You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

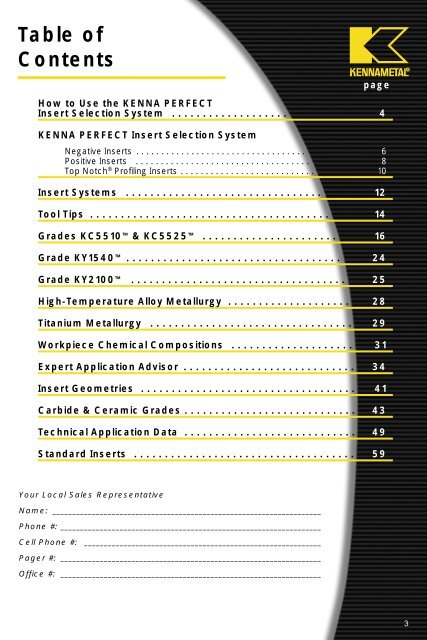

<strong>Table</strong> <strong>of</strong><br />

<strong>Contents</strong><br />

page<br />

How to Use the KENNA PERFECT<br />

Insert Selection System . . . . . . . . . . . . . . . . . . . 4<br />

KENNA PERFECT Insert Selection System<br />

Negative Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Positive Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Top Notch ® Pr<strong>of</strong>iling Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Insert Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Tool Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Grades KC5510 & KC5525 . . . . . . . . . . . . . . . . . . . . . . 16<br />

Grade KY1540 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

Grade KY2100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

High-Temperature Alloy Metallurgy . . . . . . . . . . . . . . . . . . . . 28<br />

Titanium Metallurgy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Workpiece Chemical Compositions . . . . . . . . . . . . . . . . . . . . 31<br />

Expert Application Advisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34<br />

Insert Geometries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41<br />

Carbide & Ceramic Grades . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43<br />

Technical Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49<br />

Standard Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59<br />

Your Local Sales Representative<br />

Name: ____________________________________________________________________<br />

Phone #: __________________________________________________________________<br />

Cell Phone #:<br />

____________________________________________________________<br />

Pager #: __________________________________________________________________<br />

Office #: __________________________________________________________________<br />

3

KENNA PERFECT Insert Selection System<br />

KENNA PERFECT, Kennametal’s 3-step insert selection system, makes choosing and applying the most<br />

productive tool as easy as 1, 2, 3.<br />

Tool recommendations are based on six workpiece material groups, optimizing selection accuracy.<br />

Example:<br />

6 workpiece material groups<br />

1st Step<br />

Select the insert geometry<br />

Given:<br />

Unknown:<br />

Solution:<br />

depth <strong>of</strong> cut = .040 and<br />

feed = .016 ipr<br />

insert geometry<br />

-MS<br />

2nd Step<br />

Select the grade<br />

Given:<br />

Geometry:<br />

Unknown:<br />

Solution:<br />

cutting conditions:<br />

lightly interrupted cut<br />

-MS<br />

grade<br />

KC5525<br />

3rd Step<br />

Select the cutting speed<br />

Given:<br />

Unknown:<br />

Solution:<br />

grade KC5525<br />

cutting conditions<br />

cutting speed<br />

150 sfm<br />

4

KENNA PERFECT Insert Selection System<br />

Steel<br />

Stainless Steel<br />

Cast Iron<br />

Non-Ferrous<br />

High-Temp Alloy<br />

Hardened Material<br />

Negative Inserts<br />

Roughing<br />

1st Step – Selection <strong>of</strong> the Insert Geometry 125 40<br />

-RP<br />

Medium Machining<br />

-MS<br />

-MS<br />

Finishing<br />

.NG<br />

-FS<br />

2nd Step –<br />

heavily<br />

interrupted cut<br />

lightly<br />

interrupted cut<br />

Cutting Condition<br />

varying depth <strong>of</strong> cut,<br />

casting or forging skin<br />

smooth cut,<br />

pre-turned surface<br />

3rd Step –<br />

grade 50 150 250 350<br />

(15) (45) (75) (105)<br />

K313<br />

Selection <strong>of</strong> the Grade<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

Starting Conditions<br />

550<br />

(170)<br />

650<br />

(200)<br />

Insert Geometry<br />

-FS ..NG -MS -RP<br />

KC5525 — KC5525 KC9245<br />

KC5510 KY1540 KC5525 KC5525<br />

KC5510 KY1540 KC5510 KC5525<br />

KC5510 / K313 KY2100 KC5510 / K313 KC5510<br />

Selection <strong>of</strong> the Cutting Speed<br />

750 850 950 1050 1150 1250<br />

(230) (260) (290) (350) (350) (380)<br />

sfm m/min<br />

KC5510<br />

KC5525<br />

KC9245<br />

KY1540<br />

KY2100<br />

225 70<br />

125 40<br />

125 40<br />

700 215<br />

750 230<br />

5

KENNA PERFECT Negative Inserts<br />

High-Temp Alloys<br />

1st Step – Select the Insert Geometry<br />

Negative Inserts<br />

Roughing<br />

-RP<br />

Medium Machining<br />

-MS<br />

Finishing<br />

.NG<br />

-FS<br />

2nd Step – Select the Grade<br />

heavily<br />

interrupted cut<br />

lightly<br />

interrupted cut<br />

varying depth <strong>of</strong> cut,<br />

casting or forging skin<br />

smooth cut,<br />

pre-turned surface<br />

Cutting Condition<br />

Insert Geometry<br />

-FS .NG -MS -RP<br />

KC5525 — KC5525 KC9245<br />

KC5510 KY1540 KC5525 KC5525<br />

KC5510 KY1540 KC5510 KC5525<br />

KC5510 / K313 KY2100 KC5510 / K313 KC5510<br />

To further optimize your operation, please reference<br />

pages 14-15 for Tool Tips and the Expert Application Advisor<br />

— Troubleshooting Guide on pages 34-40.<br />

6

KENNA PERFECT Negative Inserts<br />

3rd Step – Select the Cutting Speed<br />

Iron Base Heat-Resistant Alloys (135-320 HB) (≤34 HRC)<br />

Wrought: A-286, Discaloy, Incoloy 801, N-155, 16-25-6, 19-9 DL Cast: ASTM A297, A351, A608, A567<br />

grade<br />

K313<br />

KC5510<br />

KC5525<br />

KC9245<br />

KY1540<br />

KY2100<br />

50<br />

(15)<br />

150<br />

(45)<br />

250<br />

(75)<br />

350<br />

(105)<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

550<br />

(170)<br />

650<br />

(200)<br />

750<br />

(230)<br />

850<br />

(260)<br />

950<br />

(290)<br />

1050<br />

(350)<br />

1150<br />

(350)<br />

1250<br />

(380)<br />

Starting Conditions<br />

sfm m/min<br />

100 30<br />

180 55<br />

125 40<br />

100 30<br />

550 170<br />

600 185<br />

Cobalt-Base Heat-Resistant Alloys (150-425 HB) (≤45 HRC)<br />

Wrought: AiResist 213, Haynes 25 (L605), Haynes 188, J-1570, Stellite<br />

Cast: AiResist 13, Haynes 21, MAR-M302, MAR-M509, NASA Co-W-Re, WI-52<br />

grade<br />

K313<br />

50<br />

(15)<br />

150<br />

(45)<br />

250<br />

(75)<br />

350<br />

(105)<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

550<br />

(170)<br />

650<br />

(200)<br />

750<br />

(230)<br />

850<br />

(260)<br />

950<br />

(290)<br />

1050<br />

(350)<br />

1150<br />

(350)<br />

1250<br />

(380)<br />

Starting Conditions<br />

sfm m/min<br />

110 35<br />

KC5510<br />

195 60<br />

KC5525<br />

100 30<br />

KC9245<br />

110 35<br />

KY1540<br />

600 185<br />

KY2100<br />

650 200<br />

Nickel-Base Heat-Resistant Alloys (140-475 HB) (≤48 HRC)<br />

Astroloy, Hastelloy B/C/C-276/X, Inconel 601/617/625/700/706/718, IN102, Incoloy 901, MAR-M200,<br />

Nimonic, Rene 41, Udimet, Waspaloy, Monel<br />

grade<br />

K313<br />

50<br />

(15)<br />

150<br />

(45)<br />

250<br />

(75)<br />

350<br />

(105)<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

550<br />

(170)<br />

650<br />

(200)<br />

750<br />

(230)<br />

850<br />

(260)<br />

950<br />

(290)<br />

1050<br />

(350)<br />

1150<br />

(350)<br />

1250<br />

(380)<br />

Starting Conditions<br />

sfm m/min<br />

125 40<br />

KC5510<br />

225 70<br />

KC5525<br />

125 40<br />

KC9245<br />

125 40<br />

KY1540<br />

700 215<br />

KY2100<br />

750 230<br />

Titanium and Titanium Alloys (110-450 HB) (≤48 HRC)<br />

Pure: Ti98.8, Ti99.9<br />

grade<br />

K313<br />

KC5510<br />

50<br />

(15)<br />

Alloyed: Ti-5Al-2.5Sn, Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-8V-6Cr-4Mo-4Zr, Ti-10V-2Fe-3Al, Ti-13V-11Cr-3Al<br />

Speed - sfm (m/min)<br />

Starting Conditions<br />

150 250 350 450 550 650 750 850 950 1050 1150 1250 sfm m/min<br />

(45) (75) (105) (140) (170) (200) (230) (260) (290) (350) (350) (380)<br />

150 45<br />

225 70<br />

KC5525<br />

175 55<br />

7

KENNA PERFECT Positive Inserts<br />

High-Temp Alloys<br />

1st Step – Select the Insert Geometry<br />

Positive Inserts<br />

Medium Machining<br />

MT-LF<br />

Finishing<br />

R.GV-T<br />

..GT-LF<br />

R.GV<br />

Fine Finishing<br />

..GT-HP<br />

2nd Step – Select the Grade<br />

Cutting Condition<br />

Insert Geometry<br />

..GT-HP R.GV<br />

..GT-LF R.GV-T MT-LF<br />

heavily<br />

interrupted cut<br />

lightly<br />

interrupted cut<br />

varying depth <strong>of</strong> cut,<br />

casting or forging skin<br />

smooth cut,<br />

pre-turned surface<br />

— — KC5025 — KC5025<br />

KC5025 KY1540 KC5025 KY1540 KC5025<br />

KC5010 KY1540 KC5010 KY1540 KC5010<br />

KC5010/K313 KY2100 KC5010/K313 KY2100 KC5010<br />

To further optimize your operation, please reference<br />

pages 14-15 for Tool Tips and the Expert Application Advisor —<br />

Troubleshooting Guide on pages 34-40.<br />

8

KENNA PERFECT Positive Inserts<br />

3rd Step – Select the Cutting Speed<br />

Iron Base Heat-Resistant Alloys (135-320 HB) (≤34 HRC)<br />

Wrought: A-286, Discaloy, Incoloy 801, N-155, 16-25-6, 19-9 DL Cast: ASTM A297, A351, A608, A567<br />

grade<br />

K313<br />

KC5010<br />

KC5025<br />

KY1540<br />

KY2100<br />

50<br />

(15)<br />

150<br />

(45)<br />

250<br />

(75)<br />

350<br />

(105)<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

550<br />

(170)<br />

650<br />

(200)<br />

750<br />

(230)<br />

850<br />

(260)<br />

950<br />

(290)<br />

1050<br />

(350)<br />

1150<br />

(350)<br />

1250<br />

(380)<br />

Starting Conditions<br />

sfm m/min<br />

100 30<br />

140 45<br />

100 30<br />

550 170<br />

600 185<br />

Cobalt-Base Heat-Resistant Alloys (150-425 HB) (≤45 HRC)<br />

Wrought: AiResist 213, Haynes 25 (L605), Haynes 188, J-1570, Stellite<br />

Cast: AiResist 13, Haynes 21, MAR-M302, MAR-M509, NASA Co-W-Re, WI-52<br />

grade<br />

K313<br />

50<br />

(15)<br />

150<br />

(45)<br />

250<br />

(75)<br />

350<br />

(105)<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

550<br />

(170)<br />

650<br />

(200)<br />

750<br />

(230)<br />

850<br />

(260)<br />

950<br />

(290)<br />

1050<br />

(350)<br />

1150<br />

(350)<br />

1250<br />

(380)<br />

Starting Conditions<br />

sfm m/min<br />

110 35<br />

KC5010<br />

150 45<br />

KC5025<br />

90 25<br />

KY1540<br />

600 185<br />

KY2100<br />

650 200<br />

Nickel-Base Heat-Resistant Alloys (140-475 HB) (≤48 HRC)<br />

Astroloy, Hastelloy B/C/C-276/X, Inconel 601/617/625/700/706/718, IN102, Incoloy 901, MAR-M200,<br />

Nimonic, Rene 41, Udimet, Waspaloy, Monel<br />

grade<br />

K313<br />

50<br />

(15)<br />

150<br />

(45)<br />

250<br />

(75)<br />

350<br />

(105)<br />

450<br />

(140)<br />

Speed - sfm (m/min)<br />

550<br />

(170)<br />

650<br />

(200)<br />

750<br />

(230)<br />

850<br />

(260)<br />

950<br />

(290)<br />

1050<br />

(350)<br />

1150<br />

(350)<br />

1250<br />

(380)<br />

Starting Conditions<br />

sfm m/min<br />

125 40<br />

KC5010<br />

175 55<br />

KC5025<br />

100 30<br />

KY1540<br />

700 215<br />

KY2100<br />

750 230<br />

Titanium and Titanium Alloys (110-450 HB) (≤48 HRC)<br />

Pure: Ti98.8, Ti99.9<br />

grade<br />

K313<br />

KC5010<br />

50<br />

(15)<br />

Alloyed: Ti-5Al-2.5Sn, Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-8V-6Cr-4Mo-4Zr, Ti-10V-2Fe-3Al, Ti-13V-11Cr-3Al<br />

Speed - sfm (m/min)<br />

Starting Conditions<br />

150 250 350 450 550 650 750 850 950 1050 1150 1250 sfm m/min<br />

(45) (75) (105) (140) (170) (200) (230) (260) (290) (350) (350) (380)<br />

150 45<br />

200 60<br />

KC5025<br />

150 45<br />

9

KENNA PERFECT Top Notch ® Pr<strong>of</strong>iling Inserts<br />

High-Temp Alloys — Nickel, Iron, and Cobalt-Based Alloys,<br />

and Titanium Alloys<br />

1st Step – Select the Insert Geometry<br />

Roughing<br />

NP.13M..R, NP.332<br />

Medium Machining<br />

NP.5M, NP.13.. , NP-N,<br />

NP-F, NP.5..<br />

Finishing<br />

NPGR<br />

NP.5M<br />

NP.13..<br />

NP-N<br />

NP-F<br />

NP.5..<br />

NOTE: See Technical Section for<br />

chipbreaker details.<br />

Finishing<br />

NP.5..<br />

Medium Machining<br />

VCMR<br />

Finishing<br />

.PGR,<br />

VBMR<br />

Finishing<br />

VPGN<br />

NOTE: See Technical Section for<br />

chipbreaker details.<br />

10

KENNA PERFECT Top Notch Pr<strong>of</strong>iling Inserts<br />

2nd Step – Select the Grade<br />

Cutting Condition<br />

heavily<br />

interrupted cut<br />

lightly<br />

interrupted cut<br />

varying depth <strong>of</strong> cut,<br />

casting or forging skin<br />

smooth cut,<br />

pre-turned surface<br />

Application<br />

Finishing Medium Machining Roughing<br />

KC5025 K68 K68<br />

KC5010 KC5010 KC8050<br />

KD120 KC5010 KC5010<br />

KD050 KC5010 KC5010<br />

3rd Step – Select the Cutting Speed<br />

grade<br />

KD050<br />

50<br />

(15)<br />

120<br />

(40)<br />

180<br />

(55)<br />

Speed - sfm (m/min)<br />

250<br />

(80)<br />

330<br />

(100)<br />

550<br />

(170)<br />

655<br />

(200)<br />

750<br />

(230)<br />

Starting Conditions<br />

sfm m/min<br />

600 180<br />

KD120<br />

400 120<br />

KC5010<br />

200 60<br />

KC5025<br />

170 50<br />

KC8050<br />

230 70<br />

K68<br />

100 30<br />

To further optimize your operation, please reference<br />

pages 14-15 for Tool Tips and the Expert Application Advisor —<br />

Troubleshooting Guide on pages 34-40.<br />

11

Negative Insert Systems<br />

Kenloc ® Negative Inserts<br />

• Kenloc inserts are your first choice for<br />

general machining <strong>of</strong> all materials on<br />

medium to large lathes.<br />

• Kenloc inserts <strong>of</strong>fer the best economy<br />

for high metal removal rates.<br />

• Inserts are available in flat top and<br />

chip control geometries with both<br />

molded and ground peripheries,<br />

suitable for all workpiece materials.<br />

Kendex ® Negative Inserts<br />

• Ceramic Kendex inserts are a great<br />

choice for medium machining <strong>of</strong><br />

high-temperature alloys.<br />

• Kendex negative rake inserts<br />

are also recommended for the<br />

machining <strong>of</strong> hardened materials<br />

and cast irons.<br />

• Inserts are available in flat top<br />

geometries with molded and<br />

ground peripheries.<br />

• Wide selection <strong>of</strong> standard toolholders<br />

are <strong>of</strong>fered.<br />

K-Lock Inserts<br />

• K-Lock inserts are ideal for deep<br />

grooving and pr<strong>of</strong>iling.<br />

• A unique insert clamping system<br />

allows for unimpeded chip flow.<br />

• Available in molded and<br />

ground peripheries.<br />

12

Positive Insert Systems<br />

Screw-On Positive Inserts<br />

• Screw-on inserts are your<br />

first choice for ID turning <strong>of</strong><br />

all materials and OD turning on<br />

small to medium size lathes.<br />

• Inserts are available in flat top and<br />

chip control geometries with molded<br />

and ground peripheries, suitable for<br />

all workpiece materials.<br />

Kendex Positive and V-Bottom Inserts<br />

• Kendex positive V-Bottom inserts<br />

are your first choice for productive<br />

machining <strong>of</strong> high-temperature<br />

alloys on medium to large lathes.<br />

• Available in flat top geometries<br />

with ground periphery.<br />

Top Notch ® Pr<strong>of</strong>iling Inserts<br />

• First choice for high<br />

production pr<strong>of</strong>iling.<br />

• Unique insert clamping<br />

design <strong>of</strong>fers superior rigidity.<br />

• Inserts are available in chip control<br />

geometries with molded and<br />

ground peripheries. Suitable<br />

for all workpiece materials.<br />

13

KENNA PERFECT Inserts – Heat-Resistant Alloys & Titanium<br />

Tool Tips:<br />

Grade KC5510 <br />

Grade KC5510 is your first choice for finishing to medium machining in heat-resistant materials and<br />

titanium. The PVD coating has been specially formulated to address the high heat generated when<br />

machining these materials. Processing speeds can be doubled over conventional TiAlN coated<br />

products. The fine-grain tungsten carbide substrate <strong>of</strong>fers excellent strength and deformation<br />

resistance and is ideal for the positive sharp geometries utilized in machining these materials.<br />

Grade KC5525 <br />

Grade KC5525 utilizes the same high-temperature PVD coating as grade KC5510 combined<br />

with a higher cobalt, fine-grain tungsten carbide substrate to add additional strength to the cutting<br />

edge. Grade KC5525 is your first choice for interrupted cuts.<br />

GG-FS<br />

The ground high positive -FS geometry is ideal for finishing cuts where size control, finish and<br />

minimization <strong>of</strong> part deflection are considerations. In combination with grade KC5510 finishing<br />

cuts at 250 to 350 sfm are possible greatly reducing processing time.<br />

MG-MS<br />

The precision molded -MS geometry utilizes a micro-finished edge preparation to increase edge<br />

toughness for medium machining applications where sharp edges are not required. In combination<br />

with advanced grades KC5510 and KC5525, metal removal rates can be greatly increased while<br />

maintaining process security.<br />

Grade KY1540 <br />

Replace whisker ceramics with KY1540 and pay less for the same or better performance. The<br />

toughness <strong>of</strong> KY1540 enables it to be used at high ceramic speeds where only whisker ceramics<br />

have been run in the past, and at higher feed rates. KY1540 can also effectively run at speeds lower<br />

than whisker ceramics (< 500 sfm) when speed is constrained by machine capability or fixturing.<br />

14

KENNA PERFECT Inserts – Heat-Resistant Alloys & Titanium<br />

Tool Tips:<br />

Grade KY2100 <br />

Kyon 2100 is compositionally designed to minimize chemical interaction with the workpiece material.<br />

KY2100 excels at high-speed milling and finish turning <strong>of</strong> high-temperature alloys.<br />

Ceramic Inserts, Geometry<br />

The strength and property retention <strong>of</strong> high-temperature alloys make it important to choose ceramic<br />

insert shapes that maximize edge strength. When possible, use round ceramic inserts for the<br />

best results.<br />

Ceramic Inserts, Edge Preparation<br />

For turning <strong>of</strong> high-temperature alloys, the general recommendation is to use a T-land width or hone<br />

size that is smaller than the feed rate. The exceptions to this rule are milling, turning with heavy<br />

interruptions, or turning hardened materials (>50 HRC). In those instances, it is recommended to use<br />

a T-land width greater than the feed rate.<br />

Pre-chamfering<br />

Pre-chamfering parts in the initial and intermediate stages <strong>of</strong> machining can greatly increase tool life<br />

by reducing the shock that occurs when entering the cut and breaking through scale.<br />

High-Pressure Coolant<br />

When machining heat resistant alloys, high-pressure coolant can be used to reduce the high heat<br />

generated at the cutting zone. This allows for higher cutting speeds with similar tool life. Typically,<br />

speeds can be doubled with properly applied high-pressure coolant.<br />

15

New Cutting Tool Technologies<br />

Grades KC5510 and KC5525<br />

Kennametal’s newly developed advanced PVD<br />

TiAIN coated carbide grades KC5510 and KC5525,<br />

in high positive rake geometries GG-FS and<br />

MG-MS, have overcome many <strong>of</strong> the problems<br />

associated with machining heat-resistant alloys<br />

and titanium materials. These new products are<br />

revolutionizing productivity in finishing and medium<br />

machining <strong>of</strong> super alloys. Cutting speeds as high<br />

as 400 sfm can be attained with finishing grade<br />

KC5510. Typically, speeds can be doubled over<br />

a conventional PVD product with no impact on<br />

tool life (see figures 1 and 2).<br />

CNGG-432FS KC5510<br />

Tool life: 26.5 minutes<br />

CNGG-432 TiAlN<br />

Tool life: 7.5 minutes<br />

Figure 1: Comparison <strong>of</strong> a conventional<br />

TiAIN coated carbide insert vs. Kennametal’s<br />

advanced PVD grade.<br />

(300 sfm, .005 ipr, .010 doc, 718 Inconel 38 HRC)<br />

Figure 2: Kennametal's advanced PVD grade KC5510 compared to best in class competitive grades.<br />

16

New Cutting Tool Technologies<br />

Grade KC5510 is an advanced PVD coated<br />

fine-grained tungsten carbide grade specifically<br />

engineered for the productive yet demanding<br />

machining <strong>of</strong> high-temperature alloys. The finegrain<br />

tungsten carbide (6% cobalt) substrate has<br />

excellent toughness and deformation resistance.<br />

The advanced PVD coating allows for metal<br />

cutting speeds double those <strong>of</strong> conventional PVD<br />

coated materials.<br />

Grade KC5525 utilizes the same advanced PVD<br />

coating as grade KC5510 combined with a finegrain<br />

tungsten carbide (10% cobalt) substrate.<br />

The higher cobalt content provides added security<br />

in interrupted cuts while the fine grain tungsten<br />

maintains deformation resistance.<br />

In conjunction with grades KC5510 and KC5525,<br />

Kennametal has engineered two new chip control<br />

geometries specifically designed for machining <strong>of</strong><br />

superalloys. The GG-FS geometry is precision<br />

ground for optimal performance in finish cuts where<br />

low forces are required and dimensional control is<br />

critical. The MG-MS geometry is designed for medium<br />

to heavy cuts and is precision molded for<br />

added economy. Both geometries are high positive.<br />

Scanning electron microscope micrographs <strong>of</strong> grade KC5510<br />

GG-FS finishing sharp<br />

MG-MS medium sharp<br />

17

New Cutting Tool Technologies<br />

In developing these products, Kennametal<br />

conducted extensive metal cutting tests internally<br />

and in conjunction with our customers. In over<br />

100 tests, these new high-performance products<br />

outperformed the competition 95% <strong>of</strong> the time.<br />

Figures 3-11 (pages 19-21) document tool life in<br />

minutes, helical cutting length in feet, and volume<br />

<strong>of</strong> metal removed in in 3 for grade KC5510<br />

CNGG-432FS and CNMG-432MS. Materials<br />

machined were ~6 inch diameter bars <strong>of</strong> Inconel<br />

718 (39 HRC) and Ti-6Al-4V (30 HRC). Feed rates<br />

and depth <strong>of</strong> cuts employed in these internal tests<br />

are indicated in the test results. End-<strong>of</strong>-tool-life<br />

criteria used are .012 flank-wear, nose wear, or<br />

depth <strong>of</strong> cut, and .004 crater depth. Use this<br />

metalcutting data as a benchmark for planning your<br />

machining operations to realize optimum economy.<br />

Calculate the helical cutting length based on the<br />

feed rate, workpiece diameter and length <strong>of</strong> cuts.<br />

Determine the optimum cutting speed from data in<br />

the following charts.<br />

Note that when machining Inconel 718, grade<br />

KC5510 in CNGG432-FS geometry delivers tool life<br />

as high as ~50 min at 200 sfm, .005 ipr, and .005<br />

doc (fig. 3). This insert can be run even at 400 sfm,<br />

with good tool life. For carbide tools, these speeds<br />

represent a 100% plus improvement in productivity<br />

over conventional PVD coated tools. Under the<br />

conditions employed, the maxiumum amount <strong>of</strong><br />

metal removed is over 6 in 3 .<br />

Formulas for Helical Cutting Length (feet):<br />

= [length <strong>of</strong> cut (inch) / feed (ipr)] x [π d (inch) / 12]<br />

= [time in cut (min.)] x [speed (sfm)]<br />

18

Finishing <strong>of</strong> Inconel 718<br />

ipr-doc<br />

Figure 3: Tool life for Inconel 718<br />

ipr-doc<br />

Figure 4: Helical cutting length for Inconel 718<br />

ipr-doc<br />

Figure 5: Cubic inches <strong>of</strong> material removed cutting Inconel 718<br />

19

Medium Machining <strong>of</strong> Inconel 718<br />

ipr-doc<br />

Figure 6: Tool life machining Inconel 718<br />

ipr-doc<br />

Figure 7: Helical cutting length on Inconel 718<br />

ipr-doc<br />

Figure 8: Cubic inches <strong>of</strong> material removed machining Inconel 718<br />

20

Finishing & Medium Machining <strong>of</strong> Inconel 718 and Ti-6Al-4V<br />

Figure 9: Tool life cutting Inconel 718 and Ti-6Al-4V<br />

Figure 10: Helical cutting length on Inconel 718 and Ti-6Al-4V<br />

Figure 11: Cubic inches <strong>of</strong> material removed machining Inconel 718 and Ti-6Al-4V<br />

21

Grade KC5510 Proven Solutions<br />

market:<br />

product:<br />

material:<br />

aerospace<br />

engine component<br />

713 Inconel<br />

COMPETITOR<br />

KENNAMETAL<br />

KC5510 on 713 Inconel<br />

Savings: 38%<br />

<strong>of</strong> process cost,<br />

or $6,590.<br />

grade: coated carbide KC5510<br />

insert: CNGP-432 CNGG-432FS<br />

speed: 100 sfm 200 sfm<br />

feed: .0065 ipr .0065 ipr<br />

doc: .010 .010<br />

RESULT:<br />

Grade KC5510 ran twice as fast as the competitve grade and<br />

produced the same number <strong>of</strong> parts.<br />

market:<br />

product:<br />

material:<br />

aerospace<br />

shaft<br />

Inconel 718 triple melt<br />

COMPETITOR<br />

KENNAMETAL<br />

KC5510 on Inconel 718 Triple Melt<br />

Savings: 49%<br />

<strong>of</strong> process cost,<br />

or $1,821.<br />

grade: coated carbide KC5510<br />

insert: DNGG-432TF DNGG-432FS<br />

speed: 180 sfm 400 sfm<br />

feed: .004 ipr .004 ipr<br />

doc: .010 .010<br />

RESULT:<br />

Grade KC5510 ran 120% faster, reducing the processing time<br />

from 12 minutes to 5.4.<br />

market:<br />

product:<br />

material:<br />

oil and gas<br />

piston rod<br />

718 Inconel (40 HRC)<br />

COMPETITOR<br />

KENNAMETAL<br />

KC5510 on Inconel 718<br />

Savings: 57%<br />

<strong>of</strong> process cost,<br />

or $5,760.<br />

grade: coated carbide KC5510<br />

insert: CNMG-643GJ CNMG-432MS<br />

speed: 110 sfm 185 sfm<br />

feed .0085 ipr .010 ipr<br />

doc: .100 .100<br />

RESULT:<br />

Cycle time was reduced by over 50% while tool life doubled.<br />

22

Grade KC5525 Proven Solutions<br />

market:<br />

product:<br />

oil and gas<br />

valve<br />

KC5525 on Stellite Weld<br />

material:<br />

stellite weld<br />

COMPETITOR<br />

KENNAMETAL<br />

Savings: 61%<br />

<strong>of</strong> process cost,<br />

or $1,424.<br />

grade: coated carbide KC5525<br />

insert: CNMG-432MA CNMG-432MS<br />

speed: 60 sfm 60 sfm<br />

feed: .006 ipr .006 ipr<br />

doc: .050 .050<br />

RESULT:<br />

Grade KC5525 produced 4 times the number <strong>of</strong> parts with<br />

significantly less tool wear as compared to the competitive insert<br />

that catastrophically failed.<br />

market:<br />

product:<br />

material:<br />

oil and gas<br />

component<br />

Ti-6Al-4V<br />

KC5525 on Ti-6Al-4V<br />

Savings: 23%<br />

<strong>of</strong> process cost,<br />

or $1,029.<br />

COMPETITOR<br />

KENNAMETAL<br />

grade: coated carbide KC5525<br />

insert: DNMG-432P CNMG-432MS<br />

speed: 150 sfm 195 sfm<br />

feed: .010 ipr .010 ipr<br />

doc: .100 .100<br />

RESULT:<br />

Grade KC5525 produced 2 parts vs. the competitive grade’s 1 at<br />

a 35% higher speed.<br />

market:<br />

product:<br />

material:<br />

aerospace<br />

fastener<br />

718 Inconel (34 HRC)<br />

COMPETITOR<br />

KENNAMETAL<br />

KC5525 on Inconel 718<br />

Savings: 64%<br />

<strong>of</strong> process cost,<br />

or $125,496.<br />

grade: coated carbide KC5525<br />

insert: WNMG-432ENG WNMG-432MS<br />

speed: 93 sfm 150 sfm<br />

feed .003 ipr .0055 ipr<br />

doc: .030 .030<br />

RESULT:<br />

Grade KC5525 produced 80 parts vs. 35 for the competition at a<br />

50% higher speed and 80% greater feed rate. This reduced the<br />

overall cycle time by 64%.<br />

23

New Cutting Tool Technologies<br />

Shave Your Whisker Ceramic Costs with Kyon 1540!<br />

Kyon 1540 is Kennametal’s revolutionary sialon<br />

ceramic cutting material specifically developed for<br />

high-temperature alloy applications. Replace costly<br />

whisker ceramics with KY1540 today to achieve<br />

proven performance at a lower cost.<br />

Whisker-shaped beta sialon grains enhance<br />

fracture toughness.<br />

Uniform alpha sialon grain size and composition<br />

enhance hardness.<br />

The KY1540 microstructure is engineered to<br />

enhance both toughness (dependability) and<br />

hardness (abrasive wear resistance).<br />

The unique combination <strong>of</strong> properties<br />

developed in KY1540 significantly broaden<br />

the effective machining range <strong>of</strong> sialon<br />

ceramics for high-temperature alloy<br />

turning and milling applications. KY1540<br />

dramatically upgrades Kennametal's already<br />

strong sialon ceramic cutting tool <strong>of</strong>fering<br />

for high-temp alloys.<br />

higher speed / wear resistance<br />

higher feed / toughness<br />

24

New Cutting Tool Technologies<br />

KY1540 … your first choice ceramic solution<br />

for a wide variety <strong>of</strong> high-temperature alloy machining<br />

conditions! Kyon 1540 excels in tough aerospace<br />

engine and power generation applications.<br />

KY1540 is a proven performer…<br />

• in turning and milling applications<br />

• as a cost-effective replacement for expensive<br />

whisker ceramic cutting tools<br />

• in a broad range <strong>of</strong> high-temp alloy<br />

applications including<br />

– Inconels and other nickel-based materials<br />

– Stellites and other cobalt-based materials<br />

• in a wide variety <strong>of</strong> machining conditions,<br />

including interrupted cuts and applications involving<br />

scale<br />

For high-temperature alloy finishing, use Kyon 2100 .<br />

KY2100 excels at high-speed turning and milling <strong>of</strong><br />

high-temperature alloys<br />

It’s ideal for:<br />

• high-speed turning and milling applications<br />

• finishing cuts involving a broad range <strong>of</strong><br />

high-temperature alloys<br />

• turning <strong>of</strong> hardened high-temperature<br />

alloys (>48 HRC)<br />

25

Grade KY1540 Proven Solutions<br />

market: aerospace<br />

product: ring<br />

material: Inconel 901<br />

COMPETITOR<br />

KENNAMETAL<br />

KY1540 on Inconel 901<br />

Cost savings <strong>of</strong><br />

$86,000, or an<br />

84% improvement.<br />

grade: carbide KY1540<br />

insert: CNMG-644 RNG-45T0420<br />

speed: 100 sfm 1000 sfm<br />

feed: .016 ipr .010 ipr<br />

doc: .150 .150<br />

RESULTS:<br />

Kyon 1540 ran 10 times faster than the carbide grade<br />

and produced 80 times more pieces per insert.<br />

The net cost savings was $86,000.<br />

market:<br />

product:<br />

material:<br />

aerospace<br />

disk<br />

Inconel 718 rough forging<br />

with scale<br />

KY1540 on Inconel 718 rough forging<br />

Cost savings <strong>of</strong><br />

$620, or a 23%<br />

improvement.<br />

COMPETITOR<br />

KENNAMETAL<br />

grade: Si 3 N 4 ceramic KY1540<br />

insert: SNG-656 SNG-656<br />

speed: 900 sfm 900 sfm<br />

feed: .008 ipr .008 ipr<br />

doc: .200 .200<br />

RESULTS:<br />

KY1540 ran 2 times the pieces per edge. Cost savings $620.<br />

market: aerospace<br />

product: ring<br />

material: Inconel 718<br />

COMPETITOR<br />

KENNAMETAL<br />

KY1540 on Inconel 718<br />

Cost savings <strong>of</strong><br />

$1750, or a 20%<br />

improvement.<br />

grade: whisker ceramic KY1540<br />

insert: SNG-654 SNG-654<br />

speed: 500 sfm 500 sfm<br />

feed .009 ipr .009 ipr<br />

doc: .130 .130<br />

RESULTS:<br />

KY1540 performed equivalent to whisker ceramic at a lower price.<br />

Cost savings $1,750.<br />

26

Grade KY2100 Proven Solutions<br />

market:<br />

product:<br />

material:<br />

power generation<br />

stud<br />

Inconel 718 bar stock<br />

COMPETITOR<br />

KENNAMETAL<br />

KY2100 on Inconel 718 bar stock<br />

Cost savings <strong>of</strong><br />

$1,390, or a 25%<br />

improvement.<br />

grade: Si 3 N 4 ceramic KY2100<br />

insert: SMG-433 SMG-433T0420<br />

speed: 350 sfm 350 sfm<br />

feed: .005 ipr .005 ipr<br />

doc: .040 .040<br />

RESULTS:<br />

KY2100 cut 3 times the pieces per edge. Cost savings $1,390<br />

market:<br />

product:<br />

material:<br />

energy<br />

cage<br />

Stellite Weld, 55 HRC<br />

KY2100 on Stellite Weld, 55 HRC<br />

Cost savings <strong>of</strong><br />

$1,565, or a 13%<br />

improvement.<br />

COMPETITOR<br />

KENNAMETAL<br />

grade: Si 3 N 4 ceramic KY2100<br />

insert: CNGA-433 CNGA-433<br />

speed: 400 sfm 400 sfm<br />

feed: .003 ipr .003 ipr<br />

doc: .005 .005<br />

RESULTS:<br />

KY2100 ran 3 times the pieces per edge. Cost savings $1,565.<br />

market:<br />

product:<br />

material:<br />

aerospace<br />

ring<br />

Waspaloy<br />

COMPETITOR<br />

KENNAMETAL<br />

KY2100 on Waspaloy<br />

Cost savings <strong>of</strong><br />

$700, or a 16%<br />

improvement.<br />

grade: Si 3 N 4 ceramic KY2100<br />

insert: RPGV-45T0320 RPGV-45T0320<br />

speed: 750 sfm 750 sfm<br />

feed .004 ipr .004 ipr<br />

doc: .075 075<br />

RESULTS:<br />

KY2100 cost savings $700.<br />

27

High-Temperature Materials<br />

Metallurgy<br />

High-temperature materials are alloys that are<br />

generally used above ~1000°F (540°C) because <strong>of</strong><br />

their ability to retain strength at high temperatures.<br />

These materials are also referred to as<br />

“superalloys”. They are usually classified into three<br />

groups: iron-nickel-, nickel-, and cobalt-base alloys.<br />

The properties are developed by a combination <strong>of</strong><br />

cast or wrought processing (e.g. forging) followed<br />

by heat treatment. Chemical composition and<br />

processing steps are keys to obtaining optimum<br />

properties. The processing may include solution<br />

annealing or solution annealing followed by aging<br />

or precipitation hardening treatment. The purpose<br />

<strong>of</strong> solution annealing is either to homogenize an<br />

alloy or dissolve all second phases in the matrix to<br />

produce maximum corrosion resistance or to<br />

prepare an alloy for subsequent aging treatment.<br />

The precipitation (aging) treatment involves heating<br />

the solution-annealed alloy to a predetermined<br />

temperature and holding it at that temperature until<br />

precipitation <strong>of</strong> one or more phases occurs.<br />

Superalloys are extensively used in aircraft engines<br />

and industrial gas turbines for power generation.<br />

They also find application in petrochemical, oil, and<br />

biomedical industries due to their excellent<br />

corrosion resistance.<br />

Titanium alloys are also included in this category in<br />

view <strong>of</strong> their high temperature strength, high<br />

strength/weight ratio, and corrosion resistance.<br />

They are used in the aerospace, medical, and<br />

chemical industries.<br />

Iron-Nickel-Base Alloys<br />

Iron-nickel-base alloys are the weakest <strong>of</strong> the<br />

superalloys at elevated temperatures. They owe<br />

their high temperature strength to solid solution<br />

hardening (hardening produced by solute atoms<br />

dissolved in the alloy matrix) or precipitation<br />

hardening (hardening produced by precipitate<br />

particles). The most common precipitates are<br />

gamma prime, γ’, Ni 3 (Al,Ti) [e.g. A-286], and<br />

gamma double prime, γ” (Ni 3 Nb) [Incoloy 909].<br />

Alloys such as 19-9DL and Haynes 556 are solid<br />

solution hardened with molybdenum, tungsten,<br />

titanium and niobium.<br />

Iron-nickel-base alloys are primarily used in the<br />

wrought condition for gas turbine disks and blades.<br />

Most wrought alloys contain high levels <strong>of</strong><br />

chromium to provide corrosion resistance.<br />

Nickel-Base Alloys:<br />

Like iron-nickel-base materials, the nickel-base<br />

alloys are either solid solution strengthened or<br />

hardened by intermetallic compound precipitation in<br />

a face centered cubic (fcc) matrix. Alloys like Inconel<br />

625 and Hastelloy X are solid solution strengthened.<br />

The solid solution hardened alloys may get<br />

additional strengthening from carbide precipitation.<br />

Alloys such as Inconel 718 are precipitation<br />

hardened. A third class <strong>of</strong> nickel-base superalloys,<br />

typified by MA-754, is strengthened by dispersion <strong>of</strong><br />

inert particles such as yttria (Y2O3) coupled in some<br />

cases with γ’ precipitation (MA-6000E).<br />

Cast nickel-base alloy (Inconel 718). Nickel-base alloy, Hastelloy B,<br />

solution annealed.<br />

Nickel-base alloy, Udimet 720,<br />

as forged.<br />

28

High-Temperature Materials<br />

Nickel-base alloys are available in both the cast<br />

and wrought forms. Highly alloyed compositions<br />

such as -Rene 95, Udimet 720, and IN100 are<br />

produced by powder metallurgy followed by forging.<br />

For the above wrought alloys and for cast alloys<br />

(e.g. Rene 80 and Mar-M-247), the strengthening<br />

precipitate is γ’. For Inconel 718, the strengthening<br />

precipitate is primarily γ”.<br />

Alloys such as Inconel 725 containing niobium,<br />

titanium, and aluminum are strengthened by both γ’<br />

and γ” precipitates.<br />

Cobalt-Base Alloys<br />

Cobalt-base alloys are generally stronger and<br />

possess superior corrosion resistance at<br />

temperatures above 2000° F (1093° C). They are<br />

strengthened by a combination <strong>of</strong> solid solution<br />

hardeners (iron, chromium, and tungsten) and<br />

carbides (titanium, tantalum, hafnium, and niobium).<br />

These alloys are available in cast or wrought form.<br />

The cast alloys such as Stellite 31 are used in the<br />

hot sections <strong>of</strong> gas turbines (as air-foils, i.e. blades<br />

and vanes). A typical wrought alloy is Haynes 25.<br />

The wrought alloys are produced principally as<br />

sheet and are used in combustor parts.<br />

Titanium Alloys<br />

Pure titanium (Ti) undergoes a crystallographic<br />

transformation from hexagonal close packed, hcp<br />

(alpha, α) to body centered cubic, bcc (beta, β)<br />

structure as its temperature is raised through 882°<br />

C. Alloying elements such as tin (Sn) when<br />

dissolved in titanium do not change the<br />

transformation temperature, but elements such as<br />

aluminum (Al) and oxygen (O) cause it to increase.<br />

Such elements are called “α stabilizers”. Elements<br />

that decrease the phase-transformation<br />

temperature are called “β stabilizers”. They are<br />

generally transition metals. Commercial titanium<br />

alloys are thus classified as “α”, “α-β”, and “β”.The<br />

α-β alloys may also include “near α” and “near β”<br />

alloys depending on their composition.<br />

Alpha (α) Alloys<br />

Pure titanium and titanium alloyed with α stabilizers<br />

such as tin and aluminum (e.g. Ti-5Al-2.5Sn) are<br />

classified as α alloys. They are non-heat treatable<br />

and are generally weldable. They have low to<br />

medium tensile strength, good notch toughness,<br />

and possess excellent mechanical properties at<br />

cryogenic temperatures.<br />

Cobalt-base alloy (L605) solution annealed.<br />

Microstructure <strong>of</strong> α-alloy Ti-5%Al-2.5%Sn.<br />

Photomicrographs compliments <strong>of</strong> Buehler Ltd., Lake Bluff,<br />

Illinois, USA, www.Buehler.com<br />

29

High-Temperature Materials<br />

Beta (β) Alloys<br />

Beta (β) alloys contain transition metals such as V,<br />

Nb, Ta, and Mo that stabilize the β phase.<br />

Examples <strong>of</strong> commercial β alloys include<br />

Ti-11.5Mo-6Zr-4.5Sn and Ti-15V-3Cr-3Al-3Sn.<br />

Beta alloys are readily heat treatable, generally<br />

weldable, and have high strengths. Excellent<br />

formability can be expected in the solution treated<br />

condition. However, β alloys are prone to ductilebrittle<br />

transition and thus are unsuitable for<br />

cryogenic applications. Beta alloys have a good<br />

combination <strong>of</strong> properties for sheet, heavy sections,<br />

fasteners, and spring applications.<br />

Alpha-beta alloy Ti-6%Al-4%V showing primary alpha grains<br />

and a fine alpha-beta matrix structure.<br />

Near α alloy Ti-6%Al-2%Sn-4%Zr-2%Mo showing alpha grains<br />

and a fine alpha-beta matrix structure.<br />

Beta alloy Ti-3%Al-8%V-6%Cr-4%Mo-4%Zr.<br />

Alpha-Beta Alloys<br />

These alloys feature both α and β phases and<br />

contain both α and β stabilizers. The simplest and<br />

most popular alloy in this group is Ti-6Al-4V, which<br />

is primarily used in the aerospace industry. Alloys<br />

in this category are easily formable and exhibit high<br />

room temperature strength and moderate hightemperature<br />

strength. The properties <strong>of</strong> these<br />

alloys can be altered through heat treatment.<br />

Photomicrographs compliments <strong>of</strong> Buehler Ltd., Lake Bluff,<br />

Illinois, USA, www.Buehler.com<br />

Text reference:<br />

1.) “ Superalloys – A Technical Guide” second edition, by M.J.<br />

Donachie and S.J. Donachie, ASM Intl., Materials Park, Ohio<br />

(2002)<br />

2.) “ The Physical Metallurgy <strong>of</strong> Titanium Alloys,” by E. W.<br />

Collings, American Society for Metals, Metals Park, OH (1984)<br />

30

Workpiece Chemical Compositions<br />

High-Temperature Alloys — Iron (Fe) Base<br />

UNS<br />

commercial<br />

designation<br />

ultimate tensile strength<br />

at 70°F (21°C)<br />

MPa<br />

ksi<br />

avg.<br />

hardness<br />

HB<br />

ann.<br />

HB<br />

aged<br />

Fe Ni Co Cr Mo W Si Mn C Al Ti Ta Nb Zr other<br />

S17400 17-4-PH 795 115 250 75.0 4.0 16.5 0.5 0.25 0.04 0.3V<br />

S63198 19-9 DL 756 109 250 66.8 9.0 19.0 1.3 1.25 0.6 1.1 0.30 0.30 0.40<br />

S66286 A-286 1005 146 55.2 25.0 15.0 1.25 2.0 0.04 0.2 2.0<br />

R66220 Discaloy 1000 145 280 55.0 26.0 14.0 3.0 0.06 0.25 1.75<br />

S41800 Greek Ascoloy 944-1344 137-195 300 80.0 2.0 13.0 0.15 0.3 0.4 0.15<br />

R30556 Haynes 556 (HS 556) 815 118 260 29.0 21.0 20.0 22.0 3.0 2.50 1.5 0.1 0.3 0.50 0.10<br />

N08800 Incoloy 800 595 86 184 45.7 32.5 21.0 0.05 0.37 0.37<br />

N08801 Incoloy 801 785 114 180 46.3 32.0 20.5 0.05 1.1<br />

N08802 Incoloy 802 690 100 180 44.8 32.5 21.5 0.4 0.6 0.75<br />

R30155 N 155 815 118 260 32.2 20.0 20.0 21.0 3.0 2.50 0.5 1.5 0.15 1.00<br />

R30590 S 590 (Unitemp) 1048 152 270 28.9 20.0 20.0 21.0 4.0 4.00 1.25 0.4 0.43<br />

V-57 (Udimet, Carpenter) 1172 170 280 52.0 27.0 14.8 1.25 0.75 0.35 0.08 0.25 3.00<br />

High-Temperature Alloys — Cobalt (Co) Base<br />

UNS<br />

commercial<br />

designation<br />

ultimate tensile strength<br />

at 70°F (21°C)<br />

MPa<br />

ksi<br />

avg.<br />

hardness<br />

HB<br />

ann.<br />

HB<br />

aged<br />

Co Ni Fe Cr Mo W Si Mn C Al Ti Ta Nb Zr other<br />

AirResist 13 (cast) 62.0 21.0 11.00 0.45 3.50 2.00<br />

AirResist 213 1120 162 64.0 0.5 0.5 20.0 4.50 0.20 3.50 6.50<br />

HS-31 (X-40) 54.0 10.0 1.5 25.0 7.50 0.75 0.75 0.50<br />

R30188 Haynes 188 960 139 37.0 22.0 3.0 22.0 14.50 0.50 1.00 0.10<br />

J-1570 46.0 28.0 2.0 20.0 0.20 4.00<br />

Jetalloy 209 52.0 10.0 1.0 20.0 15.00 2.00 0.02<br />

L 251 55.0 10.0 1.0 19.0 14.00 0.40<br />

R30605 L 605 (Haynes 25) 1005 146 50.0 10.0 3.0 20.0 15.00 1.70 0.10<br />

MAR M-302 58.0 0.5 21.5 10.00 0.85 9.00 0.20<br />

MAR M-322 60.5 0.5 21.5 9.00 0.10 0.10 1.00 0.75 4.50 2.00<br />

MAR M-509 54.5 10.0 23.5 7.00 0.10 0.10 0.60 0.20 3.50 0.50<br />

MAR M-918 895 130 52.0 20.0 20.0 0.10 0.10 0.05 0.05 7.50 0.10<br />

R30035 MP 35-N 1792 260 35.0 35.0 20.0 10.0 0.02<br />

R30159 MP 159 1896 275 36.0 25.0 9.0 19.0 7.0 0.20 3.00 0.60<br />

R30006 Stellite 6 (HS6) 1010 146 60.0 3.0 3.0 28.0 5.00 1.00<br />

R30021 Stellite 21 (HS 21) 64.0 3.0 1.0 27.0 5.0 0.25<br />

R30031 Stellite 31 (HS 31) 54.0 10.0 1.5 25.0 7.50 1.00 0.60 0.40<br />

V-36 42.0 20.0 3.0 25.0 4.0 2.00 0.40 1.00 0.26 2.00<br />

WI-52 63.5 2.0 21.0 11.00 0.45 2.00<br />

31

Workpiece Chemical Compositions<br />

High-Temperature Alloys — Nickel (Ni) Base<br />

UNS<br />

commercial<br />

designation<br />

ultimate tensile strength<br />

at 70°F (21°C)<br />

MPa<br />

ksi<br />

avg.<br />

hardness<br />

HB<br />

ann.<br />

HB<br />

aged<br />

Ni Co Fe Cr Mo W Si Mn C Al Ti Ta Nb Zr other<br />

N13017 Astroloy 1415 205 56.5 15.0 15.0 5.0 0.06 4.40 3.50<br />

N10001 Hastelloy B 925 134 140 63.0 2.0 5.0 1.0 28.0 0.05 0.50 0.02<br />

N10276 Hastelloy C-276 779 113 59.0 5.0 15.5 16.0 3.7 0.02<br />

N10003 Hastelloy N 793 115 72.0 5.0 7.0 16.0 0.06<br />

N06635 Hastelloy S 845 130 67.0 1.0 15.5 15.5 0.02 0.20<br />

N10004 Hastelloy W 965 140 61.0 2.5 5.5 5.0 24.5 0.12<br />

N06002 Hastelloy X (680) 785 114 160 49.0 1.5 15.8 22.0 9.0 0.6 0.15 2.00<br />

N10242 Haynes 242 1290 187 62.5 2.5 2.0 8.0 25.0 0.10<br />

N08825 Incoloy 825 690 100 42.0 2.0 3.0 21.0 3.0 0.03 0.20 0.90<br />

N09901 Incoloy 901 1158 168 180 300 42.5 36.2 12.5 6.0 0.10 2.70<br />

N19903 Incoloy 903 1310 190 380 38.0 15.0 41.0 0.1 0.1 0.04 0.70 1.40 3.00<br />

N09925 Incoloy 925 1213 176 44.0 29.0 20.5 2.8 0.20 2.10 1.6 Cu<br />

Inconel 100 1018 147 60.5 15.0 10.0 3.0 0.18 5.50 5.00 0.06 1.0 V<br />

N06600 Inconel 600 660 96 170 76.0 8.0 15.5 0.08 0.25 Cu<br />

N06601 Inconel 601 740 107 150 60.5 14.1 23.0 0.05 1.35<br />

N06617 Inconel 617 770 112 55.0 12.5 22.0 9.0 0.07 1.00<br />

N06625 Inconel 625 965 140 180 61.0 2.5 21.5 9.0 0.05 0.20 0.20 3.60<br />

N09706 Inconel 706 1310 190 41.5 37.5 16.0 0.03 0.20 1.80 2.90<br />

N07718 Inconel 718 1435 208 180 380 52.5 18.5 19.0 3.1 0.08 0.50 0.90 5.10 0.15 Cu<br />

N07751 Inconel 751 1275 185 72.5 7.0 15.5 0.05 1.20 2.30 1.00 0.25 Cu<br />

N07750 Inconel X-750 1200 174 390 73.0 7.0 15.5 0.04 0.70 2.50 1.00 0.25 Cu<br />

N07252 M-252 1207 175 320 56.0 10.0 20.0 10.0 0.15 1.00 2.60<br />

Proprietary MAR-M 200 930 135 59.0 10.0 1.0 9.0 12.5 0.15 5.00 2.00 1.00 0.05<br />

Proprietary MAR-M 246 985 139 270 60.0 10.0 9.0 2.5 10.0 0.15 5.50 1.50 1.50 0.05<br />

Proprietary MAR-M 421 910 132 62.5 10.0 15.5 1.7 3.5 0.15 4.25 1.75<br />

Proprietary MAR-M 432 1241 180 52.5 20.0 15.5 3.0 0.15 2.50 4.30<br />

N06075 Nimonic 75 745 108 170 75.0 4.0 20.0 0.12 0.15 0.40<br />

N07080 Nimonic 80A 1000 145 350 73.0 1.0 1.5 19.5 0.05 1.40 2.40<br />

N07090 Nimonic 90 1235 179 345 55.5 18.0 1.5 19.5 0.06 1.40 2.40<br />

Nimonic 105 1180 171 320 54.0 20 0.5 15.0 5.0 0.08 4.70 1.20<br />

Nimonic 115 1240 180 350 55.0 15.0 1.0 15.0 4.0 0.20 5.00 4.00<br />

N09901 Nimonic 901 1240 180 350 43.0 1.0 35.0 12.5 6.0 0.05 2.80<br />

Nimonic C-263 965 140 275 51.5 20.0 20.0 6.0 0.06 0.45 2.10<br />

Nimonic PE 16 827 120 250 43.5 1.0 1.2 16.5 3.5 0.05 1.20 1.20<br />

Nimonic PK 33 1172 170 350 55.0 14.0 0.5 18.0 7.0 0.25 0.25 0.05 2.10 2.00<br />

Refractaloy 26 1172 170 38.0 20.0 16.0 18.0 3.2 1.00 0.80 0.03 0.20 2.60<br />

N07041 Rene 41 1420 206 55.0 11.0 0.3 19.0 10.0 0.09 1.50 3.10<br />

Rene 63 1447 210 55.0 15.0 3.5 14.0 6.0 3.5 0.20 0.10 0.05 3.80 2.50<br />

Rene 77 861 125 58.0 15.0 15.0 4.2 0.10 0.10 0.07 4.30 3.30<br />

Rene 80 60.0 9.5 14.0 4.0 4.0 0.17 3.00 5.00<br />

Rene 95 1620 235 61.0 8.0 0.3 14.0 3.5 3.5 0.15 3.50 2.50<br />

N07500 Udimet 500 1310 190 48.0 19.0 4.0 19.0 4.0 0.08 3.00 3.00<br />

N07520 Udimet 520 1310 190 57.0 12.0 19.0 6.0 1.0 0.08 2.00 3.00<br />

Udimet 630 1520 220 50.0 0.5 18.0 17.0 3.0 3.0 0.04 0.70 1.00 6.50<br />

Udimet 700 1410 204 53.0 18.5 15.0 5.0 0.07 4.30 3.40<br />

Udimet 710 1185 172 55.0 15.0 18.0 3.0 1.5 0.07 2.50 5.00<br />

N07720 Udimet 720 1570 228 55.0 15.0 18.0 3.0 1.3 0.04 2.50 5.00<br />

N07001 Waspaloy 1275 185 57.0 13.5 1.0 19.5 4.3 0.07 1.40 3.00<br />

32

Workpiece Chemical Compositions<br />

Titanium Alloys — Alpha<br />

ultimate tensile strength<br />

UNS<br />

commercial<br />

at 70°F (21°C)<br />

designation<br />

MPa<br />

ksi<br />

Al Sn Mo V Zr Nb Cr Ta Fe<br />

R54520 Ti-5Al-2.5Sn (Annealed) 827 120 5.0 2.5<br />

R54521 Ti-5Al-2.5Sn-ELI* 724 105 5.0 2.5<br />

*ELI = Extra Low Interstitials<br />

Titanium Alloys — Near Alpha, Alpha-Beta, Near Beta<br />

ultimate tensile strength<br />

UNS<br />

commercial<br />

at 70°F (21°C)<br />

designation<br />

MPa<br />

ksi<br />

Al Sn Mo V Zr Nb Cr Ta Fe<br />

R54620 Ti-6Al--2Sn-4Zr-2Mo (Ann) 930 145 6.0 2.0 2.0 4.0<br />

R56210 Ti-6Al-2Nb-1Ta-1Mo (Ann) 854 124 6.0 1.0 2.0 1.0<br />

R54810 Ti-8Al-1Mo-1V (Ann) 896 145 8.0 1.0 1.0<br />

R56400 Ti-6Al-4V (Ann) 896 144 6.0 4.0<br />

R56400 Ti-6Al-4V (Aged) 1172 170 6.0 4.0<br />

R56401 Ti-6Al-4V-ELI 896 120 6.0 4.0<br />

R56620 Ti-6Al-6V-2Sn (Ann) 1068 155 6.0 2.0 6.0<br />

R56620 Ti-6Al-6V-2Sn (Aged) 1275 185 6.0 2.0 6.0<br />

R56260 Ti-6246 (Ann) 1034 150 6.0 2.0 6.0 4.0<br />

R56260 Ti-6246 (Aged) 1206 175 6.0 2.0 6.0 4.0<br />

R56320 Allvac 3-2.5 690 100 3.0 2.5 0.1<br />

R58650 Allvac Ti-17 (Aged) 1138 165 5.0 2.0 4.0 2.0 4.0<br />

Titanium Alloys — Beta<br />

ultimate tensile strength<br />

UNS<br />

commercial<br />

at 70°F (21°C)<br />

designation<br />

MPa ksi<br />

Al Sn Mo V Zr Nb Cr Ta Fe<br />

R58010 Ti-13V-11Cr-3Al (Ann) 965 140 3.0 13.0 11.00<br />

R58010 Ti-13V-11Cr-3Al (Aged) 1206 175 3.0 13.0 11.00<br />

R58640 Ti-3Al-8V-6Cr-4Mo-4Zr (Ann) 896 130 3.0 4.0 8.0 4.0 6.0<br />

R58640 Ti-3Al-8V-6Cr-4Mo-4Zr (Aged) 1241 180 3.0 4.0 8.0 4.0 6.0<br />

R58820 Ti-8Mo-8V-2Fe-3Al 3.0 8.0 8.0 2.0<br />

Ti-10V-2Fe-3Al (Ann) 965 140 3.0 10.0 2.0<br />

Ti-10V-2Fe-3Al (Aged) 1310 190 3.0 10.0 2.0<br />

R58030 Ti-11.5Mo-6Zr-4.5Sn (Ann) 758 110 4.5 11.5 6.0<br />

R58030 Ti-11.5Mo-6Zr-4.5Sn (Aged) 1241 180 4.5 11.5 6.0<br />

33

Expert Application Advisor<br />

Machinability <strong>of</strong> Superalloys<br />

High-Temperature Alloys<br />

Generally, the high-temperature alloys have poor<br />

machinability. The very characteristics that provide<br />

high temperature strength in these materials are<br />

responsible for their poor machining behavior.<br />

Among the super alloys, iron-nickel-base alloys are<br />

easier to machine than the nickel-base and cobaltbase<br />

alloys under similar conditions <strong>of</strong> heat<br />

treatment. For aerospace applications, the surface<br />

condition <strong>of</strong> the machined workpiece is <strong>of</strong> concern<br />

because <strong>of</strong> the role it plays in the useful life <strong>of</strong> the<br />

component under cyclic loading. Great care is<br />

taken to ensure that there is no metallurgical<br />

damage to the component surface after the final<br />

finishing pass.<br />

The accompanying table compares the physical<br />

and mechanical properties <strong>of</strong> nickel-base and<br />

titanium alloys with those <strong>of</strong> AISI 4340 alloy steel.<br />

The nickel-base alloys have high tensile strength<br />

at high temperatures (650° C), lower thermal<br />

conductivity, and similar density and Young’s<br />

Modulus (measure <strong>of</strong> stiffness) as alloy steels.<br />

The titanium alloys have even lower thermal<br />

conductivity, lower stiffness, and lower density than<br />

the nickel-base alloys. These characteristics affect<br />

their machining behavior as indicated below.<br />

alloy<br />

yield<br />

strength<br />

(ksi)<br />

tensile<br />

strength<br />

(21°C)<br />

(ksi)<br />

tensile<br />

strength<br />

(650°C)<br />

(ksi)<br />

Young’s<br />

Modulus<br />

(x10 6 psi)<br />

thermal<br />

conductivity<br />

(W/m.k)<br />

density<br />

(g/cc)<br />

Inconel 600<br />

(wrought)<br />

41 96 65 31 15 8.41<br />

Inconel 625<br />

(wrought)<br />

71 140 121 30 10 8.44<br />

Inconel 718<br />

(wrought)<br />

172 208 178 29 11.4 8.22<br />

Ti-Al-4V<br />

solution treated 121 130 ~25 16 7 4.43<br />

and aged<br />

Alloy Steel<br />

(AISI 4340 125 185 29 36 7.8<br />

as rolled)<br />

34

Expert Application Advisor<br />

Factors Affecting the Machinability <strong>of</strong> Superalloys<br />

• Their high strength at cutting temperatures<br />

causes high cutting forces and generates more<br />

heat at the tool tip (compared to alloy steels).<br />

• Because <strong>of</strong> their poor thermal conductivity, heat<br />

produced during machining is transferred to the<br />

tool and increases the tool tip temperatures.<br />

High tool tip temperatures contribute to<br />

oxidation and diffusion <strong>of</strong> the tool material into<br />

the chip leading to cratering and excessive flank<br />

wear.<br />

• The presence <strong>of</strong> hard, abrasive intermetallic<br />

compounds and carbides in the microstructure<br />

causes severe abrasive wear on the tool tip.<br />

• The high capacity for work-hardening in<br />

these materials causes depth-<strong>of</strong>-cut notching<br />

on the tool.<br />

• The chip produced during machining is tough<br />

and continuous, which requires good chip<br />

control tool geometry.<br />

Speed is the single most important factor that<br />

determines tool life. Feed rate and depth <strong>of</strong> cut are<br />

also important factors. A copious amount <strong>of</strong> coolant<br />

is required with carbide tools to reduce temperature<br />

build-up and tool wear.<br />

35

Expert Application Advisor – High-Temp Alloys<br />

Nickel-Base, Heat-Resistant Alloys (140 - 475 HB) (≤ 48 HRC)<br />

Astroloy, Hastelloy, B/C/C-276/X, Inconel 601/617/625/700/706/718, IN100, Incoloy 901, MAR-M200,<br />

Nimonic, Rene 41, Udimet, Waspaloy, Monel<br />

Material Characteristics<br />

• high forces at the cutting edge<br />

• high heat concentration in cutting area<br />

• high cutting speed may cause insert failure by plastic deformation<br />

• relatively poor tool life<br />

• small depths <strong>of</strong> cut are difficult<br />

• workhardens rapidly<br />

• usually abrasive, rather than hard<br />

Common Tool Application Considerations<br />

Problem<br />

depth-<strong>of</strong>-cut notch<br />

built-up edge<br />

chipping<br />

torn workpiece<br />

surface finish<br />

workpiece glazing<br />

Solution<br />

1. Increase toolholder lead angle.<br />

2. Use tougher grades like KC5525, KC9240, or KC9245<br />

in -MS, MP and -RP geometries or ceramic grade KY1540.<br />

3. Use a .025 or greater depth <strong>of</strong> cut.<br />

4. Depth <strong>of</strong> cut should be greater than the workhardened layer resulting<br />

from the previous cut (>.005).<br />

5. Program a ramp to vary depth <strong>of</strong> cut.<br />

6. Feed greater than .005 ipr.<br />

7. Use strongest insert shape possible.<br />

8. When possible, use round inserts in carbide grade KC5510,<br />

KC5010 or Kyon® grades.<br />

9. Decrease depth to 1/7th <strong>of</strong> insert diameter for round inserts.<br />

(i.e: .075 max depth for 1/2" IC RNG45)<br />

1. Increase speed.<br />

2. Use grades KY1540 or KY2100.<br />

3. Use positive rake, sharp PVD coated grades KC5510 and KC5010.<br />

4. Use flood coolant.<br />

1. Use MG-MS geometry in place <strong>of</strong> MG-FS or ..GP geometries.<br />

2. For interrupted cutting, maintain speed and decrease feed.<br />

3. Use a tougher grade like KC5525.<br />

1. Increase speed and reduce feed rate.<br />

2. Use a GG-FS or GT-HP geometry.<br />

3. Apply KY1540 or KY2100.<br />

1. Increase depth <strong>of</strong> cut.<br />

2. Increase feed rate and decrease speed.<br />

3. Reduce insert nose radius size.<br />

36

Expert Application Advisor – High-Temp Alloys<br />

Cobalt-Base, Heat-Resistant Alloys (150 - 425 HB) (≤ 45 HRC)<br />

Wrought: AiResist 213, Haynes 25 (L605), Haynes 188, J-1570, Stellite<br />

Cast: AiResist 13, Haynes 21, Mar-M302, Mar-M509, Nasa C0-W-Re, WI-52<br />

Material Characteristics<br />

• high forces at the cutting edge<br />

• high heat concentration in cutting area<br />

• high cutting speed may cause insert failure by plastic deformation<br />

• cast material more difficult to machine than wrought<br />

• relatively poor tool life<br />

• small depths <strong>of</strong> cut are difficult<br />

• workhardens rapidly<br />

• usually abrasive, rather than hard<br />

Common Tool Application Considerations<br />

Problem<br />

depth-<strong>of</strong>-cut notch<br />

built-up edge<br />

chipping<br />

workpiece glazing<br />

torn or dull workpiece<br />

surface finish<br />

Solution<br />

1. Increase toolholder lead angle.<br />

2. Use a tougher carbide grade like KC5525 or KC9240, or ceramic grades<br />

KY1540 or KY2100.<br />

3. Use a .025 or greater depth <strong>of</strong> cut.<br />

4. Program a ramp to vary depth <strong>of</strong> cut.<br />

5. Feed greater than .005 ipr.<br />

6. Use strongest insert shape possible.<br />

7. Depth <strong>of</strong> cut should be greater than the workhardened layer resulting<br />

from the previous cut (>.005).<br />

1. Increase speed.<br />

2. Use positive rake, sharp PVD coated grades KC5510 and KC5010.<br />

3. Use ceramic grades KY1540 or KY2100<br />

1. Use MG-MS geometry in place <strong>of</strong> GG-FS or ..GP.<br />

2. For interrupted cutting, maintain speed and decrease feed.<br />

1. Increase depth <strong>of</strong> cut.<br />

2. Increase feed rate and decrease speed.<br />

3. Reduce insert nose radius size.<br />

1. Increase speed.<br />

2. Reduce feed rate.<br />

3. Use a GG-FS, GT-HP or GT-LF geometry.<br />

37

Expert Application Advisor – High-Temp Alloys<br />

Iron-Base, Heat-Resistant Alloys (135 - 320 HB) (≤ 34 HRC)<br />

Wrought: A-286, Discaloy, Incoloy 801, N-155, 16-25-6, 19-9 DL<br />

Cast: ASTM A297, A351, A608, A567<br />

Material Characteristics<br />

• relatively poor tool life<br />

• small depths <strong>of</strong> cut are difficult<br />

• workhardens rapidly<br />

• usually abrasive, rather than hard<br />

• tough and stringy chips<br />

Common Tool Application Considerations<br />

Problem<br />

depth-<strong>of</strong>-cut notch<br />

built-up edge<br />

workpiece glazing<br />

torn or dull workpiece<br />

surface finish<br />

Solution<br />

1. Increase toolholder lead angle.<br />

2. Use tougher grades, KC5525 or KC9240.<br />

3. Use a .025 or greater depth <strong>of</strong> cut.<br />

4. Feed greater than .005 ipr.<br />

5. Increase coolant concentration.<br />

6. Vary depth <strong>of</strong> cut.<br />

7. Depth <strong>of</strong> cut should be greater than the workhardened<br />

layer resulting from the previous cut (>.005).<br />

1. Increase speed.<br />

2. Use positive rake, sharp PVD coated grades KC5510 or KC5010.<br />

3. Use ceramic grades KY1540 or KY2100.<br />

1. Increase depth <strong>of</strong> cut.<br />

2. Increase feed rate and decrease speed.<br />

3. Reduce insert nose radius size.<br />

4. Use a GG-FS, GT-HP, or GT-LF geometry.<br />

5. Use PVD grade KC5510 as your first choice.<br />

1. Increase speed.<br />

2. Reduce feed.<br />

3. Increase coolant concentration.<br />

4. Use a GG-FS, GT-HP, or GT-LF geometry.<br />

38

Expert Application Advisor – High-Temp Alloys<br />

Machinability <strong>of</strong> Titanium Alloys<br />

Machining <strong>of</strong> titanium alloys is as demanding as<br />

cutting <strong>of</strong> other high temperature materials.<br />

Titanium components are machined in the forged<br />

condition and <strong>of</strong>ten require removal <strong>of</strong> up to 80%<br />

<strong>of</strong> the weight <strong>of</strong> the workpiece.<br />

The high chemical reactivity <strong>of</strong> titanium alloys<br />

causes the chip to weld to the tool leading to<br />

cratering and premature tool failure. The low<br />

thermal conductivity <strong>of</strong> these materials does not<br />

allow the heat generated during machining to<br />

dissipate from the tool edge. This causes high tool<br />

tip temperatures and excessive tool deformation<br />

and tool wear.<br />

Titanium alloys also retain strength at high<br />

temperatures and generate high heat and cutting<br />

forces. In addition, heat and cutting force are<br />

concentrated in a small chip contact area on the<br />

rake face <strong>of</strong> the tool. The low elastic modulus <strong>of</strong><br />

these materials causes greater workpiece<br />

deflection that results in tool vibration, tool chatter,<br />

and poor surface finish. In addition, the high<br />

work hardening tendency <strong>of</strong> titanium alloys<br />

causes high cutting forces that may lead to depth<strong>of</strong>-cut<br />

notching.<br />

Alpha (α) titanium alloys have low tensile strengths<br />

and produce low cutting forces. In contrast,<br />

significantly higher cutting forces are generated<br />

during machining <strong>of</strong> α-β and β alloys.<br />

A generous quantity <strong>of</strong> coolant with appropriate<br />

chemistry, should be used to minimize tool tip<br />

temperatures and rapid tool wear. Positive rake<br />

sharp tools will reduce cutting forces and<br />

temperatures and minimize part deflection.<br />

39

Expert Application Advisor – High-Temp Alloys<br />

Titanium and Titanium Alloys (110 - 450 HB) (≤ 48 HRC)<br />

Pure: Ti98.8, Ti99.9<br />

Alloyed: Ti-5Al-2.5Sn, Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-8V-6Cr-4Mo-4Zr, Ti-10V-2Fe-3Al,<br />

Ti-13V-11Cr-3Al<br />

Material Characteristics<br />

• relatively poor tool life, even at low cutting speeds<br />

• high chemical reactivity causes chips to gall and weld to cutting edge<br />

• low thermal conductivity increases cutting temperatures<br />

• usually produces abrasive, tough, and stringy chips<br />

• take precautionary measures when machining a reactive (combustible) metal<br />

• low elastic modulus easily causes deflection <strong>of</strong> workpiece<br />

• workhardens easily<br />

Common Tool Application Considerations<br />

Problem<br />

chipping<br />

built-up edge<br />

depth-<strong>of</strong>-cut notch<br />

workpiece glazing<br />

torn or dull workpiece<br />

surface finish<br />

Solution<br />

1. Avoid built-up edge (see below).<br />

2. Increase the toolholder lead angle.<br />

3. Use tougher grades like KC5525, KC9240, or KC9245... in -MS, -MP,<br />

or -RP geometries for interrupted cutting.<br />

4. Maintain speed and decrease feed rate simultaneously.<br />

5. Use MG-MS geometry in place <strong>of</strong> GP.<br />

6. Ensure proper insert seating.<br />

7. Use a large quantity <strong>of</strong> cutting fluid.<br />

1. Maintain sharp cutting edges. Use ground periphery inserts<br />

and index <strong>of</strong>ten.<br />

2. Use GG-FS or GT-LF geometry in PVD grades KC5510 and KC5010.<br />

3. Use a large quantity <strong>of</strong> cutting fluid.<br />

1. Depth <strong>of</strong> cut should be greater than the workhardened layer resulting<br />

from the previous cut (>.005).<br />

2. Use strongest insert shape possible.<br />

3. Program a ramp to vary depth <strong>of</strong> cut.<br />

1. Increase depth <strong>of</strong> cut.<br />

2. Reduce nose radius.<br />

3. Index insert to sharp edge.<br />

4. Do not dwell in the cut.<br />

1. Increase feed and reduce speed.<br />

2. Use positive rake, sharp PVD coated grade KC5510.<br />

3. Increase speed.<br />

4. Increase coolant concentration.<br />

40

Chip Control Geometries<br />

Kenloc Inserts<br />

operation<br />

insert<br />

style/<br />

application<br />

insert<br />

geometry<br />

pr<strong>of</strong>ile<br />

feed rate – inches<br />

.0015 .0025 .004 .006 .010 .016 .025 .040 .060 .100 .200<br />

.004 .006 .010 .016 .025 .040 .060 .100 .160 .250 .500<br />

depth <strong>of</strong> cut – inches<br />

medium<br />

sharp<br />

MG-MS<br />

.005 - .014<br />

(0,12 - 0,35)<br />

.030 - .200<br />

(0,76 - 5,0)<br />

finishing<br />

sharp<br />

GG-FS<br />

precision<br />

ground<br />

.003 - .010<br />

(0,07 - 0,25)<br />

.008 - .080<br />

(0,20 - 2,0)<br />

finishing<br />

_ _GP-K<br />

precision<br />

ground<br />

.004 - .012<br />

(0,1 - 0,3)<br />

.008 - .100<br />

(0,2 - 2,5)<br />

finishing<br />

GG-LF<br />

precision<br />

ground<br />

.005 - .020<br />

(0,1 - 0,5)<br />

.020 - .120<br />

(0,5 - 3,0)<br />

medium<br />

machining<br />

_ _GP*<br />

precision<br />

ground<br />

.012 - .020<br />

(0,3 - 0,5)<br />

.060 - .125<br />

(1,5 - 3,2)<br />

roughing<br />

MG-RP<br />

.010 - .025<br />

(0,2 - 0,6)<br />

.045 - .250<br />

(1,1 - 6,4)<br />

feed rate – (mm)<br />

0,04 0,063 0,01 0,16 0,25 0,4 0,63 1,0 1,6 2,5 5,0<br />

0,1 0,16 0,25 0,4 0,63 1,0 1,6 2,5 4,0 6,3 10,0<br />

depth <strong>of</strong> cut – (mm)<br />

Screw-On Inserts<br />

operation<br />

insert<br />

style/<br />

application<br />

insert<br />

geometry<br />

pr<strong>of</strong>ile<br />

feed rate – inches<br />

.0015 .0025 .004 .006 .010 .016 .025 .040 .060 .100 .200<br />

.004 .006 .010 .016 .025 .040 .060 .100 .160 .250 .500<br />

depth <strong>of</strong> cut – inches<br />

fine<br />

finishing<br />

GT-HP<br />

precision<br />

ground<br />

.007 - .015<br />

(0,1 - 0,3)<br />

.025 - .090<br />

(0,6 - 2,3)<br />

finishing<br />

GT-LF<br />

precision<br />

ground<br />

.007 - .015<br />

(0,1 - 0,3)<br />

.030 - .090<br />

(0,8 - 2,3)<br />

medium<br />

machining<br />

MT-LF<br />

.007 - .015<br />

(0,2 - 0,4)<br />

.030 - .090<br />

(0,8 - 2,3)<br />

feed rate – (mm)<br />

0,04 0,063 0,01 0,16 0,25 0,4 0,63 1,0 1,6 2,5 5,0<br />

0,1 0,16 0,25 0,4 0,63 1,0 1,6 2,5 4,0 6,3 10,0<br />

depth <strong>of</strong> cut – (mm)<br />

41

Chip Control Geometries<br />

Top Notch Pr<strong>of</strong>iling<br />

operation<br />

insert<br />

style/<br />

application<br />

insert<br />

geometry<br />

pr<strong>of</strong>ile<br />

feed rate – inches<br />

.0015 .0025 .004 .006 .010 .016 .025 .040 .060 .100 .200<br />

.004 .006 .010 .016 .025 .040 .060 .100 .160 .250 .500<br />

depth <strong>of</strong> cut – inches<br />

finishing<br />

DPGR<br />

precision<br />

ground<br />

.004 - .012<br />

(0,1 - 0,3)<br />

.010 - .070<br />

(0,3 - 1,8)<br />

finishing<br />

NPGR<br />

precision<br />

ground<br />

004 - .012<br />

(0,1 - 0,3)<br />

.010 - .070<br />

(0,3 - 1,8)<br />

finishing<br />

VBMR<br />

.004 - .014<br />

(0,1 - 0,4)<br />

.010 - .080<br />

(0,3 - 2,0)<br />

finishing<br />

VPGR<br />

precision<br />

ground<br />

004 - .014<br />

(0,1 - 0,4)<br />

.010 - .080<br />

(0,3 - 2,0)<br />

finishing<br />

NP<br />

.006 - .016<br />

(0,2 - 0,4)<br />

.030 - .110<br />

(0,8 - 2,8)<br />

medium<br />

machining<br />

NP-F<br />

.008 - .018<br />

(0,2 - 0,5)<br />

.040 - .120<br />

(1,0 - 3,0)<br />

medium<br />

machining<br />

NP-N<br />

.010 - .022<br />

(0,3 - 0,6)<br />

.045 - .140<br />

(1,1 - 3,6)<br />

roughing<br />

NP-33<br />

NP-R<br />

.012 - .026<br />

(0,3 - 0,7)<br />

.060 - .200<br />

(1,5 - 5,1)<br />

feed rate – (mm)<br />

0,04 0,063 0,01 0,16 0,25 0,4 0,63 1,0 1,6 2,5 5,0<br />

0,1 0,16 0,25 0,4 0,63 1,0 1,6 2,5 4,0 6,3 10,0<br />

depth <strong>of</strong> cut – (mm)<br />

42

Kennametal Grade System<br />

For Machining High-temperature and Titanium Alloys<br />

Ceramic Cutting Tools<br />

greater<br />

wear resistance<br />

KY2100<br />

TM<br />

KY1540<br />

TM<br />

400 -1050 sfm<br />

greater<br />

toughness<br />

Carbide Cutting Tools<br />

greater<br />

wear resistance<br />

KC5510<br />

TM<br />

KC9225<br />

K313<br />

K68<br />

TM<br />

TM<br />

TM<br />

KC5525<br />

TM<br />

KC9240<br />

TM<br />

KC9245<br />

TM<br />

50 - 500 sfm<br />

greater<br />

toughness<br />

43

Kennametal Grade System<br />

PVD Coated Carbide Grades<br />

grade coating composition and application C<br />

class<br />

KC5510<br />

KC5010<br />

(KC7310)<br />