ENERPAC hydraulics Catalogue in pdf - techsystem

ENERPAC hydraulics Catalogue in pdf - techsystem

ENERPAC hydraulics Catalogue in pdf - techsystem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

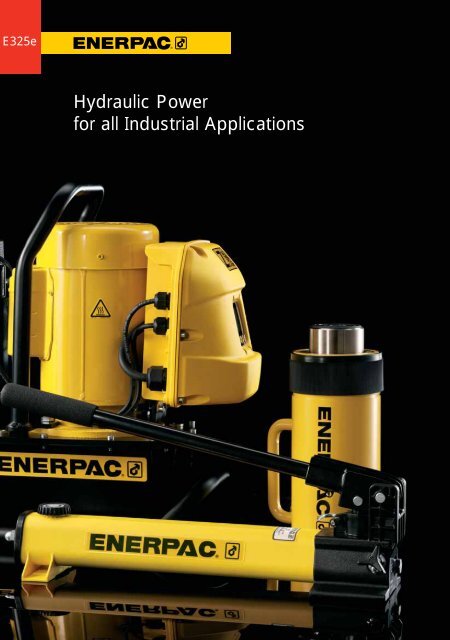

E325e<br />

Hydraulic Power<br />

for all Industrial Applications

Table of Contents<br />

<br />

Introduction<br />

The World Class Brand ............................ 4-5<br />

Cyl<strong>in</strong>ders (Hydraulic) 6-65<br />

Introduction .............................................. 6-7<br />

RC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g Cyl<strong>in</strong>ders ....... 8-11<br />

and Accessories ..................................... 12<br />

RAC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Alum<strong>in</strong>ium Cyl<strong>in</strong>ders ........................ 14-15<br />

RACL-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Alum<strong>in</strong>ium Lock Nut Cyl<strong>in</strong>ders ......... 16-17<br />

RACH-Series, S<strong>in</strong>gle-Act<strong>in</strong>g, Alum<strong>in</strong>ium<br />

Hollow Plunger Cyl<strong>in</strong>ders.................. 18-19<br />

RAR-Series, Double-Act<strong>in</strong>g<br />

Alum<strong>in</strong>ium Cyl<strong>in</strong>ders ......................... 20-21<br />

CLP-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Pancake Cyl<strong>in</strong>ders ........................... 22-23<br />

RSM-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Flat-Jac ® Cyl<strong>in</strong>ders ......................... 24-25<br />

RCS-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Low Height Cyl<strong>in</strong>ders ....................... 24-25<br />

BRC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Pull Cyl<strong>in</strong>ders ................................... 26-27<br />

BRP-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Pull Cyl<strong>in</strong>ders ................................... 26-27<br />

RCH-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Hollow Plunger Cyl<strong>in</strong>ders ................. 28-29<br />

RRH-Series, Double-Act<strong>in</strong>g<br />

Hollow Plunger Cyl<strong>in</strong>ders ................. 30-31<br />

BRD-Series, Double-Act<strong>in</strong>g<br />

Precision Cyl<strong>in</strong>ders .......................... 32-33<br />

RR-Series, Double-Act<strong>in</strong>g<br />

Long Stroke Cyl<strong>in</strong>ders ...................... 34-37<br />

CLSG-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

High Tonnage Cyl<strong>in</strong>ders ................... 38-41<br />

CLS-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

High Tonnage Cyl<strong>in</strong>ders ................... 42-45<br />

CLRG-Series, Double-Act<strong>in</strong>g<br />

High Tonnage Cyl<strong>in</strong>ders ................... 46-49<br />

CLL-Series, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Lock Nut Cyl<strong>in</strong>ders ........................... 50-53<br />

SLS-Series, Synchronous Systems ..... 54-55<br />

BLS, SL-Series, Stage Lift Systems .... 56-57<br />

SHS-Series, SyncHoist,<br />

Load Position<strong>in</strong>g Systems ............... 58-59<br />

JH, JHA-Series,<br />

Steel and Alum<strong>in</strong>ium Jacks .................... 60<br />

EBJ-Series, Steel Bottle Jacks ................. 61<br />

RC-Series, High Temperature &<br />

Corrosion Resistant Products .......... 62-63<br />

SC-Series, Cyl<strong>in</strong>der-Pump Sets .......... 64-65<br />

Pumps (Hydraulic) 66-105<br />

Introduction .......................................... 66-67<br />

P-Series, Lightweight Hand Pumps .... 68-69<br />

P-Series, Steel Hand Pumps ............... 70-71<br />

P-Series, Low Pressure Hand Pumps . 72-73<br />

MP-Series, Multifluid Hand Pumps ........... 74<br />

P-Series, Foot Pump.................................. 75<br />

P- and 11-Series,<br />

Ultra-High Pressure Hand Pumps .... 76-77<br />

PU-Series, Portable Economy<br />

Electric Pumps .................................. 78-79<br />

PE-Series, Submerged<br />

Electric Pumps .................................. 80-83<br />

Z-Class Introduction<br />

ZE3 - ZE6, ZU4-Series ...................... 84-85<br />

ZU4-Series, Electric Pumps ................. 86-89<br />

ZE-Series, Electric Pumps.................... 90-95<br />

PP-Series, Electric Pumps<br />

(8000- and 9000-Series) .................. 96-97<br />

PA-Series, Turbo II Air Pumps ............. 98-99<br />

PA-Series, Air Hydraulic Pumps ...... 100-101<br />

PAH-Series, Air Hydraulic Pumps ... 102-103<br />

PGM-Series, Atlas Gasol<strong>in</strong>e<br />

Powered Pumps ............................ 104-105<br />

Yellow Pages (Information Section) .106-118<br />

Global Warranty ...................................... 106<br />

Introduction and Standards .................... 107<br />

Safety Instructions ........................... 108-109<br />

Cyl<strong>in</strong>der-Pump Match<strong>in</strong>g and Selection . 110<br />

Hydraulic Work Sheet ............................. 111<br />

Basic Hydraulic System Set-ups ..... 112-113<br />

Basic Hydraulics .............................. 114-115<br />

Conversion Tables ................................... 116<br />

Cyl<strong>in</strong>der Speed Charts ............................ 117<br />

Valve Information ..................................... 118<br />

System Components 119-132<br />

Introduction ............................................. 119<br />

700-Series, High Pressure Hoses .... 120-121<br />

A, C, F, T-Series, Couplers ............... 122-123<br />

HF-Series, Hydraulic Oil .......................... 124<br />

A, AM-Series, Manifolds ......................... 124<br />

FZ, BFZ-Series, Fitt<strong>in</strong>gs .......................... 125<br />

GP, GF-Series, Force Gauges ......... 126-127<br />

G, H-Series, Pressure Gauges ........ 128-129<br />

T-Series, Test System Gauges ................ 130<br />

DGR-Series, Digital Gauges .................... 131<br />

GA-Series, Gauge Accessories ............... 132<br />

Valves 133-139<br />

Introduction ............................................. 133<br />

3-Way Directional Control Valves .... 134-135<br />

4-Way Directional Control Valves .... 136-137<br />

Pressure and Flow Control Valves ... 138-139<br />

Hydraulic Presses 140-149<br />

Introduction ...................................... 140-141<br />

VLP-Series, Bench and<br />

Workshop Presses ........................ 142-143<br />

BPR-Series, Roll Frame Presses ..... 144-145<br />

A-Series, C-Clamps Arbor Presses . 146-147<br />

Press Accessories ................................... 148<br />

LH-Series, Load Cells ............................. 149<br />

TM-Series, Tension Meters ..................... 149<br />

Hydraulic Technology Worldwide<br />

Pullers 150-163<br />

Introduction ...................................... 150-151<br />

BHP-Series, Hydraulic Puller Sets .. 152-155<br />

EP-Series,<br />

Mechanical Posi-Lock ® Pullers .. 156-159<br />

EPH-Series,<br />

Hydraulic Posi-Lock ® Pullers ..... 160-162<br />

EPH-Series, 100 ton Posi Lock ®<br />

Hydraulic Grip Pullers ......................... 163<br />

Tools 164-183<br />

Introduction ...................................... 164-165<br />

MS-Series, Ma<strong>in</strong>tenance Sets ......... 166-169<br />

SP-Series, 35 Ton Hydraulic Punch 170-171<br />

LW-Series, Lift<strong>in</strong>g Wedge ........................ 172<br />

SOH-Series, Hydraulic Mach<strong>in</strong>e Lifts ..... 173<br />

ER-Series,<br />

Heavy Duty Load Skates .............. 174-175<br />

A, WR-Series, Wedgies and<br />

Spread Cyl<strong>in</strong>ders ................................. 177<br />

CM-Series, Storage Cases ..................... 176<br />

WHC-WMC-Series,<br />

Cutters & Cutterheads .................. 178-179<br />

STB-Series, Pipe Benders ............... 180-181<br />

DPT, PT-Series,<br />

Post-Tension<strong>in</strong>g Tools.................... 182-183<br />

Bolt<strong>in</strong>g Tools 184-216<br />

Introduction....................................... 184-185<br />

NC-Series, Hydraulic Nut Splitters ......... 186<br />

FS-Series, Hydraulic Flange Spreaders .. 187<br />

FSH, FSM-Series, Wedge Spreaders ..... 188<br />

ATM-Series, Flange Alignment Tools ...... 189<br />

S-Series, Square Drive Steel<br />

Torque Wrenches .......................... 190-193<br />

SQD-Series, Square Drive Alum<strong>in</strong>ium<br />

Torque Wrenches .......................... 194-197<br />

W-Series, Steel Hexagon Cassette<br />

Torque Wrenches........................... 198-201<br />

HXD-Series, Alum<strong>in</strong>ium Hexagon<br />

Cassette Torque Wrenches............ 202-205<br />

Torque Wrench & Pump - Hose<br />

Selection Matrix............................. 206-207<br />

PME, PMU-Series, Portable Electric<br />

Torque Wrench Pumps.......................... 208<br />

PTE-Series, Portable Electric<br />

Torque Wrench Pumps.......................... 209<br />

ZU4T-Series, Electric<br />

Torque Wrench Pumps .................. 210-213<br />

PTA-Series, Air Driven<br />

Torque Wrench Pumps.......................... 214<br />

PMA-Series, High Flow Air Driven<br />

Torque Wrench Pumps.......................... 215<br />

Bolt, Nut and Thread Sizes ..................... 216<br />

About Enerpac 217<br />

Enerpac Worldwide Locations 218<br />

Model Number Index 219<br />

2

Model Number Index<br />

<br />

Page(s) Page(s) Page(s) Page(s) <br />

A<br />

A5-A10 . . . . . . . . . . . 166<br />

A12 . . . . . . . . . . . . . . . . . . 12<br />

A13-A28 . . . . . . . . . 166<br />

A29-A53. . . . . . . . . . . . 12<br />

A64-A66 . . . . . . . . . 124<br />

A92 . . . . . . . . . . 166, 177<br />

A102 . . . . . . . . . . . . . . . . . 12<br />

A128-A192 . . . . . . 166<br />

A183 . . . . . . . . . . . . . . . 146<br />

A185 . . . . . . . . 146, 166<br />

A200R . . . . . . . . . . . . . 148<br />

A205-A220 . . . . . . 146<br />

A218 . . . . . . . . . . . . . . . 166<br />

A242-A305 . . . . . . 166<br />

A310, A330 . . . . . 146<br />

A530-A595 . . . . . . 166<br />

A604 . . . . . . . . . . . . . . . 123<br />

A607 . . . . . . . . . . . . . . . 166<br />

A630 . . . . . . . . . . . . . . . 123<br />

A650 . . . . . . . . . . . . . . . 166<br />

AH . . . . . . . . . . . . . . . . . . 123<br />

AM . . . . . . . . . . . . . . . . . 124<br />

AR . . . . . . . . . . . . . . . . . . 123<br />

ATM . . . . . . . . . . . . . . . . 189<br />

AW . . . . . . . . . . . . . . . . . . . 12<br />

B<br />

BAD . . . . . . . . . . . . . . . . . 33<br />

BFZ . . . . . . . . . . . . . . . . 125<br />

BHP . . . . . . . . 152-155<br />

BLS . . . . . . . . . . . . . 56-57<br />

BPR . . . . . . . . 144-145<br />

BRC . . . . . . . . . . . . 26-27<br />

BRD . . . . . . . . . . . . 32-33<br />

BRP . . . . . . . . . . . . 26-27<br />

BSS . . . . . . . . . . 90, 148<br />

BZ . . . . . . . . . . . 180-181<br />

C<br />

C . . . . . . . . . . . . . . . . . . . . 123<br />

CAT . . . . . . 12, 25, 41<br />

CAT . . . . . . 49, 45, 53<br />

CATG . . . . . . . . . 15, 17<br />

. . . . . . . . . . . . . 21, 41, 49<br />

CC . . . . . . . . . . 202-205<br />

CD . . . . . . . . . . . . . . . . . 123<br />

CH . . . . . . . . . . 123, 194<br />

CLL . . . . . . . . . . . . . 50-53<br />

CLP . . . . . . . . . . . . 22-23<br />

CLRG . . . . . . . . . . 46-49<br />

CLS . . . . . . . . . . . . 42-45<br />

CLSG . . . . . . . . . . 38-41<br />

CM . . . . . . . . . . . . . . . . . 176<br />

CR . . . . . . . . . . . . . . . . . 123<br />

CW . . . . . . . . . . . . . . . . . 168<br />

D<br />

DGR . . . . . . . . . . . . . . . 131<br />

DPT . . . . . . . . . 182-183<br />

www.enerpac.com<br />

E<br />

EBJ . . . . . . . . . . . . . . . . . . 61<br />

ELP . . . . . . . . . 174-175<br />

EMB . . . . . . . . . . . . . . . 174<br />

EP . . . . . . . . . . . . . 156-159<br />

EPH . . . . . . . . 160-163<br />

EPHT . . . . . . . . . . . . . 163<br />

EPP . . . . . . . . . 157-159<br />

EPT . . . . . . . . . . . . . . . . 160<br />

EPX . . . . . . . . . . . . . . . . 159<br />

ER . . . . . . . . . . . 174-175<br />

ES . . . . . . . . . . . 174-175<br />

F<br />

F . . . . . . . . . . . . . 123-124<br />

FH . . . . . . . . . . . 123-124<br />

FR . . . . . . . . . . . 123-124<br />

FS . . . . . . . . . . . . . . . . . . 187<br />

FSB . . . . . . . . . . . . . . . . 188<br />

FSH . . . . . . . . . . . . . . . . 188<br />

FSM . . . . . . . . . . . . . . . 188<br />

FZ . . . . . . . . . . . . . . . . . . 125<br />

G<br />

G . . . . . . . . . . . . . 128-129<br />

GA . . . . . . . . . . . . . . . . . . 132<br />

GF . . . . . . . . . . . 126-127<br />

GP . . . . . . . . . . . 126-127<br />

H<br />

H . . . . . 120, 128-129<br />

HA . . . . . . . . . . . . . . . . . . 121<br />

HB . . . . . . . . . . . . . . . . . . 121<br />

HC . . . . . . . . . . . . . . . . . 121<br />

HF . . . . . . . . . . . . . . . . . . 124<br />

HP . . . . . . . . . . . . . . 29, 31<br />

HR . . . . . . . . . . 204-205<br />

HXD . . . . . . . . . 202-205<br />

I<br />

IN . . . . . . . . . . . . 204-205<br />

IPL . . . . . . . . . . . . . . . . . 148<br />

J<br />

JBI . . . . . . . . . . . . . . . . . . . 12<br />

JH . . . . . . . . . . . . . . . . . . . . 60<br />

JHA . . . . . . . . . . . . . . . . . . 60<br />

L<br />

LH . . . . . . . . . . . . . . . . . . 149<br />

LW . . . . . . . . . . . . . . . . . 172<br />

M<br />

MP . . . . . . . . . . . . . . . . . . . . 74<br />

MS . . . . . . . . . . . 166-169<br />

MSP . . . . . . . . . . . . . . . 171<br />

MZ . . . . . . . . 1568-169<br />

N<br />

NC . . . . . . . . . . . . . . . . . 186<br />

NV . . . . . . . . . . . . . . . . . . 132<br />

P<br />

P . . . . . 63, 68, 70, 72<br />

P142AL . . . . . . . 62-63<br />

P392AL . . . . . . . 62-63<br />

P392FP . . . . . . . . . . . . 75<br />

PA . . . . . . . . . . . . . . . . . . 100<br />

PAH . . . . . . . . 102-103<br />

PAM . . . . . . . . . . . . . . . 101<br />

PAMG . . . . . . . . . 98-99<br />

PATG . . . . . . . . . . 98-99<br />

PARG . . . . . . . . . . 98-99<br />

PC . . . . . . . . 68, 70, 72<br />

PE . . . . . . . . . . . . . . . 80-83<br />

PF . . . . . . . . . . . . . . . . . . . . 92<br />

PGM . . . . . . . 104-105<br />

PMA . . . . . . . 207, 215<br />

PME . . . . . . . 206, 208<br />

PMU . . . . . . . 206, 208<br />

PP . . . . . . . . . . . . . . . 96-97<br />

PT . . . . . . . . . . . 182-183<br />

PTA . . . . . . . . 207, 214<br />

PTE . . . . . . . . 206, 209<br />

PU . . . . . . . . . . . . . . 78-79<br />

R<br />

RAH . . . . . . . . . 196-197<br />

RAC . . . . . . . . . . . . . . . . . . 14<br />

RACH . . . . . . . . . . . . . . . 18<br />

RACL . . . . . . . . . . . . . . . . 16<br />

RAR . . . . . . . . . . . . . . . . . . 20<br />

RB . . . . . . . . . . . . . . . . . . . 12<br />

RC . . . . . 8-12, 62-63<br />

RCH . . . . . . . . . . . . 28-29<br />

RCS . . . . . . . . . . . . 24-25<br />

REB . . . . . . . . . . . . . . . . . 12<br />

REP . . . . . . . . . . . . . . . . . 12<br />

RFL . . . . . . . . . . . . . . . . . . 98<br />

RR . . . . . . . . . . . . . . 34-37<br />

RRH . . . . . . . . . . . . 30-31<br />

RSM . . . . . . . . . . . 24-25<br />

RWH . . . . . . . . . . . . . . 152<br />

S<br />

S . . . . . . . . . . . . . 190-193<br />

SB . . . . . 92, 172, 188<br />

SCH . . . . . . . . . . . . 64-65<br />

SCL . . . . . . . . . . . . 64-65<br />

SCP . . . . . . . . . . . . 64-65<br />

SCR . . . . . . . . . . . . 64-65<br />

SDA . . . . . . . . 192-193<br />

SHS . . . . . . . . . . . . 58-59<br />

SL . . . . . . . . . . . . . . . 56-57<br />

SLS . . . . . . . . . . . . . 54-55<br />

SOH . . . . . . . . . . . . . . . 173<br />

SP . . . . . . . . . . . 170-171<br />

SPD . . . . . . . . . . . . . . . 171<br />

SPK . . . . . . . . . . . . . . . 170<br />

SQD . . . . . . . . . .194-197<br />

STB . . . . . . . . . 180-181<br />

STC . . . . . . . . . . . . . . . . 178<br />

STF . . . . . . . . . 187-188<br />

STN . . . . . . . . . . . . . . . . 186<br />

STP . . . . . . . . . . . . . . . . 171<br />

SW . . . . . . . . . . . . . . . . . 188<br />

T<br />

T . . . . . . . . . . . . . 122-123<br />

THC . . . . . . . . . . . . . . . 207<br />

THQ . . . . . . . . . . . . . . . 207<br />

TM . . . . . . . . . . . . . . . . . 149<br />

TW . . . . . . . . . . . . . . . . . 189<br />

V<br />

V . . . . . . . . 63, 138-139<br />

VA2 . . . . . . . . . . . . . . . . 101<br />

VB . . . . . . . . . . 142, 148<br />

VC . . . . . . . . . . . 134-137<br />

VE . . . . . . . . . . . 134-137<br />

VHJ . . . . . . . . . . . . . . . . 148<br />

VLP . . . . . . . . . 142-143<br />

VM . . . . . . . . . . 134-137<br />

W<br />

W . . . . . . . . . . . . 198-201<br />

WCB . . . . . . . 178-179<br />

WHC . . . . . . . . . . . . . . 178<br />

WHR . . . . . . . . . . . . . . 178<br />

WMC . . . . . . . . . . . . . . 179<br />

WR . . . . . . . . . . . . . . . . . 177<br />

Z<br />

Z . . . . . . . . . . . . . . . . . . . . 123<br />

ZC . . . . . . . . . . . . . . 92-93<br />

. . . . . . . . . . . . . . . . 133-135<br />

ZE . . . . . . . . . 85, 90-95<br />

ZH . . . . . . . . . . . . . . . . . . . . 93<br />

ZL . . . . . . . . . . . . . . . . . . . . 92<br />

ZP . . . . . . . . . . . . . . . 92-93<br />

ZU4 . . . . . . . . . . . . . 84-89<br />

ZU4T . . . . . . . . . . . . . . 207<br />

. . . . . . . . . . . . . . . 210-213<br />

ZR . . . . . . . . . . . . . . . . . . . . 92<br />

11 . . . . . . . . . . . . . . . . 76-77<br />

25A- . . . . . . . . 196-197<br />

41- . . . . . . . . . . . . . . . . . . . 77<br />

43- . . . . . . . . . . . . 77, 130<br />

45- . . . . . . . . . . . . . . . . . . . 77<br />

50A- . . . . . . . . 196-197<br />

72- . . . . . . . . . . . . . . 76-77<br />

83- . . . . . . . . . . . . 77, 130<br />

75A- . . . . . . . . 196-197<br />

100A- . . . . . . 196-197<br />

160A- . . . . . . 196-197<br />

270A- . . . . . . 196-197<br />

Section Index<br />

<br />

Cyl<strong>in</strong>ders<br />

Page 6-65<br />

Pumps<br />

Page 66-105<br />

System<br />

Components<br />

Page 119-132<br />

Valves<br />

Page 133-139<br />

Presses<br />

Page 140-149<br />

Pullers<br />

Page 150-163<br />

Tools<br />

Page 164-183<br />

Bolt<strong>in</strong>g Tools<br />

Page 184-216<br />

3

The World-<br />

A<br />

complete range of quality high force tools for all <strong>in</strong>dustrial applications, with local<br />

availability and after sale service anywhere <strong>in</strong> the world…. this is what has made Enerpac<br />

the undisputed global market leader <strong>in</strong> high pressure <strong>hydraulics</strong>.<br />

Across every cont<strong>in</strong>ent, Enerpac’s network<br />

of authorized distributors and service<br />

centers can reach even the most remote<br />

locations, supply<strong>in</strong>g and servic<strong>in</strong>g<br />

products that are designed to enhance<br />

productivity and performance, while<br />

mak<strong>in</strong>g the workplace safer.<br />

With over 150 sales specialists and a<br />

network of service and eng<strong>in</strong>eer<strong>in</strong>g<br />

support <strong>in</strong> 17 countries across the globe,<br />

Enerpac has become the product of choice<br />

<strong>in</strong> <strong>in</strong>dustries such as manufactur<strong>in</strong>g,<br />

construction, energy, oil & gas,<br />

shipbuild<strong>in</strong>g, railroads, m<strong>in</strong><strong>in</strong>g,<br />

and metals transformation.<br />

Always at the lead<strong>in</strong>g edge of technology,<br />

Enerpac has cont<strong>in</strong>ued to develop its range<br />

of time and cost-sav<strong>in</strong>gs tools, utiliz<strong>in</strong>g<br />

modern eng<strong>in</strong>eered materials to improve<br />

productivity and m<strong>in</strong>imize operator<br />

fatigue.<br />

Enerpac’s commitment to the cont<strong>in</strong>ued<br />

development of quality high force tools<br />

ensures that the products you purchase are<br />

the best tools <strong>in</strong> the <strong>in</strong>dustry. We will<br />

cont<strong>in</strong>ue to lead the way <strong>in</strong> the<br />

development of quality high force tools for<br />

all <strong>in</strong>dustrial applications.<br />

4

Class Brand<br />

10 Good Reasons to<br />

Work with Enerpac<br />

• Expert Design<br />

• Highly Reliable<br />

• Service Excellence<br />

• Worldwide Experience<br />

• Application Support<br />

• Availability<br />

• Quality<br />

• Value<br />

• Innovative Products<br />

• Systems Solutions<br />

Logistics Excellence<br />

Enerpac’s mission is to<br />

ma<strong>in</strong>ta<strong>in</strong> service<br />

excellence <strong>in</strong> the everchang<strong>in</strong>g<br />

world of<br />

modern distribution.<br />

Provid<strong>in</strong>g our extensive<br />

range of products to our<br />

thousands of distributors<br />

worldwide demands a<br />

logistic expertise only a<br />

market leader can<br />

provide.<br />

Total Quality<br />

Our products are tested<br />

to the most exact<strong>in</strong>g<br />

standards. These high<br />

standards guarantee the<br />

quality, price and<br />

performance<br />

requirements of the<br />

markets we serve around<br />

the globe.<br />

Global Network<br />

Enerpac has an extensive network of authorized distributors and<br />

service centers located <strong>in</strong> more than 90 countries worldwide. You<br />

can rely on Enerpac for the products and technical support you<br />

need to get your job done, anywhere <strong>in</strong> the world.<br />

A Tradition of Innovation<br />

Enerpac has a long history of f<strong>in</strong>d<strong>in</strong>g new solutions to better meet<br />

the challenges of the <strong>in</strong>dustries we serve. We were the first to<br />

develop a composite hand pump and the first to offer a<br />

computerized lift<strong>in</strong>g system. Our latest <strong>in</strong>novations <strong>in</strong>clude a full<br />

range of alum<strong>in</strong>ium cyl<strong>in</strong>ders…. cyl<strong>in</strong>ders with the strength of steel<br />

and the advantages of alum<strong>in</strong>ium and the Z-Class series of power<br />

pumps…. pumps that were designed to run cooler, use less<br />

electricity and are easy to service.<br />

And to support the demands of new technologies <strong>in</strong> the<br />

construction <strong>in</strong>dustry, Enerpac has cont<strong>in</strong>ued to develop Integrated<br />

System capabilities. These capabilities will provide synchronized<br />

movement control for your most challeng<strong>in</strong>g applications.<br />

www.enerpac.com<br />

5

Enerpac Hydraulic Cyl<strong>in</strong>ders<br />

Hydraulic Technology Worldwide<br />

<strong>ENERPAC</strong> hydraulic cyl<strong>in</strong>ders are available <strong>in</strong><br />

hundreds of different configurations. Whatever the<br />

<strong>in</strong>dustrial application... lift<strong>in</strong>g, push<strong>in</strong>g, pull<strong>in</strong>g, bend<strong>in</strong>g,<br />

hold<strong>in</strong>g... whatever the force capacity, stroke length, or<br />

size restrictions... s<strong>in</strong>gle- or double-act<strong>in</strong>g, solid or hollow<br />

plunger, you can be sure that Enerpac has the cyl<strong>in</strong>der to<br />

J<br />

Z1<br />

Z<br />

suit your high force application.<br />

Enerpac cyl<strong>in</strong>ders fully comply to ASME B30.1.<br />

Hardened Saddle<br />

prevents plunger from<br />

mushroom<strong>in</strong>g and jamm<strong>in</strong>g<br />

<strong>in</strong> the top bear<strong>in</strong>g. Snap-<strong>in</strong><br />

design.<br />

Plunger Wiper<br />

reduces contam<strong>in</strong>ation,<br />

extend<strong>in</strong>g cyl<strong>in</strong>der life.<br />

Golden R<strong>in</strong>g<br />

absorbs eccentric load<strong>in</strong>g<br />

without gall<strong>in</strong>g cyl<strong>in</strong>der parts.<br />

A<br />

F<br />

B<br />

K<br />

3/8"-<br />

18NPTF<br />

Golden R<strong>in</strong>g Design<br />

The exclusive Golden<br />

R<strong>in</strong>g Design is a unique bear<strong>in</strong>g design<br />

which absorbs eccentric load stresses to<br />

protect your cyl<strong>in</strong>der aga<strong>in</strong>st abrasion,<br />

over-extend<strong>in</strong>g or plunger blow-outs and<br />

jamm<strong>in</strong>g or top-end mushroom<strong>in</strong>g.<br />

A<br />

As a result, Golden R<strong>in</strong>g cyl<strong>in</strong>ders<br />

provide long, trouble-free operation.<br />

E<br />

N<br />

P<br />

B<br />

H<br />

X<br />

W<br />

Plated Plunger<br />

resists wear and rust.<br />

F<br />

K<br />

Golden R<strong>in</strong>g<br />

absorbs eccentric load<strong>in</strong>g<br />

without gall<strong>in</strong>g cyl<strong>in</strong>der parts.<br />

F1<br />

Q<br />

Plunger Return Spr<strong>in</strong>g<br />

enables fast plunger<br />

retraction on s<strong>in</strong>gle-act<strong>in</strong>g<br />

cyl<strong>in</strong>ders.<br />

Cyl<strong>in</strong>der-Pump Sets<br />

For your order<strong>in</strong>g convenience<br />

cyl<strong>in</strong>ders are available <strong>in</strong> sets<br />

(cyl<strong>in</strong>der, gauge, couplers,<br />

hose and pump).<br />

Page:<br />

64<br />

Note: The cut-away draw<strong>in</strong>g is representative of typical cyl<strong>in</strong>der construction, and may not represent all cyl<strong>in</strong>ders <strong>in</strong> this section.<br />

6

Cyl<strong>in</strong>der Section Overview<br />

Capacity 1)<br />

ton (kN)<br />

5-95<br />

(45-933)<br />

20-150<br />

(229-1589)<br />

5-520<br />

(45-5114)<br />

2,5-50<br />

(24-505)<br />

Stroke Range<br />

(mm)<br />

16-362 RC<br />

50-250<br />

6-62<br />

16-362<br />

Cyl<strong>in</strong>der type and functions Series Page<br />

General Purpose Cyl<strong>in</strong>ders,<br />

S<strong>in</strong>gle-Act<strong>in</strong>g,<br />

(<strong>in</strong>cl. accessories)<br />

Alum<strong>in</strong>ium Cyl<strong>in</strong>ders,<br />

S<strong>in</strong>gle-Act<strong>in</strong>g, Lock Nut,<br />

Hollow Plunger, Double-Act<strong>in</strong>g<br />

Pancake and Low Height<br />

Cyl<strong>in</strong>ders, S<strong>in</strong>gle-Act<strong>in</strong>g<br />

Pull Cyl<strong>in</strong>ders,<br />

S<strong>in</strong>gle-Act<strong>in</strong>g<br />

RAC<br />

RACL<br />

RACH<br />

RAR<br />

CLP<br />

RSM<br />

RCS<br />

BRC<br />

BRP<br />

8 <br />

13 <br />

22 <br />

24 <br />

26 <br />

13-145<br />

(125-1429)<br />

8-258<br />

Hollow Plunger Cyl<strong>in</strong>ders<br />

S<strong>in</strong>gle- and Double-Act<strong>in</strong>g<br />

RCH<br />

RRH<br />

28 <br />

30 <br />

4-23<br />

(35-222)<br />

28-260<br />

Precision Production Cyl<strong>in</strong>ders,<br />

Double-Act<strong>in</strong>g<br />

(<strong>in</strong>cl. mount<strong>in</strong>g attachments)<br />

BRD<br />

32 <br />

10-520<br />

(101-5108)<br />

16-1219<br />

Long Stroke Cyl<strong>in</strong>ders,<br />

Double-Act<strong>in</strong>g<br />

RR<br />

34 <br />

50-1000<br />

(496-10260)<br />

50-300<br />

High Tonnage Cyl<strong>in</strong>ders,<br />

with <strong>in</strong>tegral stop r<strong>in</strong>g<br />

S<strong>in</strong>gle-Act<strong>in</strong>g,<br />

CLSG<br />

38 <br />

50-1000<br />

(496-10260)<br />

50-300<br />

High Tonnage Cyl<strong>in</strong>ders,<br />

with reduced collapsed height<br />

S<strong>in</strong>gle-Act<strong>in</strong>g,<br />

CLS<br />

42 <br />

50-1000<br />

(496-10265)<br />

50-300<br />

High Tonnage Cyl<strong>in</strong>ders,<br />

Double-Act<strong>in</strong>g<br />

CLRG<br />

46 <br />

50-1000<br />

(496-10260)<br />

10-1000<br />

(101-10260)<br />

1,4-150<br />

(13-1335)<br />

10-25<br />

(101-232)<br />

50-300<br />

5000 max.<br />

76-508<br />

54-158<br />

High Tonnage Cyl<strong>in</strong>ders,<br />

S<strong>in</strong>gle-Act<strong>in</strong>g with Mechanical<br />

Lock Nut, Corrosion Protected<br />

Synchronous Lift Systems<br />

Stage Lift Systems<br />

Synchronous Hoist<strong>in</strong>g Systems<br />

Alum<strong>in</strong>ium and Steel Jacks<br />

Bottle Jacks<br />

High Temperature and Corrosion<br />

Resistant Cyl<strong>in</strong>ders, Hand Pumps<br />

and Valves<br />

CLL<br />

SLS<br />

BLS, SL<br />

SHS<br />

JHA, JH<br />

EBJ<br />

RC<br />

P, V<br />

50 <br />

54 <br />

58 <br />

60 <br />

61 <br />

62 <br />

1)<br />

All ton values specified <strong>in</strong> this catalog are metric ton and are for cyl<strong>in</strong>der class identification only. Please refer to the kN data for calculations.<br />

www.enerpac.com<br />

7

RC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g Cyl<strong>in</strong>ders<br />

Hydraulic Technology Worldwide<br />

From left to right: RC-506, RC-50, RC-2510, RC-154, RC-10010, RC-55, RC-1010<br />

The Industry<br />

Standard General<br />

Purpose Cyl<strong>in</strong>der<br />

Saddles<br />

All RC cyl<strong>in</strong>ders are<br />

equipped with hardened<br />

removable grooved saddles.<br />

For tilt and flat saddles, see<br />

the RC-Series accessory page.<br />

Page:<br />

12<br />

• Collar threads, plunger threads and base mount<strong>in</strong>g<br />

holes enable easy fixtur<strong>in</strong>g (on most models)<br />

• Designed for use <strong>in</strong> all positions<br />

• Removable strap handles for unobstructed fixtur<strong>in</strong>g<br />

(RC-5013, RC-7513 and both 95 ton models)<br />

• High strength alloy steel for durability<br />

• Heavy duty return spr<strong>in</strong>gs<br />

• Baked enamel f<strong>in</strong>ish for <strong>in</strong>creased corrosion resistance<br />

• CR-400 coupler and dust cap <strong>in</strong>cluded on all models<br />

• Plunger wiper reduces contam<strong>in</strong>ation, extend<strong>in</strong>g<br />

cyl<strong>in</strong>der life<br />

Base Plates<br />

To ensure the stability of<br />

cyl<strong>in</strong>ders for lift<strong>in</strong>g<br />

applications, base plates are<br />

available for 10, 25 and 50<br />

ton RC cyl<strong>in</strong>ders.<br />

Page:<br />

12<br />

Specialty Attachments<br />

For solv<strong>in</strong>g all k<strong>in</strong>ds of<br />

application problems,<br />

specialty attachments are<br />

available for 5, 10 and 25 ton<br />

RC cyl<strong>in</strong>ders.<br />

Page:<br />

168<br />

Stage lift<strong>in</strong>g set up <strong>in</strong> Greece, where assembled pipes, 25 meters <strong>in</strong> length,<br />

were stage lifted with six RC-2514 cyl<strong>in</strong>ders.<br />

RC cyl<strong>in</strong>der mount<strong>in</strong>g attachments greatly<br />

extend the application possibilities (available<br />

for 5, 10,15 and 25 ton cyl<strong>in</strong>ders).<br />

8<br />

www.enerpac.com

S<strong>in</strong>gle-Act<strong>in</strong>g, General Purpose Cyl<strong>in</strong>ders<br />

Th<strong>in</strong>k Safety<br />

Manufacturer’s rat<strong>in</strong>g of<br />

load and stroke are<br />

maximum safe limits.<br />

Good practice encourages us<strong>in</strong>g only<br />

80% of these rat<strong>in</strong>gs.<br />

RC<br />

Series<br />

QUICK SELECTION CHART<br />

For complete technical <strong>in</strong>formation see next page.<br />

Cyl<strong>in</strong>der<br />

Capacity<br />

ton<br />

(kN)<br />

5<br />

(45)<br />

10<br />

(101)<br />

15<br />

(142)<br />

25<br />

(232)<br />

30(295)<br />

50<br />

(498)<br />

75<br />

(718)<br />

95<br />

(933)<br />

Stroke<br />

(mm)<br />

16<br />

25<br />

76<br />

127<br />

177<br />

232<br />

26<br />

54<br />

105<br />

156<br />

203<br />

257<br />

304<br />

356<br />

25<br />

51<br />

101<br />

152<br />

203<br />

254<br />

305<br />

356<br />

26<br />

50<br />

102<br />

158<br />

210<br />

261<br />

311<br />

362<br />

209<br />

51<br />

101<br />

159<br />

337<br />

156<br />

333<br />

168<br />

260<br />

Model<br />

Number<br />

RC-50**<br />

RC-51<br />

RC-53<br />

RC-55*<br />

RC-57<br />

RC-59<br />

RC-101<br />

RC-102*<br />

RC-104<br />

RC-106*<br />

RC-108<br />

RC-1010*<br />

RC-1012<br />

RC-1014<br />

RC-151<br />

RC-152<br />

RC-154*<br />

RC-156*<br />

RC-158<br />

RC-1510<br />

RC-1512<br />

RC-1514<br />

RC-251<br />

RC-252*<br />

RC-254*<br />

RC-256*<br />

RC-258<br />

RC-2510<br />

RC-2512<br />

RC-2514*<br />

RC-308<br />

RC-502<br />

RC-504<br />

RC-506*<br />

RC-5013<br />

RC-756<br />

RC-7513<br />

RC-1006*<br />

RC-10010<br />

Cyl<strong>in</strong>der<br />

Effective<br />

Area<br />

(cm 2 )<br />

6,5<br />

6,5<br />

6,5<br />

6,5<br />

6,5<br />

6,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

42,1<br />

71,2<br />

71,2<br />

71,2<br />

71,2<br />

102,6<br />

102,6<br />

133,3<br />

133,3<br />

Oil<br />

Capacity<br />

(cm 3 )<br />

10<br />

16<br />

50<br />

83<br />

115<br />

151<br />

38<br />

78<br />

152<br />

226<br />

294<br />

373<br />

441<br />

516<br />

51<br />

104<br />

205<br />

308<br />

411<br />

516<br />

619<br />

723<br />

86<br />

166<br />

339<br />

525<br />

697<br />

867<br />

1033<br />

1202<br />

880<br />

362<br />

719<br />

1131<br />

2399<br />

1601<br />

3417<br />

2239<br />

3466<br />

Collapsed<br />

Height<br />

(mm)<br />

41<br />

110<br />

165<br />

215<br />

273<br />

323<br />

89<br />

121<br />

171<br />

247<br />

298<br />

349<br />

400<br />

450<br />

124<br />

149<br />

200<br />

271<br />

322<br />

373<br />

423<br />

474<br />

139<br />

165<br />

215<br />

273<br />

323<br />

374<br />

425<br />

476<br />

387<br />

176<br />

227<br />

282<br />

460<br />

285<br />

492<br />

357<br />

449<br />

* Available as set, see note on this page.<br />

** RC-50 cyl<strong>in</strong>der has a non removable grooved saddle and no collar thread.<br />

(kg)<br />

1,0<br />

1,0<br />

1,5<br />

1,9<br />

2,4<br />

2,8<br />

1,8<br />

2,3<br />

3,3<br />

4,4<br />

5,4<br />

6,4<br />

6,8<br />

8,2<br />

3,3<br />

4,1<br />

5,0<br />

6,8<br />

8,2<br />

9,5<br />

10,9<br />

11,8<br />

5,9<br />

6,4<br />

8,2<br />

10,0<br />

12,2<br />

14,1<br />

16,3<br />

17,7<br />

18,1<br />

15,0<br />

19,1<br />

23,1<br />

37,6<br />

29,5<br />

59,0<br />

59,0<br />

72,6<br />

Capacity:<br />

5-95 ton<br />

Stroke:<br />

16-362 mm<br />

Maximum Operat<strong>in</strong>g Pressure:<br />

700 bar<br />

choice.<br />

Ultra-Lightweight<br />

Alum<strong>in</strong>ium Cyl<strong>in</strong>ders<br />

If you need a higher cyl<strong>in</strong>der<br />

capacity-to-weight-ratio the<br />

RAC-Series are the perfect<br />

Page:<br />

13<br />

High Temperature and<br />

Corrosion Resistant<br />

Cyl<strong>in</strong>ders<br />

Some cyl<strong>in</strong>ders are available<br />

with Viton seals and nickel<br />

plat<strong>in</strong>g for use <strong>in</strong> extreme environments.<br />

Page:<br />

62<br />

Gauges<br />

M<strong>in</strong>imize the risk of<br />

overload<strong>in</strong>g and ensure long,<br />

dependable service from<br />

your equipment. Refer to the<br />

System Components Section for a full<br />

range of gauges.<br />

Page:<br />

119<br />

Pump and Cyl<strong>in</strong>der Sets<br />

All cyl<strong>in</strong>ders marked<br />

with an<br />

*<br />

are available<br />

as sets (cyl<strong>in</strong>der, gauge,<br />

couplers, hose and pump) for your<br />

order<strong>in</strong>g convenience.<br />

Page:<br />

64<br />

9

RC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g Cyl<strong>in</strong>ders<br />

Hydraulic Technology Worldwide<br />

V<br />

M<br />

D<br />

L<br />

U<br />

D1<br />

Pump and Cyl<strong>in</strong>der Sets<br />

All cyl<strong>in</strong>ders marked<br />

with an<br />

*<br />

are available<br />

as sets (cyl<strong>in</strong>der, gauge,<br />

couplers, hose and pump) for your<br />

order<strong>in</strong>g convenience.<br />

Page:<br />

64<br />

3/8"-18NPTF<br />

F<br />

For full features see previous page.<br />

H<br />

RC-50<br />

RC-101 only<br />

(U1 = 19 mm)<br />

H<br />

P<br />

P<br />

X<br />

3/8"-18NPTF<br />

RC-51 - RC-7513<br />

RC-1006, RC-10010<br />

10<br />

E<br />

U1<br />

J<br />

O<br />

F<br />

W<br />

E<br />

V<br />

O<br />

A<br />

K<br />

A<br />

Z<br />

U<br />

B<br />

B<br />

D<br />

Cyl<strong>in</strong>der<br />

Capacity<br />

ton<br />

(kN)<br />

5<br />

(45)<br />

10<br />

(101)<br />

15<br />

(142)<br />

25<br />

(232)<br />

30(295)<br />

50<br />

(498)<br />

75<br />

(718)<br />

95<br />

(933)<br />

Stroke<br />

(mm)<br />

16<br />

25<br />

76<br />

127<br />

177<br />

232<br />

26<br />

54<br />

105<br />

156<br />

203<br />

257<br />

304<br />

356<br />

25<br />

51<br />

101<br />

152<br />

203<br />

254<br />

305<br />

356<br />

26<br />

50<br />

102<br />

158<br />

210<br />

261<br />

311<br />

362<br />

209<br />

51<br />

101<br />

159<br />

337<br />

156<br />

333<br />

168<br />

260<br />

Model<br />

Number<br />

RC-50**<br />

RC-51<br />

RC-53<br />

RC-55*<br />

RC-57<br />

RC-59<br />

RC-101<br />

RC-102*<br />

RC-104<br />

RC-106*<br />

RC-108<br />

RC-1010*<br />

RC-1012<br />

RC-1014<br />

RC-151<br />

RC-152<br />

RC-154*<br />

RC-156*<br />

RC-158<br />

RC-1510<br />

RC-1512<br />

RC-1514<br />

RC-251<br />

RC-252*<br />

RC-254*<br />

RC-256*<br />

RC-258<br />

RC-2510<br />

RC-2512<br />

RC-2514*<br />

RC-308<br />

RC-502<br />

RC-504<br />

RC-506*<br />

RC-5013<br />

RC-756<br />

RC-7513<br />

RC-1006*<br />

RC-10010<br />

Cyl<strong>in</strong>der<br />

Effective<br />

Area<br />

(cm 2 )<br />

6,5<br />

6,5<br />

6,5<br />

6,5<br />

6,5<br />

6,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

14,5<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

20,3<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

33,2<br />

42,1<br />

71,2<br />

71,2<br />

71,2<br />

71,2<br />

102,6<br />

102,6<br />

133,3<br />

133,3<br />

Oil<br />

Capacity<br />

(cm 3 )<br />

10<br />

16<br />

50<br />

83<br />

115<br />

151<br />

38<br />

78<br />

152<br />

226<br />

294<br />

373<br />

441<br />

516<br />

51<br />

104<br />

205<br />

308<br />

411<br />

516<br />

619<br />

723<br />

86<br />

166<br />

339<br />

525<br />

697<br />

867<br />

1033<br />

1202<br />

880<br />

362<br />

719<br />

1131<br />

2399<br />

1601<br />

3417<br />

2239<br />

3466<br />

Collapsed<br />

Height<br />

A<br />

(mm)<br />

41<br />

110<br />

165<br />

215<br />

273<br />

323<br />

89<br />

121<br />

171<br />

247<br />

298<br />

349<br />

400<br />

450<br />

124<br />

149<br />

200<br />

271<br />

322<br />

373<br />

423<br />

474<br />

139<br />

165<br />

215<br />

273<br />

323<br />

374<br />

425<br />

476<br />

387<br />

176<br />

227<br />

282<br />

460<br />

285<br />

492<br />

357<br />

449<br />

Extended<br />

Height<br />

B<br />

(mm)<br />

57<br />

135<br />

241<br />

342<br />

450<br />

555<br />

115<br />

175<br />

276<br />

403<br />

501<br />

606<br />

704<br />

806<br />

149<br />

200<br />

301<br />

423<br />

525<br />

627<br />

728<br />

830<br />

165<br />

215<br />

317<br />

431<br />

533<br />

635<br />

736<br />

838<br />

596<br />

227<br />

328<br />

441<br />

797<br />

441<br />

825<br />

525<br />

709<br />

* Available as set, see note on this page.<br />

** RC-50 cyl<strong>in</strong>der has a non removable grooved saddle and no collar thread.<br />

*** D1 = 41 mm, L = 20 mm, M = 25 mm.<br />

Outside<br />

Dia.<br />

D<br />

(mm)<br />

58***<br />

38<br />

38<br />

38<br />

38<br />

38<br />

57<br />

57<br />

57<br />

57<br />

57<br />

57<br />

57<br />

57<br />

69<br />

69<br />

69<br />

69<br />

69<br />

69<br />

69<br />

69<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

85<br />

101<br />

127<br />

127<br />

127<br />

127<br />

146<br />

146<br />

177<br />

177

S<strong>in</strong>gle-Act<strong>in</strong>g, General Purpose Cyl<strong>in</strong>ders<br />

Speed Chart<br />

See the Enerpac Cyl<strong>in</strong>der<br />

Speed Chart <strong>in</strong> our<br />

‘Yellow Pages’ to<br />

determ<strong>in</strong>e your approximate<br />

cyl<strong>in</strong>der speed.<br />

Page:<br />

117<br />

Capacity:<br />

5-95 ton<br />

Stroke:<br />

16-362 mm<br />

Maximum Operat<strong>in</strong>g Pressure:<br />

700 bar<br />

RC<br />

Series<br />

Cyl<strong>in</strong>der<br />

Bore<br />

Dia.<br />

E<br />

(mm)<br />

Plunger<br />

Dia.<br />

F<br />

(mm)<br />

Base to<br />

Adv.<br />

Port<br />

H<br />

(mm)<br />

Saddle<br />

Dia.<br />

J<br />

(mm)<br />

Saddle<br />

Protr.<br />

from Plgr.<br />

K<br />

(mm)<br />

Plunger<br />

Internal<br />

Thread<br />

O<br />

Plunger<br />

Thread<br />

Length<br />

P<br />

(mm)<br />

Bolt<br />

Circle<br />

U<br />

(mm)<br />

Base Mount<strong>in</strong>g Holes<br />

Thread<br />

V<br />

Thd.<br />

Depth<br />

Z<br />

(mm)<br />

Collar<br />

Thread<br />

W<br />

(kg)<br />

Model<br />

Number<br />

28,7<br />

28,7<br />

28,7<br />

28,7<br />

28,7<br />

28,7<br />

42,9<br />

42,9<br />

42,9<br />

42,9<br />

42,9<br />

42,9<br />

42,9<br />

42,9<br />

50,8<br />

50,8<br />

50,8<br />

50,8<br />

50,8<br />

50,8<br />

50,8<br />

50,8<br />

65,0<br />

65,0<br />

65,0<br />

65,0<br />

65,0<br />

65,0<br />

65,0<br />

65,0<br />

73,2<br />

95,2<br />

95,2<br />

95,2<br />

95,2<br />

114,3<br />

114,3<br />

130,3<br />

130,3<br />

25,4<br />

25,4<br />

25,4<br />

25,4<br />

25,4<br />

25,4<br />

38,1<br />

38,1<br />

38,1<br />

38,1<br />

38,1<br />

38,1<br />

38,1<br />

38,1<br />

41,4<br />

41,4<br />

41,4<br />

41,4<br />

41,4<br />

41,4<br />

41,4<br />

41,4<br />

57,2<br />

57,2<br />

57,2<br />

57,2<br />

57,2<br />

57,2<br />

57,2<br />

57,2<br />

57,2<br />

79,5<br />

79,5<br />

79,5<br />

79,5<br />

95,2<br />

95,2<br />

104,9<br />

104,9<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

57<br />

33<br />

33<br />

35<br />

35<br />

30<br />

30<br />

41<br />

41<br />

**<br />

25<br />

25<br />

25<br />

25<br />

25<br />

–<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

35<br />

38<br />

38<br />

38<br />

38<br />

38<br />

38<br />

38<br />

38<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

50<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

71<br />

**<br />

6<br />

6<br />

6<br />

6<br />

6<br />

–<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

9<br />

9<br />

9<br />

9<br />

9<br />

9<br />

9<br />

9<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

2<br />

2<br />

2<br />

2<br />

5<br />

5<br />

2<br />

2<br />

**<br />

3<br />

/4"- 16<br />

3<br />

/4" - 16<br />

3<br />

/4" - 16<br />

3<br />

/4" - 16<br />

3<br />

/4" - 16<br />

#10 - 24UN<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1" - 8<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

**<br />

14<br />

14<br />

14<br />

16<br />

16<br />

6<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

19<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

25<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

28<br />

25<br />

25<br />

25<br />

25<br />

25<br />

39<br />

39<br />

39<br />

39<br />

39<br />

39<br />

39<br />

39<br />

47<br />

47<br />

47<br />

47<br />

47<br />

47<br />

47<br />

47<br />

58<br />

58<br />

58<br />

58<br />

58<br />

58<br />

58<br />

58<br />

—<br />

95<br />

95<br />

95<br />

95<br />

—<br />

—<br />

139<br />

139<br />

5,6 mm<br />

1<br />

/4"- 20UN<br />

1<br />

/4"- 20UN<br />

1<br />

/4"- 20UN<br />

1<br />

/4"- 20UN<br />

1<br />

/4"- 20UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

5<br />

/16"- 18UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

3<br />

/8"- 16UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

—<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

1<br />

/2"- 13UN<br />

—<br />

—<br />

3<br />

/4"- 10UN<br />

3<br />

/4"- 10UN<br />

—<br />

14<br />

14<br />

14<br />

14<br />

14<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

19<br />

—<br />

19<br />

19<br />

19<br />

19<br />

—<br />

—<br />

25<br />

25<br />

—<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

1 1 /2" - 16<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 1 /4" - 14<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

2 3 /4" - 16<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

3 5 /16" - 12<br />

5" - 12<br />

5" - 12<br />

5" - 12<br />

5" - 12<br />

5 3 /4" - 12<br />

5 3 /4" - 12<br />

6 7 /8"- 12<br />

6 7 /8" - 12<br />

Collar<br />

Thread<br />

Length<br />

X<br />

(mm)<br />

—<br />

28<br />

28<br />

28<br />

28<br />

28<br />

26<br />

28<br />

26<br />

28<br />

26<br />

28<br />

26<br />

26<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

49<br />

49<br />

49<br />

49<br />

49<br />

49<br />

49<br />

49<br />

49<br />

55<br />

55<br />

55<br />

55<br />

44<br />

44<br />

44<br />

44<br />

1,0<br />

1,0<br />

1,5<br />

1,9<br />

2,4<br />

2,8<br />

1,8<br />

2,3<br />

3,3<br />

4,4<br />

5,4<br />

6,4<br />

6,8<br />

8,2<br />

3,3<br />

4,1<br />

5,0<br />

6,8<br />

8,2<br />

9,5<br />

10,9<br />

11,8<br />

5,9<br />

6,4<br />

8,2<br />

10,0<br />

12,2<br />

14,1<br />

16,3<br />

17,7<br />

18,1<br />

15,0<br />

19,1<br />

23,1<br />

37,6<br />

29,5<br />

59,0<br />

59,0<br />

72,6<br />

RC-50**<br />

RC-51<br />

RC-53<br />

RC-55*<br />

RC-57<br />

RC-59<br />

RC-101<br />

RC-102*<br />

RC-104<br />

RC-106*<br />

RC-108<br />

RC-1010*<br />

RC-1012<br />

RC-1014<br />

RC-151<br />

RC-152<br />

RC-154*<br />

RC-156*<br />

RC-158<br />

RC-1510<br />

RC-1512<br />

RC-1514<br />

RC-251<br />

RC-252*<br />

RC-254*<br />

RC-256*<br />

RC-258<br />

RC-2510<br />

RC-2512<br />

RC-2514*<br />

RC-308<br />

RC-502<br />

RC-504<br />

RC-506*<br />

RC-5013<br />

RC-756<br />

RC-7513<br />

RC-1006*<br />

RC-10010<br />

www.enerpac.com<br />

11

RC-Series, Cyl<strong>in</strong>der Accessories<br />

Hydraulic Technology Worldwide<br />

SELECTION CHART<br />

For use<br />

with<br />

Cyl<strong>in</strong>der<br />

Capacity<br />

Saddles<br />

Base<br />

Plate<br />

Mount<strong>in</strong>g<br />

Block<br />

Clevis Eyes<br />

Flat Grooved 1) Tilt Base 4) Plunger<br />

ton (kN)<br />

5 (45)<br />

10 (101)<br />

15 (142)<br />

25 (232)<br />

30 (295)<br />

50 (498)<br />

75 (718)<br />

95 (933)<br />

A-53F 2)<br />

A-12 5) , A-102F 3)<br />

–<br />

A-29 5)<br />

A-29 5)<br />

–<br />

–<br />

–<br />

A-53G 2)<br />

A-102G 3)<br />

A-152G<br />

A-252G<br />

A-252G<br />

–<br />

–<br />

–<br />

–<br />

CAT-10 3)<br />

CAT-10<br />

CAT-50<br />

CAT-50<br />

CAT-100<br />

CAT-100<br />

CAT-100<br />

1)<br />

Standard on 5-30 ton RC-cyl<strong>in</strong>ders<br />

2)<br />

Except RC-50<br />

3)<br />

Except RC-101<br />

4)<br />

Mount<strong>in</strong>g screws are <strong>in</strong>cluded.<br />

5)<br />

Used with Bender Sets.<br />

–<br />

JBI-10<br />

–<br />

JBI-25<br />

–<br />

JBI-50<br />

–<br />

–<br />

RB-5 2) ,<br />

AW-51 2) , AW-53 2)<br />

RB-10, AW-102<br />

RB-15<br />

RB-25<br />

RB-25<br />

–<br />

–<br />

–<br />

REB-5 2)<br />

REB-10<br />

REB-15<br />

REB-25<br />

–<br />

–<br />

–<br />

–<br />

REP-5 2)<br />

REP-10 3)<br />

REP-10<br />

REP-25<br />

REP-25<br />

–<br />

–<br />

–<br />

DIMENSION CHARTS<br />

Model Nr.<br />

A-53F<br />

A-102F<br />

A-12<br />

A-29<br />

A-53G<br />

A-102G<br />

A-152G<br />

A-252G<br />

Saddle Dimensions (mm) A-53F, A Model Nr. Tilt Saddle Dimensions (mm)<br />

A<br />

B<br />

C<br />

A-102F B<br />

A<br />

B C<br />

Flat<br />

C<br />

Tilt<br />

25<br />

6<br />

17 A-12,<br />

A CAT-10 35 15 22<br />

35<br />

6<br />

22 A-29 B<br />

CAT-50 50 23 35<br />

51 48 1''-8UNC<br />

51<br />

1 1 /2''-16UNC<br />

C<br />

25<br />

35<br />

38<br />

50<br />

48<br />

Grooved<br />

6<br />

6<br />

9<br />

9<br />

17<br />

22<br />

22<br />

35<br />

B<br />

A<br />

C<br />

CAT-100<br />

71<br />

Tilt<br />

24<br />

–<br />

B<br />

0-5°<br />

C<br />

A<br />

B 0-5°<br />

A<br />

Model Nr.<br />

JBI-10<br />

JBI-25<br />

JBI-50<br />

A<br />

228<br />

279<br />

304<br />

Base Plate Dimensions (mm)<br />

B C D E<br />

228<br />

279<br />

15<br />

135<br />

140<br />

95<br />

58<br />

86<br />

131<br />

20<br />

26<br />

31<br />

A<br />

E<br />

B<br />

D<br />

C<br />

JBI-10, - 25<br />

B<br />

E<br />

D<br />

A<br />

JBI-50<br />

C<br />

Model Nr.<br />

RB-5<br />

AW-51<br />

AW-53<br />

RB-10<br />

AW-102<br />

RB-15<br />

RB-25<br />

Mount<strong>in</strong>g Block Dimensions (mm)<br />

A B C D E F G H<br />

1 1 /2"- 16<br />

1 1 /2"- 16<br />

1 1 /2"- 16<br />

2 1 /4"- 14<br />

2 1 /4"- 14<br />

2 3 /4"- 16<br />

3 5 /16"- 12<br />

88<br />

70<br />

72<br />

114<br />

100<br />

101<br />

127<br />

76<br />

59<br />

7<br />

88<br />

82<br />

114<br />

165<br />

–<br />

10<br />

7<br />

–<br />

16<br />

–<br />

–<br />

25<br />

24<br />

19<br />

25<br />

30<br />

38<br />

50<br />

–<br />

54<br />

57<br />

–<br />

76<br />

–<br />

–<br />

–<br />

1<br />

/4"- 20<br />

1<br />

/4"- 20<br />

–<br />

7<br />

/16"- 20<br />

–<br />

–<br />

–<br />

41<br />

10<br />

–<br />

58<br />

–<br />

–<br />

B<br />

E<br />

C<br />

A<br />

RB-5, -10<br />

RB-15, -25<br />

B<br />

D<br />

E<br />

F<br />

G<br />

D<br />

AW-51<br />

H<br />

A<br />

C<br />

E<br />

C<br />

D<br />

G<br />

H<br />

A<br />

B<br />

AW-53<br />

F<br />

G<br />

B<br />

E<br />

I<br />

F<br />

D<br />

H<br />

A<br />

C<br />

AW-102 (I=4,8)<br />

Type<br />

Base 4)<br />

Plunger<br />

Model Nr.<br />

REB-5<br />

REB-10<br />

REB-15<br />

REB-25<br />

REP-5<br />

REP-10<br />

REP-25<br />

44<br />

63<br />

76<br />

95<br />

28<br />

42<br />

57<br />

Clevis Eye Dimensions (mm)<br />

A B C D E F<br />

47<br />

66<br />

66<br />

79<br />

41<br />

61<br />

74<br />

14<br />

25<br />

25<br />

38<br />

14<br />

25<br />

38<br />

16<br />

22<br />

22<br />

31<br />

16<br />

22<br />

31<br />

16<br />

25<br />

25<br />

31<br />

16<br />

25<br />

31<br />

25<br />

35<br />

35<br />

41<br />

19<br />

28<br />

35<br />

B<br />

E F<br />

B<br />

F E<br />

C D D<br />

A<br />

REB<br />

REP<br />

C<br />

A<br />

See our<br />

‘Yellow<br />

Pages’<br />

for application<br />

<strong>in</strong>formation<br />

on these<br />

accessories.<br />

12

The Enerpac Lightweight Alum<strong>in</strong>ium Cyl<strong>in</strong>ders<br />

From left to right: RAC-5010, RACL-5010, RAC-1504, RAR-5010<br />

RAC, RACL, RACH, RAR<br />

Series<br />

Capacity:<br />

20-150 ton @ 700 bar<br />

Stroke:<br />

50-250 mm<br />

• Lightweight, easy to carry and position to allow a higher<br />

cyl<strong>in</strong>der capacity-to-weight-ratio<br />

• Non-corrosive by design, alum<strong>in</strong>ium has always been a<br />

good material for use <strong>in</strong> many caustic environments<br />

• Composite Bear<strong>in</strong>gs on all mov<strong>in</strong>g surfaces guarantee NO<br />

metal-to-metal contact, to resist side loads and <strong>in</strong>crease<br />

cyl<strong>in</strong>der life<br />

Removable Hardened Saddle, protects plunger from<br />

be<strong>in</strong>g damaged by abrasive surface contact.<br />

Stop R<strong>in</strong>g on all models absorbs eccentric load<strong>in</strong>g<br />

and prevents plunger over-extension.<br />

Composite Bear<strong>in</strong>g material to prevent metal to<br />

metal contact, reduc<strong>in</strong>g side-load issues and<br />

<strong>in</strong>creas<strong>in</strong>g life.<br />

Hard-coated Plunger and Base resist wear and<br />

prevent gall<strong>in</strong>g.<br />

7075-T6 Alum<strong>in</strong>ium Alloy Components for<br />

maximum strength and m<strong>in</strong>imum weight.<br />

Plunger Return Spr<strong>in</strong>g on all s<strong>in</strong>gle-act<strong>in</strong>g models<br />

for prompt cyl<strong>in</strong>der return.<br />

Composite Bear<strong>in</strong>g material to prevent metal to<br />

metal contact, reduc<strong>in</strong>g side-load issues and<br />

<strong>in</strong>creas<strong>in</strong>g life.<br />

Steel Base Plate protects cyl<strong>in</strong>der base from<br />

abrasive surfaces and load-<strong>in</strong>duced damage.<br />

Alum<strong>in</strong>ium versus Steel<br />

Alum<strong>in</strong>ium cyl<strong>in</strong>ders, while<br />

offer<strong>in</strong>g the most lightweight<br />

solution, also have some unique<br />

limitations due to material properties. It<br />

differs from steel <strong>in</strong> that it has a lower<br />

f<strong>in</strong>ite fatigue life. Alum<strong>in</strong>ium cyl<strong>in</strong>ders<br />

should NOT be used <strong>in</strong> high-cycle<br />

applications such as production.<br />

These cyl<strong>in</strong>ders are designed to provide<br />

5000 cycles at their recommended<br />

pressure. This limit should not be<br />

exceeded. In normal lift<strong>in</strong>g and many<br />

ma<strong>in</strong>tenance applications, this should<br />

provide a lifetime of use.<br />

hold<strong>in</strong>g.<br />

RAC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g,<br />

Cyl<strong>in</strong>ders<br />

The lightweight general<br />

purpose spr<strong>in</strong>g return<br />

alum<strong>in</strong>ium cyl<strong>in</strong>ders.<br />

Page:<br />

RACL-Series, Lock Nut,<br />

Cyl<strong>in</strong>ders<br />

The lightweight spr<strong>in</strong>g return<br />

alum<strong>in</strong>ium cyl<strong>in</strong>ders with lock<br />

nut for mechanical load<br />

Page:<br />

RACH-Series, Hollow<br />

Plunger Cyl<strong>in</strong>ders<br />

For both push and pull forces<br />

with a s<strong>in</strong>gle-act<strong>in</strong>g cyl<strong>in</strong>der.<br />

Page:<br />

RAR-Series, Double-Act<strong>in</strong>g<br />

Cyl<strong>in</strong>ders<br />

The lightweight alum<strong>in</strong>ium<br />

cyl<strong>in</strong>ders for lift<strong>in</strong>g and<br />

lower<strong>in</strong>g.<br />

Page:<br />

14<br />

16<br />

18<br />

20<br />

www.enerpac.com<br />

13

RAC-Series, S<strong>in</strong>gle-Act<strong>in</strong>g Alum<strong>in</strong>ium Cyl<strong>in</strong>ders<br />

Hydraulic Technology Worldwide<br />

Shown from left to right: RAC-5010, RAC-15010, RAC-304, RAC-208<br />

Lightweight for<br />

Maximum<br />

Portability<br />

Saddles<br />

All RAC-cyl<strong>in</strong>ders are<br />

equipped with bolt-on<br />

removable hardened steel<br />

saddles. For Tilt Saddles see<br />

next page.<br />

Page:<br />

15<br />

Lightweight Hand Pumps<br />

The Enerpac composite<br />

lightweight hand pumps<br />

P-392 or P-802 make the<br />

optimal lightweight set.<br />

• Composite bear<strong>in</strong>gs prevent metal-to-metal contact,<br />

<strong>in</strong>creas<strong>in</strong>g cyl<strong>in</strong>der life and resistance to side-loads of up<br />

to 10%<br />

• Hard-Coat f<strong>in</strong>ish on all surfaces resists damage and<br />

extends cyl<strong>in</strong>der life<br />

• Handles standard on all models<br />

• Steel base plate and saddle for protection aga<strong>in</strong>st load<strong>in</strong>duced<br />

damage<br />

• Integral stop r<strong>in</strong>g prevents plunger over-travel and is<br />

capable of withstand<strong>in</strong>g the full cyl<strong>in</strong>der capacity<br />

• High strength return spr<strong>in</strong>g for rapid cyl<strong>in</strong>der retraction<br />

• CR-400 coupler and dustcap <strong>in</strong>cluded on all models<br />

• All cyl<strong>in</strong>ders meet ASME B-30.1 and ISO 10100 standards<br />

14<br />

The unique Enerpac RA-<br />

Series jacks – lightweight<br />

and entirely made of<br />

alum<strong>in</strong>ium alloy – these<br />

RAC-506 jacks are ideal for<br />

the submergence and<br />

position<strong>in</strong>g procedure of<br />

tunnel elements at the<br />

bottom of the the rivers <strong>in</strong><br />

the High Speed Tra<strong>in</strong> L<strong>in</strong>e<br />

(HSL) project <strong>in</strong> Holland.<br />

t SELECTION CHART<br />

Cyl<strong>in</strong>der<br />

Capacity<br />

@ 700 bar<br />

ton<br />

(kN)<br />

20 (218)<br />

30 (309)<br />

50 (496)<br />

100 (1002)<br />

Stroke<br />

(mm)<br />

50<br />

100<br />

150<br />

50<br />

100<br />

150<br />

50<br />

100<br />

150<br />

100<br />

150<br />

200<br />

150<br />

Model<br />

Number *<br />

Page:<br />

Lock Nut Cyl<strong>in</strong>ders<br />

When positive mechanical<br />

load hold<strong>in</strong>g is required,<br />

RACL-Series Alum<strong>in</strong>ium<br />

Lock Nut Cyl<strong>in</strong>ders are the<br />

ideal choice.<br />

Page:<br />

RAC-202<br />

RAC-204<br />

RAC-206<br />

RAC-302<br />

RAC-304<br />

RAC-306<br />

RAC-502<br />

RAC-504<br />

RAC-506<br />

RAC-1004<br />

RAC-1006<br />

RAC-1008<br />

RAC-1506<br />

68<br />

16<br />

Cyl<strong>in</strong>der<br />

Effective<br />

Area<br />

(cm 2 )<br />

31,2<br />

31,2<br />

31,2<br />

44,2<br />

44,2<br />

44,2<br />

70,9<br />

70,9<br />

70,9<br />

143,1<br />

143,1<br />

143,1<br />

227,0<br />

150 (1589)<br />

* Note: Every RAC-cyl<strong>in</strong>der is available with a stroke<br />

of 50, 100, 150, 200 and 250 mm.

S<strong>in</strong>gle-Act<strong>in</strong>g, Alum<strong>in</strong>ium Cyl<strong>in</strong>ders<br />

Optional Bolt On Tilt Saddle Dimensions (mm)<br />

RAC<br />

Series<br />

For Cyl<strong>in</strong>der<br />

Model /<br />

Capacity<br />

ton<br />

RAC-50<br />

RAC-100<br />

RAC-150<br />

Tilt Saddle<br />

Model<br />

Number<br />

CATG-50<br />

CATG-150<br />

CATG-200<br />

Tilt<br />

Saddle<br />

Diameter<br />

J1<br />

50<br />

91<br />

118<br />

Saddle<br />

Protrusion<br />

from Plunger<br />

K1<br />

24<br />

31<br />

35<br />

K1<br />

J1<br />

0-5˚<br />

Capacity:<br />

20-150 ton<br />

J<br />

Stroke:<br />

50-250 mm<br />

Steel Base Plate<br />

Mount<strong>in</strong>g Holes<br />

The mount<strong>in</strong>g holes <strong>in</strong><br />

these alum<strong>in</strong>ium<br />

cyl<strong>in</strong>ders are designed for fixtur<strong>in</strong>g<br />

the steel base plate. They will not<br />

withstand the capacity of the<br />

cyl<strong>in</strong>der. The steel base plate<br />

protects the cyl<strong>in</strong>der from damage<br />

and should not be removed.<br />

Steel Base Plate Mount<strong>in</strong>g Holes<br />

F<br />

E<br />

K<br />

A<br />

B<br />

Maximum Operat<strong>in</strong>g Pressure:<br />

700 bar<br />

High Temperature and<br />

Corrosion Resistant<br />

Products<br />

Some cyl<strong>in</strong>ders, hand pumps<br />

and valves are available with<br />

Viton seals and nickel plat<strong>in</strong>g for use <strong>in</strong><br />

extreme environments.<br />

Cyl<strong>in</strong>der<br />

Model /<br />

Capacity<br />

ton<br />

RAC-20<br />

RAC-30<br />

RAC-50<br />

RAC-100<br />

RAC-150<br />

Bolt<br />

Circle<br />

U<br />

(mm)<br />

70,0<br />

80,0<br />

110,0<br />

160,0<br />

200,0<br />

Thread<br />

V<br />

(mm)<br />

M6<br />

M6<br />

M6<br />

M6<br />

M6<br />

Thread<br />

Depth 1)<br />

Z<br />

(mm)<br />

12<br />

12<br />

12<br />

12<br />

12<br />

H<br />

V<br />

3/8"-18NPTF<br />

6<br />

Z<br />

U<br />

D<br />

Page:<br />

Hoses<br />

Enerpac offers a complete<br />

l<strong>in</strong>e of high quality hydraulic<br />

hoses. To ensure the<br />

<strong>in</strong>tegrity of your system,<br />

specify only Enerpac hydraulic hoses.<br />

62<br />

1) Includ<strong>in</strong>g Base Plate Height of 6 mm.<br />

Page:<br />

120<br />

Oil<br />

Capacity<br />

(cm 3 )<br />

Collapsed<br />

Height<br />

A<br />

(mm)<br />

Extended<br />

Height<br />

B<br />

(mm)<br />

Outside<br />

Diameter<br />

D<br />

(mm)<br />

Cyl<strong>in</strong>der<br />

Bore<br />

Diameter<br />

E<br />

(mm)<br />

Plunger<br />

Diameter<br />

F<br />

(mm)<br />