v072010 - Who-sells-it.com

v072010 - Who-sells-it.com

v072010 - Who-sells-it.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>v072010</strong>

Mission Statement 2<br />

OD6: Overdrive 6-Speed 3<br />

Right Side Drive 4<br />

RT250 aka Mr.Potato Head 5<br />

Baker Drive Brake & Bonneville 3-Speed 6<br />

SBD:Softail Belt Drive 7<br />

FFP: Function Formed Primary 8<br />

TorqueBox 9<br />

PowerBox 10<br />

Sprockets & Pulleys 11<br />

Drivetrain Options 12<br />

Baker Clutches 13<br />

XL Products 15<br />

Big Dog Products 16<br />

Baker Online 17<br />

Baker Apparel and Spectro Oils 18<br />

BAKER’s Unbeatable Warranty:<br />

Let’s face <strong>it</strong>: when you are buying a top-of-the-line transmission, primary, or clutch you expect the best. You want to go the distance w<strong>it</strong>h<br />

years of trouble free service. The BAKER R&D department rigorously validates each and every BAKER Drivetrain product to guarantee<br />

customer satisfaction w<strong>it</strong>hin our warranty periods. Because of the work we do in advance and our ongoing qual<strong>it</strong>y control measures, <strong>it</strong><br />

is rare that customers have problems w<strong>it</strong>h our products. That’s why BAKER Drivetrain offers one of the best warranties in the business.<br />

Complete transmissions and gearsets carry a 5 year 50,000 mile warranty. Clutches, primaries, and ancillary parts carry a 2 year 20,000<br />

mile warranty.<br />

This is the way <strong>it</strong> should be. We guarantee that when you buy BAKER you buy premium, American-made top of the line innovations - but<br />

we can also guarantee that we are going to stand by that product w<strong>it</strong>h unbeatable service for the long haul.<br />

There’s something to be said these days for an American-made product w<strong>it</strong>h that kind of support. Our factory is just outside of Detro<strong>it</strong>, the<br />

Motor C<strong>it</strong>y, in Michigan. We’re part of the every day grind just like you are. Each BAKER product is built to order when you order <strong>it</strong>, w<strong>it</strong>h<br />

all parts made right here in the USA, by guys who know their sh<strong>it</strong> about gearboxes inside and out.<br />

We are the Drivetrain Author<strong>it</strong>y: often im<strong>it</strong>ated (by <strong>com</strong>munist China slopes), never duplicated. We’ve changed the face of the Harley<br />

aftermarket w<strong>it</strong>h our original overdrive 6-speed (OD6), Right Side Drive (RSD), DD6, DD7, N1 drums, FF primaries, reverse k<strong>it</strong>s, and the<br />

KKK clutch. Evolving and improving the iconic Harley Davidson ® motorcycle is our business and we are really friggin’ good at <strong>it</strong>.<br />

What does this give you? Peace of mind. Every time you push that button or climb on that kicker - you know there is a strong, dependable<br />

drivetrain ready to go and that BAKER is right beside you every mile along the way.<br />

Go ahead, give BAKER a call today and talk to one of our Sales/Tech professionals... We can promise you clear, English-speaking, tech<br />

savvy people on our end of the line. Guys who ride and appreciate your bike like you do.<br />

9804 E. Saginaw, Haslett, MI 48840<br />

Phone (517) 339-3835, Fax (517) 339-4590, Toll Free (877) 640-2004<br />

info@bakerdrivetrain.<strong>com</strong><br />

All prices in this book subject to change.<br />

We have no relationship w<strong>it</strong>h any of the Asian knock-off artists that copy our products and pollute our great country w<strong>it</strong>h inferior gears and shafts made from steel alloys that would be more<br />

appropriate for the manufacturing of soup cans. Any mention of other manufactures is for reference only. Mr.PotatoHead, JIMS, S&S, RevTech, Big Dog, are all trademarks of their respective<br />

ent<strong>it</strong>ies. BAKER Drivetrain and BAKER Inc. are not associated w<strong>it</strong>h the Harley-Davidson Motor Company. Sportster, Buell, Softail, Dyna, Road King, Ultra Classic, FXR, FLT, FLST, FLSTC,<br />

FLSTF, FLSTFI, FLSTCI, FLH, FLTR, FLTRI, FLTCUI, FLHTC, FLHR, FLHRI, FLHRC, FXRS, FXRT, FXR2, FXR3, FXRSP, FXD, FXDL, FXDT, FXDLI, FXDXI, Shovelhead, Panhead,<br />

Knucklehead, Evo, Evolution, Twin Cam, Screamin’ Eagle, FLH, Cruise Drive, Harley, H-D, Harley-Davidson and anything else we may have missed in this disclaimer that Harley-Davidson says<br />

they own unless they are BAKER Drivetrain trademarks listed below are all trademarks of the Harley-Davidson Motor Company. BAKER Drivetrain, BAKER Six-Speed Overdrive, Function-<br />

Formed, OD6, DD6, DD5, DSSC, Torquebox, 6-into-4, BAKER Billet Series,XL6, BAKER KKK, King Kong Klutch, Klassic Kicker Gears,BAKER 300, F6F, PowerBox, DD7, Street Performance<br />

Clutch, FFP, FFPS,Synchronous Belt Drive, Drivetrain Author<strong>it</strong>y and BAKER are trademarks of BAKER Inc., Haslett, Michigan.<br />

1

The older pilots refer to <strong>it</strong> as the Sound of Round. That’s the beautiful mechanical cacophony you hear from an<br />

airplane w<strong>it</strong>h a Pratt & Wh<strong>it</strong>ney R-985 when <strong>it</strong>s crawling through sky. That 985 cubic inch 9-cylinder radial makes a<br />

sound that can’t be duplicated or im<strong>it</strong>ated. Same goes for a Harley engine. A big displacement 45° V-twin w<strong>it</strong>h high<br />

<strong>com</strong>pression and a really nervous camshaft w<strong>it</strong>h lots of valve overlap sounds better than every girl in a strip club<br />

simultaneously screaming your name.<br />

At BAKER Drivetrain we are gear-heads and motor-heads; we love this sh<strong>it</strong>. But we don’t make motors; we make<br />

drivetrains and they often take a back seat to the iconic presence of the motor. The Custom and Performance catalog<br />

is proof that we won’t let the drivetrain be overlooked. It’s importance as the caretaker of delivering that juicy V-twin<br />

torque to the rear tire cannot be emphasized enough.<br />

So you have some torque. The OD6 and PowerBox will handle 165 ft-lbs of torque. Both have a <strong>com</strong>mon gearset<br />

but the PowerBox borrows heavily gusseted arch<strong>it</strong>ecture from Satan’s transmission, the TorqueBox which begs for<br />

250 ft-lbs of torque. The Function Formed Primary (FFP) has that classic belt drive look but <strong>it</strong>’s enclosed wet design<br />

has a through-hole in the middle and is ready for mid control fabrication. And don’t forget the clutch, <strong>it</strong> is surrounded<br />

by two bullies; the torque from the motor and the rear tire/pavement but the KKK clutch was born from a Cadillac<br />

transmission, grew up in Detro<strong>it</strong>, and can kick anybody’s ass. And there’s more unique drivetrain <strong>com</strong>ponents that are<br />

only available in the catalog you are holding right now, so please check <strong>it</strong> out.<br />

This <strong>com</strong>pany was started 12 years ago because motors were making more and more power, but nobody was taking<br />

the drivetrain seriously. Make sure to choose the right drivetrain, chassis, and rear wheel to put the power to the<br />

ground.<br />

The <strong>com</strong>ponents we offer for the Harley Davidson® drivetrain aftermarket are now broken up into 4 catalogs: Cruise<br />

Drive era (2007-later), 5-speed era (1984-2006), 4-speed era (1936-86), and Custom/Performance (includes Big Dog<br />

and Sportster/Buell). All four catalogs are available in hard copy or can be downloaded from our webs<strong>it</strong>e. Each catalog<br />

is technically informative, includes some reference pricing, and should provide the information necessary to improve the<br />

performance of your American V-Twin. If, after reading this catalog, you still have questions then give our experienced<br />

tech or sales staff a call at (877) 640-2004 or send an Email to info@bakerdrivetrain.<strong>com</strong>.<br />

Photo courtesy of Steve Berner<br />

2

Available as a builder’s k<strong>it</strong> or <strong>com</strong>plete transmission assembly for the following<br />

applications:<br />

PN DESCRIPTION FITMENT<br />

T401 Builder’s K<strong>it</strong>, 2.94 1st, Tapered Shaft 1985-89 FL, Softail,<br />

T401S Builder’s K<strong>it</strong>, 2.94 1st, Tapered Shaft 1985-89 FXR<br />

T701 Complete Build, 2.94 1st, Tapered Shaft 1985-89 Softail<br />

T702 Complete Build, 2.94 1st, Tapered Shaft 1985-89 FL, FXR<br />

401 Builder’s K<strong>it</strong>, 2.94 1st 90-92 FL, 90-97 Softail,<br />

90-94 FXR, 91-97 Dyna<br />

401S Builder’s K<strong>it</strong>, 2.94 1st 99 FXR, 98 Dyna, 98-99<br />

Softail<br />

401SP Builder’s K<strong>it</strong>, 2.94 1st 1999-00 Dyna<br />

401P Builder’s K<strong>it</strong>, 2.94 1st 2000-06 Softail, 2001-05<br />

Dyna<br />

402 Builder’s K<strong>it</strong>, 2.94 1st 1993-97 FL<br />

402S Builder’s K<strong>it</strong>, 2.94 1st 1998 FL<br />

404SP Builder’s K<strong>it</strong>, 2.94 1st 1999-00 FL<br />

404P Builder’s K<strong>it</strong>, 2.94 1st 2001 FL<br />

404P2 Builder’s K<strong>it</strong>, 2.94 1st 2002-06 FL<br />

701 Complete Build, 2.94 1st 1990-97 Softail<br />

702 Complete Build, 2.94 1st 1990-02 FL<br />

703 Complete Build, 2.94 1st 1991-97 Dyna<br />

704 Complete Build, 2.94 1st 1993-97 FL<br />

801 Complete Build, 2.94 1st 98-99 Softail<br />

803 Complete Build, 2.94 1st 1998 Dyna<br />

804 Complete Build, 2.94 1st 1998 FL<br />

901 Complete Build, 2.94 1st 2000-06 Softail<br />

902 Complete Build, 2.94 1st 1999 FXR<br />

903 Complete Build, 2.94 1st 1999-00 Dyna<br />

904 Complete Build, 2.94 1st 1999-00 FL<br />

003 Complete Build, 2.94 1st 2001-2005 Dyna<br />

004 Complete Build, 2.94 1st 2001 FL<br />

0042 Complete Build, 2.94 1st 2002-06 FL<br />

the original 6-speed transmission<br />

This is the ORIGINAL 6-speed design that revolutionized the American V-Twin<br />

industry. Yet, <strong>it</strong>’s still the best overdrive 6-speed built to this day...hands down.<br />

Our OD6 is built to <strong>com</strong>fortably handle the power from todays big-inch motors.<br />

This transmission is rated for motors putting out up to 165ft/lbs of continuous use.<br />

It is available as a <strong>com</strong>plete transmission w<strong>it</strong>h a wide variety of case options and<br />

configurations, or as a builder’s k<strong>it</strong> for your stock case application, which requires l<strong>it</strong>tle<br />

to no modification. The BAKER OD6 is available w<strong>it</strong>h many optional gear ratios to<br />

match your engine torque and riding style.<br />

Certain 94 and newer models require use<br />

2-6C door (w<strong>it</strong>h<br />

exhaust bracket<br />

mount ear) shown<br />

OPTIONAL OD6<br />

STANDARD DOOR<br />

CONFIGURATIONS:<br />

1) Ear Type (all finishes)<br />

2) Carlini-type<br />

3) Merch-type<br />

4) 1984-86 type<br />

5) No Ear (all finishes)<br />

OPTIONAL CASE<br />

FINISHES:<br />

1) Wrinkle Black<br />

2) Polished<br />

3) Raw<br />

4) Chrome (on Evo<br />

Billet cases only)<br />

Available No Cost<br />

Options:<br />

- N-1 Shift Drum<br />

- Reverse Pattern Shift Drum<br />

Available Upgrade<br />

Options:<br />

- Complete build transmission<br />

- Front or Rear Feed Hydrualic<br />

Side Cover<br />

- +1 Oil Pans<br />

- BAKER Clutches<br />

MSRP $40<br />

of separately purchased BAKER re-cal box<br />

PN 95E-56 for correct electronic speedo<br />

operation.<br />

MSRP $135<br />

TOP GEAR RPM:<br />

5-SPEED VS. OD6<br />

MPH 5-speed OD6<br />

In 5th In 6th<br />

65 2945 2533<br />

70 3172 2723<br />

75 3398 2923<br />

80 3625 3118<br />

Calculated data based on a 24/37<br />

primary, a 32/70 secondary, and<br />

a 25” rear tire.<br />

STANDARD RATIOS<br />

2.94, 2.21, 1.60, 1.23, 1.00, .86<br />

OPTIONAL RATIOS:<br />

1st gear: 3.24 & 2.82(R)<br />

2nd gear: 2.08(R)<br />

6th gear: .80 (deep overdrive)<br />

FUNCTION-FORMED OD6 TRAP<br />

DOOR AND ACTUATOR END COVER<br />

AVAILABLE FOR UPGRADE!<br />

Polished<br />

FF oil<br />

spout<br />

included<br />

in FL k<strong>it</strong>s<br />

and <strong>com</strong>plete<br />

builds<br />

MSRP<br />

starting at<br />

$2395<br />

3<br />

We highly re<strong>com</strong>mend<br />

installing the separately<br />

purchased high torque<br />

bearing k<strong>it</strong>,<br />

BAKER PN 189-56<br />

FUNCTION FORMED OPTION:<br />

- Available upgrade on Builder’s K<strong>it</strong> or <strong>com</strong>plete assembly<br />

- Hydraulic or mechanical for BAKER LSD OD6’s only.<br />

- Narrower, sleek, FF design<br />

- Cleaner design; no fill plug or dipstick to clutter the look<br />

- Available black anodized, polished or chrome<br />

- Door PN: 490-6<br />

- Mechanical Cover PN: 491-6<br />

- Hydraulic Cover PN: 492-6<br />

- Designed to f<strong>it</strong> all BAKER Softail, Dyna, and FXR doors. Will f<strong>it</strong><br />

stock FL case.<br />

- Will work w<strong>it</strong>h all stock and aftermarket wet primaries. As well as<br />

all aftermarket belt drives that f<strong>it</strong> an OEM 5-speed.<br />

WITH ALL THE OPTIONS AND THE PROVEN DEPENDABILITY,<br />

OUR OD6 IS THE PERFORMANCE TUNER’S CHOICE.

We introduced RSD in 2001 when the 240 tires came out as<br />

a solution to balance big tire customs and <strong>it</strong> ac<strong>com</strong>plished<br />

just that. More than ever w<strong>it</strong>h the popular 300+ tires and the<br />

radical 360’s in circulation, RSD translates to zero offset<br />

and a perfectly balanced radical custom. See below for a<br />

short course in offset 101.<br />

AVAILABLE RSD6 GEAR RATIOS<br />

GEAR<br />

RATIO<br />

1ST<br />

2.82 (‘R’ RATIO)<br />

or 2.94<br />

or 3.24<br />

2ND<br />

2.08 (‘R’ RATIO)<br />

or 2.21<br />

3RD 1.60<br />

4TH 1.23<br />

5TH 1.00<br />

6TH .86<br />

AVAILABLE RSD5 GEAR RATIOS<br />

GEAR<br />

RATIO<br />

1ST 2.82 (‘R’ RATIO)<br />

or 2.94<br />

or 3.24<br />

2ND 2.08 (‘R’ RATIO)<br />

or 2.21<br />

3RD 1.60<br />

4TH 1.23<br />

5TH 1.00<br />

‘R’ ratio 1st and 2nd is available as an option at no cost. For drag racers, an ‘R’ Ratio<br />

setup means harder launches. For street racers, <strong>it</strong> gives the stoplight-to-stoplight<br />

performance advantage.<br />

Front Wheel<br />

Heavy<br />

Big-Inch<br />

Engine<br />

Transmission<br />

Assembly<br />

Fatter, Wider<br />

Rear Tire<br />

OFFSET 101:<br />

The Evo powered Harley Softail is the<br />

design basis for custom aftermarket<br />

<strong>com</strong>ponents like frames, transmissions,<br />

and engines. The pos<strong>it</strong>ional relationships<br />

between engine and transmission, engine<br />

and frame, and transmission and frame<br />

all go back to the Softail. The stock<br />

Softail from the factory is a well-balanced<br />

machine w<strong>it</strong>h no significant weight bias<br />

from the left to the right.<br />

If a wider than stock rear tire is used on<br />

a Softail, the powertrain (engine and<br />

transmission) must be moved to the left<br />

to allow the 1-1/2” wide drive belt to clear<br />

the left side of the rear tire. Moving the<br />

powertrain to the left is referred to as<br />

powertrain offset.<br />

Powertrain offset can be achieved by<br />

moving the transmission and/or engine to<br />

the left, away from the stock pos<strong>it</strong>ion. The<br />

math to explain this is easy; see the figure<br />

to the left. The stock H-D Softail has a 130<br />

size rear tire that is roughly 5.5” wide. The<br />

300 tire is roughly 12” wide, which means<br />

there is 3.25 more inches of rubber on<br />

each side. This means the powertrain has<br />

to move to the left about 3.25” or so.<br />

BAKER RIGHT SIDE DRIVE SYSTEMS<br />

ARE AVAILABLE FOR YOUR CUSTOM<br />

APPLICATION, SOFTAIL, FLT, FXR, OR<br />

DYNA (EVO OR TWIN CAM)<br />

FF Door and Actuator<br />

optional, see page 12.<br />

PN 465-6P Door and<br />

Actuator set shown<br />

Many choices in<br />

offset pulleys<br />

BAKER standard<br />

hydraulic pulley shroud<br />

-or-<br />

BAKER standard<br />

cable-type rear loader<br />

pulley shroud<br />

FLT style RSD door<br />

-or-<br />

Dyna style RSD door<br />

w<strong>it</strong>h removable tail section<br />

No charge upgrade<br />

RSD6 ign<strong>it</strong>ion kill shift drum<br />

Call a BAKER Tech guy for transmission<br />

applications and part numbers<br />

in several<br />

finish options:<br />

4

Mr. Potato Head® was conceived in R&D a few years back to study the configurational possibil<strong>it</strong>ies of putting universal<br />

bosses on a featureless tranny case. Just like the Mr. Potato Head® toy, you can end up w<strong>it</strong>h a genetic hermaphrod<strong>it</strong>e<br />

w<strong>it</strong>h a l<strong>it</strong>tle off-the-menu creativ<strong>it</strong>y. The universal tranny case accepts an A-flange, B-flange or Evo flange. It also accepts<br />

all kinds of tail stocks. This exercise yielded the easiest solution<br />

to offsetting a tranny case side-to-side or up-and-down in<br />

short production runs.<br />

The RT250 vision began at Rolling<br />

Thunder when they divulged plans to<br />

develop a FL-type Bagger frame that<br />

was setup for a 250 tire and Softail<br />

length primary in a balanced RSD<br />

chassis. They approached us about<br />

doing a special tranny that was<br />

specific to this frame. Mr. Potato<br />

Head® technology finally<br />

found <strong>it</strong>s first home and we<br />

named <strong>it</strong> the RT250 project.<br />

Left side view shows tail stock<br />

and front flange removed. PN RT250A-P<br />

MSRP $3995<br />

Pn<br />

Description<br />

RT250*-P RT250 Transmission assembly, polished<br />

RT250*-B RT250 Transmission assembly, wrinkle black<br />

*Specify “A” for A-flange, “B” for B-flange, and “E” for Evo Flange<br />

Features:<br />

- Utilizes stock Softail primaries or BAKER FFP<br />

- Tranny is offset ½” to the left to tuck the drive belt/chain “<br />

inside the frame rail<br />

- No ½” motor sprocket extension required; tranny is slammed<br />

against the inner primary<br />

- Tranny mainshaft is ½” shorter than stock<br />

- Oil bag is separate and below the tranny case for superior<br />

cooling<br />

- Frame has +2” in backbone for add<strong>it</strong>ional primary length<br />

- Stock Harley® FL frames converted by Rolling Thunder and<br />

original VIN retained for no registration hassle<br />

- Frames accept stock seat, bags, tank, and front end<br />

Note the following:<br />

- Tail stock is securely located via two thick walled<br />

hollow dowels and three 3/8” bolts<br />

- Front flange is pinned down w<strong>it</strong>h seven 5/16 screws and<br />

two dowels<br />

- ½” deep relief in starter ear and case shows<br />

½” left offset<br />

- Low profile shift lever on tranny case required to<br />

clear inside of inner primary<br />

- DD6R gearset w<strong>it</strong>h 3.45 1st, 2.56 2nd, 1.87 3rd,<br />

1.44 4th,1.15 5th, &1.00 6th<br />

- Low profile hydraulic pulley included w<strong>it</strong>h choice of low<br />

pro 32 pulley or chain sprocket<br />

- Other pulley covers, including cable type, available<br />

- TorqueBox inspired detent system for smooth precise shifting<br />

5<br />

low-profile pulley cover<br />

PN RT127-56HC<br />

MSRP $599<br />

PN RT292<br />

MSRP $169<br />

PN<br />

RT127-56HC<br />

RT127-56HP<br />

RT292<br />

Description<br />

RSD pulley cover, chrome, hydraulic Low Pro<br />

RSD pulley cover, polished, hydraulic Low Pro<br />

32 tooth low profile pulley, long life steel<br />

F<strong>it</strong>ment<br />

All BAKER RSD except PowerBox, TorqueBox, & Drive Brake<br />

Low Profile features<br />

- Designed for 1-1/8” wide belts and smaller<br />

- FF aesthetics chiseled out of 6061-T6 aluminum<br />

- Low profile external features for maximum exhaust clearance<br />

- 1.5” diameter piston included<br />

- Compatible w<strong>it</strong>h H-D® or 11/16” hydraulic master cylinders<br />

- Must use low profile RT292 pulley or chain sprocket; will not f<strong>it</strong><br />

over standard width pulleys

Drive brake transmissions<br />

clean up the rear wheel brake related clutter.<br />

We designed our Drive Brake transmission as a <strong>com</strong>plete system to<br />

address some concerns we had w<strong>it</strong>h bolt on systems. Some bolt on<br />

systems had small diameter rotors w<strong>it</strong>h partial brake pad engagement;<br />

the one we evaluated wouldn’t even allow us to lock up and skid the rear<br />

wheel. So we designed our system w<strong>it</strong>h an 8” rotor and full pad engagement.<br />

W<strong>it</strong>h a prototype we were able to lock up the rear wheel and throw <strong>it</strong> sideways.<br />

Aesthetically, <strong>it</strong> is super clean w<strong>it</strong>h the caliper located in between the belt rungs and<br />

a minimalistic Function Formed hydraulic actuator spider.<br />

Features:<br />

- 8” stainless steel rotor<br />

- 6061-T6 aluminum clutch actuator spider w<strong>it</strong>h<br />

1.5” diameter piston (hydraulic only). 11/16”<br />

master cylinder re<strong>com</strong>mended<br />

- Dual piston brake caliper w<strong>it</strong>h PM guts<br />

- Inboard piston bore is an integral part of the door<br />

- Polished stainless steel stand-offs under front spider legs<br />

- Dual brake bleeders; one above each piston<br />

- Available w<strong>it</strong>h show polished or chrome finishes<br />

- Chrome top cover available w<strong>it</strong>h or w<strong>it</strong>hout neutral sw<strong>it</strong>ch<br />

- 29 tooth .5” offset pulley standard<br />

- N1 drum optional<br />

- ‘R’ ratio no cost option for big motor applications<br />

F<strong>it</strong>s 1990-99 Softail-based and custom Right Side Drive<br />

Pn<br />

Description<br />

R701PB-BRK Show polished Drive Brake transmission assembly w/ standard ratios<br />

R7211PB-BRK Show polished Drive Brake transmission assembly w/ ‘R’ ratio<br />

R701CB-BRK Chrome Drive Brake transmission assembly w/ standard ratios<br />

R7211CB-BRK Chrome Drive Brake transmission assembly w/ ‘R’ ratio<br />

Gear ratios:<br />

1st 2.54<br />

2nd 1.60<br />

3rd 1.00<br />

PN R7211PB-BRK<br />

MSRP $4495<br />

Standard ratio gears<br />

1st through 6th:<br />

2.94, 2.21, 1.60, 1.23, 1.00, .86<br />

R-Ratio gear ratios<br />

1st through 6th:<br />

2.82, 2.08, 1.60, 1.23, 1.00, .86<br />

The 3-speed cartridge style<br />

gearset installs into any<br />

1990-2006 5-speed based<br />

Big Twin transmission case<br />

w<strong>it</strong>h no modification.<br />

The Direct Drive 3-speed was developed for<br />

high horsepower <strong>com</strong>pet<strong>it</strong>ion applications like<br />

hill climbing, Bonneville and ¼ mile.<br />

The special 3-speed shift drum is the N1 type<br />

w<strong>it</strong>h neutral on bottom for a 0-down, 3-up<br />

shift pattern. The drum has no provision to<br />

trigger a neutral sw<strong>it</strong>ch.<br />

PN 301K<br />

MSRP $1495<br />

Countershaft and 3rd gear are cut out of one<br />

piece of 8620 steel for superior strength over<br />

a stock 5-speed. Other than the countershaft<br />

and the special 2.54 ratio 1st gear pair, the<br />

shafts, and other gears are stock BAKER<br />

5-speed <strong>it</strong>ems.<br />

6

We’ve been making transmission pulleys for years, both<br />

aluminum and steel. In short, aluminum pulleys are great for<br />

racing but do not hold up w<strong>it</strong>h miles. Deformed aluminum<br />

pulley teeth will lead to saggy belts. So we manufacture our<br />

SBD belt drive w<strong>it</strong>h steel pulleys front and rear for those<br />

who plan on putting on some miles.<br />

Using steel on the clutch basket pulley also greatly reduced<br />

the loose bolts rattling sound that is heard on some belt<br />

drives. Both steel pulleys are plated for corrosion protection.<br />

Available w<strong>it</strong>h zero and ½” offsets for wider rear tire<br />

applications.<br />

PN shown SBD-0-NS<br />

MSRP $2575<br />

FEATURES:<br />

- 1.54 pulley ratio w<strong>it</strong>h a 28 tooth<br />

pulley on front and a 43 in the rear<br />

for a 7% increase in torque to the<br />

rear wheel on stock Softails from<br />

1994 to present.<br />

- Motor plate and edge guard are<br />

made of 6061-T6 plate stock. Pulley<br />

caps and dog bone are made of<br />

6061-T6 forgings.<br />

- 10 plate clutch<br />

- 2.4” Wide, 14MM Tooth Proprietary<br />

Designed Belt<br />

- Available w<strong>it</strong>h or w<strong>it</strong>hout the<br />

outside bearing support<br />

(dog bone), however the dog<br />

bone configuration is highly<br />

re<strong>com</strong>mended.<br />

- Available in show<br />

polished or black<br />

anodized finishes<br />

- 66 tooth ring gear <strong>com</strong>es w<strong>it</strong>h<br />

matching 9 tooth, one piece<br />

starter jackshaft riding on a teflon<br />

impregnated busing.<br />

SBD belt drives for 1990-2006 softail applications:<br />

Pn<br />

DEscription<br />

SBD-0-S<br />

No Offset, Outside Support, Polished<br />

SBD-0-S-BA No Offset, Outside Support, Black Anodized<br />

SBD-1/2-S 1/2” Offset, Outside Support, Polished<br />

SBD-1/2-S-BA 1/2” Offset, Outside Support, Black Anodized<br />

SBD-0-NS No Offset, No Outside Support, Polished<br />

SBD-0-NS-BA No Offset, No Outside Support, Black Anodized<br />

SBD-1/2-NS 1/2” Offset, No Outside Support, Polished<br />

SBD-1/2-NS-BA 1/2” Offset, No Outside Support, Black Anodized<br />

7

PN 4100-FFP-P<br />

POLISHED<br />

MSRP $1995<br />

The primary drive housing is the most recognizable piece of arch<strong>it</strong>ecture on<br />

American motorcycles. It is centrally located and transfers power from the<br />

engine to the transmission.<br />

Available in a Black<br />

Anodized finish.<br />

FEATURES:<br />

-6061-T6 forged Inner and Outer<br />

-1 Piece starter jackshaft for strength<br />

-Full wet Primary set up<br />

-F<strong>it</strong>s stock and custom applications<br />

PN 4100-FFP-B<br />

BLACK ANODIZED<br />

MSRP $2,145<br />

We sculpted our forged 6061-T6 Function Formed Primary (FFP) to enhance<br />

the natural mechanical beauty of the elements inside. A SolidWorks 3D model<br />

of the clutch, chain, starter pinion, and motor sprocket was created and then<br />

we sparingly started adding material to wrap around those elements. No extra<br />

aluminum, just mechanical beauty. And there’s a glory hole in the middle for<br />

that open look, w<strong>it</strong>h the benef<strong>it</strong>s of the chain intact.<br />

FFP f<strong>it</strong>s all Softail models, Evo and Twin Cam w<strong>it</strong>hout modification.<br />

Compatible w<strong>it</strong>h stock 66-tooth and 102-tooth clutches, <strong>com</strong>pensating<br />

sprocket, chain, and starter motors. Each primary k<strong>it</strong> includes an inner primary<br />

housing, outer primary cover, special starter jackshaft, chain adjustment shoe<br />

and mechanism, gaskets, and fasteners.<br />

For performance junkies w<strong>it</strong>h mountain motors, the FFP has an optional<br />

internal outside bearing support (FFPS). Applications above 150 ft-lbs<br />

require the outside clutch support to keep the transmission mainshaft from<br />

flexing. The outside bearing support version is the first enclosed, wet primary<br />

available. Belt drives have been available for years w<strong>it</strong>h outside supports. Our<br />

new KKK clutch is required w<strong>it</strong>h outside support spider. See page 13 for<br />

KKK clutch details.<br />

The <strong>com</strong>pact design of the FFP dictates the<br />

following available sprocket/chain <strong>com</strong>binations:<br />

Motor Clutch Chain length<br />

sprocket sprocket (# of p<strong>it</strong>ches)<br />

21 36 80<br />

22 35 80<br />

23 38 82<br />

24 37 82<br />

25 36 82<br />

27 38 84<br />

28 37 84<br />

FFP for 1990-2006 softail applications:<br />

Pn<br />

Description<br />

4100-FFP-P Polished (9 tooth jackshaft)<br />

4100-FFP-B Black Anodized (9 tooth jackshaft)<br />

4101-FFP-P Polished (10 tooth Jackshaft)<br />

4101-FFP-B Black Ano (10 tooth Jackshaft)<br />

8

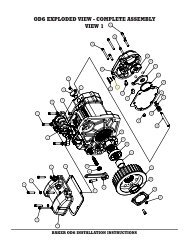

THE TORQUEBOX has 250 foot pounds of torque load capac<strong>it</strong>y!<br />

The torque output of an engine is proportional to the bore and stroke. Engines make torque and drivetrain <strong>com</strong>ponents<br />

take torque. It is torque, not horsepower that destroys clutches, transmissions, and drive belts. The torque capac<strong>it</strong>y of a<br />

transmission is proportional to the gear width and the center distance between the two shafts.<br />

All stock Harley transmissions and aftermarket transmissions have a center distance of 2.5”*. By increasing the center<br />

distance 20% to 3.0” the Torquebox conservatively increases the torque capac<strong>it</strong>y to 250 ft-lbs, continuous duty!<br />

In the early Torquebox design stages, the goal was set to design a continuous duty 250 ft-lb gearbox that visually<br />

looked like a 450 ft-lb gearbox on the outside. We achieved this by taking design cues from classic race-bred American<br />

superchargers and not having any excess material, anywhere. We achieved our goal.<br />

The Torquebox is available as a 5 or 6-speed, left or right side drive. The 6-speed is identical to the 5-speed except for the<br />

add<strong>it</strong>ion of two gears and a different drum. The right side drive version is the same as the left except for the mainshaft. All<br />

frame, starter, and clutch interfaces are identical to stock<br />

1990-1999 models.<br />

FEATURES:<br />

- Compatible w<strong>it</strong>h most softails and custom builds<br />

- Two rail shift form system w<strong>it</strong>h <strong>com</strong>mon fork used three times<br />

- 2” diameter shift drum suspended by two radial ball bearings mounted to a<br />

fixed spindle axis<br />

- Ratchet pawl has overshift inhib<strong>it</strong>or (up and down) and is mounted on two<br />

radial ball bearings. Shift lever shaft cross sectional area is 65% larger<br />

than stock.<br />

- Frictionless detent system. A 3/8” primary ball bearing is cradled by, and<br />

rolls on, 50 secondary micro ball bearings. In turn, the cradle is part of a<br />

plunger that actuates during shifting and is guided by a tertiary linear micro<br />

ball bearing system.<br />

- Ign<strong>it</strong>ion kill and neutral sw<strong>it</strong>ches top mounted for easy dwell timing<br />

adjustment.<br />

- Shift system lever ratio is 35% less than stock. Bearing mounted shift shaft<br />

yields low system hysteresis. Short, tight shifts are the result. N-1-2-3-4-5-<br />

6 shift pattern for false-neutral avoidance.<br />

- Shaft material is super strong 9310 – the best steel made – this isn’t<br />

standard by any means. Gears material is 8620. Very large 8.125 diameter<br />

p<strong>it</strong>ch gear teeth. The gear teeth are 2x circumferentially thicker than stock.<br />

Tooth flanks are finish-ground after heat treat on a 1.5 million dollar<br />

grinder. AGMA class 12 grade gears.<br />

- Housing is all billet construction from 6061-T651 aluminum. We start w<strong>it</strong>h<br />

95 lbs of aluminum and end up w<strong>it</strong>h 17 lbs of case and 78 lbs of chips.<br />

GEAR RATIOS:<br />

R-RATIO Z-Ratio<br />

1st 2.75 2.61<br />

2nd 2.05 1.89<br />

3rd 1.55 1.50<br />

4th 1.18 1.12<br />

5th 1.00 1.00<br />

6th .86 .95<br />

Pn Description F<strong>it</strong>ment<br />

TB521L R-Ratio Polished LSD 5 spd Evo Softail and Custom<br />

TB621L R-Ratio Polished LSD 6 spd Evo Softail and Custom<br />

TB521R<br />

R-Ratio Polished RSD 5 spd Right Side Drive<br />

TB621R<br />

R-Ratio Polished RSD 6 spd Right Side Drive<br />

TBZ5L Z-Ratio Polished LSD 5 spd Evo Softail and Custom<br />

TBZ6L Z-Ratio Polished LSD 6 spd Evo Softail and Custom<br />

TBZ5R<br />

Z-Ratio Polished RSD 5 spd Right Side Drive<br />

TBZ6R<br />

Z-Ratio Polished RSD 6 spd Right Side Drive<br />

PN TB521L,<br />

PN TBZ6R, Z-ratio<br />

R-ratio left side<br />

right side drive<br />

drive 5-speed,<br />

6-speed<br />

MSRP $4695 MSRP $5595<br />

9

PN PBL701PN<br />

PN PBR7211PN<br />

MSRP $3595 MSRP $3695<br />

approachable function-formed look<br />

w<strong>it</strong>hout having to pay for overkill strength<br />

The design directives for the TorqueBox were clearly established in the early stages of development. This flagship<br />

gearbox had to have a 250 ft-lb torque capac<strong>it</strong>y gearset but externally look like 400 ft-lb standing still. Development<br />

costs and resultant retail price were deemed irrelevant. By choosing the venerable 6-71 blower for arch<strong>it</strong>ectural<br />

inspiration, we inadvertently gave rise to what is now trademarked as Function Formed design.<br />

Enter the new PowerBox; Function Formed looks w<strong>it</strong>hout the need to pawn your guns or your wife’s jewelry. Design<br />

inspiration from the TorqueBox coupled w<strong>it</strong>h a diamond ground 8620 steel 6-speed overdrive gearset gives the<br />

PowerBox an input torque capac<strong>it</strong>y of 165 ft-lb, w<strong>it</strong>h a 400 ft-lb curb appeal; some may argue more. More because the<br />

tidy <strong>com</strong>pact design of the PowerBox makes the function Formed design elements pop out more. 34Ds will always be<br />

noticed more on a pet<strong>it</strong>e chick than a larger chick; same concept.<br />

Pn Description FItment<br />

PBR701PN Show polished RSD PowerBox transmission assembly w<strong>it</strong>h standard ratios 1990-99 Softail-based RSD bikes<br />

PBR7211PN Show polished RSD PowerBox transmission assembly w<strong>it</strong>h ‘R’ ratio gearset 1990-99 Softail-based RSD bikes<br />

PBL701PN Show polished LSD PowerBox transmission assembly w<strong>it</strong>h standard ratios 1990-99 Softail and Custom frames<br />

PBL7211PN Show polished LSD PowerBox transmission assembly w<strong>it</strong>h ‘R’ ratio gearset 1990-99 Softail and Custom frames<br />

GEAR RATIOS:<br />

- Standard ratio gears 1st through 6th: 2.94,<br />

2.21, 1.60, 1.23, 1.00, .86<br />

- R-Ratio gear ratios 1st through 6th; 2.82, 2.08,<br />

1.60, 1.23, 1.00, .86<br />

Features:<br />

- Hydraulic actuator w<strong>it</strong>h 1.5” piston standard.<br />

11/16” master cylinder re<strong>com</strong>mended<br />

- RSD <strong>com</strong>es w<strong>it</strong>h choice of 29 tooth zero offset<br />

pulley, 23 tooth or 24 tooth .2” chain sprocket<br />

- RSD can be upgraded w<strong>it</strong>h various offset chain<br />

sprockets and sizes to su<strong>it</strong> application. No pulley<br />

option available due to tight actuator spider size<br />

- LSD <strong>com</strong>es w<strong>it</strong>h choice of pulley or sprocket<br />

- LSD can be upgraded to all pulley and chain sizes<br />

and offsets to su<strong>it</strong> application<br />

- No neutral sw<strong>it</strong>ch for clean look<br />

- No cost upgrade to N1 drum<br />

- Speed sensor provision located on<br />

back of case requires .120 spacer<br />

- 12 point stainless steel ARP fasteners<br />

- Choice of standard and ‘R’ ratio gearsets<br />

10

Aluminum Alloy Race Pulley<br />

Race pulleys are the lightest pulleys available. A stock 32 tooth Harley pulley weighs 5.2 lbs and the equivalent Race<br />

pulley weighs 2.0 lbs; a 61% weight savings. This reduction in mass translates into reduced ‘flywheel effect’ and<br />

allows the engine to rev quicker. Hard anodized for wear resistance and corrosion protection. Absolutely required for<br />

performance applications but not re<strong>com</strong>mended for high mile touring. Part numbers listed are zero offset and f<strong>it</strong> 1994-<br />

2006 applications. 1985-93 applications require sprocket spacer and seal retrof<strong>it</strong>. Call tech line to inquire about 32 tooth<br />

offset pulleys available in .25, .50”, 1.0”, 1.5”, and 2.0” offsets. Custom offsets available by<br />

special order.<br />

# of teeth Aluminum PN<br />

29 29BD-56<br />

30 30BD-56<br />

31 31BD-56<br />

32 32BD-56<br />

34 34BD-56<br />

PN 32BD-56<br />

MSRP $180<br />

Steel Long Life Pulley<br />

Made from a solid chunk of 1045 steel and are 23% lighter than stock. Re<strong>com</strong>mended for performance applications<br />

where 100,000 mile pulley life is required. Part numbers listed are zero offset and f<strong>it</strong> 1994-2006 applications. 1985-93<br />

applications require sprocket spacer and seal retrof<strong>it</strong>. Call tech line to inquire about 32 tooth<br />

offset pulleys available in .25, .50”, .80”, .875”, and 1.0” offsets.<br />

# of teeth Steel PN<br />

29 29BD-56F<br />

30 30BD-56F<br />

31 31BD-56F<br />

32 32BD-56F<br />

33 33BD-56F<br />

34 34BD-56F<br />

PN 32BD-56F<br />

MSRP $169<br />

530 chain sprockets<br />

Moderate to extreme engine performance can raise hell w<strong>it</strong>h the stock secondary belt drive. The bullet proof remedy for<br />

this short<strong>com</strong>ing is to convert to a 530 chain. Sprockets are available in 3 offsets; .2”, .5”, and .9”. The .2” sprocket is<br />

based off the PN 37709-89 21 tooth Sportster sprocket. The .9” sprocket is the maximum offset that can be used and still<br />

allow room for the chain to clear the inside of the inner primary housing. .5” and .9” sprockets are generally used for wider<br />

rear tire applications. Part numbers listed f<strong>it</strong> 1994-2006 applications. 1985-93 applications require sprocket spacer and<br />

seal retrof<strong>it</strong>.<br />

# of Teeth .2” Pn .5” Pn .9” offset<br />

19 19T02-56<br />

20 20T02-56<br />

21 21T02-56 21T05-56<br />

22 22T02-56 22T05-56<br />

23 23T02-56 23T05-56 23T09-56<br />

24 24T02-56 24T05-56 24T09-56<br />

PN 24T02-56<br />

MSRP $65<br />

MSRP $19- Spacer<br />

$5- Seal<br />

Sprocket Spacer<br />

Our sprocket spacer is a direct replacement for the stock spacer except<br />

ours is case hardened steel that has a Rockwell ‘C’ hardness of 55. No<br />

more gouging, no more leaks.<br />

PN 33344-94S Sprocket Spacer, 94-Up Big Twin & Sportster<br />

PN 12067B Main Drive Gear Seal, 94-06 Big Twin<br />

11

The BAKER Heavy Duty Throwout Bearing K<strong>it</strong> replaces the failure-prone stock parts and eliminates throwout<br />

bearing associated headaches. The larger thrust bearing features a 97% greater surface area and<br />

77% greater static load capac<strong>it</strong>y than that of the stock throwout bearing. The brass spacer eliminates the<br />

possibil<strong>it</strong>y of bearing crush and disintegration. It is the perfect <strong>com</strong>pliment for those running heavy duty<br />

clutches in a high horsepower abusive environment.<br />

Features<br />

- Larger thrust bearing w<strong>it</strong>h 97% greater surface area than the stock throwout bearing.<br />

- 77% greater static load capac<strong>it</strong>y than the stock throwout bearing.<br />

- Brass spacer eliminates the possibil<strong>it</strong>y of bearing crush and disintegration which can lead to costly<br />

transmission failures.<br />

MSRP $79<br />

PN F<strong>it</strong>ment<br />

TBK-56L 1987-2011 5 and 6-speed Big Twin models w<strong>it</strong>h left side drive and cable actuated clutch.<br />

PN<br />

BW127-56MC<br />

Description<br />

Pulley cover, chrome, cable type, Bat Wing<br />

F<strong>it</strong>ment<br />

- All BAKER RSD except PowerBox, TorqueBox, & DriveBrake<br />

MSRP $399<br />

BATWING PULLEY COVER FEATURES<br />

- Designed for extra pulley and belt coverage<br />

- Compatible w<strong>it</strong>h standard -87 style clutch cables<br />

- Includes ball ramp actuator assembly<br />

- Lim<strong>it</strong>ed production run<br />

- Upgrade option on <strong>com</strong>plete assemblies only $200<br />

- Thicker Billet Function Formed design of actuator eliminates flex from heavy duty clutches<br />

- Dipstick is deleted for neater packaging<br />

- Hydraulic line routing is hidden and cleaner<br />

- Black anodized, polished or chrome finish<br />

FITMENT:<br />

- BAKER RSD OD6 cast Softail cases<br />

- All 530 chain sprockets and 30-tooth belt pulleys<br />

PN<br />

Description<br />

465-6P Door and Hydraulic Actuator - Polished<br />

465-6C Door and Hydraulic Actuator - Chrome<br />

465-6BA<br />

Door and Hydraulic Actuator - Black Anodized<br />

The Voyeur top cover is <strong>com</strong>patible w<strong>it</strong>h the late style (small pawl pin) ratchet pawls used from 1999-2006 except<br />

1999 Softail and gives you a full view of the shift system and partial of the gearset through the top cover made from<br />

billet optical grade Zelux, annealed and vapor polished for a clear view.<br />

Will f<strong>it</strong> all BAKER products from Mid-2004-up w<strong>it</strong>h BAKER 555-56A & 555-56L ratchet pawls. Voyeur top cover can<br />

be used on other 5&6 speed applications if upgraded w<strong>it</strong>h a BAKER ratchet pawl. The old style ratchet is bulky and<br />

interferes w<strong>it</strong>h the inside of the top cover on downshifts. Note: Not <strong>com</strong>patible w<strong>it</strong>h any Dyna applications, BAKER<br />

Billet series transmissions, TorqueBox, & DSSC<br />

Pn<br />

Description<br />

441-56P Top Cover, Zelux Voyeur<br />

MSRP $295<br />

BAKER Clutch Pack Replacement K<strong>it</strong>s contain all necessary fiber and steel plates<br />

to restore like new performance to your BAKER clutch.<br />

The Trans Rebuild K<strong>it</strong> is an all inclusive k<strong>it</strong> designed to freshen up those high<br />

mileage bikes. Developed to work specifically w<strong>it</strong>h our OD6, DD6, DD5 and OEM5<br />

left side drive transmissions. Includes bearings, snap rings, gaskets, seals and<br />

retaining nuts.<br />

Call the BAKER tech line for part numbers and applications.<br />

Rebuild K<strong>it</strong> MSRP $175<br />

Clutch Pack K<strong>it</strong>, MSRP $200<br />

12

MSRP $1395 MSRP $695<br />

MSRP $95<br />

AC/DC Pinion<br />

Used to convert your<br />

102 tooth configuration to<br />

a 66 tooth configuration<br />

“Torque capac<strong>it</strong>y of a clutch is dictated by the diameter and<br />

the number of clutch plates.” So the goal was to implement<br />

the biggest diameter clutch plates that would f<strong>it</strong> underneath<br />

the starter ring gear minor diameter. We found the biggest<br />

ones in a Cadillac 5-speed automatic tranny so we designed<br />

a clutch around 20 of these massive plates.<br />

FEATURES:<br />

- F<strong>it</strong>s any Big Twin from 1990-2006 (except 2006 Dyna).<br />

- 20, 7 inch diameter, single sided K2 friction plates<br />

- Three interchangeable coil spring options. Light, medium and heavy.<br />

- BAKER’S exclusive1-piece clutch basket and 66 tooth ring gear design<br />

- Larger torque capac<strong>it</strong>y<br />

- Pos<strong>it</strong>ive pressure plate alignment w<strong>it</strong>h Perma-Glide bearings<br />

- Red anodized clutch carrier and pressure plate<br />

OPTIONS:<br />

- AC/DC Pinion gear available for use w<strong>it</strong>h 102 tooth configurations<br />

- 35, 36, 37,or 38-Tooth 8620 steel sprocket options<br />

- Outer bearing support. ** Designed to work directly w<strong>it</strong>h the FF Primary<br />

PN: SP1000<br />

F<strong>it</strong>ment 1994-2006<br />

(except 06 Dyna)<br />

The 9-plate clutch is the <strong>com</strong>pet<strong>it</strong>ively priced smaller<br />

brother of the KKK. A must have for all 1990-93 Big<br />

Twins, and 1994 and newer Big Twins w<strong>it</strong>h 9 tooth pinion,<br />

this clutch <strong>com</strong>es w<strong>it</strong>h BAKER Drivetrain’s standard for<br />

premium products. It has a one piece basket, which is 23%<br />

larger than stock, and a hard anodized hub for increased<br />

strength and durabil<strong>it</strong>y. We moved the friction material<br />

towards the outer diameter of the plate, which increases<br />

torque capac<strong>it</strong>y and reduces heat build-up, all resulting in<br />

a longer clutch life.<br />

FEATURES:<br />

- F<strong>it</strong>s any Big Twin from 1990-2006 (except 2006 Dyna).<br />

- Blue anodized clutch carrier and pressure plate<br />

- Compatible w<strong>it</strong>h applications up to 125 ft-lbs. Diaphragm-type pressure<br />

plate spring w<strong>it</strong>h ergonomic break-over feel during disengagement.<br />

- Comes w<strong>it</strong>h standard diaphragm spring installed, and a seperate heavy<br />

duty rated spring.<br />

- 9 Kevlar 2-sided clutch plates w<strong>it</strong>h large mean radius<br />

- BAKER’S exclusive1-piece clutch basket and 66 tooth ring gear design<br />

- Standard and Heavy-duty springs included<br />

PN<br />

20P200-KK-35<br />

20P200-KK-36<br />

20P200-KK-37<br />

20P200-KK-38<br />

20P200-KK-S-35<br />

20P200-KK-S-36<br />

20P200-KK-S-37<br />

20P200-KK-S-38<br />

Description<br />

KKK w/35 Tooth Clutch Sprocket<br />

KKK w/36 Tooth Clutch Sprocket<br />

KKK w/37 Tooth Clutch Sprocket<br />

KKK w/38 Tooth Clutch Sprocket<br />

KKK w/35 Tooth Clutch Sprocket & Outer Bearing Support<br />

KKK w/36 Tooth Clutch Sprocket & Outer Bearing Support<br />

KKK w/37 Tooth Clutch Sprocket & Outer Bearing Support<br />

KKK w/38 Tooth Clutch Sprocket & Outer Bearing Support<br />

OPTIONS:<br />

- available w<strong>it</strong>h a 35, 36, 37, or 38 tooth 8620 steel sprocket<br />

- AC/DC Pinion gear available for use w<strong>it</strong>h 102 tooth applications<br />

PN<br />

9P300-56-35<br />

9P300-56-36<br />

9P300-56-37<br />

9P300-56-38<br />

Description<br />

9 Plate w/35 Tooth Clutch Sprocket<br />

9 Plate w/36 Tooth Clutch Sprocket<br />

9 Plate w/37 Tooth Clutch Sprocket<br />

9 Plate w/38 Tooth Clutch Sprocket<br />

13

STRONGEST CLUTCH BY DESIGN<br />

Street performance 9-plate<br />

clutch basket<br />

King Kong Klutch basket<br />

Both our King Kong Klutch and<br />

Street Performance 9-plate Clutch<br />

have 66 Tooth ring gears - the stock<br />

basket here has 102 teeth.<br />

Stock clutch<br />

Starting tip of the day<br />

Never snap the throttle open and<br />

closed when the starter is engaged<br />

and turning over the motor. If you<br />

have a clutch w<strong>it</strong>h a 102 tooth ring<br />

gear, you could shear teeth. If you<br />

have a 66 tooth ring gear, you<br />

could bend the mainshaft on the<br />

transmission.<br />

The fundamental design approach of the BAKER clutches is different than anything available from the factory or other<br />

aftermarket manufacturers. For strength reasons, we manufacture our clutch w<strong>it</strong>h a 1-piece ring gear/basket. First, a<br />

large donut shaped forging is turned on a CNC lathe to the shape of the finished basket. Next the internal splines for the<br />

friction plates are formed w<strong>it</strong>h a 6-foot long broach. Threads for attachment of the carrier are machined on a mill, then<br />

the ring gear teeth are hobbed on the same type of machine that makes our gears. It is not cheap to make the heart and<br />

soul of our clutches in this manner but the end result justifies the expense.<br />

The radial strength gained by integrally putting the ring gear around the basket is analogous to the steel bands placed<br />

around a whisky barrel. W<strong>it</strong>hout the steel bands, the barrel would explode and that would be alcohol abuse. Add<strong>it</strong>ionally,<br />

the ring gear is supported by the hoop of the basket and this guarantees the T.I.R. at the p<strong>it</strong>ch line of the ring gear teeth<br />

(no egg shaped ring gear).<br />

We only manufacture clutches w<strong>it</strong>h the 66 tooth ring gear. In 1994, Harley migrated from the 66 tooth ring to a 102 tooth<br />

design to achieve more starting torque. The flip side of that is the teeth sheer off especially on modified motors.<br />

35-Tooth Sprocket 36-Tooth Sprocket 37-Tooth Sprocket 38-Tooth Sprocket<br />

KKK clutch diameter dwarfs the<br />

factory clutch plate<br />

Clutches f<strong>it</strong> 1990-2006 big twin models<br />

(except for 06 Dyna).<br />

14

The BAKER XL6 is a six-speed overdrive ‘cartridge style’ gearset<br />

that converts any existing 1991-2003 Sportster/Buell to a BAKER<br />

six speed. 2nd through 5th gear ratios are effectively the same as<br />

stock, 6th gear is a true overdrive for a 511rpm drop at 75mph.<br />

XL6 KITS INCLUDE:<br />

- 6061-T6 trap door<br />

- Complete gearset including shafts and gears, less<br />

the 5th (maindrive) gear pair. 5th gear pair from<br />

existing 5-speed is re-used w<strong>it</strong>h the XL6 installation.<br />

- Gearset is assembled to the trap door including<br />

bearings, ball bearings, thrust washers, and<br />

retaining rings.<br />

- Shift drum and detent plate w<strong>it</strong>h optimized geometry.<br />

No flimsy retaining clip to hold the detent plate to the<br />

drum. Ours is bolted on w<strong>it</strong>h a machine screw.<br />

- Low effort detent spring.<br />

- Three billet steel shift forks w<strong>it</strong>h roller pins and<br />

cotter pins.<br />

- Steel template for accurate case modification.<br />

- ‘XL6’ engraved derby cover (P/N 202 & 203).<br />

PN 202 XL6 cartridge gearset<br />

MSRP $2350<br />

Other drivetrain <strong>com</strong>ponents for Sportster/Buell:<br />

Steel Long Life Pulley<br />

PN DESCRIPTION F<strong>it</strong>ment<br />

271-5 Smooth shift k<strong>it</strong>, for stock 5-speed 5-speed<br />

291-5 Reverse pattern drum, stock 5-speed 5-speed<br />

299-5 Trap door, Stock 5-speed 5-speed<br />

292-56 26 tooth pulley, aluminum race 5-speed or XL6<br />

292-56F 26 tooth pulley, long life steel 5-speed or XL6<br />

293-56 28 tooth pulley, aluminum race 5-speed or XL6<br />

293-56F 28 tooth pulley, long life steel 5-speed or XL6<br />

230-56S 530 Chain conversion k<strong>it</strong>, 48/23 ft/rr 1991-2003 Buell<br />

231-56S 530 chain conversion k<strong>it</strong>, 50/23 ft/rr 1991-2003 Buell<br />

232-56S 530 chain conversion k<strong>it</strong>, 52/23 ft/rr 1991-2003 Buell<br />

233-56S 530 chain conversion k<strong>it</strong>, 54/23 ft/rr 1991-2003 Buell<br />

Race Pulley<br />

XL 5-Speed Smooth<br />

Shift K<strong>it</strong><br />

PN DESCRIPTION F<strong>it</strong>ment<br />

201 XL6 Builder’s K<strong>it</strong> 91-94 Sportster/Buell<br />

202 XL6 Builder’s K<strong>it</strong> 95-03 Sportster/Buell<br />

203 XL6 Builder’s K<strong>it</strong> For S&S Dry 91-03 S&S dry xl case<br />

Primary Case Only<br />

NOTES:<br />

- Standard ratios for the PNs shown above are 2.52,<br />

1.96, 1.44, 1.18, 1.00, .86<br />

- Specify ‘S’ ratio 1st (2.37) and 2nd (1.88) by<br />

changing the ‘0’ in the PN to a ‘2’<br />

- Specify no-cost reverse pattern (1-up, 5-down) drum<br />

by adding an “R” to the PN<br />

15<br />

Billet 5-Speed Door

shown PN BD-BDM-1/2<br />

$2995 MSRP<br />

We manufacture the whole drivetrain for 2005-later Big Dogs. The center distance of the primary drive is based on our<br />

DSSC and is not <strong>com</strong>mon w<strong>it</strong>h Softail. We used our knowledge of the factory system to develop our Synchronous Belt<br />

Drive. The pulleys are hobbed from stainless steel blanks for durabil<strong>it</strong>y and corrosion resistance. The structural integr<strong>it</strong>y<br />

of the stainless steel clutch pulley significantly reduces that loose tappet rattling sound that some other belt drives make<br />

when the clutch is disengaged. The indestructible pulleys are driven w<strong>it</strong>h a large tooth 2.4 inch belt and coupled w<strong>it</strong>h a<br />

radial ball bearing suspended outside bearing support.<br />

PN DESCRIPTION F<strong>it</strong>ment<br />

BD-BDM-1/2 Synchronous Belt drive, ½” offset, polished 2005-later, 250 tire bikes<br />

BD-BDM-0 Synchronous Belt drive, 0 offset, polished 2005-later, 300 tire bikes<br />

Service and support for Big Dog<br />

We service Big Dog transmissions and clutches and offer individual <strong>com</strong>ponents for both. However we re<strong>com</strong>mend our<br />

in-house rebuild service. Given our experience and our $50/hour shop rate <strong>it</strong> is highly re<strong>com</strong>mended. Add<strong>it</strong>ionally, we<br />

offer derby covers, motor sprocket covers, inspection covers, inspection cover seal rings, pulley covers and pulley cover<br />

parts, optional primary paper gaskets, OEM primary O-rings, motor sprockets, and chains. Call our sales department for<br />

availabil<strong>it</strong>y and pricing.<br />

16

WE’VE GOT SOCIAL NETWORKING SKILLS YO!<br />

BAKER is hip to the new way that our customers are learning and<br />

<strong>com</strong>municating - We have been paying attention the past few years to the<br />

growing number of bikers who spend their time online. We have also noticed<br />

that information passes quickly, and freely online.<br />

W<strong>it</strong>h that in mind: we have also launched a BAKER MySpace, BAKER<br />

Facebook and you can even catch up to the minute BAKER sales and<br />

updates on your phone by following us on Tw<strong>it</strong>ter.<br />

So look us up on your favor<strong>it</strong>e social networking s<strong>it</strong>e to keep up w<strong>it</strong>h the<br />

latest happenings at BAKER. You will hear about what sales are hot, what<br />

deals we’re passing to our dealers, and more... we can’t gaurantee that you<br />

won’t get a random dirty joke or bathroom update. You’ve been forewarned.<br />

LOG ON AND FOLLOW US!<br />

BAKER ONLINE STORE:<br />

BAKER product offerings 10 years ago were pretty damn simple. We offered 8 different part numbers and that was <strong>it</strong>. Our<br />

printed catalog easily captured and conveyed our product line. American motorcycle enthusiasts got their information by<br />

calling our toll free number, reading magazines, and attending bar stool seminars. Back then, nobody in our world relied<br />

on, or trusted, the internet to obtain n<strong>it</strong>ty-gr<strong>it</strong>ty details on neat new stuff for their scoot. But today, thanks to pornography,<br />

bikers are as web-savvy as the rest of the population. And <strong>it</strong>’s a good thing because BAKER product offerings these days<br />

number in the thousands and many configurational options are available for any one application. In 2009 we launched the<br />

new BAKER E-Commerce s<strong>it</strong>e to simplify the task of product selection for our dealers (password required) and the public.<br />

Look for the E-Commerce button prominently displayed on our home page. It will guide you interactively, through the<br />

maize of options, so you end up w<strong>it</strong>h the right configuration for your application.<br />

The ECommerce store has proved very quickly to be an excellent tool for our dealers and retail customers alike. For<br />

<strong>com</strong>plete updates, log on, and make sure we have your email address in our database! It’s the best way not to miss out!<br />

17

6-speed baker brand made in the usa baker logo<br />

MSRP $20<br />

twisted fuck king of gears vintage baker<br />

dont forget your annual<br />

official baker calendar<br />

poster!<br />

BAKER has a full line of apparel including t-shirts, hats, stickers, tin signs<br />

and even shop jackets and shirts for men and women. Check out our<br />

Official BAKER Online Store for availabil<strong>it</strong>y and the latest merchandise<br />

out there! What better way to brag about your BAKER?<br />

There Is More To A Transmission<br />

Than Just Metal<br />

As a <strong>com</strong>pany tenaciously focused on any improvement to the<br />

American Big Twin drivetrain, BAKER Drivetrain recognizes the<br />

fluid in the transmission is key in the performance and life of a<br />

transmission. It is a mechanical part of <strong>it</strong> as much as the gears,<br />

case, bearings, etc…so <strong>it</strong> must be of qual<strong>it</strong>y. The Spectro<br />

Platinum Heavy Duty 6-Speed Transmission Lubricant meets<br />

our BAKER Drivetrain qual<strong>it</strong>y standards for re<strong>com</strong>mended<br />

transmission oil. Our standard for re<strong>com</strong>mending oil is that <strong>it</strong><br />

must have optimized properties tailored only for <strong>com</strong>ponents<br />

in a V-Twin motorcycle transmission and <strong>it</strong> must exceed all<br />

others in excellence – like our own products do. Cheaper oils<br />

cannot provide all these qual<strong>it</strong>ies.Spectro’s 6-Speed formula<br />

base is synthetic group 4 base stock which is the highest rating<br />

for a synthetic lubricant. It is pure w<strong>it</strong>h absolutely no petroleum<br />

product blended into <strong>it</strong>.<br />

PN BD-75W140<br />

MSRP $14<br />

18

The V-8 car culture and V-twin bike scene are similar in many ways; American muscle, performance, and<br />

torque . If you drop a ZZ572 into your project car, don’t overlook your transmission and rear end because that<br />

650 ft-lbs of torque is not kind to drivetrain <strong>com</strong>ponents. Same goes for your project bike. Today’s 124+ inch<br />

motors can grenade an anemic clutch and slope transmission. Make sure to choose drivetrain <strong>com</strong>ponents that<br />

are up to the task. Our tech experts have the street and strip knowledge necessary to help you determine the<br />

right gear ratios and drivetrain <strong>com</strong>ponents for your application. After that, the biggest challenge will be finding<br />

new rear tires.