June 2006 - Plumbing & HVAC

June 2006 - Plumbing & HVAC

June 2006 - Plumbing & HVAC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

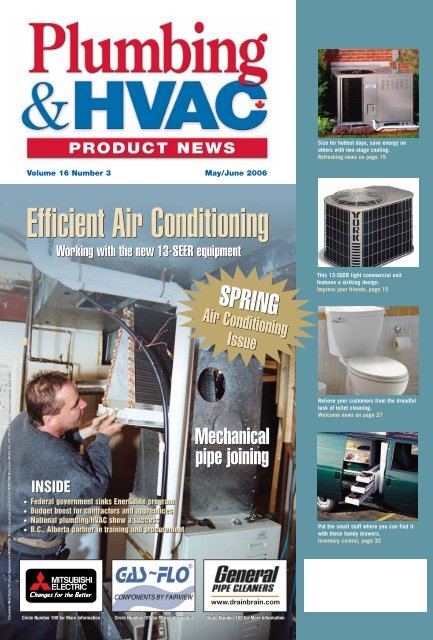

Size for hottest days, save energy on<br />

others with two-stage cooling.<br />

Refreshing news on page 15<br />

Volume 16 Number 3 May/<strong>June</strong> <strong>2006</strong><br />

Efficient Air Conditioning<br />

Working with the new 13-SEER equipment<br />

SPRING<br />

This 13-SEER light commercial unit<br />

features a striking design.<br />

Impress your friends, page 15<br />

Air Conditioning<br />

Issue<br />

Canadian Mail Sales Product Agreement #40063170. Return postage guaranteed NEWCOM Business Media Inc. 451 Attwell Drive, Toronto, Ontario M9W 5C4<br />

INSIDE<br />

• Federal government sinks EnerGuide program<br />

• Budget boost for contractors and apprentices<br />

• National plumbing/<strong>HVAC</strong> show a success<br />

• B.C., Alberta partner in training and procurement<br />

Circle Number 100 for More Information<br />

Circle Number 101 for More Information<br />

Mechanical<br />

pipe joining<br />

www.drainbrain.com<br />

Circle Number 102 for More Information<br />

Relieve your customers from the dreadful<br />

task of toilet cleaning.<br />

Welcome news on page 27<br />

Put the small stuff where you can find it<br />

with these handy drawers.<br />

Inventory control, page 32

FASTER. EASIER.<br />

ANVIL’S COPPER METHOD.<br />

When it comes to saving you time and money<br />

during installation of <strong>HVAC</strong> and <strong>Plumbing</strong> systems,<br />

nobody does it better than Anvil ® . Anvil’s Gruvlok ®<br />

method for grooved pipe systems is 1/3 less<br />

expensive than brazed or sweat systems. And,<br />

because there is a union at every joint and<br />

consistent take-outs, change orders are minimized.<br />

Anvil offers a complete line of Gruvlok products<br />

for grooved piping systems: couplings, fittings,<br />

valves, pump protection components, and<br />

tools - everything you need from one source.<br />

experience. Our products have earned your trust,<br />

our company will keep it.<br />

To learn more about our products and services, or<br />

to get help updating your specifications and files,<br />

call Anvil at 877-478-8565 or visit our Website<br />

www.anvilintl.ca<br />

Call today for your<br />

FREE Gruvlok ® Catalog!<br />

In addition to Gruvlok, Anvil is the largest and most<br />

complete fitting and hanger manufacturer<br />

in the world with over 150 years on industry<br />

BUILDING CONNECTIONS THAT LAST<br />

Circle Number 103 for More Information<br />

www.anvilintl.ca

Volume 16 Number 3 May/<strong>June</strong> <strong>2006</strong><br />

• Federal government sinks EnerGuide program<br />

• Budget boost for contractors and apprentices<br />

• National plumbing/<strong>HVAC</strong> show a success<br />

• B.C., Alberta partner in training and procurement<br />

Circle Number 100 for More Information<br />

Circle Number 101 for More Information<br />

www.drainbrain.com<br />

Circle Number 102 for More Information<br />

Size for hottest days, save energy on<br />

others with two-stage cooling.<br />

Refreshing news on page 15<br />

This 13-SEER light commercial unit<br />

features a striking design.<br />

Impress your friends, page 15<br />

Relieve your customers from the dreadful<br />

task of toilet cleaning.<br />

Welcome news on page 27<br />

Put the small stuff where you can find it<br />

with these handy drawers.<br />

Inventory control, page 32<br />

Features<br />

National show a hit 9<br />

<strong>Plumbing</strong>, <strong>HVAC</strong> industries under<br />

one roof<br />

In This Issue<br />

Departments<br />

Products & Technologies<br />

Hot Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Air Conditioning . . . . . . . . . . . . . . . . . . . . . .12<br />

Industry News . . . . . . . . . . . . . . . . . . . . . . . .7 Hot Water Heating . . . . . . . . . . . . . . . . . . . .19<br />

Western Update . . . . . . . . . . . . . . . . . . . . . .33 Pipes, Valves & Fittings . . . . . . . . . . . . . . . .22<br />

Atlantic Focus . . . . . . . . . . . . . . . . . . . . . . .34 Refrigeration . . . . . . . . . . . . . . . . . . . . . . . .25<br />

People & Places . . . . . . . . . . . . . . . . . . . . . .35 Faucets & Fixtures . . . . . . . . . . . . . . . . . . . .27<br />

Coming Events . . . . . . . . . . . . . . . . . . . . . . .36 Tools & Instruments . . . . . . . . . . . . . . . . . . .29<br />

Mechanical Marketplace . . . . . . . . . . . . . . . .37 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . .31<br />

Shop Management . . . . . . . . . . . . . . . . . . . .38 Trucks for the Trade . . . . . . . . . . . . . . . . . . .32<br />

Working with 13-SEER 12<br />

New air conditioners a quantum leap<br />

for industry<br />

Mechanical joining 22<br />

A revolution in pipefitting<br />

Milestone marked 35<br />

David Suzuki stirs up celebration<br />

Canadian Mail Sales Product Agreement #40063170. Return postage guaranteed NEWCOM Business Media Inc. 451 Attwell Drive, Toronto, Ontario M9W 5C4<br />

Efficient Air Conditioning<br />

INSIDE<br />

Working with the new 13-SEER equipment<br />

SPRING<br />

Air Conditioning<br />

Issue<br />

Mechanical<br />

pipe joining<br />

Comfort starts long before installation.<br />

Before it’s a home, it’s a jobsite. Not an easy place for a contractor to relax. This<br />

is where Uponor reliability starts to shine. Our innovative radiant heating, PEX<br />

plumbing and fire protection systems not only make homeowners comfortable,<br />

our proven dependability will put you at ease, too. To learn about Uponor products<br />

first hand, visit www.uponor.ca.<br />

Cover photo: <strong>HVAC</strong> technician Mike Palmer<br />

installs a new 15-SEER air conditioner.<br />

(Photo by Simon Blake)<br />

Circle Number 104 for More Information<br />

www.plumbingandhvac.ca May/<strong>June</strong> <strong>2006</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 3

Circle Number 105 for More Information

Hot Seat<br />

May/<strong>June</strong> <strong>2006</strong><br />

Volume 16, Number 3<br />

ISSN 1499-5271<br />

Editor<br />

Simon Blake<br />

(416) 614-5820<br />

sblake@newcom.ca<br />

Operating on faith<br />

Editor Emeritus<br />

Ronald H. (Ron) Shuker<br />

(416) 614-5816<br />

rshuker@newcom.ca<br />

If I were to use typical newspaper jargon,<br />

I might say that the <strong>HVAC</strong><br />

industry is “reeling” from the recent<br />

decision by Stephen Harper’s<br />

Conservative government to end the<br />

EnerGuide for Houses program. But<br />

that would be too strong.<br />

However, I think I can safely say that<br />

just about everyone in the industry is<br />

very disappointed. The program, which<br />

provided rebates to homeowners that<br />

had energy audits done on their homes<br />

and then upgraded to more efficient<br />

<strong>HVAC</strong> equipment, was developed with<br />

considerable input from the industry<br />

and has been quite successful in its threeyear<br />

run. The oil heating sector had only<br />

just received approval for its equipment<br />

to be included in the program.<br />

Manufacturers, wholesalers and contractors<br />

were all counting on a boost<br />

from the EnerGuide for Houses program<br />

when they created their production<br />

and sales projections for <strong>2006</strong>.<br />

Many <strong>HVAC</strong> contractors have made the<br />

EnerGuide rebate a key part of their<br />

sales pitch.<br />

However, it appears that the new<br />

Conservative federal government<br />

regards EnerGuide as just another<br />

example of Liberal largesse with the<br />

public purse. They have made it clear<br />

that they don’t support the Kyoto<br />

Protocol on climate change nor any<br />

program that was created as part of the<br />

Liberal initiative to meet Kyoto goals.<br />

One can’t really blame them for<br />

being suspicious as the examples of<br />

foolish spending by various Liberal governments<br />

over the years are many. The<br />

Quebec sponsorship scam and the metric<br />

fiasco are two big ones that come<br />

immediately to mind.<br />

But one can only wish that Harper<br />

and his government had done more<br />

homework on the EnerGuide for<br />

Houses program before brushing it off.<br />

The move is reminiscent of another<br />

famous Liberal faux pas – the cancellation<br />

of the military helicopter purchase<br />

arranged by the Conservative government<br />

of Brian Mulroney as the<br />

Canadian Forces’ ancient Sea King helicopters<br />

were falling out of the sky<br />

around them.<br />

The Harper government has promised<br />

to come up with a “made in<br />

Canada” replacement by this fall. If it’s<br />

well thought out and developed<br />

through consultation with Canada’s<br />

<strong>HVAC</strong> industry, it is difficult to see that<br />

it could be much different from the program<br />

it replaces. The timeline is short<br />

and any in-depth consultation with the<br />

industry will be difficult to achieve over<br />

the summer. But even if it is delayed,<br />

one can only hope that the government<br />

is serious about creating a meaningful<br />

program.<br />

Most Canadians haven’t yet passed<br />

judgment on Stephen Harper and his<br />

government. They may not always agree<br />

with his policies, but it is refreshing to<br />

have a prime minister who seems intelligent,<br />

articulate and genuinely interested<br />

in doing the right thing. It is a welcome<br />

change to listen to someone with ideas –<br />

a vision even – of where this country<br />

needs to go.<br />

If we haven’t heard a lot of screaming<br />

from the industry over the cancellation<br />

of EnerGuide, it is because there is a<br />

degree of faith that those qualities will<br />

make everything work out in the longterm.<br />

We’re not reeling yet!<br />

Contributors<br />

Roy Collver<br />

John Carr<br />

Ron Coleman<br />

Barry Cunningham<br />

Arthur Irwin<br />

Publisher<br />

Mark Vreugdenhil<br />

(416) 614-5819<br />

mark@plumbingandhvac.ca<br />

National Sales Manager<br />

John Pallante<br />

(416) 614-5805<br />

john@plumbingandhvac.ca<br />

Design and Production<br />

Tim Norton<br />

production@nytek.ca<br />

Circulation Manager<br />

Pat Glionna<br />

Corporate Services<br />

Anthony Evangelista<br />

PLUMBING & <strong>HVAC</strong> PRODUCT NEWS Magazine is<br />

published six times annually by NEWCOM Business<br />

Media Inc. and is written for individuals who purchase/<br />

specify/approve the selection of plumbing, piping, hot<br />

water heating, fire protection, warm air heating, air<br />

conditioning, ventilation, refrigeration, controls and<br />

related systems and products throughout Canada.<br />

Head Office<br />

NEWCOM Business Media Inc.<br />

451 Attwell Drive, Toronto,<br />

Ontario, Canada M9W 5C4<br />

Tel: (416) 242-8088<br />

Fax (416) 242-8085<br />

POSTMASTER: Send all address changes and circulation<br />

inquiries to: <strong>Plumbing</strong> & <strong>HVAC</strong> Product News<br />

magazine, 451 Attwell Drive, Toronto, Ontario, Canada<br />

M9W 5C4. Canadian Publications Mail Sales Product<br />

Agreement No. 40063170. Postage paid at Winnipeg,<br />

MB. Annual Subscription: $34.00 plus $2.38 GST,<br />

single copy $5.00 plus $0.35 GST in Canada;<br />

United States $40.00 U.S. One year subscription<br />

in U.S.: $40.00 US, One year subscription foreign:<br />

$65.00 U.S.<br />

Copyright <strong>2006</strong>. The contents of this magazine<br />

may not be reproduced in any manner without the<br />

prior written permission of the Publisher.<br />

We acknowledge the financial support of the<br />

Government of Canada through the Publications<br />

Assistance Program toward<br />

our mailing costs.<br />

PAP Registration No. 10796<br />

A member of:<br />

Canadian Institute of <strong>Plumbing</strong> & Heating<br />

Canadian Circulation Audit Board<br />

Mechanical Contractors Assoc. of Canada<br />

Ontario <strong>Plumbing</strong> Inspectors Association<br />

Hydronics Marketing Group<br />

American Society of Heating Refrigerating &<br />

Air Conditioning Engineers<br />

Heating Refrigeration Air Conditioning<br />

Institute of Canada<br />

Refrigeration Service Engineers Society of Canada<br />

Circle Number 106 for More Information

Shower upgrades without<br />

knocking out the wall?<br />

“Cool.”<br />

A Masco Company | ©<strong>2006</strong> Masco Corporation of Indiana | Delta Faucet Company<br />

MultiChoice Universal. The revolutionary tub/shower valve that lets you change style and<br />

function without having to change the plumbing behind the wall. Delta. We work wonders<br />

with water. 800.345.DELTA www.deltafaucet.com/multichoice.<br />

Circle Number 107 for More Information

Industry News<br />

In Brief<br />

Habitat fundraiser<br />

tops $1-million<br />

The Canadian Institute of<br />

<strong>Plumbing</strong> and Heating (CIPH) has<br />

exceeded its $1-million fundraising<br />

goal for Habitat for Humanity<br />

over the past year. Institute<br />

members raised a record-breaking<br />

$1,021,678 in cash and products,<br />

reported CIPH charity committee<br />

chairman Paul Lachance<br />

(president, Wolseley Canada) at<br />

the group’s Habitat Gala Dinner<br />

held March 22 at the Fairmont<br />

Royal York Hotel in Toronto. The<br />

group has raised $3,521,613 for<br />

Habitat since 1994.<br />

Programmable thermostat<br />

efficiency gain questioned<br />

Tests on Energy Star-rated programmable<br />

thermostats by the<br />

U.S. Environmental Protection<br />

Agency (EPA) indicate that they do<br />

not save energy because many<br />

homeowners do not program their<br />

units. Canada’s Office of Energy<br />

Efficiency (OEE) has recommended<br />

that, rather than discontinue<br />

the program, the EPA suspend the<br />

Energy Star criteria in order to<br />

gather more information, reports<br />

the Heating, Refrigeration and Air<br />

Conditioning Institute of Canada<br />

(HRAI).<br />

N.S. gas association<br />

The Heating, Refrigeration and Air<br />

Conditioning Contractors of<br />

Canada (HRAC) is working with<br />

contractors and suppliers in Nova<br />

Scotia to form a new “Nova Scotia<br />

Natural Gas Association”, reports<br />

HRAI. The group would serve the<br />

needs of the province’s budding<br />

natural gas heating industry. The<br />

proposal may see the group use<br />

management services from the<br />

HRAC Halifax office and draw<br />

upon the HRAI for membership.<br />

The group hopes to be operational<br />

by the fall. Contact Martin Luymes<br />

at 1-800-267-2231 for more<br />

information.<br />

Harper government cuts<br />

EnerGuide programs<br />

By Ron Shuker<br />

Hardly had the ink dried on the<br />

announcement of the five-year<br />

$500 million EnerGuide for Low-<br />

Income Households program early this<br />

year when the new federal government<br />

cancelled it.<br />

The announcement came hard on<br />

the heels of the cancellation of the parent<br />

EnerGuide for Houses program. It<br />

was initially launched in 1998, but<br />

ramped up three years ago. Both programs<br />

offered homeowner incentives to<br />

replace their existing heating and air<br />

conditioning equipment with high efficiency<br />

units. Many manufacturers,<br />

wholesalers and contractors were<br />

counting on these incentives to boost<br />

<strong>2006</strong> sales.<br />

“The government’s cancellation (of<br />

these programs) is an enormous blow<br />

to Canada’s developing home energy<br />

efficiency industry,” stated Clifford<br />

Maynes, executive director of Green<br />

Communities Canada, a major stakeholder<br />

in the program. “We have called<br />

on the government to reconsider its<br />

decision. It could set back the cause of<br />

residential energy efficiency by a<br />

decade,” he said.<br />

“It’s definitely unfortunate for many<br />

of our contractors who have been working<br />

with the EnerGuide home energy<br />

auditing companies to be certified<br />

providers of those upgrades their audits<br />

recommended,” said Warren Heeley,<br />

president of the Heating Refrigeration<br />

& Air Conditioning Institute of Canada.<br />

HRAI has worked closely with Natural<br />

Resources Canada and Environment<br />

Canada for years on these and many<br />

other energy efficiency programs.<br />

“We are also concerned that the<br />

NRCan program encouraging training<br />

to meet upgraded energy efficiency programs,<br />

including R2000, by providing a<br />

$150 per course subsidy may also end.”<br />

These grants helped hundreds of technicians<br />

upgrade their training through<br />

HRAI SkillTech courses over the past<br />

three years “to better apply energy efficient<br />

heating and ventilation systems,<br />

which was NRCan’s objective,” Heeley<br />

pointed out.<br />

The new federal government plans to<br />

implement its own “made-in-Canada”<br />

plan this fall.<br />

Is appliance rebate next?<br />

The energy efficient appliance rebate is<br />

also a question mark. It has been jointly<br />

funded by gas and electric utilities and<br />

NRCan to encourage more homeowners<br />

and businesses to purchase Energy Star<br />

rated gas furnaces, boilers, fireplaces and<br />

other appliances the past few years.<br />

The oil heat industry is specifically<br />

concerned since it has been left out of<br />

these programs for years. “This was the<br />

first time the oil heat industry had a<br />

place at the rebate table, said Scott<br />

Andison, president of the Canadian Oil<br />

Heat Association (COHA).<br />

“We were ready to roll out our high<br />

efficiency oil heating program Feb. 1<br />

after more than a year of discussions. It<br />

was delayed to March and April and<br />

then Treasury Board announced in<br />

mid-May that the NRCan funding for<br />

these programs had been withdrawn,”<br />

he reported.<br />

“We understand Ottawa wants a sustainable,<br />

effective and economical longterm<br />

program and not just a subsidy for<br />

energy used,” Andison reported. “They<br />

are planning more comprehensive cost<br />

relief programs, and less piece-meal. We<br />

will continue to dialogue with NRCan<br />

officials through the summer to achieve<br />

this objective.”<br />

COHA planned to discuss the topic<br />

and create a new mandate for further<br />

negotiations with the federal government<br />

at the COHA annual meeting and<br />

Symposium <strong>June</strong> 1-3 in Huntsville,<br />

Ont.., he added.<br />

Steven Harper’s Conservative government<br />

has offered a number of incentives<br />

for industry in its first federal<br />

budget, including a major boost for<br />

apprenticeship programs.<br />

Contractors are eligible for $2,000 for<br />

each apprentice they hire under the<br />

Apprenticeship Job Creation Tax Credit.<br />

Apprentices will receive a $1,000 per<br />

year grant for the first two years in a<br />

Apprenticeship boost<br />

Red Seal recognized trade program or<br />

other “economically strategic apprenticeship<br />

programs.” The Ontario residential<br />

<strong>HVAC</strong> technician program, for<br />

example, would seem a natural.<br />

Workers are also eligible for a $500<br />

tax deduction for tools they must buy as<br />

a condition of employment in excess of<br />

$1,000. And the $200 limit is raised to<br />

$500 on construction tools eligible for<br />

the 100 percent capital cost deduction.<br />

Other changes that may help contractors<br />

are:<br />

• Raising the small business income eligible<br />

for the 12 percent tax rate to<br />

$400,000, up $300,000, effective Jan. 1.<br />

•<br />

Reducing the 12 percent small business<br />

tax rate to 11.5 percent in 2008<br />

and to 11% in 2009.<br />

• Eliminating the federal capital surtax<br />

retroactive to Jan. 1.<br />

•<br />

Lowering the general corporate tax<br />

rate to 19 percent from 21 percent by<br />

2010.<br />

The Pros Know.<br />

®<br />

Oil tank rule changes<br />

The Fuels Safety Division of the<br />

Technical Standards and Safety<br />

Authority of Ontario (TSSA) has<br />

revised its rules on the re-use of<br />

single wall underground tanks.<br />

Variances will no longer be considered<br />

if the applicant cannot provide<br />

a complete history of the<br />

cathodic protection for the tank.<br />

However, it will allow “existing<br />

ULC certified S602 tanks installed<br />

outdoors and bearing a ULC label<br />

for indoor use to continue to be<br />

used outdoors.” It requires that<br />

“every calendar year, the external<br />

condition of the tank and installation<br />

is visually inspected and<br />

Continued on page 11<br />

The pros know that the new KeepRite® line of<br />

air conditioners and heat pumps proves again<br />

that KeepRite gets it just right. Every time.<br />

• Copeland® scroll compressor on all models<br />

• Advanced air management technology<br />

optimizes performance without<br />

increasing sound levels<br />

keepritedlr.com<br />

© <strong>2006</strong> International Comfort Products, LLC<br />

A member of the United Technologies Corporation family. Stock symbol UTX.<br />

• Two-speed fan motors<br />

• Deep-drawn fan orifice<br />

• Sound-suppressing jackets<br />

• Industry-leading warranties<br />

Circle Number 108 for More Information<br />

www.plumbingandhvac.ca May/<strong>June</strong> <strong>2006</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 7

General Gen-Eye Junior<br />

<br />

What a package!<br />

Looking for a camera system that handles small lines down to 1-1/2", but has the<br />

features found on top of the line models? The Gen-Eye Junior delivers the goods.<br />

Looking for a system that can run 200 feet in 3" to 6" lines? The Gen-Eye Junior<br />

comes through again. Same package, but with a longer, stronger pushrod.<br />

■ Integral self-contained unit with reel, pushrod and monitor all in one<br />

portable package.<br />

■ Sleek, rugged housing built for durability,<br />

versatility and ease of use. Makes rough<br />

handling part of a day’s work.<br />

■ Big 7-inch LCD screen is mounted on an<br />

extending 4-way adjustable arm, so you<br />

can position the screen where it works<br />

best for you.<br />

■ AC/DC power supply with optional<br />

rechargeable battery lasts up to three hours.<br />

■ Two unit options: 100 ft. of micro-pushrod and color<br />

micro-camera for 1-1/2" to 4" lines, or 200 ft.of mini-pushrod<br />

with color mini-camera for 2" to 6" lines.<br />

■ Built-in dual frequency transmitter (512 hz and 874 hz) reduces<br />

interference andmake the camera easier to locate.<br />

■ There’s lots more included as standard equipment, like a picture<br />

inverter, on-screen footage counter, built-in text writer, time and<br />

date stamp, microphone jack and video and audio jacks for<br />

external recording devices.<br />

Call the Drain Brains ® at 877-273-7246 or 412-771-6300 for more<br />

information or to arrange a free demonstration.<br />

For a wholesaler in your area, contact:<br />

Alberta – Tom Donaldson Co.,<br />

Calgary 403-287-7933 – Edmonton 780-486-2288<br />

British Columbia – West-Am, 877-600-0210<br />

Manitoba – Tom Beggs Agency, 204-953-1900<br />

Ontario – Newgen Sales, 905-895-5999<br />

Quebec & Atlantic Canada<br />

Rafales Agency, 514-731-3212<br />

Saskatchewan – Asta Sales,<br />

306-933-4125<br />

When not in use, the 7" LCD screen<br />

retracts into housing behind<br />

protective cover.<br />

Pushrod, reel, and<br />

monitor are all<br />

contained in this lightweight<br />

all in one package that<br />

weighs as little as 28 lbs.<br />

www.drainbrain.com/geneye<br />

© General Wire Spring <strong>2006</strong><br />

Circle Number 109 for More Information

Industry News<br />

Upbeat mood at<br />

national trade show<br />

By Simon Blake<br />

Visitors and exhibitors alike were<br />

enthusiastic about the <strong>2006</strong> version<br />

of the Canadian Mechanicals<br />

Exposition.<br />

The first show in 10 years to include<br />

the plumbing industry, organizers of<br />

CMX-CIPHEX <strong>2006</strong> were beaming by<br />

the end of three days. “We had a<br />

tremendous start,” reported show manager<br />

Patrick Shield. “There were high<br />

expectations. I think the show delivered…”<br />

added show chairman Ed<br />

Seaward, manager of marketing and<br />

major accounts for Union Gas, Toronto.<br />

Over 500 exhibitors packed the North<br />

Hall of the Toronto Convention Centre<br />

March 23-25. Total attendance was 14,087<br />

(including exhibitors) – a 30 percent<br />

increase over the<br />

2004 event.<br />

Exhibit space<br />

was sold out well<br />

in advance, with<br />

a few potential<br />

exhibitors on a<br />

waiting list. The<br />

number of heating<br />

exhibitors –<br />

both forced air<br />

and hydronic –<br />

was up significantly<br />

at this<br />

year’s event, Shield reported. And, of<br />

course, the plumbing fixture and faucet<br />

manufacturers were back for first time<br />

in 10 years.<br />

The combined show, which brought<br />

together the CMX and CIPHEX<br />

Ontario shows, was the result of an<br />

agreement between the Heating,<br />

Refrigeration and Air Conditioning<br />

Institute of Canada (HRAI) and the<br />

Canadian Institute of <strong>Plumbing</strong> &<br />

Heating (CIPH). A number of manufacturers<br />

and contractors had been urging<br />

the amalgamation for some time.<br />

“Today, if you are not partnering with<br />

others, a show cannot sustain itself,”<br />

remarked Ralph Suppa, CIPH president.<br />

“I think both associations brought<br />

“There were high<br />

expectations.<br />

I think the show<br />

delivered…”<br />

value to the combined effort … it really<br />

worked out well.”<br />

“Everything I am hearing is positive,”<br />

agreed Warren Heeley, HRAI president.<br />

The only question that organizers<br />

must wrestle with is how to make space<br />

for future expansion, he added. There<br />

has been some debate about moving the<br />

show to the larger South Hall, but few<br />

exhibitors favour that because it will<br />

take the show away from the Front<br />

Street restaurants and hotels that play a<br />

key role for industry networking.<br />

Learning opportunities<br />

The event’s theme was “Joining forces.<br />

Sharing knowledge.” This year’s<br />

Learning Forum featured a lengthy<br />

seminar schedule<br />

along with<br />

manufacturer’s<br />

sessions in a<br />

show floor theatre.<br />

More than<br />

3212 visitors attended<br />

the sessions.<br />

“There was<br />

standing room<br />

only in some<br />

seminars,” remarked<br />

Seaward.<br />

The education<br />

theme continued in the east end of the<br />

building where the Skills competitions<br />

for students and – for the first time –<br />

experienced technicians occurred. The<br />

high school and masters events were<br />

well supported, but a strike by college<br />

instructors reduced participation in the<br />

Skills Ontario competition. Nick<br />

D’Alessandro of Mohawk College won<br />

the gold medal, Cory Hoffer, also from<br />

Mohawk, took second with Don Faithful<br />

of George Brown College in third.<br />

Elmira District High School swept the<br />

Secondary School Student Challenge<br />

with Josh Pond in first, Jonathan Forwell<br />

in second and Menno Wicher in third.<br />

Tim Lukacs of Lukacs <strong>Plumbing</strong> &<br />

Heating in North Bay, Ont. earned the<br />

title of Grand Master in the Masters<br />

Challenge.<br />

Competitors in the Masters Challenge identify historic <strong>HVAC</strong> artifacts.<br />

Other success stories included a daycare<br />

on Saturday. Telus supplied MIKE<br />

phones so that parents could keep in<br />

touch with the daycare. “We had about<br />

40 kids,” reported Shield.<br />

There was considerable interest in a<br />

‘virtual showroom’ in which about 40<br />

manufacturers displayed products on a<br />

video screen, he added.<br />

The door prize, a new GM van fully<br />

Reitzel Heating & Sheet Metal Ltd.,<br />

Waterloo, Ont.<br />

At the end of the day, the key was to<br />

provide enough variety to draw people<br />

that are involved in many different<br />

aspects of the industry, said Seaward.<br />

“All of these things bring people to the<br />

show. They take time off from their revenue-generating<br />

jobs to attend. We<br />

needed to give them lots of choices.”<br />

outfitted by DC Van Outfitters, The next CMX-CIPHEX show will<br />

Markham, Ont., went to Alan Reitzel of take place in Toronto in 2008.<br />

HRAI president Warren Heeley, left,<br />

and CMX-CIPHEX <strong>2006</strong> show chairman<br />

Ed Seaward pulled the winning<br />

ballot in the truck draw.<br />

Many activities<br />

The Canadian Hydronics Council held<br />

its popular Pump Challenge in which<br />

technicians race each other and the<br />

clock to change out a pump for cash<br />

prizes. Visiting Danish student Michael<br />

Eriksen took home the $300 prize with<br />

a time of two minutes, 23 seconds, far<br />

shy of the record set at the Foothills<br />

Conference in Edmonton last year of<br />

one minute, 37 seconds.<br />

The <strong>HVAC</strong>/R Heritage Centre displayed<br />

historic equipment adjacent to<br />

the Skills area. This allowed organizers to<br />

make the identification of relics from the<br />

past a part of the Masters Fun Challenge.<br />

Circle Number 110 for More Information<br />

www.plumbingandhvac.ca May/<strong>June</strong> <strong>2006</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 9

Beautifully cool.<br />

LG Flex Multi Air Conditioning Systems<br />

Combination solutions to suit every customer.<br />

LG’s NEW Flex Multi Split system operates two or three interior<br />

units that are mounted in separate rooms. Each indoor unit comes with<br />

it’s own remote control, allowing the customer to set the temperature<br />

individually in different rooms. These units are connected to a single<br />

exterior unit.<br />

9,000 and 12,000 Flex Multi indoor units can be combined to<br />

achieve between 18,000 and 24,000 BTUs on a Dual Zone system,<br />

and from 27,000 to 36,000 BTUs on a Tri-Zone system. The interior<br />

units are available in a variety of styles, including Art Cool and Standard<br />

models. Both Dual Zone and Tri-Zone are available in Cooling Only<br />

or Heat Pump systems.<br />

These units are covered by an industry-leading 2 year warranty on<br />

parts & labour, and a 5 year warranty on the compressor.<br />

12,000 BTUs<br />

DUAL ZONE - Flex Multi System<br />

Combine with any 2 Interior Units<br />

achieving 18,000 to 24,000 BTUs<br />

9,000 BTUs<br />

LG , Art Cool and the LG logo are registered trade marks of LG Electronics Inc.<br />

TRI-ZONE - Flex Multi System<br />

Combine with any 3 Interior Units<br />

achieving 27,000 to 36,000 BTUs<br />

9,000 BTUs<br />

12,000 BTUs<br />

FOR LOCATION NEAR YOU, VISIT www.isc.tv<br />

17 ONTARIO LOCATIONS 905-364-0720<br />

4 WESTERN CANADA LOCATIONS 204-775-9731<br />

14 QUEBEC / EASTERN CANADA LOCATIONS 514-329-5349<br />

12,000 BTUs<br />

Call your LG Dealer to learn more<br />

Circle Number 111 for More Information<br />

www.LG.ca

Industry News<br />

In Brief<br />

Continued from page 9<br />

accepted by the fuel oil distributor…and<br />

a written record of the<br />

inspection provided to the tank<br />

owner/operator,” stated Roland<br />

Hadaller, P.Eng., director for fuel<br />

oil regulation. Both types of tanks<br />

are tested and certified to the<br />

same ULC standard.<br />

Time to upgrade?<br />

TSSA has issued a Director’s Order<br />

to remove, render inoperable or<br />

relocate propane and gas-fired unvented<br />

Servel refrigerators produced<br />

between 1933 and 1957.<br />

The refrigerators are prone to produce<br />

carbon monoxide in levels<br />

that may be lethal. Where relocation<br />

provides a solution, every unit<br />

must be inspected and serviced by<br />

a TSSA certified gas technician<br />

annually.<br />

Letters<br />

Where are the smaller<br />

air conditioners?<br />

Dear editor:<br />

I am and have been a huge supporter<br />

of 13-SEER air conditioning. What<br />

worries me is, what about our smaller<br />

homes requiring less than 18,000 Btu/h?<br />

I wrote last fall when I read in the<br />

trade press that we (contractors) were<br />

not properly sizing air conditioners –<br />

shame on us. Well, here we are and we<br />

have managed to source only one manufacturer<br />

(with seven units on backorder<br />

at our wholesaler). Other companies<br />

have all discontinued building a<br />

12,000 Btu/h unit.<br />

Recently a customer wanted air conditioning<br />

in a 650 sq. ft. home. Every<br />

company that he spoke to recommended<br />

a 1 1/2 ton (18,000 Btu/h) unit. Contractors<br />

told him that there was no such<br />

thing as a 12,000 Btu/h air conditioner<br />

and never has been.<br />

In Winnipeg, like many places, we<br />

have condos in multi-storey buildings<br />

that are up to 1,000 sq. ft. where we can<br />

use a 12,000 Btu/h air conditioner. We<br />

build tight and I think that it’s absolutely<br />

sick that we cannot access 12,000<br />

Btu/h units with R410A refrigerant,<br />

never mind R-22.<br />

We could install ductless if we had<br />

too, but the cost would be much higher.<br />

In this day and age of telling us (contractors)<br />

to do a better job, size properly<br />

and up-sell, my advice to all the<br />

manufacturers is: GET OFF THE POT<br />

AND SUPPLY PRODUCTS THAT<br />

SERVE THE CONSUMER!<br />

D. Brian Baker, president<br />

Custom Vac Limited<br />

Winnipeg<br />

Non-residential permits<br />

jump<br />

After a strong 15.3 percent<br />

increase in February, the value of<br />

non-residential permits surged<br />

another 15.1 percent in March to<br />

$2.1 billion. This was 16.1 percent<br />

higher than the average<br />

monthly level in 2005, an exceptional<br />

year for the non-residential<br />

sector. Institutional permits<br />

increased 52.6 percent to $773<br />

million, the second highest level<br />

on record, largely from hospitalrelated<br />

projects. The total value of<br />

all building permits increased 5.3<br />

percent in March, also the second<br />

highest level on record at $5.5 billion.<br />

The non-residential results<br />

are explained by strong retail<br />

sales, high industrial capacity utilization,<br />

record high operating<br />

profits earned, lower vacancy rates<br />

for commercial buildings and<br />

favorable interest rates, Statistics<br />

Canada reported.<br />

Near record residential<br />

permits<br />

A total of 59,100 new dwelling<br />

units were approved in the first<br />

three months of <strong>2006</strong>. This was<br />

the best first quarter in Canada<br />

since 1990 when 61,600 units<br />

were approved. B.C. had the<br />

largest gain in March (up 30.7<br />

percent to $729 million), mainly<br />

in multi-family housing. Nova<br />

Scotia set a new record high<br />

($98 million) in March. Alberta<br />

had the second highest level in<br />

March after setting the record in<br />

February. Regionally, 21 out of the<br />

28 census metropolitan areas<br />

showed stronger results in <strong>2006</strong>.<br />

The largest first quarter advances<br />

(in dollars) were in Calgary,<br />

Edmonton and Vancouver, and<br />

centres east of Toronto.<br />

iSeries<br />

Mixing Valves<br />

Software<br />

Radiant Mixing<br />

Blocks<br />

JOIN THE GREEN TEAM!<br />

Save Time and Earn More!<br />

As a member of Taco’s Green Team, you’ll benefit from special training in hydronic systems from<br />

basic to advanced. We’ll also teach you how to best sell systems and upgrades for excellent<br />

profitability. You’ll have access to a special toll-free tech help number and the highly informative<br />

Green Team website – with links to industry associations. Plus you’ll receive a host of bulletins,<br />

guides and specialized information designed to keep you at the leading edge.<br />

So join the Green Team, and profit from the experience!<br />

Circulators Air Eliminators Electronic<br />

Controls<br />

TACO CANADA LTD.<br />

6180 Ordan Drive, Mississauga, Ontario L5T 2B3<br />

Tel. 905-564-9422 Fax. 905-564-9436<br />

www.taco-hvac.com/greenteam<br />

Hot Water on ProFit Parts Mixing Valves<br />

D’MAND ®<br />

Circle Number 112 for More Information<br />

www.plumbingandhvac.ca May/<strong>June</strong> <strong>2006</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 11

Air Conditioning<br />

13 -SEER<br />

Working with the new air conditioning equipment<br />

By Simon Blake<br />

New higher efficiency minimum<br />

standards for air conditioners<br />

have created dramatic challenges<br />

for the <strong>HVAC</strong> industry.<br />

Already in effect in Ontario and<br />

expected to be approved in the rest of<br />

the country this fall, the new 13-SEER<br />

(Seasonal Energy Efficiency Ratio) has<br />

required manufacturers to redesign<br />

their equipment platforms and shift to<br />

thermal expansion valve technology to<br />

control refrigerant flow.<br />

The U.S. adopted the 13-SEER minimum<br />

in January and the older equipment<br />

is no longer being produced.“We stopped<br />

building the 10-SEER equipment back in<br />

January,” remarked Tim Hawkins, engineering<br />

manager for residential air<br />

conditioning products for Rheem<br />

Manufacturing, Fort Smith, Arkansas.<br />

As a result, Canadian contractors<br />

need to get their technicians up to speed<br />

quickly even though leftover 10-SEER<br />

stock will likely be available for much of<br />

this cooling season.<br />

The equipment<br />

On 13-SEER equipment, both the condensing<br />

(outdoor) and evaporator<br />

(indoor) coils are substantially larger<br />

than with 10-SEER equipment.<br />

In a retrofit, the technician may have<br />

to build a larger pad for the outdoor<br />

unit. The bigger unit may require two<br />

people to move it into place. In the<br />

worst case, he may have to find a different<br />

location if the nook that housed the<br />

old condensing unit is too tight.<br />

All of that is easier said than done in<br />

crowded urban areas, noted David<br />

Morden, director of Canadian sales for<br />

ECR International, Olsen Division, in<br />

Wallaceburg, Ont. “It has a tremendous<br />

impact on urban areas like the greater<br />

Toronto area where developers maximize<br />

profits by having smaller lots …<br />

You are really limited as to where you<br />

can put the 13-SEER air conditioning.”<br />

The indoor picture is more complicated.<br />

A-coils are generally larger and<br />

use thermal expansion (TX) valves to<br />

control refrigerant flow.<br />

The technician may be able to stuff<br />

the larger coil into an existing plenum,<br />

but that may restrict airflow in the heating<br />

mode to the point where the furnace<br />

runs on the limit control. In most cases<br />

the technician will have to rebuild the<br />

plenum to house<br />

a wider or taller<br />

coil. In low basements,<br />

the contractor<br />

will have<br />

to specify a lowheight<br />

A-coil and<br />

build the sheet<br />

metal out to suit.<br />

“There will be<br />

challenges to<br />

replacement and<br />

the temptation will be to keep the old<br />

(indoor) unit,” remarked Hawkins.<br />

That’s not a good strategy, he added.<br />

In the best case, the unit will simply<br />

operate below 13-SEER. However, if the<br />

coil has a fixed restrictor – piston or cap<br />

tubes – they will not be sized correctly<br />

for 13-SEER. The operating pressure on<br />

“It has a tremendous<br />

impact on urban areas …<br />

You are really limited as to<br />

where you can put the<br />

13-SEER air conditioning.”<br />

Mike Palmer, a heating and air conditioning technician with<br />

Design Air Climatecare, Thornhill, Ont., illustrates the size difference between<br />

the old 9.5 SEER A-coil, left, and the new 15-SEER coil. Both are Carrier units.<br />

13-SEER is considerably lower than for<br />

10-SEER. “You will get a significant<br />

reduction in capacity and compressor<br />

reliability.”<br />

Some older furnaces may be too tall,<br />

but that’s a sales opportunity to sell the<br />

customer a new<br />

high-efficiency<br />

furnace. If the<br />

contractor specifies<br />

a variable<br />

speed or two-stage<br />

heating/cooling<br />

unit, it can be<br />

sized for the hottest<br />

days but will<br />

run at half capacity<br />

most of the<br />

time, suggested Brooke MacLaren, residential<br />

territory manager for Carrier<br />

Canada.<br />

Some manufacturers have redesigned<br />

existing 13-SEER lines to make them<br />

more compact. Trane, for example,<br />

maintained the same footprint while<br />

going to a taller outdoor unit (in the<br />

smaller tonnages), reported Ian McTeer,<br />

field service representative for Trane<br />

Canada, Scarborough, Ont. “The footprint<br />

remains the same … until you get<br />

up into the four and five-ton units.” The<br />

company has also gone to three-row<br />

coils on all indoor units.<br />

Carrier’s new Comfort Line series is<br />

20 percent smaller, 30 percent lighter<br />

and uses 40 percent less refrigerant than<br />

company’s previous 13-SEER models,<br />

reports MacLaren. At least two manufacturers,<br />

Olsen and Carrier, offer compact<br />

side discharge condensing units<br />

originally designed for ductless systems<br />

that can be used with conventional<br />

A-coils in tight urban areas.<br />

Thermal expansion valves<br />

Manufacturers have almost universally<br />

adopted fixed superheat thermal expansion<br />

(TX) valves as a way of increasing<br />

efficiency without going to excessively<br />

large indoor coils. Like electronic fuel<br />

injection on today’s automobiles, a<br />

thermal expansion valve more precisely<br />

meters the refrigerant going into the<br />

coil – controlling refrigerant flow to<br />

maintain the occupant’s comfort under<br />

On their own, these Weil-McLain family members are great,<br />

a wide range of indoor conditions.<br />

but as a team they shine. The new Ultra Oil Boiler and<br />

Warm high-pressure refrigerant from<br />

Ultra Plus Water Heater love being in hot water together,<br />

the outdoor unit is metered through an<br />

providing more domestic hot water with less<br />

orifice in the TX valve that reduces the<br />

maintenance and easy installation.<br />

pressure and causes the refrigerant to<br />

cool. “It responds to the temperature of<br />

the suction line and it … adjusts that<br />

flow to maintain a certain superheat<br />

level,” explained Hawkins.<br />

When the unit shuts off, it maintains<br />

pressure in the system – rather than<br />

equalizing – so that when it restarts it is<br />

immediately operating at optimum efficiency.<br />

This avoids the lag time of the<br />

Visit www.weil-mclain.ca<br />

older systems.<br />

to see the entire family of<br />

Reciprocating compressors working<br />

Weil-McLain Canada products.<br />

with non-bleed valves have factory installed<br />

start assist capacitors and relays<br />

– technicians should brush-up on how<br />

starting circuits work, added McTeer.<br />

The technician has to be careful<br />

about brazing near the sensor bulb on<br />

the suction line, added McTeer. “If it<br />

overheats, the diaphragm in the thermal<br />

Tel: 905-456-8300 Fax: 905-456-8582 E-mail: info@weil-mclain.ca<br />

North American ingenuity.Ultra results.<br />

element can easily rupture and the<br />

entire valve has to be replaced.”<br />

Circle Number 113 for More Information<br />

12 <strong>Plumbing</strong> & <strong>HVAC</strong> Product News – May/<strong>June</strong> <strong>2006</strong> www.plumbingandhvac.ca

Air Conditioning<br />

The refrigerants<br />

The new 13-SEER air-conditioning<br />

equipment uses either R-22 or R-410A<br />

refrigerant. R-22 equipment is currently<br />

less expensive, although that will<br />

change. R-22 is an ozone depleting substance<br />

and equipment will not be manufactured<br />

after 2010.<br />

The higher cost of R-410A equipment<br />

relates to its high-tech materials<br />

and the more expensive compressors<br />

required with POE oil. As well, manufacturers<br />

haven’t yet achieved the<br />

volume necessary to bring the price<br />

down, noted Hawkins.<br />

However, manufacturers have achieved<br />

better operating efficiencies with the<br />

R-410A units than with the R-22 versions.“That<br />

wasn’t the case with 10-SEER<br />

or 11 or even 12,” he added.<br />

at higher pressures than traditional<br />

refrigerants and have blown out their<br />

test instruments. A good set of test instruments<br />

designed specifically for R-<br />

410A is a must. Hoses must be rated<br />

with a minimum 800-psi burst pressure.<br />

Selling 13-SEER<br />

The law requires or will require 13-SEER<br />

equipment, so this takes the onus off the<br />

dealer in justifying the cost to the customer.<br />

However, customers will appreciate<br />

learning there are real benefits.<br />

Unfortunately, quick payback is not<br />

one of them. In Canada’s short cooling<br />

season, the electrical savings from 13-<br />

SEER equipment over 10-SEER – about<br />

30 percent – will not cover the cost of<br />

the new equipment within its lifetime.<br />

It is worthwhile to talk to the customer<br />

about their satisfaction or dissatisfaction<br />

with their current system. Air<br />

conditioning can have a direct impact<br />

on indoor air quality and humidity levels,<br />

said Hawkins.<br />

The new equipment is quiet. Manufacturers<br />

have gained efficiency by using<br />

larger fans turning at slower speeds.<br />

The Energy Star rating for air conditioners<br />

is now 14-SEER. In many cases, it<br />

may be less expensive for the customer to<br />

go to 14-SEER in those provinces that<br />

offer rebates to homeowners that install<br />

Energy Star equipment.<br />

The new outdoor unit is also substantially<br />

larger than the old one.<br />

Upgrading the air conditioning gives<br />

the contractor an opportunity to<br />

improve the overall comfort of the<br />

home. That is something the customer<br />

will appreciate.<br />

Commissioning the equipment<br />

As with any piece of equipment, the<br />

steps taken in commissioning a 13-<br />

SEER air conditioning system are critical<br />

to ensure that it operates at design<br />

efficiencies.<br />

The two most critical things are airflow<br />

– the CFM over the evaporator coil<br />

– and the accuracy of the refrigerant<br />

charge, remarked McTeer. “If either one<br />

of those elements is at fault – usually<br />

improper airflow leads to improper<br />

charging …” the unit won’t achieve its<br />

rated SEER.<br />

A proper evacuation of the system is<br />

critical. The system should run for about<br />

20 minutes before the technician checks<br />

the refrigerant pressures against the charge<br />

chart supplied by the manufacturer.<br />

With a TX valve in the system, the<br />

technician must use a subcooling<br />

method to measure the charge rather<br />

than a superheat method. “The tech will<br />

have to measure the liquid line temperature<br />

now and he will have to use his<br />

head pressure gauge instead of his suction<br />

pressure gauge to glean the appropriate<br />

data to make sure that the charge<br />

is correct,” said McTeer. “Pressure gauge<br />

and thermometer accuracy are vital and<br />

should be verified at the start of each<br />

cooling season,” he added.<br />

A 13-SEER unit is a little less critical<br />

than an older unit because the TX valve<br />

will maintain the superheat on the<br />

compressor if the charge is reasonably<br />

close, added Hawkins.<br />

Some technicians have already learned<br />

the hard way that R-410A functions<br />

St. Lawrence Chemical Inc.<br />

Exclusive distributor of Genetron refrigerants in Canada<br />

Ontario and Western Canada, Tel: 416-243-9615 Fax: 416-243-9731<br />

Quebec and the Maritime Provinces, Tel: 514-457-3628 Fax: 514-457-9773<br />

A compact side-discharge condensing<br />

unit might be the answer in tight<br />

urban areas. (ECR-Olsen unit pictured)<br />

Circle Number 114 for More Information<br />

www.plumbingandhvac.ca May/<strong>June</strong> <strong>2006</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 13

Make the choice thatʼs RELIABLE & FLEXIBLE.<br />

Our Coils have drain pans made from high-temperature<br />

polymer that won’t rust and are UV resistant. The Hydrotec<br />

pan holds less water than the competition and features the<br />

Microban anti-microbial additive that resists mold and<br />

mildew formation. They have dual-drain connections for<br />

increased installation flexibility. R-22 and R-410A compatible<br />

with the proper ARI coil sizing and expansion device.<br />

Choose coils & air handlers that rate with all SEERs.*<br />

Our air handlers offer a wide range of factory- or field-installed<br />

options. These include: PSC and ECM fan motors, electric<br />

heating, hydronic heating and cooling, R-22 and R-410A DX<br />

cooling compatibility.The multi-position cabinet, designed with<br />

right or left hand connections, allows complete flexibility for all<br />

your installations.<br />

More than you expect. ADP.<br />

Warming up chilly spaces could not be easier; ADP features<br />

a full line of unit heaters to meet your exact needs. Trust us for<br />

quality products at a competitive price with one of the fastest<br />

lead times in the industry.<br />

Distributed in Canada by:<br />

* Depending on outside unit match.<br />

Circle Number 115 for More Information<br />

www.adpnow.com

Air Conditioning<br />

Cooling products<br />

Dave Lennox Signature Collection<br />

XC15 and XP15 air conditioners and<br />

heat pumps feature<br />

the company’s<br />

Silent<br />

Comfort technology<br />

for very<br />

low noise levels.<br />

They are rated<br />

up to 16 SEER<br />

and 8.5 HSPF.<br />

Other features<br />

include Operations Monitor controller,<br />

direct-drive fan, Copeland Scroll compressors<br />

and Humiditrol dehumidifier.<br />

Lennox Industries Circle no. 301<br />

removable louver panels for easy<br />

service. They are available in R-410A or<br />

R-22 versions.<br />

AirEase/Lennox Circle no. 304<br />

Light commercial AC<br />

York Latitude and Luxaire Climasure heat<br />

pumps feature a 13-SEER rating (cooling)<br />

and a Heating Season Performance Factor<br />

(HSPF) up to 9.0. Features include<br />

demand defrost, large condenser coil sur-<br />

Compact cooling<br />

Luxaire and Coleman MicroChannel<br />

MiniCube 13-SEER air conditioners are<br />

said to be the<br />

smallest on<br />

the market.<br />

An aluminum<br />

tube coil features<br />

microchannel<br />

technology<br />

for<br />

higher efficiency<br />

without<br />

higher coil surface area and less<br />

refrigerant. They are available in one to<br />

three-ton capacities.<br />

York Unitary Products Circle no. 307<br />

electronic controls, digital temperature<br />

readout, tangential blower wheel, twomotor<br />

design, digital electronic self-diagnostics<br />

and universal heater. Sizes are<br />

7,000 – 15,000 Btu/h with cool only, cooling/electric<br />

heat and heat pump/electric<br />

heat models in 115 and 208/230 volts.<br />

Fedders Corp. Circle no. 309<br />

Commercial cooling<br />

Affinity 13-SEER light commercial air<br />

conditioning and heat pumps by York<br />

are Energy Star rated, add a striking<br />

design and seven exterior finish colours.<br />

Features include the QuietDrive system<br />

with its swept-wing fans and scroll<br />

Two-stage cooling<br />

KeepRite’s <strong>2006</strong> package air conditioners<br />

and heat pumps feature 13-SEER<br />

efficiency with two-stage cooling. They<br />

are available in R-410A or R-22 versions<br />

in two to five-ton capacities. Installation<br />

can be horizontal or downshot. Other<br />

features include external gauge ports,<br />

scroll compressors on PAF3 models and<br />

integral base rails with forklift access<br />

and for lifting lugs.<br />

Int’l Comfort Products Circle no. 302<br />

Packaged cooling units<br />

The new line of Rheem 13-SEER package<br />

heat pumps, air conditioners and<br />

gas-electric packages are available in<br />

two to five-ton sizes. Features include<br />

Emerson Comfort Alert diagnostics,<br />

faces for greater heat transfer, solid core<br />

filter drier, high-pressure relief valve and<br />

copper tubing with aluminum fins.<br />

York Unitary Products Circle no. 305<br />

Mini splits<br />

Tempstar 13-SEER duct-free mini-splits<br />

from ICP feature capacities from 3/4 to<br />

3 tons, two-stage compressor for 2-3<br />

ton models, noise levels between 45 and<br />

65 dB(A), 30 volt DC power on 3/4 to<br />

1-1/2-ton units, accumulators on outdoor<br />

sections and a permanent washable<br />

two-layer carbon and anti-bacterial<br />

filter. The control is programmable<br />

for three time periods per day.<br />

Int’l Comfort Products Circle no. 306<br />

Air conditioners<br />

Heil QuietComfort DX1300 models by<br />

ICP feature Copeland scroll compressors,<br />

two-speed fan motors, a new Air<br />

Management System with increased fan<br />

propeller diameters, an innovative control<br />

box, easily-removed panels for servicing<br />

controls, compressor and internal<br />

components, and Comfort Alert troubleshooting<br />

LED fault indicators.<br />

Int’l Comfort Products Circle no. 308<br />

Commercial PTAC<br />

Fedders’ PTACs feature wireless remote<br />

control, first centre-mount touch pad<br />

compressors to reduce noise levels, plus<br />

ECM motors and ClimaTrak custom<br />

comfort control system.<br />

York Unitary Products Circle no. 310<br />

High-efficiency motors<br />

GE’s X13 motor is designed to replace<br />

conventional PSC motors with a standard<br />

ECM model to meet 13-SEER ratings.<br />

The X13 provides up to 200 percent<br />

greater efficiency than a PSC<br />

model, and is 33 percent greater at rated<br />

operating speed. Features include<br />

brushless DC design and a permanentmagnet<br />

rotor.<br />

GE/Regal-Beloit Circle no. 311<br />

A Refreshing Change<br />

Copeland scroll compressors, slide-out<br />

blower section, TEV valve, rugged base<br />

rail and easy refrigerant connections.<br />

Rheem Air Conditioning Circle no. 303<br />

Split systems<br />

AirEase has added a line of split system<br />

air conditioners and heat pumps with<br />

SEER ratings of 13 to 18. They feature<br />

Copeland scroll compressors, Copeland<br />

Comfort Alert diagnostics, new platinum<br />

gray colour and design and<br />

Stay Cool With Forane ® .<br />

Arkema’s Forane ® 410A and 407C are<br />

the contractors best choice for R-22<br />

replacement and retrofit. Meet the next<br />

generation with the refrigerants most<br />

accepted by OEMs and customers.<br />

With Arkema products<br />

you get the performance and<br />

after-market support you need.<br />

1-800-567-5726 • www.arkemagroup.ca<br />

Circle Number 116 for More Information<br />

www.plumbingandhvac.ca May/<strong>June</strong> <strong>2006</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 15

Hot Water Heating<br />

Loop lengths for radiant<br />

floor heating systems<br />

Getting it right is critical in achieving customer satisfaction<br />

By Roy Collver<br />

Anumber of years<br />

ago I came up<br />

with what I<br />

called the three<br />

“golden rules” of<br />

comfortable radiant<br />

floor heating systems.<br />

These rules are:<br />

1) RADIANT FLOORS SHOULD OPERATE<br />

WITH THE LOWEST POSSIBLE SUR-<br />

FACE TEMPERATURE.<br />

2) THEY SHOULD MAINTAIN THE MOST<br />

EVEN SURFACE TEMPERATURE POSSI-<br />

BLE.<br />

3) THEY SHOULD MAINTAIN THE MOST<br />

CONSTANT, UNCHANGING SURFACE<br />

TEMPERATURE POSSIBLE.<br />

To conform to the above rules, a<br />

system should be designed so:<br />

• The water temperature to the slab is<br />

kept as low as possible at all times.<br />

• The tubing is spaced as close together<br />

as is practical.<br />

• The tubing is spaced as evenly as is<br />

practical.<br />

• The tubing loops are kept as short as<br />

is practical.<br />

• The insulation below the panel is adequate<br />

to prevent excessive downward<br />

heat losses.<br />

• The floor coverings on top of the slab<br />

don’t have a high R-value.<br />

•<br />

The floor surface temperature is<br />

changed only when the heating load<br />

changes.<br />

I will examine most of these topics in<br />

future articles, but one that seems to<br />

need constant review<br />

is the matter of tubing<br />

loop lengths.<br />

Anyone who has<br />

been in this business<br />

long enough has<br />

heard the oftenrepeated<br />

story of the<br />

person who had a<br />

one thousand square<br />

foot slab and was<br />

told to install 1/2<br />

inch tubing on 12<br />

inch centers. The<br />

person (most often portrayed as a dumb<br />

homeowner) goes to a wholesaler and<br />

buys a one thousand foot roll of tubing.<br />

They then proceed to lay the tubing<br />

down in one continuous loop, hook it<br />

up to a boiler (or water heater) and a<br />

pump and expect it to heat the room.<br />

Demanding shorter<br />

loop lengths isn’t<br />

a conspiracy by<br />

radiant suppliers to<br />

sell you more<br />

manifolds …<br />

No urban myth<br />

Unfortunately, this story is not an urban<br />

myth. I have personal experience with<br />

two such jobs and know of many others.<br />

But why, they ask, won’t it work? Let<br />

me explain:<br />

It takes energy to move a fluid<br />

through a pipe, valve or fitting. To<br />

develop a specific fluid volume movement,<br />

we add mechanical energy to the<br />

fluid with a circulating pump. In hydronic<br />

systems, this energy is described as<br />

“pump head” and is measured in “feet”<br />

of head. There are four factors that<br />

determine how much energy is needed<br />

to maintain a constant fluid flow in a<br />

hydronic system:<br />

1) How fast (fluid velocity) do we<br />

need to move the fluid? This really<br />

means how much fluid do we want to<br />

put through the pipe in a certain period<br />

of time. The more we want to push<br />

through, the harder it is to push, and<br />

problems start to occur.<br />

If there is too much friction, the pressure<br />

drop becomes so high that we have<br />

to select an overly large, “high head”<br />

pump to maintain our flow at the<br />

desired rate. The fluid itself can damage<br />

system components as it creates more<br />

and more friction.<br />

In the case of a one thousand foot<br />

loop of 1/2" tubing, the pressure drop is<br />

so extreme that you can hardly get any<br />

fluid through it at all – they don’t make<br />

a pump with a high enough head to<br />

overcome the resistance in that much<br />

pipe. Remember that many 1000 square<br />

foot rooms (normal construction, normal<br />

windows) in<br />

Canada’s climate will<br />

require a minimum of<br />

2.5 US gpm fluid flow<br />

– some much higher.<br />

2) How much resistance<br />

is the fluid<br />

going to encounter on<br />

its trip through the<br />

system? To get the<br />

most fluid through a<br />

hydronic loop, the<br />

pipe should be as large<br />

as is practical, as<br />

smooth as possible inside and there<br />

should be few turns in the pipe to cause<br />

turbulence. Every time you change the<br />

direction of the fluid flow, or add restrictions<br />

in the pipe such as valves and fittings,<br />

you create turbulence and friction, which<br />

requires more energy to overcome.<br />

3) What is the viscosity (how “thick”<br />

is the fluid)? Thicker fluid creates more<br />

friction and pushes back harder. Many<br />

hydronic systems have chemicals such<br />

as propylene glycol added to the water<br />

for freeze protection. The addition of<br />

such chemicals thickens the fluid and<br />

adds to the pump head requirement.<br />

4) How hot is the fluid? Hotter fluid<br />

tends to be “thinner.” It will flow more<br />

easily than cold fluid. When designing<br />

low temperature systems that use glycol,<br />

such as snow-melting systems, you have<br />

an extreme situation for eating up<br />

pump head.<br />

There are two things we can do to<br />

increase our gallons per minute without<br />

increasing the head pressure too much.<br />

One is to use short tubing loops and<br />

split the flow as in the illustration<br />

above, the other is to use larger diameter<br />

tubing. Both solutions add cost to an<br />

installation and the designer has to find<br />

the right balance between a smaller<br />

Delta T, and the higher costs associated<br />

with shorter and therefore more<br />

numerous tubing loops (more manifold<br />

positions), larger diameter pipe, or<br />

higher head pumps.<br />

The recommended maximum loop<br />

lengths, below, are based on reasonable<br />

flow rates and Btu/h deliveries<br />

versus reasonable pressure drops (less<br />

than eight feet of head with 100 percent<br />

water). Check with your tubing<br />

manufacturer to obtain the pressure<br />

drop information specific to their<br />

product as they may have different<br />

recommendations.<br />

It is important not to confuse flow<br />

rate and velocity with pressure drop. We<br />

PRESSURE DROP AND Btuh CHART FOR 1/2” PEX TUBING<br />

FLOW - GPM<br />

0.2<br />

0.3<br />

0.4<br />

0.5<br />

0.6<br />

0.7<br />

0.8<br />

0.9<br />

1.0<br />

1.5<br />

2<br />

FLOW - GPM<br />

0.6<br />

0.7<br />

0.8<br />

0.9<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

3.5<br />

4.0<br />

1 FOOT OF TUBE<br />

HEAD LOSS/ft<br />

0.002<br />

0.004<br />

0.007<br />

0.01<br />

0.014<br />

0.019<br />

0.024<br />

0.03<br />

0.037<br />

0.078<br />

0.133<br />

PRESSURE DROP AND Btuh CHART FOR 3/4” PEX TUBING<br />

1 FOOT OF TUBE<br />

HEAD LOSS/ft<br />

0.03<br />

0.004<br />

0.005<br />

0.006<br />

0.007<br />

0.015<br />

0.025<br />

0.037<br />

0.052<br />

0.07<br />

0.089<br />

250 FT OF TUBE<br />

HEAD LOSS<br />

0.5<br />

1<br />

1.75<br />

2.5<br />

3.5<br />

4.75<br />

6<br />

7.5<br />

9.25<br />

19.5<br />

33.25<br />

350 FT OF TUBE<br />

HEAD LOSS<br />

0.9<br />

1.2<br />

1.5<br />

1.8<br />

2.1<br />

4.5<br />

7.5<br />

11.1<br />

15.6<br />

21.0<br />

26.7<br />

Btuh DELIVERY<br />

20T<br />

2,000<br />

3,000<br />

4,000<br />

5,000<br />

6,000<br />

7,000<br />

8,000<br />

9,000<br />

10,000<br />

15,000<br />

20,000<br />

Btuh DELIVERY<br />

20T<br />

6,000<br />

7,000<br />

8,000<br />

9,000<br />

10,000<br />

15,000<br />

20,000<br />

25,000<br />

30,000<br />

35,000<br />

40,000<br />

can push 2 gpm through 1/2" PEX pipe<br />

and we will remain below the industry<br />

accepted four feet per second velocity<br />

limit, but we can see from the chart<br />

below that it is unlikely that we would<br />

ever want to push that much through a<br />

“normal” 200 to 250' x 1/2" hydronic<br />

radiant floor loop. At two gpm, our<br />

head loss is 0.133 feet of head per foot<br />

of tube. That would mean that by the<br />

time we got up to a 100' loop length, we<br />

would be looking at a head loss of 13.3<br />

ft., already approaching the need for a<br />

high head pump.<br />

At 250' we are at 33.25 ft., which<br />

exceeds the available head of just about<br />

every residential circulator. If we go<br />

back to our 2.5 gpm, 1000' loop<br />

example, we would be so far off the<br />

16 <strong>Plumbing</strong> & <strong>HVAC</strong> Product News – May/<strong>June</strong> <strong>2006</strong> www.plumbingandhvac.ca

All-new interior and redesigned<br />

fenders, headlamps, and grille<br />

Numerous improvements to<br />

reduce noise and vibration<br />

5.7L HEMI ® V8 now equipped<br />

w/MDS for improved highway<br />

cruising fuel economy*<br />

New Sport and<br />

TRX4 Off-Road models<br />

New 20" wheels available<br />

New frame and<br />

suspension tuning for<br />

better ride and comfort<br />

NOT EVEN OFF THE LINE<br />

AND ALREADY WAY AHEAD.<br />

THE NEW <strong>2006</strong> DODGE RAM 1500 from $26,020 † ; as shown $41,535 †<br />

For more information, visit your Dodge Retailer, check out dodge.ca, or call 1 800 361-3700.<br />

*Fuel economy improvements vary depending on accessories, driving habits and conditions.†MSRP for <strong>2006</strong> Dodge Ram 1500 Regular Cab 4x2 ST SB is $26,020; MSRP for <strong>2006</strong> Dodge Ram 1500 Laramie Quad Cab 4x2 SB with 20” chrome-clad aluminum<br />

wheels with 20” OWL all season tires and 3.92 axle ratio, as shown, is $41,535; taxes, freight ($1,225), insurance, registration, licence, retailer administration fees, new tire duties (in Quebec) and A/C excise tax not included. Retailers may sell for less.<br />

Circle Number 117 for More Information

V I C T A U L I C • N E W A D V A N C E D G R O O V E S Y S T E M<br />

NEW! The fastest Victaulic pipe joints for 14" to 24"<br />

piping—with only two housings, you can easily<br />

complete a top-quality joint in minutes—more<br />

than twice as fast as welding.<br />

NEW!<br />

Flat-out fast.<br />

Introducing the Advanced Groove System <br />

for 14" to 24" pipes. It’s fast. It’s strong.<br />

Imagine how quickly your crew could assemble a 24" pipe<br />

joint with only two housings—and only two bolts. That<br />

speed is yours, thanks to the patent-pending Advanced<br />

Groove System (AGS)—an all-new design by the<br />

worldwide industry leader. Get the productivity<br />

welding can’t offer. Watch our demonstration<br />

video at www.victaulic.com/ags—and see how<br />

fast and easy dependable joints can be.<br />

<br />

Housing<br />

Gasket<br />

Pipe<br />

NEW!<br />

Tighten just two bolts to<br />

complete joint assembly—<br />

a union at every joint for<br />

simple service*.<br />

NEW!<br />

NEW!<br />

Get visual confirmation of a proper<br />

joint—if these faces meet on both<br />

sides, you know it’s right.<br />

Locks in place into a deeper, wider,<br />

wedge-shaped groove for extremely<br />

strong, dependable joints.<br />

Piping. Systems. Solutions.<br />

NEW!<br />

A complete system—with rigid and flexible couplings, valves, fittings, and more.<br />

*For complete installation instructions refer to the Victaulic I-100 Installation Manual.<br />

For more information about our<br />

Advanced Groove System products,<br />

log onto www.victaulic.com/ags.<br />

Circle Number 118 for More Information

Hot Water Heating<br />

chart we could never find our way back home again.<br />

Even if we went to 3/4" tubing as in the second chart, it<br />

is clear our pressure drop would be way out to lunch.<br />

It’s clear that the amount of head pressure in a loop<br />

builds up very quickly once we reach a certain flow<br />

rate. Keeping loop lengths below 250' for 1/2" PEX and<br />

below 400' for 3/4 is a rule of thumb based on<br />

economy of component selection.<br />

2.5 gpm IN<br />

0.625 gpm<br />

0.625 gpm<br />

0.625 gpm<br />

0.625 gpm<br />

2.5 gpm OUT<br />

2.5 gpm HEAD LOSS THROUGH 1000’ OF<br />

1/2” PEX SPLIT 4-WAYS = APPROX. 4 FEET<br />

Half-inch tubing, for example, is generally used in<br />

small to medium residential and small commercial<br />

systems. The most common and economical<br />

circulators used in these systems develop between 10<br />

and 15 feet of head at “normal” flow rates (being six<br />

to 12 gpm, which will allow us to deliver 60,000 to<br />

120,000 Btuh in a system designed with a 20°F<br />

Delta-T).<br />

If we design our loops for no more than an eight<br />

foot head loss, we have approximately two to seven feet<br />

of head loss left over to “give up” between the boiler,<br />

distribution piping and other components. Keeping<br />

your head loss as low as six feet in the tubing loops will<br />