in 140.0 24 35 26 220 3001956752 6550-02 1/4 6.3 2-11 20-100 5 lbf·in 0,5 lbf·in 140.0 24 35 26 220 3001956779 6550-05 3/8 10.0 6-28 50-250 10 lbf·in 1 lbf·in 230.0 33 43 35 307 8001956787 6550-15 3/8 10.0 17-113 150-1000 50 lbf·in 5 lbf·in 303.5 33 44 35 394 9001956795 6551-07 3/8 10.0 10-68 7-50 2,5 lbf·ft 0,25 lbf·ft 303.5 33 44 35 394 9001956817 6551-10 1/2 12.5 15-102 10-75 2,5 lbf·ft 0,25 lbf·ft 303.5 33 44 35 394 9001956833 6551-30 1/2 12.5 40-205 30-150 5 lbf·ft 0,5 lbf·ft 394.5 33 44 35 485 11001956841 6551-60 3/4 20.0 81-407 60-300 10 lbf·ft 1 lbf·ft 583.5 31 67 46 686 20001956868 6551-120 3/4 20.0 163-810 120-600 10 lbf·ft 1 lbf·ft 1,133.0 31 69 327 1236 4500Quantities in packs may vary.283

TORCOFIX Z4400 - 4405TORQUE WRENCH TORCOFIX Z 2-50 N·m / 1.5-37 lbf·ftUse:T Controlled screw tightening in the most widely used range of 2 - 50 N·m / 1.5 - 37 lbf·ftT For use in almost all industrial manufacturing areasFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Working accuracy:+/- 3 % tolerance of scale set torque. The specification of the standard (+/- 4 %) is exceeded.T 16 mm spigot endT For controlled bi-directional tighteningT Release system triggers a tactile and audible signalT With micrometre scale for setting interim valuesT Sturdy, satin chrome-plated tubular steel design and high-quality plastic parts; ergonomicallyshaped plastic handgrip with marking in the middle of the handgripT Factory depth gauges: 32 mmT Operation only with end fittings with standardised depth gauges, otherise inaccuracies can ariseT Depending on the application, access is possible from the front (e.g. open-end fitting) or side(e.g. reversible ratchet and socket)j&ß¿9Code No. Ø N·m lbf·ft 9 scale ring lwZ lcZ a b c /1646168 4400-02 16 2-25 1,5-18 1 N·m 0,1 N·m 211.0 32 20.0 30 279.0 3301646176 4405-05 16 5-50 3,5-37 2,5 N·m 0,25 N·m 261.0 32 20.0 30 329.0 3904400-G - 4405-GTORQUE WRENCH SET TORCOFIX Z 2-50 N·m / 1.5-37 lbf·ftT The TORCOFIX Z as a practical tool setT Most-widely-used tools in a robust sheet-metal caseT Clearly organised - everything always ready to handT With foam-material inlay modules (on request, these can be customised or extended individually)j& ß¿ 9Code No. Ø N·m lbf·ft Contents 01663259 4400-G02 16 2-25 1,5-18 " No. 4400-02 - in sheet-metal case3.01 10 13 17 4 10 13 17and c-ratchet head1663267 4405-G05 16 5-50 3,5-37 " No. 4405-05 - in sheet-metal case1 10 13 17 4 10 13 17and c-ratchet head3.3Technical information ZT The large cross-section of the spigot end transfers a maximum torque. "Quick-fittingchange-system"with a locking pin mechanism guarantees that work takes placeflexibly and rapidly.T Ideal for bolted connections in cramped and hard-to-access locations. Depending onhow the torque wrench Z is used, it is possible to work both in the forward directionand also to the side. For anti-clockwise tightening, simply turn the torque wrenchthrough 180°284Quantities in packs may vary.

TORCOFIX SE4101TORQUE WRENCH TORCOFIX SE 2-50 N·m / 1.5-37 lbf·ftUse:T Controlled screw tightening in the most widely used range of 2 - 50 N·m / 1.5 - 37 lbf·ftT For use in almost all industrial manufacturing areasFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class A, with a factory certificate. Workingaccuracy: +/- 3 % tolerance of scale set torque. The specification of the standard(+/- 4 %) is exceeded.T 9x12 mm rectangular cavityT For controlled bi-directional tighteningT Release system triggers a tactile and audible signalT With micrometre scale for setting interim valuesT Sturdy, satin chrome-plated tubular steel design and high-quality plastic parts;ergonomically shaped plastic handgrip with marking in the middle of the handgripT Factory depth gauges: 17.5 mm (9x12)T Operation only with end fittings with standardised depth gauges,otherwise inaccuracies can ariseT Depending on the application, access is possible from the front (e.g. rectangularopen-end fitting) or side (e.g. reversible ratchet and socket)}& ß ¿ 9Code No. : N·m lbf·ft 9 scale ring lwSE lcSE a b c /1646192 4101-02 9 x 12 2-25 1,5-18 1 N·m 0,1 N·m 213.0 17.5 20.0 32 274.0 3001646206 4101-05 9 x 12 5-50 3,5-37 2,5 N·m 0,25 N·m 263.0 17.5 20.0 32 324.0 4504101-GTORQUE WRENCH SET TORCOFIX SE 2-50 N·m / 1.5-37 lbf·ftT The TORCOFIX SE as a practical tool setT Most-widely-used tools in a robust sheet-metal caseT Clearly organised - everything always ready to handT With foam-material inlay modules (on request, these can be customised or extended individually)}& ß ¿ 9Code No. : N·m lbf·ft Contents 01663224 4101-G02 9 x 12 2-25 1,5-18 " No. 4101-02 - in a sheet-metal case3.01 10 13 17 4 10 13 17 and c-ratchet head1663232 4101-G05 9 x 12 5-50 3,5-37 " No. 4101-05 - in a sheet-metal case3.31 10 13 17 4 10 13 17 and c-ratchet headTORCOFIX FS4150 - 4151TORQUE WRENCH FOR PRE-SETTING TORCOFIX FS 2-200 N·mUse:T Controlled screw tightening in the most widely used range of 2 - 200 N·m without scaleT For use in almost all industrial serial manufacturing areasFeatures:T Classified to DIN EN ISO 6789:2003 Type II Class B, with a factory certificate. Working accuracy: +/- 3%tolerance of scale set torque. The specification of the standard (+/- 4%) is exceeded.T Pre-set torque wrench with rectangular cavityT For controlled bi-directional tighteningT With certificate acc. to DIN EN ISO 6789, traceable via in-house DKD laboratory to national standardsT Release system triggers a tactile and audible signalT Robust, satin chrome-plated tubular steel constructionT Factory depth gauges: 17.5 mm (9x12) or 25 mm (14x18)T Operation only with end fittings with standardised depth gauges, otherwise inaccuracies can ariseT Depending on the application, access is possible from the front (e.g. rectangular open-end fitting)or side (e.g. reversible ratchet and socket)T If a factory setting is required, please specify the N·m value on the order}~Code No. : N·m min / max lwFS lcFS a b c /7601960 4150-25 9 x 12 2 / 25 134 17.5 22 31 186 2107602180 4150-50 9 x 12 5 / 50 194 17.5 22 31 246 2707602850 4150-85 9 x 12 15 / 85 277 17.5 22 31 329 3407603580 4151-20 14 x 18 20 / 200 354 25.0 33 42 407 750Quantities in packs may vary.&¿ 9 ß285

E-torc IIMicroprocessor-controlled torquewrenchTorque / rotary angle control: Visual, acoustic and sensorysignal when the set torque is achieved. Additional LEDprogress bar display of the increasing torque. Optional graphicreadout via software. High-contrast backlit graphic display.Lightweight and comfortable: The aluminiumhousing and ergonomically designedhandgrip enable easy and safe operation,even over wide tightening rangesData transmission:RS232Drive: 22 mm spigot socket, with 1/4" driveor 9x12 / 14x18 mm rectangular cavity withpin-locking mechanism. For hard-to-access andconfined locations. Special tools on requestFunction keys: Easy-to-operate /Push-button calibration function /Selectable readings in N·m or lbf·ft /lbf·in via softwareE-torc IIElectronic torque wrench with angle measurementT Calibration at the push of a buttonT High-contrast backlit graphic displayT Aluminium housing, can be rotated by 120°T Visual, acoustic and sensorial signalT Free of charge, comprehensive softwareT 5 models from 2 upto 1000 N·mGeneral information:T 1/4" square drive, 9x12 and 14x18 rectangular cavity,22 and 28 mm spigot endT Signal: visual (LED progress bar), acoustic (beep),sensorial (vibration)T Measurement accuracy torque +/- 1 % tolerancefor all read-off values, +/- 1 digitT Measurement accuracy torque angle +/- 1 %,but min. +/- 1° on 360°T Test certificate acc. to DIN EN ISO 6789:2003 Type IClass CT Memory: 2000 valuesT Curve memory (1 curve at 100 values/sec.)T Serial interface to read data (RS232)T Flowchart with 5 screw parametersT Operation with disposable-battery or rechargeablebattery(2 Standard Mignon AA)T Incl. analysis software and data transfer cableT Delivered in a robust sheet-metal case with insertOptions:T Curve memory (extended to 50 curveseach 100 values/sec.)T Flowcharts extendable to100 parametersT Barcode scanner/input ident number(reading of a barcode or identnumber inputT Wireless data transmission(868 Mhz range)T Power/Communication tray(loading of the key and data transfer)T First movementT Yield point detectionT Customised programming (on request)T Calibration to DAkkS-DKD-R 3-7, Class 1(on request)Barcode scannerWireless data transmissionPower/Communication trayE-torc IISoftware basic functions286Main screenWrench settingsCurve diagramCurve diagram in MS Excel®

TT3KELECTRONIC TORQUE WRENCH TORCOTRONIC III 10-350 N·m / 7.4-258.2 lbf·ftUse:T For everyday requirements in installation and torque controlT For use in all areas of manufacturing and developmentFeatures:T Microprocessor-controlled, electronic torque wrenchT For controlled bi-directional tighteningT Acc. to DIN EN ISO 6789, traceable to national standardsT Robust workshop designT Broad measurement range in N·m, can be switched to lbf·ftT With 1/2" reversible ratchet. The ratchet is exchangeable, providingthe option of using a 9x12 mm (TT3H 120) or 14x18 mm (TT3H 350) square socketFeatures:T Torque measureT Torque and torque angle measureT 5 different measuring modesT 5 parameters storableT USB interface for data exchangeT 2000 storage placesT Measurement accuracy torque +/- 1 %, +/- 1 digitT Measurement accuracy torque angle +/- 1 %, but min. +/- 1° on 360° with min. 4°/secT Different depth gauges for end fittings programmableT Simple to operate with easy to understand Icon-menu navigation and 4 functional keysT Clearly readable, illuminated LCD displayT Resolution torque: 0.1 N·mT Resolution torque angle: 0.1°T PC-software easy to operate for uncomplicated programming and documentation of dataT Data can be transfered to MS Excel®T Keyboard lockT Operation with standard Mignon AA or optional with rechargeable-battery (NiMH)T Visual signal: 3x LED (yellow, green, red)T Acoustic signal: buzzerT TÜV certified, CE and RoHST 2 models in the range 10 - 350 N·mT Test certificate acc. to DIN EN ISO 6789:2003 Type I Class CT Calibration to DAkkS-DKD-R 3-7, Class 1 (on request)Scope of delivery:T Electronic torque wrench TorcoTronic III HighLineT Reversible ratchet 1/2"T USB cableT Software on CD-RT Test certificate acc. to DIN EN ISO 6789:2003 Type I Class CT Delivered in a transparent plastic box with insertAttention:T A PC, running a Windows® operating system (from Windows XP®) is required to obtain the full benefit of all the functions of this product.d}~Code No. a " a : N·m lbf·ft 02648636 TT3KH 120 1/2 12.5 9 x 12 10-120 7,4-88,5 0.92648644 TT3KH 350 1/2 12.5 14 x 18 70-350 51,6-258,2 1.2OUR SERVICE -qualified and customised312 -319K 19 236208DKDQuantities in packs may vary.287

TORQUE SCREWDRIVERT Ideal for serial productionT 3 Torque screwdriver handles for 3 working rangesT 23 different plug-in blades for all common screw profiles (slotted,cross-slotted PH + PZ, TORX® and TORX PLUS®)T All items are available individually - from torque screwdriver handle to each plug-in blade)2140TORQUE SCREWDRIVER HANDLE 0.6-5.4 N·mT Adjustable, with tactile impulse and audible signalT For guaranteed controlled screw tightening in the range of 0.6 - 5.4 N·mT With test certificate acc. to DIN EN ISO 6789, traceable to national standardsT Including hexagon socket key set 42 6 mmTActuation accuracy:T model 2140 1,5 NM: +/- 10 % tolerance of the set valueT model 2140 3,0 NM and 2140 5,4 NM: +/- 6 % tolerance of the set valueY2140TORQUE SCREWDRIVER SET 25 piecesT Ideal for working in a small torque range, e.g. electronics, precision mechanicsT GEDORE-Check-Tool systemT For screwdriver function simply add the 2C multi-handle with appropriate accessoryT Adjustable, with tactile impulse and audible signalT For guaranteed controlled screw tightening in the range of 1.5-3 / 3-5.4 N·mT With test certificate acc. to DIN EN ISO 6789, traceable to national standardsT Actuation accuracy: +/- 6 % tolerance of the set valueT Delivered with test certificate and operating instructionsib?;53Code No. N·m y 9 / l1802364 2140 1,5 NM 0,6-1,5 108 0,1 145 11802372 2140 3,0 NM 1,5-3,0 108 0,1 147 11802380 2140 5,4 NM 3,0-5,4 108 0,2 152 12141 IPPLUG-IN BLADE 1/4" HEX for recessed TORX PLUS® head screwsT TORX PLUS® = reg. trademark of Acument Intellectual Properties, LLC. USAi7Code No. Contents N·m / l1953761 2140-3,0-025 ? 680 4 6,51,5-3,0 595 15 685 2 2,5 3 4 5 6; 690 0 1 23 D 20 4 4,5 5 5,5 6 7 8 9 105 42 6 673 L 676 699 L2140 3,0 N·m1802429 2140-5,4-025 ? 680 4 6,55 685 2 2,5 3 4 5 6; 690 0 1 23 D 20 4 4,5 5 5,5 6 7 8 9 105 42 6 673 L 676699 L 2140 5,4 N·m3,0-5,4 595 1Code No. + y / l1802658 2141 6IP M2 170 42 11802666 2141 7IP - 170 42 11802674 2141 8IP M2,5 - M3 170 42 11802682 2141 9IP - 170 42 11802690 2141 10IP M3 - M3,5 170 42 11802704 2141 15IP M3,5 - M4 170 44 1AccessoriesActivating tools and screwdriver bitsas well as adaptors are listed up frompage245-253288Quantities in packs may vary.

2141 TXPLUG-IN BLADE 1/4" HEX for recessed TORX® head screwsT TORX® = reg. trademark of Acument Intellectual Properties, LLC. USA2141 PHPLUG-IN BLADE HEX for cross-slotted head screws PHi7i;Code No. 7 + & y / l1802569 2141 TX T6 T6 M2 1.69 170 42 11802577 2141 TX T7 T7 M2,5 1.99 170 42 11802585 2141 TX T8 T8 M2,5 2.31 170 42 11802593 2141 TX T9 T9 M3 2.50 170 42 11802607 2141 TX T10 T10 M3 - M3,5 2.74 170 42 11802615 2141 TX T15 T15 M3,5 - M4 3.27 170 44 11802623 2141 TX T20 T20 M4 - M5 3.86 170 45 11802631 2141 TX T25 T25 M4,5 - M5 4.43 170 46 1Code No. ; PH + y / l1802496 2141 PH 0 0 M1,6 - M2 170 42 11802518 2141 PH 1 1 M2 - M3 170 44 11802526 2141 PH 2 2 M3,5 - M5 170 46 12141 ISPLUG-IN BLADE 1/4" HEX for slotted head screwsi?2141 PZPLUG-IN BLADE HEX for cross-slotted head screws PZi

Torque screwdriver Technical featuresA range of compact and versatile torque screwdrivers with automatically actuating,dial-indicating and measuring torque.Type FS 755Pre-set torque screwdriverwithout scale for durableand identical valuetighteningAuto settingBidirectionalAnodised aluminiumhandgripType 756Adjustable torque screwdriver withmicrometer scale"Positive-lock"-systemDrive type made of stainless steelAuto settingBidirectionalNon-slip rubber handgripEPA > see productType S 757Adjustable torquescrewdriver with micrometerscaleAuto settingBidirectionalAnodised aluminiumhandgripType SP 758Dial-indicating torque screwdriverwith dual scaleLocking of maximum values /maximum value-displayBidirectionalAnodised aluminium handgripEPA > see productScope of deliveryWe supply a 1/4"-1/4"-drive adaptorwith all modelsTo make work easier, a sliding orremovable T-bar is included withseveral modelsSpecial modelsOptionally, all torque screwdriversare also available with a 1/4"male square drive spindle.Apart from that: Torquescrewdrivers for the medical"clean-room" area are availableon request.757TORQUE SCREWDRIVER TYPE S 0.2-9 N·mUse:T Controlled screw tightening in the range 20 cN·m - 9 N·mT High-speed, controlled tightening enables serial productionT Electrical and electronic hardware industry, instrument-making industryand industrial manufacturing or in quality controlFeatures:T Adjustable torque screwdriver with scaleT With 1/4" female hexagon drive for use with 1/4" hexagon bits as per DIN 3126 - C 6.3T With adaptor also suitable for 1/4" square drive sockets as per DIN 3124T Working accuracy: +/- 6 % tolerance of the set torqueT Acc. to DIN EN ISO 6789, traceable to national standardsT Precision radial ball clutch and cam design for controlled bi-directional tighteningT Precision mechanism slips very noticeably through when set torque is reachedT Automatic resetting to the starting positionT Locking of the value by means of an adjusting knobT 3 models in the range 20 cN·m to 9 N·mT Micrometer scale graduation: 1 cN·m / 0.1 N·mT Lightweight construction by virtue of anodised aluminium handgripsScope of delivery:T Torque screwdriver type 757T 1/4" square/hexagon drive adaptor (no. 757-20)T Models 757-06/-09 with additional sliding T-bar (no. 757-21) - for ease of useT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packaging757-01757-09757-06Yb&¿95Code No. - " - a " a cN·m N·m y 9 Colour /7718050 757-01 1/4 6.3 1/4 6.3 20-120 169 1,0 cN·m black 1657718130 757-06 1/4 6.3 1/4 6.3 1-6 184 0,1 N·m red 4007718210 757-09 1/4 6.3 1/4 6.3 4-9 184 0,1 N·m green 400290Quantities in packs may vary.

Torque screwdrivers 756Drive adaptor 1/4"-squaredrive: To fit industry-stabdardnut sockets.1/4“-drive type: Made ofstainless steel, for industrystandardbits.Sliding T-Bar: Made ofquality steel, can beadapted to enhance userstransmission of power.Drive adaptor 1/4"-hexagonmale:Guarantees a safe andstable connection to the tool."Positiv-Lock"-system:Locks the set torque, reliablypreventing it from wrongsetting.Scale: Clearly readablemicrometer ring; enables youto make the setting accurately,quickly and without error.Rubber handgrip:Ergonomic, can be heldsecurely in your hand.756TORQUE SCREWDRIVER TYPE S 0.05-9 N·mUse:T Controlled screw tightening in the range 0.05 - 9 N·mT High-speed, controlled tightening enables serial productionT Electrical and electronic hardware industry, instrument-making industry and industrial manufacturing or in quality controlFeatures:T Adjustable torque screwdriver - with scaleT With 1/4" female hexagon drive for use with 1/4" hexagon bits as per DIN 3126 - C 6.3T With adapter also suitable for 1/4" square drive sockets as per DIN 3124T Actuation accuracy: +/- 6 % tolerance of the set valueT Acc. to DIN EN ISO 6789, traceable to national standardsT Precision radial ball clutch and cam design for controlled bi-directional tighteningT Precision mechanism slips very noticeably through when the set torque is reachedT Automatic resetting to the starting positionT "Positive-Lock" system automatically fixes the set value preventing it from wrong setting.T 4 models in the range 0.05 N·m to 9 N·mT Micrometre scaling: 1 cN·m and 0.1 N·mT Very convenient, lightweight and non-slip rubber handgripT EPA-conformant (Electrostatic Protected Area), for use in sensitive electrostatic applicationsScope of delivery:T Torque wrench type 756T 1/4" square/hexagon drive adapter (no. 757-20)T Models 756-06/-09 with additional sliding T-bar (no. 757-21) - for ease of useT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packagingYb& 9¿ 5756-01Code No. - " - a " a cN·m N·m y 9 Colour /1498738 756-00 1/4 6.3 1/4 6.3 5-40 159 1 cN·m silver 1241400150 756-01 1/4 6.3 1/4 6.3 20-120 183 1 cN·m blue 1651400169 756-06 1/4 6.3 1/4 6.3 1-6 196 0,1 N·m red 3401400177 756-09 1/4 6.3 1/4 6.3 4-9 196 0,1 Nm green 340685 69020 IN 20245 178 -181Quantities in packs may vary.291

755TORQUE SCREWDRIVER TYPE FS 0.02-13.6 N·mUse:T Controlled screw tightening in the range 0.02 - 13.6 N·mT Serial manufacture with constant tightening valueT Electronic industry, precision mechanics and industrial manufacturingFeatures:T Pre-set torque screwdriver without a scaleT With 1/4" female hexagon drive for use with 1/4" hexagon bits as per DIN 3126 - C 6.3T With adaptor also suitable for 1/4" square drive sockets as per DIN 3124T Working accuracy: +/- 6 % tolerance of the set torqueT Acc. to DIN EN ISO 6789, traceable to national standardsT Precision radial ball clutch and cam design for controlled bi-directional tighteningT Precision mechanism slips very noticeably through when the set torque is reachedT Automatic resetting to the starting positionT 5 models in the range 0.02 to 13.6 N·mT Lightweight construction by virtue of anodised aluminium handgripsT The pre-setting can be made at the factory or by the user on suitable torque testersT If ordering, please specify the N·m value - if a fixed factory setting is desired (price on request)Scope of delivery:T Torque screwdriver type 755T 1/4" square/hexagon drive adaptor (no. 757-20)T Model 755-05 with additional removable T-bar - for ease of useT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packagingYb755-01&¿95755-02755-04755-05Code No. - " - a " a cN·m N·m y Colour /1471481 755-01 1/4 6.3 1/4 6.3 2-22 76 red 501471473 755-02 1/4 6.3 1/4 6.3 0,5-22 104 gold 721471465 755-03 1/4 6.3 1/4 6.3 2-135 111 blue 2101471457 755-04 1/4 6.3 1/4 6.3 6-406 127 green 2801228501 755-05 1/4 6.3 1/4 6.3 1-13,6 137 black 325690 685245246292Quantities in packs may vary.

758TORQUE SCREWDRIVER TYPE SP 10-500 cN·m / 14 ozf·in - 40 lbf·inUse:T In the torque range 10 cN·m - 500 cN·mT For test and installation work in the electrical and electronic hardware industry,instrument-making industry and industrial manufacturing or in quality controlFeatures:T Dial-indicating torque and test screwdriver - with dual scale (cN·m/ozf·in/lbf·in)T With 1/4" female hexagon drive for use with 1/4" hexagon bits as per DIN 3126 - C 6.3T With adapter also suitable for 1/4" square drive sockets as per DIN 3124T Display accuracy: +/- 6 % tolerance of the indicated valueT Acc. to DIN EN ISO 6789, traceable to national standardsT For controlled bi-directional tighteningT With slave-pointer functionT For locking of maximum values / maximum-value displayT 4 models in the range 10 cN·m to 500 cN·mT Lightweight construction by virtue of anodised aluminium handgripsT EPA-conformant (Electrostatic Protected Area), for use in sensitive electrostatic applicationsScope of delivery:T Torque screwdriver type 758T 1/4" square/hexagon drive adapter (no. 757-20)T Models 758-25/-50 with additional sliding T-bar (no. 757-21) - for ease of useT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packagingYb&9/758-25758-10758-05758-50757-20757-21Code No. - " - a " a cN·m ozf·in / lbf·in y 9 Colour /7096380 758-05 1/4 6.3 1/4 6.3 10-50 14-70 ozf·in 178 2 cN·m / 2 ozf·in gold 1907096460 758-10 1/4 6.3 1/4 6.3 20-100 28-140 ozf·in 178 5 cN·m / 5 ozf·in blue 1907096540 758-25 1/4 6.3 1/4 6.3 50-250 4-20 lbf·in 250 10 cN·m / 0,5 lbf·in red 4657096620 758-50 1/4 6.3 1/4 6.3 100-500 8-40 lbf·in 250 20 cN·m / 1 lbf·in green 46520178Quantities in packs may vary.293

TSN SLIPPERPre-set ratchet head torque wrench with automatic actuation and slipfunction. Over-tightening is not possible.ß ¿ 5Integrated ratchet function: Particularlydependable ratchet having 36 teeth(759-00/-01) or 48 teeth (759-02/-03).Slip-through function guarantees controlledand safe screw tightening, even in hard-toaccesslocations.&High repeatability: Guarantees constanttightening torques.Rubber handgrip: Ergonomic andpleasant to hold in your hand.Prevents slipping.Solid light-metal tube:With plastic sleeving.Robust casting part:Made of corrosion-resistant,rustproof materialOutput square drive: Made ofquality steel with ball-lockingmechanismTSN SLIPPERWorking principleWhen the pre-set torque value is achieved, the mechanism slipsthrough over the ball (without the possibility of over-tightening).The torque wrench is then immediately ready for the next operation.TSN SLIPPER TBN BREAKERTechnical informationAll TSN SLIPPER and TBN BREAKER torque wrenches (apart from760-00/-01) are fitted with the patented "Mechanical TorqueAdjustment Locking Device" to modify torque tester.294

759TORQUE WRENCH TSN SLIPPER 3-125 N·mUse:T Controlled screw tightening in the range 3 - 125 N·mT Serial / production-line assemblingT Extremely long-term workFeatures:T Pre-set production torque wrench - without scaleT 1/4", 3/8" or 1/2" square drive with ball locking deviceT With integrated ratchet-function for controlled clockwise tighteningT Working accuracy: +/- 4 % tolerance of the set torqueT Acc. to DIN EN ISO 6789, traceable to national standardsT Precision mechanism slips very noticeably and audibly ("click") when the pre-setvalue is achieved - over-tightening is not possibleT Automatic resetting to the starting positionT 4 models in the range 3 to 125 N·mT Lightweight yet robust and corrosion-resistant construction designT Very convenient non-slip rubber handgripT The pre-setting can be made at the factory or by the user on suitable torque testersT If ordering, please specify the N·m value - if a factory pre-setting is desired (price on request)T EPA-conformant (Electrostatic Protected Area), for use in sensitive electrostatic applicationsScope of delivery:T Torque wrench type TSN SLIPPERT Special adjusting key for changing the pre-set torque valueT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packagingbcd759-00&¿5ß759-01759-02759-03T TSN SLIPPER - the pre-set production torque wrench (without scale).T With this torque wrench, accidental adjustment while working is ruled out.T The state-of-the-art lightweight production wrenches “slip” through as soonas the set torque is achieved.T Over-tightening is impossible.T The ideal torque tool for all jobs where for a longer time only one tighteningtorque value is required.T The automatic resetting and integrated ratchet are the ideal assistance forworking swiftly.T TSNs for counter-clockwise tightening, bi-directional tightening without aratchet-function or as a VDE-Wrench can be manufactured specially -on request.Code No. a " a N·m y Cams per turn /7091900 759-00 1/4 6.3 3-25 216 10 3407092040 759-01 3/8 10.0 3-25 216 10 3407092120 759-02 3/8 10.0 15-55 324 10 8007092200 759-03 1/2 12.5 40-125 460 8 1360Quantities in packs may vary.295

761TORQUE WRENCH TSP SLIPPER 1-10 N·m / 10-90 lbf·inUse:T Controlled screw tightening in the range 1 - 10 N·mT Ideal for assembly work where controlled tightening with low torque values is required(e.g. electronic hardware sector, precision mechanics etc.)Features:T Pre-set production torque wrench - without scaleT 1/4" square drive with ball locking deviceT With integrated ratchet-function for controlled clockwise tighteningT Working accuracy: +/- 6 % tolerance of the set torqueT Acc. to DIN EN ISO 6789, traceable to national standardsT Precision mechanism slips very noticeably and audibly ("click") when the pre-set value is reached -over-tightening is not possibleT Automatic resetting to the starting positionT 2 models in the range 1 N·m to 10 N·mT Extremely lightweight yet robust and corrosion-resistant construction designT Very convenient non-slip rubber handgripT EPA-conformant (Electrostatic Protected Area), for use in sensitive electrostatic applicationsT The pre-setting can be made at the factory or by the user on suitable torque testersT If ordering, please specify the N·m value - if a fixed factory pre-setting is desired (price on request)Scope of delivery:T Torque wrench type TSP SLIPPERT Adjusting tool for changing the pre-set torque valueT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packagingb&¿5ßT TSP SLIPPER - the pre-set production torque wrench (without scale) for thelower torque range 1 - 10 N·m.T Accidental adjustment while working is ruled out.T The built-in ratchet with clockwise tightening and the corrosion-resistantlightweight construction design make this torque wrench the optimumworking partner for quick and controlled screw tightening.T The integrated slipping mechanism reliably prevents over-tightening -the guarantee for high repeatability and controlled tightening values.Code No. a " a N·m lbf·in y /1196650 761-05 1/4 6.3 1-5 10-45 185 1901196731 761-10 1/4 6.3 2-10 20-90 185 19020 IN 20 ITX 20178–181296Quantities in packs may vary.

762TORQUE WRENCH TSC SLIPPER 1-10 N·mUse:T Controlled screw tightening in the range 1 - 10 N·mT Ideal for assembly work where controlled tightening with low torque values is required(e.g. electronic hardware sector, precision mechanics etc.)Features:T Adjustable torque wrench - with scaleT 1/4" square drive with ball locking deviceT With integrated ratchet-head function for controlled clockwise tighteningT Working accuracy: +/- 6 % tolerance of set torqueT Acc. to DIN EN ISO 6789, traceable to national standardsT Precision mechanism slips very noticeably and audibly ("click") when the set torque is reached -over-tightening is not possibleT Automatic resetting to the starting positionT Micrometer scale graduation: 0.05 N·m / 0.1 N·mT 2 models in the range 1 N·m to 10 N·mT Extremely lightweight yet robust and corrosion-resistant construction designT Very convenient non-slip rubber handgripT EPA-conformant (Electrostatic Protected Area), for use in sensitive electrostatic applicationsScope of delivery:T Torque wrench type TSC SLIPPERT Test certificate acc. to DIN EN ISO 6789T Delivered in sturdy cardboard packagingb&¿5ßTechnical informationT The scale is situated on the body tube.T The setting is made by rotating the unlocked handgrip withthe integrated micrometer ring.T TSC SLIPPER - the adjustable torque wrenches (with scale) for the lowertorque range 1 - 10 N·m.T The built-in ratchet with clockwise tightening and the corrosion-resistantlightweight construction design make this torque wrench the optimumworking partner for quick and controlled screw tightening.T The integrated slipping mechanism reliably prevents over-tightening -the guarantee for high repeatability and controlled tightening values.Code No. a " a N·m y 9 /1196480 762-05 1/4 6.3 1-5 195 0,05 N·m 2351196510 762-10 1/4 6.3 2-10 195 0,1 N·m 235T On request, all torque wrenches can be factory pre-set.T When ordering, please specify the N·m value.T Pre-setting2090182Quantities in packs may vary.297

TBN BREAKERPre-set torque wrench with automaticsnap actuation. Torque wrench offeringmaximum accuracy. Guaranteedtightening values without overtightening.9 % ¿Drive: 16 mm spigot end or 9x12 mmrectangular cavity made of quality steelwith pin-locking mechanismBreaking: All TBN breaking torquewrenches break by 20° at the pivot pointwhen the set torque is achieved.The models 760-00/-01 can also be setto a breaking angle of 90°.Rubber handgrip: Ergonomic andpleasant to hold in your hand.Prevents slipping.&Patented mechanism: Guarantees along product lifespan with guaranteedaccuracy valuesLightweight steel tube: Firm,solid, and free of corrosionTBN Knickerj5 - 135 N·mTBN Knicker}0,2 - 135 N·mAs an option, we alsomanufacture the TBN BREAKERmodels 760-00/-01 withexchangeable fittings directlypositioned on the tool.TBN BREAKERTBN BREAKER 760-00/-01 valuesare changed using the "DoublePositive" adjustment system.TBN BREAKERWorking principleWhen the TBN breaking torque wrench is operated, the rearsection of the driver unit presses the roller. When the pre-settorque value is achieved, the lever switches over and thefront section of the drive unit breaks.298