OPERATING AND MAINTENANCE INSTRUCTION ... - larius.org

OPERATING AND MAINTENANCE INSTRUCTION ... - larius.org

OPERATING AND MAINTENANCE INSTRUCTION ... - larius.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

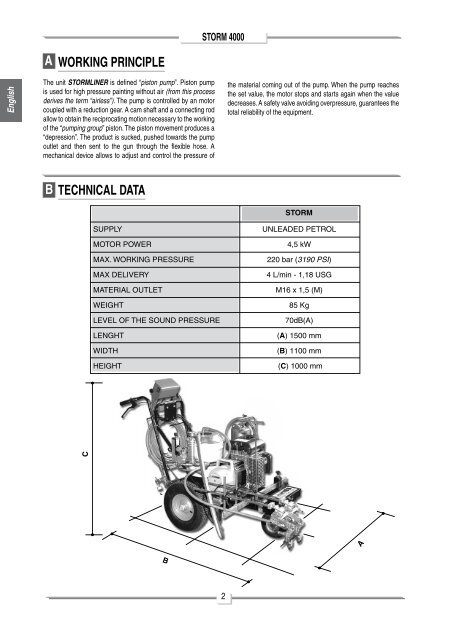

STORM 4000<br />

A<br />

Working principle<br />

English<br />

The unit STORMLINER is defined “piston pump”. Piston pump<br />

is used for high pressure painting without air (from this process<br />

derives the term “airless”). The pump is controlled by an motor<br />

coupled with a reduction gear. A cam shaft and a connecting rod<br />

allow to obtain the reciprocating motion necessary to the working<br />

of the “pumping group” piston. The piston movement produces a<br />

“depression”. The product is sucked, pushed towards the pump<br />

outlet and then sent to the gun through the flexible hose. A<br />

mechanical device allows to adjust and control the pressure of<br />

the material coming out of the pump. When the pump reaches<br />

the set value, the motor stops and starts again when the value<br />

decreases. A safety valve avoiding overpressure, guarantees the<br />

total reliability of the equipment.<br />

B<br />

Technical data<br />

STORM<br />

Supply<br />

Motor power<br />

Max. working pressure<br />

Max delivery<br />

Material outlet<br />

Weight<br />

Level of the sound pressure<br />

Lenght<br />

Width<br />

Height<br />

UNLEADED PETROL<br />

4,5 kW<br />

220 bar (3190 PSI)<br />

4 L/min - 1,18 USG<br />

M16 x 1,5 (M)<br />

85 Kg<br />

70dB(A)<br />

(A) 1500 mm<br />

(B) 1100 mm<br />

(C) 1000 mm<br />

C<br />

A<br />

B<br />

2