Controllers - AGCO Parts

Controllers - AGCO Parts

Controllers - AGCO Parts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Clean Sprayers Help<br />

Prevent Crop Injury<br />

Careful cleaning of sprayers is the applicator’s responsibility.<br />

Even small amounts of product from sulfonylurea<br />

herbicides, such as Exceed ® , Beacon ® , Glean ® , Amber<br />

® , Permit ® and Accent ® , may cause injury to sensitive<br />

crops.<br />

Use caution when using products, like emulsifiable<br />

concentrates (EC), that contain solvents and surfactants<br />

that help remove herbicide residue from spray<br />

tanks. These products may free SU herbicide residue<br />

from the sprayer which could cause injury to non-labeled<br />

crops.<br />

There are steps you can take to ensure your sprayers are<br />

clean.<br />

SPRAY TANK<br />

SETUP<br />

TANK<br />

RINSING NOZZLES<br />

The Basics of Clean Equipment<br />

u Start with a thoroughly-cleaned sprayer before beginning<br />

a spray job.<br />

u Mix only as much spray solution as needed.<br />

u Wear appropriate protective clothing.<br />

u Carry a rinse tank filled with clean water or a wash<br />

solution on the sprayer. Immediately after spraying, flush<br />

the sprayer thoroughly before changing (or switching) to<br />

another chemical. Use a pressure washer to clean all<br />

interior and exterior surfaces with cleaning solution.<br />

Commercial Tank Cleaners<br />

There are several commercial tank cleaners which have<br />

been approved for removal of Novartis sulfonylurea compounds<br />

from sprayers. Most tank cleaners contain materials<br />

which raise the pH to a range of 7.3–14. These<br />

alkaline conditions help the sulfonylurea materials to<br />

dissolve so they can be rinsed more easily from the<br />

sprayer.<br />

Some tank cleaners are advertised as “neutralizers.”<br />

Those cleaners may degrade certain classes of chemical<br />

compounds when used according to instructions. However,<br />

none of the cleaning materials tested in Novartis<br />

U.S. Patent Nos. 4,478,635; 4,514,212; 4,671,819.<br />

u Flush the sprayer in the field to minimize handling<br />

issues with waste water. Take special care to rinse all<br />

hoses and lines. Materials may settle in the lines if not<br />

flushed out daily.<br />

u Consider installing a set of tank-rinsing nozzles on the<br />

spray tank. The rinsing nozzles should be connected to<br />

a separate tank which is used only for holding cleaning<br />

solution.<br />

u Dedicating a sprayer to one crop while using highlyactive<br />

products will also minimize potential problems.<br />

labs cause sulfonylurea compounds to decompose.<br />

Be sure to read and follow the tank cleaner manufacturer’s<br />

directions for use of a tank cleaner and wear proper<br />

protective clothing, including gloves, and eye protection.<br />

<strong>AGCO</strong> Dry Tank Cleaner has been tested in Novartis labs<br />

and is approved!<br />

Novartis Crop Protection, Inc., Greensboro, NC 27419-8300<br />

Technical Pages<br />

Important: Always read and follow label instructions before buying or using these products.<br />

No information or advice given here shall constitute a warranty as to any matter; all such information and advice is being given and accepted at your sole risk. Novartis Crop Protection, Inc. assumes no<br />

responsibility or liability for any statements given in this information.<br />

Amber ® , Beacon ® , Exceed ® , Peak ® and the Novartis logo are trademarks of Novartis.<br />

Accent ® and Glean ® are trademarks of E.I. duPont de Nemours and Company.<br />

Permit ® is a trademark of Monsanto Company.<br />

Clorox ® is a trademark of Clorox Company.<br />

RS 2954<br />

NCP 990-00185-A 10/97<br />

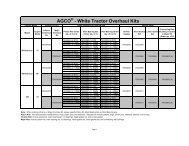

Please Note: For a complete <strong>AGCO</strong> part number; please add AG to the front of the six digit number.<br />

255