Premise Indirect - przewodnik kliniczny - Kerr Hawe

Premise Indirect - przewodnik kliniczny - Kerr Hawe

Premise Indirect - przewodnik kliniczny - Kerr Hawe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Bio... what?<br />

<strong>Premise</strong> <strong>Indirect</strong> | Biomimetic nanotechnology<br />

<strong>Premise</strong> <strong>Indirect</strong>. The new biomimetic nanotechnology tempered composite<br />

programme which uniquely offers restorations that look, feel, mature and<br />

perform just like natural teeth... just as nature intended.<br />

For more information, log on to www.kerrhawe.com or call 00800 41 05 05 05<br />

©2008 <strong>Kerr</strong> Corporation<br />

Lab for life.

Press Release<br />

Biomimetic Story<br />

Product Presentation: The strength of <strong>Premise</strong> <strong>Indirect</strong> is the long history<br />

with belleGlass<br />

Historical and Provisional Studies<br />

Frequently Asked Questions

INDIRECTaddressesallthemodernrequirementsofprofessionalsseekingtheultimateinatempered compositeprogrammethatmostcloselyresemblesnaturaltoothstructurebothintermsofformand function. TheresultofsciencebornfromthesuccessofHerculiteXRV,belleGlassNGand<strong>Premise</strong>-newPREMISE<br />

<strong>Indirect</strong>withanalmostceramiclikeappearancethankstoprovenoptimisedtriomodalpolymerisation butwithalltheadditionaladvantagesof<strong>Kerr</strong>’suniqueheatandpressurecuringsystem;thepresenceof nitrogenreplacesairtouniquelyannihilatetheinhibitionlayerandproducewhatiseffectivelya98% Continuousimprovementsintermsofhandling,aestheticsandpolishabilityprovidesnew<strong>Premise</strong><br />

totallypolymerisedrestoration.Marginalintegrityandcolourstabilityaremaximisedwithbothwear<br />

terminlay,onlay,crown,bridgeandveneerrestorations.WhenincorporatedwithCONSTRUCTfibre matrix,unprecedentedopportunitiesmayalsoberealised. andflexuralratesmimickingnaturaltoothstructureunsurpassedbyanycompetitivesystemforlong<br />

‘forgiving’proprioceptiverestorativealternativeispreferredandtimeisoftheessence. Thefulllineof<strong>Kerr</strong>productsisavailablefromauthorizeddentaldistributors.Formoredetailed NewPREMISEINDIRECTisespeciallysuitedforimmediateloadimplantpatientswhereamore<br />

www.<strong>Kerr</strong>Dental.com,contactyourlocal<strong>Kerr</strong>representative,orcall<strong>Kerr</strong>InternationalFreephone informationonPREMISEINDIRECToranyother<strong>Kerr</strong>dentalproducts,pleasevisitourwebsiteat<br />

KERR (00800)41050505.<br />

ViaStrecce4 6934Bioggio Switzerland <strong>Kerr</strong><strong>Hawe</strong>SA<br />

InternationalFreephone:(00800)41050505<br />

www.<strong>Kerr</strong>Dental.com www.<strong>Kerr</strong><strong>Hawe</strong>.com

BIOMIMETICS<br />

Biomimeticsistheapplicationofbiologicalmethodsandsystemsfoundinnaturetothestudyand dentistandtechnicianwhoareconcernedwithproviding‘virtuallylife-longaestheticrestorations’.<br />

thatmostofuswouldreadilyappreciate. Twoeasilyrecognisedexamplesofthistransferfrombiologytotechnologyaretheintroductionof designofengineeringsystemsandmoderntechnology:‘life-like’wouldbeapopularinterpretation<br />

certainanimals(GeorgedeMestral,SwissEngineer,1948)andofcoursetheUK’sveryownPercy Shaw‘s‘cat’seye’reflectorfornighttimeroaddelineation:his1935inventionwasbasedonthefact thatthemakeupofacat’seyeincorporatesasystemofreflectingcells(tapetumlicidum)capable theVelcrofasteningfollowingresearchintothewayburrhooksfromsomeplantsclungtothefurof<br />

Nelumbolotusleafhasbeensimilarlymimickedbysomemanufacturersofself-cleaningpaints,roof tilesandevensheetglass,isanothercleveradaptationofman’sharbouringofnaturalphenomena ofreflectingthetiniestamountoflight.The‘Lotuseffect,’wherebytheselfcleaningnatureofthe<br />

Thebiomimeticprocessisofcourseatwowayaffairandtheflowofideasandsolutions,especially thosewithmedicalpositivesenhancingalongerandbetterqualityoflifeforushumans,bringsus forapplicationinatotallynovelway.<br />

hypeconcerningceramicrestorations,notablyCAD/CAMmilling,itisalltooeasytoforgetthegreat synergisticqualitiesthatalaboratorytemperedCOMPOSITEcrown,bridge,inlay,veneeroronlaycan provideforthepatient.<strong>Kerr</strong>’sbelleGlassNGsystem,constantlyratedNo1initsclassby’Reality’, neatlytodentistryingeneralandanextendedstorylinefrom<strong>Kerr</strong>inparticular.Withallthecurrent<br />

forindirectresinmaterial:itsuniqueformulaandspecialtri-modalcuringprocess(heat,pressure andlight)hashelpedsecureitsfavouredpositionwiththousandsofrestorationssuccessfullyplaced representswithoutdoubttheindustrystandardandhasstoodthetestoftimeasproductofchoice<br />

TheclinicalandtechnicalexcellenceofbelleGlassNGisbeyonddoubtwithcountlessin-vitroandinvivostudiessupportingitsheritagepositionstatus.Restorationsthathavealmostthesamewear<br />

overa13yearhistory.<br />

naturaldentitionisasadirectresultofbelleGlass‘uniqueandpatentedmaterialpropertiesand curingprocess.<strong>Kerr</strong>’sambitionistocontinuetoprovidepatientswithrestorationsthatwillgive countlessyearsofaestheticfunctionandanew,improvedbellleGlassunderthenamePREMISE rateashumanteethandcombinecoefficientofthermalexpansionresultswhichvirtuallymirror<br />

New<strong>Premise</strong><strong>Indirect</strong>sharesalltheyears’ofheritagestatusgainedfrombelleGlass,HerculiteXRV INDIRECTisthecompany’swayofcontinuingtofulfilthisintention.<br />

evenbetterceramiclikeaesthetics,minimumplaqueattractionandsuperbplacementhandlingfor effortlessfabrication.AswithbelleGlassCONSTRUCTpolyethylenefibremayalsobeaddedto <strong>Premise</strong><strong>Indirect</strong>restorationsespeciallyforbridgeworkorcrownswheretrulyexceptionalstrengthis and<strong>Premise</strong>chairsidecompositeswiththeaddedbonusoflongtermglossespeciallyintheanterior,<br />

required.Allinalllongtermcolourstabilitywithlowwaterabsorptioncombinetomakepossible<br />

MartinLindsay<strong>Kerr</strong>LabProductManagerEuropediscussesanewperspectiveofinteresttoboth

thiswiththehugegrowthinimplantworksundertakenandthenecessitytouseamoreforgiving proprioceptiverestorativesuperstructurematerialotherthanceramic,thenthereareevenmore reasonstobeexcitedaboutnew<strong>Premise</strong><strong>Indirect</strong>.Addtothesefactstheuseof<strong>Kerr</strong>’sawardwinning trulylife-likebiomimeticrestorationsthatwear,feel,lookandagejustlikenaturalteeth.Combine<br />

trulyharmonised,scientificallybalancedandlong-livedrestorativeapproach. NX3dualcureresincementthenwinningcombinationsarecertainlytheorderofthedaywitha<br />

toshowofftheirinnateartisticskillsbyprovidingbespokeandaestheticallypleasingyetalone Fabricating<strong>Premise</strong><strong>Indirect</strong>restorationsextra-orallygivesbothtechniciansanddentistsachance<br />

oftime.Withmuchdentistryalsoconcernedwith‘repairandmaintenance’itiscomfortingtoknow thatintheunlikelyeventofchippingorfracture,<strong>Premise</strong><strong>Indirect</strong>restorationscanbeswiftly repairedintra-orallywiththeminimumofstressfordentistorpatient. functionalandlonglivedpatientfriendlyrestorativesolutionssimplyandinarelativelyshortperiod<br />

contactyourlocal<strong>Kerr</strong>representativeorcall<strong>Kerr</strong>InternationalFreephone(00800)41050505. Tofindoutmoreregarding<strong>Kerr</strong>’snewPREMISEINDIRECTbiomimeticnanotechnologyrestorative

Lab for Life. <br />

<strong>Premise</strong> <strong>Indirect</strong> | Biomimetic nanotechnolgy

History<br />

• 1891, <strong>Kerr</strong> Brothers founded Detroit Dental Manufacturing<br />

Company Only Product, Gas Fired Porcelain Furnace<br />

• 1920’s, Impression Compounds & Waxes<br />

• 1950’s Investments, Denture Base Material<br />

• ‘60s & 80’s, Division of Sybron Corporation, market leader in<br />

alloys, endo, impression material, composite, bonding<br />

& amalgamators.<br />

• 1993 - Sybron Dental Specialties, acquisitions; Demetron,<br />

Metrex, E&D, belle de st. Claire, Precision Rotary<br />

Instruments<br />

• 2000 SDS spins off from Sybron International<br />

.06% Camphoroquinone + .01% Aromatic or .04%<br />

Aliphatic Tertiary Amine + 450 nm Light Source =<br />

Higher Conversion

Benzoyl Peroxide + Heat = FREE RADICALS<br />

Allows higher curing temperature<br />

= higher conversion - 98.5%

Chemistry<br />

Conversion of Heat and Pressure Cured Composite<br />

Bennet ME, Puckett AD, Parsall DE, Roberts SB, J Dent Res 1996:<br />

75-291. Abstr #2188<br />

5 min 10 min 15 min 20 min<br />

Hardness (V) 69.5 (6.8) 79.7 (4.4) 81.6 (4.4) 90.7 (2.4)<br />

Diametral<br />

Tensile 34.7 (7.3) 53.9 (10.9) 62.5 (11.2) 65.8 (4.9)<br />

Strength<br />

% Conversion 86.5 92.8 96.2 98.5<br />

Eliminate The<br />

oxygen-inhibited<br />

layer = conversion to<br />

the surface and<br />

any voids that may<br />

remain after<br />

pressure curing.

Features<br />

Result:<br />

Heat & Pressure Processed Polymer-Glass Restorative<br />

• Increased Productivity<br />

• Improved Aesthetics<br />

• Physical properties more closely matching that of human dentin<br />

Features<br />

History:<br />

• Based on 19 Years of HerculiteXRV Technology<br />

• Leader in Resin & Composite Technology (Herculite, Prodigy, Point 4)

Indications<br />

Anterior Veneers<br />

Opalescent particles<br />

within enamel layer<br />

exhibits a natural vitality<br />

Indications<br />

Opalescence<br />

Definition:<br />

Opalescence is the<br />

reflection of an iridescent<br />

light.

Indications<br />

Single Crowns<br />

• Metal Understructure or<br />

• Construct<br />

Polyethylene<br />

Reinforcement<br />

Indications<br />

Implant Restorations<br />

• Kind and forgiving to<br />

opposing dentin<br />

• Simulation of lost<br />

periodontal ligament

Indications<br />

Metal Free Bonded Bridges &<br />

Perio Splints<br />

• Connect / Construct Polyethylene Fiber Reinforcement<br />

Features<br />

<strong>Premise</strong> <strong>Indirect</strong> / Biomimetics<br />

“Clinicians now have a restorative material available that alleviates<br />

our concerns about abrasion to opposing dentition, and one that<br />

matches if not surpasses the aesthetic level of porcelain.”<br />

Gregg A. Helvey, DDS

Features<br />

Advantages of <strong>Indirect</strong><br />

Composites over Ceramics<br />

• Simple Fabrication<br />

• Margins when finished are impeccable<br />

• Restoration/Luting Cement: same type of material<br />

• Less than 1% Shrinkage<br />

• Can be repaired at Chairside<br />

• Kind to the opposing teeth<br />

Features<br />

Vs. Porcelain<br />

belleGlass Intra-oral Repair:<br />

· Freshen restoration<br />

· Silane surface<br />

· Apply modeling resin<br />

· Repair w/ <strong>Kerr</strong> resin<br />

· Trim & Polish<br />

· Dismiss patient<br />

· 1 Hour<br />

Porcelain Intra-oral Repair:<br />

· Remove restoration<br />

· Re-appoint patient<br />

· Mail restoration to<br />

lab<br />

· Wait 7 to 10 days<br />

· Anesthetize patient<br />

· Re-cement<br />

restoration<br />

· 10 Days

Developments<br />

Coefficient of Thermal Expansion of<br />

Restorative Materials<br />

MATERIAL<br />

CTE (ppm/°C)<br />

AMALGAM 25<br />

PORCELAIN 7.8<br />

GOLD 14.4<br />

BG OPACEOUS DENTIN 13.1<br />

Natural Enamel 12<br />

Natural Dentin 11.4<br />

COMPOSITE RESIN 30<br />

GLASS IONOMER CEMENT 5.7*<br />

Skinner, E.W. and Phillips, R.W. The Science of Dental Materials; W.B.<br />

Saunders, Co. Phil. 1967.<br />

* Puckett, A.D. et al, Quint. Int. 26 (8), p577-581, 1996.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Biomimetics<br />

Biomimetic refers to human-made processes,<br />

substances, devices or systems that imitate nature.<br />

Burs on a dog’s coat<br />

led to the invention of<br />

Velcro.

<strong>Premise</strong> <strong>Indirect</strong> / Biomimetics<br />

The art and science of designing and building<br />

biomimetic apparatus is called biomimetics.<br />

Replicating the water<br />

repellant nature of<br />

certain leaves in the<br />

manufacturing of paint.<br />

Picture Courtesy of David Zielinski RDT, USA

<strong>Premise</strong> <strong>Indirect</strong> / Nanotechnology<br />

Nanotechnology involves the creation and<br />

manipulation of complex structures on the scale of<br />

nanometers – something organisms have done for<br />

about 3.8 billion years.<br />

The ideal nanohybrid<br />

restorative that ages,<br />

feels, wears, functions<br />

and looks like a natural<br />

tooth.<br />

Picture Courtesy of Ronnie van Eeden RDT, South Africa

Picture Courtesy of Gabriel Palazzi RDT, Switzerland<br />

<strong>Premise</strong> <strong>Indirect</strong> / Features<br />

The result of science born from the<br />

success of Heruculite XRV,<br />

belleGlassNG and <strong>Premise</strong>.<br />

<strong>Premise</strong> <strong>Indirect</strong> utilizes the same<br />

optimized trimodal polymerization as<br />

belleGlass NG, the most respected<br />

indirect restorative of its kind.<br />

Indications: Inlays, onlays, crowns,<br />

veneers, bridges, splints and ideal for<br />

implant restorations with proprioceptive<br />

tooth-like response.

<strong>Premise</strong> <strong>Indirect</strong> / Features<br />

Natural look and wear. Closely matches<br />

natural dentition in wear characteristics,<br />

as well as an opalescent appearance that<br />

virtually replicates natural enamel like no<br />

other restorative material.<br />

Performance. Trimodal curing (light, heat<br />

and pressure) achieves over 98% material<br />

conversion, as compared to 60 – 70%<br />

achieved with light-cure only materials.<br />

Proven History. Twelve years of positive<br />

clinical history, and tens of thousands of<br />

successful restorations placed since 1996.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Research<br />

Nanohybrid technology. The combination of large prepolymerized filler<br />

(PPF) particles, 0.4 micron structural filler and small silica nanoparticles<br />

allows higher filler loading, improved physical properties, optimal handling,<br />

higher surface gloss and reduced polymerization shrinkage.<br />

Prepolymerized filler<br />

Point 4 filler<br />

Silica nanoparticles

<strong>Premise</strong> <strong>Indirect</strong> / Research<br />

High gloss retention. The particle size of fillers in PPF particles is below<br />

the wavelength of visible light and light-scattering effects are minimal.<br />

Plucking of PPF particles is reduced because mechanical properties are<br />

more similar to the cured paste number rather than ceramic particles.<br />

Cured traditional composites wear<br />

unevenly causing a loss of luster and<br />

gloss.<br />

<strong>Premise</strong> <strong>Indirect</strong> PPF particles wear<br />

more uniformly, wear resistance is<br />

improved and surface remains<br />

smoother and glossier with time.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Research<br />

In-vivo measurements of wear over a<br />

In-vivo measurements of wear over a<br />

five year period shows an average of<br />

1.2 microns a year – closer to the wear<br />

of natural teeth than any other material<br />

tested.

<strong>Premise</strong> <strong>Indirect</strong> / Research<br />

<strong>Premise</strong> <strong>Indirect</strong> more closely<br />

matches the coefficient of<br />

thermal expansion (CTE) of<br />

natural dentin – resulting in a<br />

material that looks and acts<br />

virtually the same as natural<br />

tooth structure.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Systems<br />

Intro System<br />

Starter system offering everything<br />

needed for Inlays and Onlays.<br />

Master System<br />

Complete system offering<br />

everything needed for Inlays to<br />

full bridges.

<strong>Premise</strong> <strong>Indirect</strong> / Materials<br />

Primary Dentins are used for foundation<br />

and coping layers and improve strength.<br />

Facial Dentins cover all foundation and<br />

coping layers to produce a stable long<br />

lived polished surface.<br />

Incisals are placed onto the incisal /<br />

cuspal area and are designed to match the<br />

vitality of tooth enamel.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Materials<br />

Modeling Resin is an unfilled<br />

universal wetting agent used for<br />

sculpturing.<br />

Rubber Sep is a removable<br />

latex release agent and spacer<br />

applied to all dies and contact<br />

areas creating a 20 micron<br />

space.<br />

Opaques are applied after metal<br />

prep and block out any<br />

underlying metal color.<br />

Silane Primer is applied to the<br />

fitting surface of any metal free<br />

restoration prior to bonding.<br />

Cervicals simulate root and<br />

cervical color,<br />

Kolor Plus is applied<br />

internally to add effect on<br />

occlusal and interproximal<br />

surfaces.

<strong>Premise</strong> <strong>Indirect</strong> / Inlays & Onlays<br />

When layering note that maximum Facial Dentin<br />

thickness should not exceed 1.5 mm.<br />

Primary Facial Incisal<br />

<strong>Premise</strong> <strong>Indirect</strong> / Inlays & Onlays<br />

If desired, duplicate the working die and<br />

articulate. Isolate adjacent tooth contact<br />

points and opposing dentition with Rubber<br />

Sep.<br />

Prepare the model and working die. Block<br />

out all undercuts.<br />

Apply a thin layer of Primary Dentin into<br />

the floor and axial walls and adapt to the<br />

desired contour. Finish slightly short of the<br />

marginal periphery. Apply Kolor Plus to<br />

modify the occlusal color if needed. Light<br />

cure all aspects for 20 seconds.

<strong>Premise</strong> <strong>Indirect</strong> / Inlays & Onlays<br />

Adapt Facial Dentin in small increments to<br />

desired contour. Continuously verify<br />

occlusal clearance. Work one cusp at a<br />

time. Apply Kolor Plus modifier to simulate<br />

occlusal staining. Light cure each<br />

increment for 10 seconds.<br />

Finalize the occlusal scheme with Cuspal /<br />

Incisal to desired contour. Remove the die<br />

from the working model. Add contact areas<br />

if needed. Light cure all aspects for 20<br />

seconds. Polymerize for 20 minutes in the<br />

curing unit. Remove the restoration from<br />

the die as soon as possible after full<br />

polymerization.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Inlays & Onlays<br />

The completed restoration after polishing.

<strong>Premise</strong> <strong>Indirect</strong> / Crowns & Veneers<br />

When layering note that maximum Facial Dentin<br />

thickness should not exceed 1.5 mm.<br />

Primary Facial Incisal<br />

<strong>Premise</strong> <strong>Indirect</strong> / Crowns & Veneers<br />

If desired, duplicate the working die and<br />

articulate. Isolate adjacent tooth contact<br />

points with Rubber Sep.<br />

Prepare the model and working die.<br />

Apply Primary Dentin and contour to the<br />

desired shape. Finish slightly short of the<br />

marginal periphery. Light cure each aspect<br />

for 20 seconds.

<strong>Premise</strong> <strong>Indirect</strong> / Crowns & Veneers<br />

Adapt Facial Dentin onto the margin for<br />

precision fit.<br />

Adapt Facial Dentin to the desired contour.<br />

Repeat on all aspects. Light cure at<br />

frequent intervals. Once final contour has<br />

been achieved, light cure all aspects for 20<br />

seconds.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Crowns & Veneers<br />

Adapt Incisal material in small increments.<br />

Light cure each increment for 10 seconds.<br />

Finalize contour at the incisal edge. Create<br />

a restoration that is slightly longer than the<br />

tooth being replicated. (This allows for<br />

correct morphology after polishing<br />

procedures). Remove the die from the<br />

working model. Add contact areas. Light<br />

cure all aspects for 20 seconds.

<strong>Premise</strong> <strong>Indirect</strong> / Crowns & Veneers<br />

Polymerize for 20 minutes in the curing unit.<br />

Remove the restoration from the die as<br />

soon as possible after full polymerization.<br />

The completed restoration after polishing.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

<strong>Premise</strong> <strong>Indirect</strong> can be incorporated onto<br />

any recommended dental alloy. Use of<br />

mechanical retention is recommended.<br />

Metal frameworks should incorporate<br />

smooth rounded edges especially for incisal<br />

and occlusal areas. Produce a framework<br />

thickness of 0.3 – 0.5 mm. For bridges,<br />

design the framework for correct placement<br />

of pontics and connectors. Ensure adequate<br />

space for veneering material.<br />

Primary Facial Incisal Metal Opaque

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

Wax to full contour.<br />

Remove waxed crown.<br />

Assess available space.<br />

Trim framework to desired shape.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

Ideal margin space.<br />

Rounded and smoothed.<br />

Trim and polish backings<br />

before applying material.<br />

Rounded and smoothed.

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

To achieve maximum bond strength, it is<br />

essential to ensure cleanliness of the metal.<br />

Sandblast all veneering areas with 50 micron<br />

Aluminum Oxide at no more than 2 bar (30<br />

PSI) pressure.<br />

After cleaning, apply Metal Prep with an<br />

applicator brush or directly from the bottle.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

All veneering areas are covered with Metal<br />

Prep. Allow to fully dry approximately 1<br />

minute. Blast excess metal prep off with<br />

compressed air at 1 bar (15 PSI) pressure.<br />

Apply Opaque to a final thickness of 0.1 –<br />

0.2 mm. Ensure that there are no visible grey<br />

areas. This may require 2 – 3 applications.<br />

Light cure each opaque layer for 40 seconds<br />

per surface. Create a first wash Opaque. If<br />

desired, mix a small amount of Modeling<br />

Resin with Opaque.

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

If desired, modify Opaque shades with Kolor<br />

Plus.<br />

Orange modifier is ideal for cervical areas or<br />

for producing a warmer color.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Metal Restorations<br />

Wash application of Opaque with cervical<br />

area completed. Light cure each layer for 40<br />

seconds.<br />

Complete masking of the underlying metal<br />

framework. Note a slight surface shine.

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

Construct reinforcing braid is the ideal<br />

“building block”. It has a patented weave<br />

designed for more complete resin wetting.<br />

• Delivers superior strength and toughness<br />

• Made from polyethylene fiber<br />

• Cold gas plasma treated<br />

• Three widths available<br />

• Three times stronger than steel<br />

• Impregnated with Silane and Resin<br />

• Available in three shades, one neutral<br />

and two opaque shades designed to<br />

eliminate “shine through”.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

Indications<br />

• Single-unit posterior crowns<br />

• Posterior bridges<br />

• Anterior bridges<br />

• Selected anterior single crowns<br />

• Selected Inlays and Onlays<br />

Guidelines<br />

• Assess all prescribed cases to ensure a successful outcome.<br />

• Always use the largest width of Construct fiber available.<br />

• Ensure complete wetting of the fiber with Construct Resin.<br />

• Keep the design of frameworks as simple as possible.

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

Prepare the model and working die.<br />

Asses size and area of the preparation.<br />

Forma a flat disc of Primary Dentin 0.5 – 0.6<br />

mm thick.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

Apply the disc to the occlusal surface and adapt<br />

excess material over the axial walls to form a<br />

coping. Finish short of the margin periphery.<br />

Light cure each aspect for 20 seconds. The<br />

ideal coping thickness is 0.2 mm.<br />

Construct needs to be wrapped around the<br />

periphery of the preparation. Apply to the<br />

occlusal surface if space permits. Follow the<br />

preparations contour for optimal placement.<br />

Using Construct scissors, cut a length of<br />

fiber. Wet one end of the fiber with Construct<br />

Resin. Apply to the proximal axial walls into<br />

its desired position. After full adaptation and<br />

saturation, light cure for 3 – 5 seconds.

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

Apply Construct Resin in small increments 1<br />

– 2 mm at a time. Wrap around the<br />

periphery. After each adaptation and<br />

saturation of the fiber, light cure for 3 – 5<br />

seconds.<br />

Wrap around the entire periphery. Light cure<br />

little and often.<br />

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

After full adaptation overlay by 0.1 – 0.2 mm<br />

and cut the fiber. Light cure 3 – 5 seconds.<br />

Measure a length of Construct for the<br />

occlusal surface.

<strong>Premise</strong> <strong>Indirect</strong> / Construct<br />

Apply Construct as before and light cure 3 –<br />

5 seconds. Once completed light cure all<br />

aspects for 20 seconds.<br />

Continue layering of the crown to final<br />

completed restoration.<br />

<strong>Premise</strong> <strong>Indirect</strong><br />

Continued improvements over the years<br />

with our indirect restorative line has resulted<br />

in superior handling characteristics as well<br />

as exceptional polishability.<br />

Please refer to the complete Directions for<br />

Use for more information.<br />

Visit www.kerrlab.com for more information.

Historical and Provisional<br />

Studies

Primary research information courtesy of<br />

Prof. D Watts,<br />

Dr. Nick Silikas (BSc, MPhil, PhD, FADM),<br />

The University of Manchester<br />

Higher Cambridge Street<br />

Manchester M15 6FH

Dental Materials 19 (2003) 393–398<br />

www.elsevier.com/locate/dental<br />

In vitro characterization of two laboratory-processed resin composites<br />

A. Kakaboura a, *, C. Rahiotis a , S. Zinelis b , Y.A. Al-Dhamadi c , N. Silikas c , D.C. Watts c<br />

a Department of Operative Dentistry, University of Athens, Thivon 2, 115 27, Goudi, Athens, Greece<br />

b Biomaterials Laboratory, University of Athens, Greece<br />

c Dental School, University of Manchester, Manchester, UK<br />

Received 15 January 2002; revised 20 May 2002; accepted 11 June 2002<br />

Abstract<br />

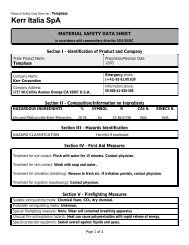

Purpose. To compare various characteristics of two new-generation laboratory-processed resin composites (BelleGlass HP/SDS-<strong>Kerr</strong> and<br />

Sinfony/3M-ESPE). The properties evaluated were degree of CyC conversion, microhardness, roughness, biaxial flexural strength and<br />

polymerization shrinkage-strain.<br />

Materials and methods. All specimens were subjected to a first and a second polymerization cycle according to the manufacturers’<br />

instructions. The degree of CyC conversion (DC) was recorded on rectangular (3 £ 2 £ 0.5 mm 3 ) specimens (n ¼ 3) by FT-IR<br />

micromultiple internal reflectance spectroscopy immediately after each of the two polymerization cycles. Twenty cylindrical specimens<br />

(10 £ 2mm 2 ) of each material were prepared for surface microhardness (n ¼ 10, VHN, 200 g load, 20 s) and surface roughness (n ¼ 10, Ra)<br />

measurements. The biaxial flexural strength and stiffness were determined on disk-shaped (n ¼ 8, 15 £ 0.7 mm 2 ) specimens loaded to<br />

fracture at 1 mm/min crosshead speed. The polymerization shrinkage-strain was calculated with the bonded-disk method. All values were<br />

statistically analyzed by Student’s unpaired t-test ( p , 0.05).<br />

Results. The second polymerization cycle significantly increased the degree of CyC conversion for both materials ( p , 0.05). BelleGlass<br />

HP exhibited significantly higher degree of CyC conversion, surface microhardness, surface roughness, biaxial flexural strength and stiffness<br />

values compared to Sinfony ( p , 0.05).<br />

Significance. Several differences exist between the materials although both products are recommended for the same clinical applications.<br />

q 2003 Academy of Dental Materials. Published by Elsevier Science Ltd. All rights reserved.<br />

Keywords: Belleglass HP; Sinfony; Degree of cure; Microhardness; Roughness; Biaxial flexural strength; Shrinkage-strain; Load-to-failure rates<br />

1. Introduction<br />

Although porcelain is a well-accepted esthetic material<br />

for prosthodontic applications, the metal–ceramic and allceramic<br />

restorations show some undesirable characteristics.<br />

The opaque nature of metal substructure does not simulate<br />

natural translucency; fabrication is time-consuming and<br />

technically demanding and the abrasiveness of porcelain is<br />

destructive to the opposing natural tooth structure [1].<br />

Moreover, in all ceramic restorations, the absence of a metal<br />

framework gives the potential for low fracture resistance,<br />

limiting the clinical application in high stress areas.<br />

In an effort to overcome some of these disadvantages, the<br />

manufacturers, even in the early 1980s, introduced numerous<br />

products of laboratory-processed resin composites [2].<br />

These materials provided alternative ways for clinicians to<br />

* Corresponding author. Tel.: þ30-317788575; fax: þ30-31-8033129.<br />

E-mail address: afrodite1@otenet.gr (A. Kakaboura).<br />

overcome some inherent deficiencies of direct composites<br />

restorations, including polymerization shrinkage,<br />

inadequate polymerization in deep interproximal areas and<br />

restoration of proximal contacts and contour [3].<br />

However, these resin composites were microfill materials<br />

which demonstrated poor clinical performance due to low<br />

flexural strength and wear characteristics attributed to the<br />

low inorganic filler content [4]. In the early 1990s a second<br />

generation of laboratory-processed resin composites was<br />

developed, advocated for a wide range of fixed prosthodontic<br />

applications such as inlays, onlays, veneering, metal-free<br />

single unit crowns and short span anterior bridges [4]. A<br />

variety of materials with remarkable differences in composition,<br />

polymerization modes and curing conditions comprise<br />

the second generation of the laboratory-processed<br />

resin composites. Ultra-small filler particles and polyfunctional<br />

methacrylate monomers are used in these composites.<br />

They are processed by different laboratory techniques based<br />

on combinations of heat, pressure, vacuum and light<br />

0109-5641/03/$ - see front matter q 2003 Academy of Dental Materials. Published by Elsevier Science Ltd. All rights reserved.<br />

doi:10.1016/S0109-5641(02)00082-9

394<br />

A. Kakaboura et al. / Dental Materials 19 (2003) 393–398<br />

Table 1<br />

Composition and polymerization modes of the materials tested<br />

Materials Batch number # Composition Polymerization mode<br />

First cycle: photopolymerization (Light<br />

Teklite) 650 mW/cm 2 ,40s;<br />

Second cycle: heat 140 8C, pressure 60 psi, N 2<br />

(BelleGlass HP curing unit), 20 min<br />

BelleGlass HP shade: enamel natural 808B93 Aliphatic urethane dimethacrylate, aliphatic<br />

dimethacrylate oligomers, fillers: 74 wt% barium<br />

silicate glasses and SiO 2 , mean size: 0.6 mm<br />

First cycle: photopolymerization (Visio<br />

Alpha), 400 mW/cm 2 ,15s;<br />

Second cycle: photopolymerization<br />

(Visio Beta) up to 40 8C, vacuum, 15 min<br />

Sinfony shade: enamel natural FW0059863 Aliphatic and cycloaliphatic monomers,<br />

fillers: 50 wt% aluminum glass and SiO2<br />

mean size: 0.6 mm<br />

polymerization. Although, second generation products<br />

became available in 1995, their characteristics and clinical<br />

performance have not been adequately investigated [2,<br />

5–10]. Additional products, such as Sinfony (3M-ESPE<br />

Dental AG, Germany), were introduced claiming improved<br />

performance and esthetics. The purpose of this study was to<br />

evaluate the in vitro performance of two second-generation<br />

laboratory-processed resin composites. Properties to be<br />

examined include: the degree of CyC conversion, surface<br />

microhardness, surface roughness, biaxial flexural strength<br />

and polymerization shrinkage-strain which are acknowledged<br />

to be related to the clinical performance of composite<br />

restorations.<br />

The null hypothesis to be tested, was that no significant<br />

differences would be found in the properties examined,<br />

between the two materials.<br />

2. Materials and methods<br />

The resin composites examined were BelleGlass HP<br />

(SDS-<strong>Kerr</strong>, Orange, CA, USA) and Sinfony (3M-ESPE<br />

Seefeld, Germany). The composition of each material and<br />

their required polymerization mode are shown in Table 1.<br />

The degree of CyC conversion (DC) was evaluated after the<br />

first and second polymerization cycles with a reflectance<br />

FT-IR spectroscopy (Perkin–Elmer, Norwalk, CT, USA).<br />

Three rectangular specimens (3 £ 2 £ 0.5 mm 3 ) were prepared<br />

per material. Spectra of the original pastes and of the<br />

directly irradiated surfaces were acquired after the first and<br />

second polymerization cycle under the following conditions:<br />

4000–400 cm 21 range, 4 cm 21 resolution, 458 para<br />

edge KRS-5 minicrystal of seven internal reflections, 40<br />

scans coaddition at 35 ^ 1 8C. The quantitative measurements<br />

of DC were performed based on the two-frequency<br />

method [11,12].<br />

For surface microhardness measurements, the resin<br />

composite pastes were packed into disk-shaped Teflon<br />

molds (10 mm diameter, 2 mm height), pressed against<br />

transparent polyester matrix strips and subjected to the two<br />

polymerization cycles. Ten specimens per material were<br />

prepared. After the second polymerization cycle the specimens<br />

were stored in water under dark conditions at 37 8C for<br />

24 h, the flat surfaces were ground slightly with 1000 grit<br />

size wet silicon carbide (SiC) papers and the microhardness<br />

values were obtained after application of 200 g load for 20 s<br />

using a Microhardness instrument (HMV 2000, Shimadzu<br />

Corp., Tokyo, Japan) equipped with a Vickers diamond<br />

indenter.<br />

For surface roughness measurements, 10 disk-shaped<br />

specimens per material were prepared, as described above.<br />

Mean roughness values (Ra) were measured using an<br />

electronic profilometer (Diavite DH-5, Asmeto AG, Richterswill,<br />

Germany) operated with a 5 mm diamond stylus,<br />

908 reading angle and 0.80 mm cut-off length. Six<br />

recordings per specimen surface were recorded.

A. Kakaboura et al. / Dental Materials 19 (2003) 393–398 395<br />

Fig. 1. Schematic representation of the biaxial flexural method of fracture.<br />

Eight disk-shaped specimens (15 mm diameter,<br />

0.7 mm height) per material were prepared for the<br />

biaxial flexural strength test, which were subjected to the<br />

two individual polymerization cycles. The specimens<br />

were ground, as described earlier and were immersed in<br />

water at 37 ^ 1 8C for 24 h. Then, each specimen was<br />

transferred on a biaxial flexure device consisting of three<br />

stainless steel balls (3.2 mm in diameter) equally spaced<br />

along the periphery of 10 mm diameter supporting circle<br />

(Fig. 1). The specimens of each group were loaded at<br />

the center with a stainless steel ball of 3.2 mm diameter<br />

until fracture, in a universal testing machine (Model<br />

6022, Instron Corp, Canton MA, USA) operating in<br />

compression at 1 mm/min crosshead speed. The biaxial<br />

flexural strength was calculated according to the<br />

equation [13]<br />

BS ¼ AP=h 2 and<br />

A ¼ð3=4pÞ½2ð1 þ nÞlnða=r p 0Þþð1 þ nÞð2a 2 2 r p2<br />

0 Þ=2b 2<br />

þð1 þ nÞŠ<br />

r p 0 ¼ð1:6r 2 0 þ h 2 Þ 1=2 2 0:675h<br />

where BS is the biaxial flexural strength, P the load at<br />

failure, n the Poisson’s ratio (0.24) [14], a the radius of<br />

supporting circle, b the radius of the specimen disk, h<br />

the thickness of the sample and r 0 the ball radius.<br />

The load-to-failure rate was determined directly from the<br />

load versus time graphs plotted as the ratio of the fractured<br />

load to the failure time.<br />

The polymerization shrinkage-strain during the primary<br />

cure cycle was measured with the bonded-disk<br />

method [15,16].<br />

Statistical analysis was performed by unpaired Student’s<br />

t-test to define any significant differences in the properties<br />

tested between the two resin composites for each testing<br />

condition. A 95% confidence level was chosen ( p ¼ 0.05).<br />

3. Results<br />

The mean values of all the properties are shown in<br />

Table 2. The second polymerization cycle significantly<br />

improved the percentage degree of CyC conversion (DC) in<br />

both materials ( p , 0.05). BelleGlass HP showed significantly<br />

higher final DC values, higher surface microhardness<br />

and higher roughness (Ra) values, compared to Sinfony<br />

( p , 0.05). BelleGlass HP exhibited lower final shrinkagestrain<br />

values compared to Sinfony during the primary cure<br />

cycle, and also had remarkably lower shrinkage-strain<br />

values in the early stages of the polymerization, 10–40 s<br />

(Tables 3 and 4). No statistically significant differences<br />

were detected between the two materials regarding the<br />

biaxial flexural strength. Nevertheless, BelleGlass HP

396<br />

A. Kakaboura et al. / Dental Materials 19 (2003) 393–398<br />

Table 2<br />

Results (mean ^ SD) of all characteristics evaluated. The properties were measured after the second cure cycle<br />

Material<br />

Degree of CyC<br />

conversion, first cycle<br />

Degree of CyC<br />

conversion, second cycle<br />

Micro-hardness<br />

(VHN)<br />

Roughness<br />

(Ra, mm)<br />

Biaxial flexural strength<br />

(MPa)<br />

Load-to-failure rate<br />

(MPa/s)<br />

BelleGlass HP 60 (7.2) 80 (10.4) 174 (22.1) 0.31 (0.05) 49.4 (9.4) 5.5 (0.4)<br />

Sinfony 50 (5.1) 66 (6.8) 77.8 (16.5) 0.16 (0.03) 53.4 (8.1) 2.6 (0.3)<br />

exhibited a significantly higher load-to-failure rate compared<br />

to Sinfony ( p , 0.05), an indication of higher<br />

material stiffness.<br />

4. Discussion<br />

The null hypothesis was rejected. The two materials<br />

exhibited significant differences in most of the properties<br />

studied. The degree of CyC conversion for direct resin<br />

composites has been reported to vary from 50 to 75% [17,<br />

18]. The results of the present study indicate that after the<br />

second polymerization, Sinfony reached a value within this<br />

range, whereas BelleGlass HP demonstrated an even higher<br />

degree of CyC conversion (80%), which is in accordance<br />

with the results reported by Knobloch et al. [2]. Differences<br />

in monomer composition and polymerization conditions<br />

may explain the higher degree of CyC conversion provided<br />

by BelleGlass HP. BelleGlass HP contains aliphatic<br />

urethane monomers, which are known to provide an<br />

increased degree of CyC conversion [18]. However, the<br />

main differences are expected to arise from the temperatures<br />

used in the second cure cycle. The polymerization of<br />

BelleGlass HP during the second cycle was performed at a<br />

higher temperature (140 8C) than for Sinfony (40 8C).<br />

In general, the additional cure-cycle and photothermal<br />

annealing enhance the DC of the resin composites. Thus, the<br />

physicomechanical properties of the materials can be<br />

improved [19,20] and an increase in polymerization rate<br />

can be achieved which yields and promotes an annealing<br />

effect in the polymer. The high pressure (60 psi) applied<br />

during BelleGlass HP polymerization may also increase the<br />

extent of polymerization.<br />

The positive influence of the additional cure on DC found<br />

in this study has been noted in previous studies [21–23].<br />

The second polymerization cycle will increase the molecular<br />

mobility of the residual monomer and the chain segments<br />

after initial photopolymerization. However, an inherent<br />

drawback of the increased CyC conversion may be the<br />

reduction of remaining CyC bonds available for copolymerization<br />

with the resin luting cements. Jordan [24]<br />

reported that the lack of air-inhibited layer and the limited<br />

unsaturation of the laboratory-processed resins negatively<br />

affect the composite-luting cement interfacial strength.<br />

The proportional increase in DC after the second<br />

polymerization cycle was found to be essentially equivalent<br />

for both materials.<br />

The volume fraction and type of inorganic fillers as well as<br />

the DC of the organic matrix are important contributory<br />

factors to the microhardness of composite materials [19,25,<br />

26]. The higher inorganic volume fraction of BelleGlass HP,<br />

the harder type of glasses contained [27] and the higher density<br />

of the organic matrix, as a result of the enhanced conversion,<br />

can explain the higher microhardness values obtained. Surface<br />

microhardness is considered as an indicative factor of the<br />

mechanical strength of a resin [28]. A positive correlation<br />

between the hardness of a resin material and the wear<br />

resistance has been reported [7,28,29] although such a<br />

correlation has not been confirmed in other studies [30,31].<br />

Resin composite restorations with smooth outer surfaces<br />

lead to reduced plaque retention, surface staining and<br />

secondary caries incidence [32,33]. The higher roughness<br />

value obtained for BelleGlass HP may be partly explained<br />

by the higher filler volume loading and the harder type of<br />

fillers incorporated into the material. Moreover, curing of<br />

BelleGlass HP under nitrogen pressure may provide<br />

nitrogen entrapment, which may increase the porosity at<br />

the surface region. On the other hand, polymerization of<br />

Sinfony under vacuum eliminates such surface porosity.<br />

Nevertheless, both materials investigated showed initial<br />

roughness lower than the roughness values of<br />

0.64 ^ 0.25 mm reported for enamel. Enamel roughness<br />

of 0.64 mm at enamel-to-enamel occlusal contact areas is<br />

considered as a standard for roughness measurements of<br />

resin composites [34]. Plaque accumulation preferentially<br />

occurs on composite surfaces with a roughness range of<br />

Table 3<br />

Mean shrinkage-strain values for Sinfony, at three different temperatures during the first cure cycle, SD in parentheses (n ¼ 5)<br />

Temperature (8C)<br />

Sinfony<br />

10 s 20 s 40 s 30 min 60 min<br />

23 2.60 (0.15) 3.30 (0.04) 3.50 (0.03) 4.30 (0.05) 4.34 (0.06)<br />

37 2.90 (0.10) 3.55 (0.16) 3.80 (0.16) 4.40 (0.19) 4.44 (0.20)<br />

60 3.34 (0.30) 3.94 (0.35) 4.10 (0.39) 4.66 (0.47) 4.73 (0.46)

A. Kakaboura et al. / Dental Materials 19 (2003) 393–398 397<br />

Table 4<br />

Mean shrinkage-strain values for BelleGlass HP, at three different temperatures during the first cure cycle, SD in parentheses (n ¼ 5)<br />

Temperature (8C)<br />

BelleGlass HP<br />

10 s 20 s 40 s 30 min 60 min<br />

23 0.28 (0.11) 0.96 (0.10) 1.85 (0.10) 2.67 (0.12) 2.90 (0.10)<br />

37 0.24 (0.03) 1.27 (0.08) 2.30 (0.08) 3.18 (0.10) 3.28 (0.10)<br />

60 0.34 (0.10) 1.96 (0.34) 2.93 (0.32) 3.56 (0.35) 3.70 (0.40)<br />

0.7–1.4 mm [32]. The lower roughness of Sinfony compared<br />

to BelleGlass HP may be a contributory factor to the<br />

higher reported color stability of Sinfony [6]. The roughness<br />

of BelleGlass HP recorded by Soeno et al. [35] cannot be<br />

compared with the results of the present study since a<br />

different polishing procedure of the specimens was used.<br />

Mechanical strength is an important factor in the<br />

clinical success of a restoration. Resin composites are<br />

much weaker in tension than in compression. Therefore,<br />

tensile strength is generally considered as a more<br />

meaningful property for assessment of the clinical failure<br />

potential of resin materials [36]. The traditional tensile<br />

test has rarely been used for resins because of the<br />

difficulty associated with gripping and aligning of the<br />

specimens. Recently, the biaxial flexural test has been<br />

used to determine the tensile strength of composite<br />

materials [36]. In the present study, although BelleGlass<br />

HP exhibited a higher DC and a higher filler volume<br />

than Sinfony, similar biaxial flexural strength values were<br />

recorded from both materials. It is well recognized that<br />

several structural parameters, such as inclusions of voids,<br />

cracks, flaws and stress gradients influence the fracture<br />

strength of brittle materials [36]. A value of n ¼ 0.24<br />

was taken as a selected value of Poisson’s ratio which is<br />

consistent with previous measurements [14]. Other<br />

restorative materials, such as glass-ionomer cements,<br />

exhibited higher values of 0.30 [37]. If such a larger<br />

value had been selected it would have enhanced the<br />

values by 4.7%. Hence, even if the values for the<br />

materials varied widely 0.24–0.30, this would not have<br />

produced a very significant effect on the resultant<br />

strength values. It is not known whether nitrogen<br />

entrapment into BelleGlass HP during the second<br />

polymerization cycle may induce flaws, which in<br />

sequence may affect the material strength. So, despite<br />

the fact BelleGlass HP presented a higher DC than<br />

Sinfony, this cannot predict their relative strengths.<br />

The load-to-failure rates measured show that Sinfony<br />

is a more flexible material than BelleGlass HP. The<br />

lower DC in Sinfony may generate a less stiff organic<br />

network, which along with the lower filler volume<br />

content may explain the more flexible nature of Sinfony.<br />

The latter may permit higher energy absorption capacity<br />

under loading, which may appear as plastic deformation.<br />

This effectively blunts the crack tip, which then requires<br />

more energy to propagate.<br />

The polymerization shrinkage-strain during the primary<br />

cure cycle showed that Sinfony had consistently higher<br />

shrinkage values compared to Belleglass HP, despite its<br />

lower DC. This could be attributed to the higher filler<br />

percentage of Belleglass HP (74%), compared to that of<br />

Sinfony (50%). The slower shrinkage response of Belleglass<br />

HP is consistent with a lower concentration of the<br />

photosensitizer. The rate of propagation R p is proportional<br />

to the photosensitizer concentration C s [38]. This probably<br />

accounts for the slower start in the polymerization of<br />

Belleglass HP.<br />

In conclusion, significant differences were determined<br />

between the two second-generation laboratory-processed<br />

resin composites evaluated in terms of DC, surface<br />

microhardness, surface roughness, biaxial flexural strength<br />

and stiffness, which may affect the clinical behavior of each<br />

material. Nevertheless, controlled long-term clinical studies<br />

are needed to confirm the clinical significance of these<br />

differences. It is not known whether the greater compliance<br />

of Sinfony may provide a better stress distribution pattern<br />

and more efficiently preserve adjacent tissue integrity in<br />

intracoronal restorations. However, the mechanical properties<br />

of these materials may be modified when veneering<br />

metal frameworks, as the bonding capacity of the composite-metal<br />

interface may strongly influence the mechanical<br />

performance of the complex. Consequently, although the in<br />

vitro characterization of material properties cannot yet<br />

establish sound criteria for the prediction of their clinical<br />

efficacy, it provides a basis for understanding the laboratory<br />

and clinical performance of these materials and for the<br />

development of new materials.<br />

References<br />

[1] McLean JW. The science and art of dental ceramics. Oper Dent 1991;<br />

16:149–56.<br />

[2] Knobloch LA, Kerby RE, Seghi R, Van Putten M. Two body wear<br />

resistance and degree of conversion of laboratory processed<br />

composite materials. Int J Prosthodont 1999;12:432–8.<br />

[3] Roulet JF. Benefits and disadvantages of tooth coloured alternatives to<br />

amalgam. J Dent 1997;25:459–73.<br />

[4] Touati B, Aidan N. Second generation laboratory composite resins for<br />

indirect restorations. J Esthet Dent 1997;9:108–18.<br />

[5] Freiberg RS, Ferracane JL. Evaluation of cure, properties and wear<br />

resistance of Artglass dental composites. Am J Dent 1998;11:214–8.<br />

[6] Stober T, Gilbe H, Lenz P. Color stability of highly filled composite<br />

resin materials for facings. Dent Mater 2001;17:87–94.

398<br />

A. Kakaboura et al. / Dental Materials 19 (2003) 393–398<br />

[7] Mandikos MN, McGivney GP, Davis E, Bush PJ, Carter MJ. A<br />

comparison of the wear resistance and hardness of indirect composite<br />

resins. J Prosthet Dent 2001;85:386–95.<br />

[8] Douglass RD. Color stability of new-generation indirect resins for<br />

prosthodontic application. J Prosthet Dent 2000;83:166–70.<br />

[9] Kallio TT, Lastumaki TM, Vallittu PK. Bonding of restorative and<br />

veneering composite resin to some polymeric composites. Dent Mater<br />

2001;17:80–6.<br />

[10] Bouschlicher MR, Cobb DS, Vargas MA. Effect of two abrasive<br />

systems on resin bonding to laboratory-processed indirect resin<br />

composite restorations. J Esthet Dent 1999;11:185–96.<br />

[11] Ferracane JL, Greener EH. Fourier transform infrared analysis of<br />

degree of polymerization in unfilled resins-methods comparison.<br />

J Dent Res 1984;63:1093–5.<br />

[12] Urbanski J, Czerwinski W, Janicka K, Majewska F, Zowall H.<br />

Hanbook of analysis of synthetic polymers and plastics. Chichester,<br />

UK: Ellis Horwood; 1977. p. 403–13.<br />

[13] Marshall DB. An improved biaxial flexural strength test for ceramics.<br />

Am Ceram Soc Bull 1980;59:551–3.<br />

[14] O’Brien WJ. Dental materials and their selection, 2nd ed. London,<br />

England: Quintessence Publishing Co; 1997.<br />

[15] Watts DC, Cash AJ. Determination of polymerization kinetics in<br />

visible-light cured materials: methods development. Dent Mater 1991;<br />

7:281–7.<br />

[16] Watts DC, Marouf AS. Optimal specimen geometry in bonded-disk<br />

shrinkage-strain measurements on light-cured biomaterials. Dent<br />

Mater 2000;16:447–51.<br />

[17] Ruyter IE. Monomer systems and photopolymerization. In: Vanherle<br />

G, Smith DC, editors. Imternational symposium on posterior<br />

composite resin dental restorative materials. Minnesota Mining and<br />

Manufacturing Co. The Netherlands: Peter Sculz Publishing Company;<br />

1985. p. 109–35.<br />

[18] Ferracane JL, Greener EH. The effect of resin formulation on the<br />

degree of conversion and mechanical properties of dental restorative<br />

resins. J Biomed Mater Res 1986;20:121–31.<br />

[19] Wendt SL. The effect of heat as a secondary cure upon the physical<br />

properties of three composite resins: I. Diametral tensile strength,<br />

compressive strength and marginal dimensional stability. II. Wear,<br />

hardness and color stability. Quint Int 1987;18:265–71.<br />

[20] Mc Cabe JF, Kagi S. Mechanical properties of a composite inlay<br />

material following post curing. Br Dent J 1991;171:246–8.<br />

[21] Eliades GC, Vougiouklakis GL, Caputo AA. Degree of double bond<br />

conversion in light cured composites. Dent Mater 1987;3:19–25.<br />

[22] Ferracane JL, Condon JR. Post-cure heat treatments for composites:<br />

properties and fractography. Dent Mater 1992;8:290–3.<br />

[23] Park SH. Comparison of degree of conversion for light-cured and<br />

additionally heat-cured composites. J Prosthet Dent 1996;76:613–8.<br />

[24] Jordan RE. Esthetic composite bonding: techniques and materials, 2nd<br />

ed. St Louis: Mosby; 1993. p. 23–33.<br />

[25] Wassel RW, McCabe JF, Walls AWG. Subsurface deformation<br />

associated with hardness measurements of composites. Dent Mater<br />

1992;8:218–23.<br />

[26] Peutzfeldt A, Asmussen E. Mechanical properties of three composite<br />

resins for the inlay/onlay technique. J Prosthet Dent 1991;66:322–4.<br />

[27] Ferrance JL. Status of research on new fillers and new resins for dental<br />

composites. In: Tagami J, Toledano M, Prati C, editors. Advanced<br />

adhesive dentistry. Third International Kuraray Symposium. Cirimido<br />

(Como), Italy by Erredue G; 1999. p. 3–29.<br />

[28] Ferracane JL, Mitchem JC, Condon JR, Todd R. Wear and marginal<br />

breakdown of composites with various degrees of cure. J Dent Res<br />

1997;76:1508–16.<br />

[29] McCabe JF. Applied dental materials, 7th ed. Oxford, England:<br />

Blackwell; 1990. p. 78–86.<br />

[30] Lappalainen R, Yli-Upro A, Seppa L. Wear of dental restorative and<br />

prosthetic materials in vitro. Dent Mater 1989;5:35–7.<br />

[31] Kawai K, Iwami Y, Ebisu S. Effect of resin monomer composition on<br />

toothbrush wear resistance. J Oral Rehabil 1998;25:264–8.<br />

[32] Weitman RT, Eames WB. Plaque accumulation on composite surfaces<br />

after various finishing procedures. JADA 1975;91:101–6.<br />

[33] Chan KC, Fuller JL, Hormati AA. The ability of foods to stain two<br />

composite resins. J Prosthet Dent 1980;43:542–5.<br />

[34] Williams PT, Johnson LN. Composite resins revisited. J Can Dent<br />

Assoc 1993;59:538–43.<br />

[35] Soeno K, Matsamura H, Atsuta M, Kawasaki K. Effect of acidulated<br />

phosphate fluoride on veneering particulate filler composites. Int J<br />

Prosthodont 2001;14:127–32.<br />

[36] Ban S, Anusavice KL. Influence of test method on failure stress of<br />

brittle dental materials. J Dent Res 1990;69:1791–9.<br />

[37] Akinmade AO, Nicholson JW. Poisson’s ratio of glass-polyalkenoate<br />

(‘glass-ionomer’) cements determined by an ultrasonic pulse method.<br />

J Mater Sci Mater Med 1995;6:483–5.<br />

[38] Watts DC. Dental restorative materials. In: Cahn RW, Haasen P,<br />

Kramer EJ, editors. Materials science and technology: a<br />

comprehensive treatment, vol. 14. Germany: Weinheim; 1992. p.<br />

209–58.

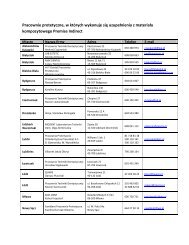

KERR - PROJECT<br />

1) GLOSS

Material<br />

<strong>Premise</strong> <strong>Indirect</strong> - Facial<br />

Dentin<br />

(3 steps cure)<br />

<strong>Premise</strong> <strong>Indirect</strong> - Primary<br />

Dentin<br />

(3 steps cure)<br />

<strong>Premise</strong> Direct - Dentin<br />

Light-cure – 40 sec<br />

<strong>Premise</strong> Direct - Enamel<br />

Light-cure – 40 sec<br />

24 h – After<br />

cure<br />

24 h –<br />

Ethanol<br />

100%<br />

% of Gloss<br />

retention<br />

Δ Gloss<br />

75.6 (1.1) 65.1 (3.9) 86.1 (4.2) 10.5 (3.0)<br />

33.7 (9.3) 17.1 (4.9) 50.7 (0.8) 16.5 (4.3)<br />

45.9 (2.9) 27.9 (14.0) 59.8 (0.8) 18.0 (11.7)<br />

66.6 (2.0) 55.5 (10.4) 83.1 (13.3) 11.1 (8.6)

2) KNOOP HARDNESS NUMBER

Material<br />

<strong>Premise</strong> <strong>Indirect</strong> - Facial Dentin<br />

(3 steps cure)<br />

<strong>Premise</strong> <strong>Indirect</strong> - Primary Dentin<br />

(3 steps cure)<br />

<strong>Premise</strong> Direct - Dentin<br />

Light-cure – 40 sec<br />

<strong>Premise</strong> Direct - Enamel<br />

Light-cure – 40 sec<br />

24 h – After cure<br />

24 h – Ethanol<br />

100%<br />

% KHN<br />

51.8 (6.4) 34.2 (6.6) 34.4 (5.4)<br />

54.7 (4.7) 39.2 (5.3) 28.1 (9.3)<br />

44.8 (2.3) 28.3 (0.8) 36.8 (4.7)<br />

43.6 (2.6) 24.2 (1.9) 44.4 (3.0)

3) COLOUR STABILITY<br />

Material<br />

<strong>Premise</strong> <strong>Indirect</strong> - Facial Dentin<br />

(3 steps cure)<br />

<strong>Premise</strong> <strong>Indirect</strong> - Primary Dentin<br />

(3 steps cure)<br />

<strong>Premise</strong> Direct - Dentin<br />

Light-cure – 40 sec<br />

<strong>Premise</strong> Direct - Enamel<br />

Light-cure – 40 sec<br />

ΔE<br />

0.89 (0.08)<br />

2.15 (0.60)<br />

1.88 (0.49)<br />

1.01 (0.18)

(InternalData) PHYSICALPROPERTIESINDIRECTCOMPOSITERESINS(Ref.139AK74)<br />

Dia.Tens. Comp. Flex.Str. Flex.Mod. Rockwell X-RayOp. Wt.%Filler Vol% CTE K1C Str.,MPa(sd)Str.,MPa(sd) MPa(sd) MPa(sd) 15THard. (%Al) (Vol.%) shrink.(sd)ppm/Deg.C.(sd)MPam1/2(sd) BelleGlassHP TranslucentDentin 63(4) 417(34) 142(10)13100(700) 87(1.0) 78(56) 3.0(0.1) 30.2(0.8) 1.04(0.04) Product<br />

56(4) 370(28) 158(11)21,000(1400) 89.1(1.0) 300 87.1(72.5) 0.94(0.1) 13.1(0.7) 1.48(0.09) Enamels 63(2) 460(50) 167(21)10,700(200) 89.6(0.4) 100 72.9(59.5) 3.1(0.03) 26.4(0.3) 0.96(0.07) BelleglassNG Trans.Dent.306-167,131-192 450(60) 150(30)11,100(200) 84.0(0.7 2.3(0.2) 28.6(1.4) OpaceousDentin<br />

50(10) 510(10) 150(10)10,900(300) 87(0.8) 100 77(70) 2.3(0.3) 33.9(0.8) MetalPlus,Op.Dent. 63(5) 450(40) 130(14)11,500(300) 82(0.5) 200 78(63) 1.9(0.1) 25.1(1.7) 1.1(0.1) <strong>Premise</strong><strong>Indirect</strong> Enamel313-79,329-5<br />

56(4) 370(28) 158(11)21,000(1400) 89.1(1.0) 300 87.1(72.5) 0.94(0.1) 13.1(0.7) 1.48(0.09) FacialDentin 450(60) 150(30)11,100(200) 84.0(0.7 200 78(63) 2.3(0.2) 28.6(1.4) Incisal 50(10) 510(10) 150(10)10,900(300) 87(0.8) 100 77(70) 2.3(0.3) 33.9(0.8) 1.1(0.1) Artglass PrimaryDentin<br />

67(4) 351(28) 109(10)8,300(400) 80(1.0) 69 3.4(0.1) 33.3(1.0) 1.17(0.05) Enamel 67(2) 365(14) 114(10)7,800(400) 79(1.0) 500 67 Targis Dentin 58(8) 415(25) 142(23)10,300(600) 84.6(1) 74 3.0(0.1) 28.2(0.6) 0.77(0.09) Dentin<br />

107(16)6,300(460) Sculpture Dentin 48(8) 395(20) 136(9)12,700(400) 84.6(1) 78.7 2.62(1.4) 24.0(1.4) 1.13(0.16) Enamel<br />

126(21)10,500(300) Cristobal+ OpaceousDentin 49(6) 450(38) 179(11)13,000(400) 87.8(0.2) 216 75.1 3.26(0.3) 27.0(1.0) 1.14(0.27) Incisal 66(10) 473(19) 156(20)12,000(200) 86.4(1.0) 200 73 2.91(0.10) 1.22(0.09) Enamel<br />

Dentin 60(9) 441(60) 155(13)16,129(601) 93(0.4) 86.8(72.4) 1.55(0.15) 15.3(2.8) 1.27(0.2) Enamel 66(4) >500 136(18)17,980(715) 93.9(0.2) 300 88.2 1.62(0.07) 13.7(1.1) 1.19(0.09) Sinfony Estenia<br />

63(3) 430(18) 89(8)3,557(338) 51.5(1.3) 83 4.53(0.04) 62.6(3.0) 1.12(0.05) Enamel 63(4) 457(43) 89(3)3,219(228) 56.6(1.2) 100 44.7 4.62(0.3) 68.6(1.5) 1.31(0.08) Dentin<br />

Dentin 54(8) 420(34) 128(17)9,700(460) 83.5(1.5) 77.9 2.4(0.2) 34.3(0.3) Enamel 59(6) 409(27) 140(8) 9700(500) 83.1(0.7) 73.5 3.2(0.2) 33.5(0.3) Ceramics DiamondCrown<br />

Feldspathic 80 In-Ceram 450 Nature 70 393 45 600

elleGlassNGTM2003TECHNICALSUMMARY 2. Eight-yearclinicalperformanceofheatandpressurecuredindirectcomposite.D.A.Givan,S.J. O’NEALandS.SUZUKI.(Univ.ofAlabamaSchoolofDentistry,Birmingham,Alabama,USA) 1.<br />

<strong>Indirect</strong>PosteriorCompositeResins;KarlFLeinfelderDDS,MS,July2005 AdjunctProfessor,UniversityofNorthCarolina,ChapelHill,NorthCarolina ProfessorEmeritus,UniversityofAlabama,Birmingham,Alabama 3.<br />

<strong>Indirect</strong>Composites:Dentistry'sBestKeptSecret,DamonC.Adams,DDS,May6,2007,Spring ScientificSession 4.<br />

AnteriorApplicationofan<strong>Indirect</strong>Composite,aDoctor/TechnicianLiaison’sPerspective,Dr. DamonC.Adams,DDS;DentistryToday,April2005 6. Wearofcompositeresinveneeringmaterialsandenamelinachewingsimulator 5.<br />

andDentalMaterials,DentalSchool,Christian-Albrechts-UniversityatKiel,Germany SoerenScheibnerb,PrivatePractice,Neuburg,Germany Publishedondentalmaterials23(2007) ChristianMehla,KlausLudwiga,MatthiasKerna,DepartmentofProsthodontics,Propaedeutics<br />

SuccesswithbelleGlass–StepbyStep-CompositeisProgress ByAxelMühlhäuser(DT),Germany,publishedondental-labinternational,Vol.3,No.1/2007 7.<br />

ClinicalPerformanceofBondedCeramicandResin-BasedCompositeInlaysandOnlaysUsinga Self-EtchBondingSystem:a51-MonthReport Jose-LuisRuiz,DDS;GordonJ.Christensen,DDS,MSD,PhD;AbdiSameni,DDS;LuisVargas,DDS PublishedonINSIDEDENTISTRY—MAY2007 8.<br />

SupplementalOneAppointmentInlay/OnlayProcedure(ForDentists) 10. Protocol–ConservativeOneAppointmentBelleglassNGOnlayProcedure–MAY2007 9.<br />

10-yearClinicalEvaluationofaSelf-etchingAdhesiveSystem-ClinicalResearch NAkimoto,MTakamizu,YMomoi 11.<br />

12. EvaluationofClinicalandInVitroWearforResinComposites. ShiroSuzuki,KarlLeinfelder,UniversityofAlabamaatBirmingham OperativeDentistry,2007,32-1,3-10<br />

AlvinKobashigawa,EdwardShellard-Sybron/<strong>Kerr</strong>

A.I.KobashigawaandE.Shellard;“CrackArrestingPropertiesofaFiberReinforcedComposite ResinLaminate.”;J.Dent.Res.V.79SpecialIssueAbst.#289,Apr.2000 14. EffectOfFiberReinforcementOnTheBreakingStrengthOfCrowns,C.A.Munoz-Viveros,etal., 13.<br />

15. CrackArrestingPropertiesOfafiberReinforcedCompositeResinLaminateA.I.Kobashigawaand E.Shellard,KERRCorporation,Orange,California,USA Abst.#1177J.Dent.Res.77SpecialIssueB,June,1998.<br />

ClinicalEvaluationofaDentinAdhesiveSystem:13YearResults;A.A.BoghosianandJ.L. DrummondandE.P.Lautenschlager,NorthwesternUniversityFeinbergSchoolofMedicine 16.<br />

W.D.Roe*,M.H.Ramp:“WearofenamelOpposingThreeEstheticMaterialsandOneAlloy”.;J. Dent.Res.V.79SpecialIssueAbst.#1090,Apr.2000 18. ALL-IN-ONEADHESIVE-NEXUS3DENTINBONDSTRENGTH:INDIRECTPROCEDURE 17.

BGNG-belleGlassNGNextGeneration BGHP-belleGlassHPHeatandPressure<br />

•<br />

PI–<strong>Premise</strong><strong>Indirect</strong><br />

Newcompositenames?<br />

•<br />

belleGlassNGEnamelsNOW<strong>Premise</strong><strong>Indirect</strong>Incisal belleGlassNGOpaceousDentineNOW<strong>Premise</strong><strong>Indirect</strong>PrimaryDentine belleGlassNGTranslucentDentineNOW<strong>Premise</strong><strong>Indirect</strong>FacialDentin<br />

Yes-thenewovenisexactlythesameastheoldoneexceptithasamoremodernfasciaand CantheoldBGNGovenbeusedtocure<strong>Premise</strong><strong>Indirect</strong>?<br />

•<br />

Isnitrogenabsolutelynecessary? CuringrestorationsinthePIovenwithoutnitrogenmeanstheywillbecoveredinthesticky touchcontrolpanel.<br />

finalrestorationwheneitherusingornotusingnitrogenbutourpreferenceisofcourseto useit. airinhibitedlayer.Thiscanbeeasilyremoved.Thereisverylittleclinicaldifferenceinthe<br />

WhatarethemajorimprovementswiththenewPIcomposite? – Evenbetterhandling(nonstickytexture,easytocarveandcondensewithminimum<br />

anterior.<br />

Closershadematchtotheshadeguide.<br />

EvenmoretoothlikeappearanceespeciallywiththeIncisal. slump)withsuperbceramic-likeappearanceandlongerlivedglossespeciallyinthe<br />

AbilitytobuilduptheentirerestorationwithpolishablePIFacialifspacedoesnot permitforPrimary,FacialandIncisal. – FacialcontainsahigherchromavaluethanbelleGlassOpaciousDentinsoismore effectiveatmaskingmetalworkssoidealforimplantsuperstructureandothermetal<br />

work.

•<br />

Simplythetransferoftechnologytobiologyorbiologytotechnologyandtheenhancement ofeitherbyboth.Thecat’seyeinthemiddleoftheroadclearlyvisibleatnightreflecting Explainbiomimetic<br />

bornwithwhichhelpsthemseebetteratnight.PIisatransferoftechnologytobiology wherebyvirtuallytoothlikerestorationsinallsensesofthewordarefabricated. surroundinglightisanearexactcopyoftheinternalsightstructuremechanismthatcatsare<br />

•<br />

•<br />

manufacture. Isitpossibletomixbotholdandnewmaterials? Yeabutcareshouldbetakentoestablishfinalshadematchespriortorestoration<br />

OursuggestionistouseMetalPrepfromGCintheinterimperiod. Nothisproducthasbeendiscontinuedandwearecurrentlyworkingonanewformulation. Is<strong>Kerr</strong>MetalPrepavailable?<br />

•<br />

•<br />

highsmilelinecases.Thecervicalred/brownshaderemainsavailable. Whataboutawiderrangeofshadesforcervicalcolouring? Thisisinhandtomanufactureabroaderrangeofpinkcoloursespeciallyforimplantand<br />

-TheFacialDentinbuildupshouldbenomorethan1.5mminthickness. Howtoachieveoptimumaesthetics? -UseA-1PrimarydentinforalloftheshadesexceptB-1forextralightshades. -Properincisalshadeselectionisimportant.Monochromaticlayeringdoesnotwork.<br />

-Usethe40secondruletomakesurethattheCQinbleached. -ProperuseofthePrimaryDentinbuildupwilldecreasethechromaonthickbuildups. -Carrytheincisalbuilduptonomorethan1/4ofthefacialbuildup.