Waterwash - RDM Industrial Services Ltd

Waterwash - RDM Industrial Services Ltd

Waterwash - RDM Industrial Services Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

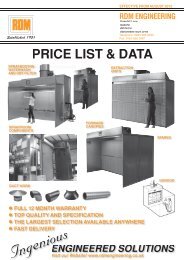

<strong>Waterwash</strong> ExtractionBooths and SystemsFor Powder Coating, Paint Spraying and Dust Extraction.<strong>RDM</strong> Aquaex Booths are based on atried and tested system manufacturedby <strong>RDM</strong> for over 20 years.Designed to remove Toxic Fumes, Paint and Powder dust from spray shopsand other industrial environments, ensuring healthy and suitable workingconditions and compliance with inspectorate requirements.A water scrubbing tower is used to prevent particles being exhaustedto atmosphere.APPLICATIONS:. Powder Coating.. Paint Spraying.. Polishing/Finishing.. Isocyanate spraying.. Dust and fume extraction.FEATURES:. No filters to replace.. Complies with all current safety and environmentallegislation.. Fully modular construction.. Belt drive fan(s) with external motor(s).. Choice of flameproof fans.. Water curtains of stainless steel.. Simple maintenance by removing clippedin front panel.. Heavy duty centrifugal pump with tungstan seals.. Supplied complete with loose starters,all chemicals, all sealants and fixings.. Duct work and full installation service available.C <strong>RDM</strong> 2008

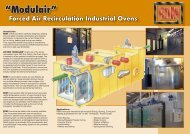

How the AQUAEX SystemWorksFume and particle laden air is drawn into thewash chamber between the top of the watertank and the base of the stainless steel curtain,it is then drawn up inside the wash chambertower by fans mounted at the top, andextracted via ducting to atmosphere. Inside thewash chamber the laden air is impinged by alarge volume of water sprayed by a series ofscrubbing nozzles which are fed by thecentrifugal pump. The water tank containsdenaturing chemicals that cause particles tosettle harmlessly in the wash tank.A series of baffles inside the wash chambertower prevents loss of water through the fans.The pump also supplies water to a trough atthe top of the stainless steel curtain causingwater to cascade down the front forming awater screen.This water then re-enters the booth at the airinlet at the base of the stainless steel curtain.Since the air speed is high at this point thewater significantly assists the scrubbingprocess as well as protecting the booth.Aquaex Booths for PaintSprayingThese booths offer significant advantagesfor Paint Spraying including:Low life cost compared to Dryfilter booths,Very safe, the water quenches the paintoverspray eliminating Fire Hazards,Simple Paint disposal by tanker,Superb operator conditions,Huge variety of size and extract ratingoptions.Aquaex Booths for PowderCoatingThese booths offer real advantages for PowderCoating including:Low capital cost, Very safe, the waterquenches the powder eliminating Fire Hazards,No need for expensive fire suppression andsensing,Large easily used open spray area,Simple powder disposal by tanker,Superb extraction and operator conditions,Can be used for Powders, Paints, Etching etc.Small footprint, no large seperate filtersrequired.CHEMICALSBooths supplied as standard with packof spraybooth additive. Liquid orpowder chemicals are available to suitspecific applications.LIGHTING(Optional) Special 18 SWG panels forroof, or sides with a strengtheningframe spot welded into place carry arough cast wired glass insert 8mmthick. Glass is either retained by arubber seal, or sits on a ribbonsealstrip. Illumination is provided bystandard ‘Fitzgerald’ twin fluorescentlights usually 5ft long, complete withwhite angled reflector. Side lights aremounted on heavy duty steel hinges.WATER CURTAINIn one metre sections across the fulllength of wash tower. Each sectionhas a galvanised steel trough at thetop with brass levelling screws, arolled galvanised steel scroll withangle and reach adjustment and abright, folded 18 SWG stainless steelfront curtain one metre high (standard)clipped into place for easymaintenance removal.CONTROL GEAROne direct-on-line no voltrelease type push buttonstarter, with thermal overloadhoused in an IP55 enclosure issupplied for each motor.Comprehensive control panelsavailable at extra cost.STANDARD SPECIFICATIONCONSTRUCTIONFrom first quality 18 SWG galvanisedsteel sheets forming a modular boltedpanelwork system, 16 SWG, orheavier used in support panels. Allpanels have 40mm/15mm doublefolded return edges for additionalstrength and to facilitate jointing.All bolts are bright zinc plated.Air flowAir flowWATER TANKOf first quality 16SWG galvanised steel sheets foldedinto 1 metre wide modular sections with returnededge flanges which bolt together and seal with’3mRibbonseal’. Bolts are bright zinc plated. Theassembled tank incorporates a separate small wiertank housing a ball cock filler as well as a removableperforated steel water filter for pump inlets. Tankcapacity 350 litres per metre length.MOTORS3 phase - 415 volts - 50Hz asstandard, Squirrel cage type.Available to IP54, or IP55, or fullyflameproof layouts. Usually ofBrook, or Asea manufacture.Water directionFANCHECK 5Ensure spraying cannotcommence unless the fansare running. Fancheck 5allows air to the gunswhen it senses the fansare powered.{optional}FANSAll fans are of the belt driven axial flow typewith polypropylene or nylon aerofoil sectionimpellors. All bearings are sealed and thebelt tunnel is sealed from theairstream. External motors sit on largeadjustment plates.Most fan cases haveintegral access doors.C <strong>RDM</strong> 2008PUMP SETA heavy duty self primingcentrifugal pump is mounted on astand alongside the water with 21/2”nominal bore steel delivery pipeswith flexible inlet connection.Typicalcirculation rate 850 litres perminute(3 metre model).WATER RECOVERYthe extracted water laden airstrikes a minimum of six angled,oversized baffle plates which trapany airbourne water particles.The air is then caused to turnsharply into the top plenumchamber to centrifugally removeany remaining moisture.WATER SCRUB SYSTEMA 21/2”nominal bore steelmanifold pipe across the fulllength of the wash tower. Threebrass spray nozzles per metrelength feed from the pipe. eachnozzle is 12.7mm diameter.hollow cone type. Nominal spraypressure 20PSI. One 3/4”nominal bore riser pipe per metresection with a brass gate valvesupplies water to troughs at thetop of the water curtain.