Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

General Information<br />

General Groove Information (reference quote sheet drawing page 10)<br />

• Grooves available on 1 3/8", 1 5/8", 1 7/8", 1.9", 2" and 2 1/2" O.D. rollers<br />

• 5/16" narrow grooves are made for 3/16" dia. belt. Narrow grooves can be placed as close as 5/8" from center of groove<br />

to center of groove.<br />

• 1/2" wide grooves are made for 1/4" dia. belt. Wide grooves can be placed as close as 1" from center of groove to<br />

center of groove.<br />

• Grooves can be placed anywhere along the length of the tube provided they are clear of the bearing and are set at<br />

least to the minimum centers noted above.<br />

Conveyor <strong>Roller</strong> Selection for a Given Load<br />

Use only 2/3 of the rollers under the product when calculating the required roller capacity because the conveying surface of products<br />

is not typically perfectly flat. Common sense tells us that it is not practical to use a 1 3/8" diameter roller on 1 1/2" centers for a 6000<br />

lb. product (12 in. wide x 120 in. long) so in addition to the note above use the following guidelines:<br />

<strong>Roller</strong> Diameter and Axle<br />

Maximum Product Weight<br />

(lbs.)<br />

Example Equation<br />

1 in. O.D. - 5 /16 hex 300<br />

1 3/8 in. O.D. - 5/16 hex 600<br />

300 lbs. capacity roller x 3 rollers = 900 lbs.<br />

1.9 in. O.D. - 7/16 hex 1,500<br />

900 lbs. x 2/3 Rule = 600 lbs. load capacity per 3 rollers<br />

2 1/2 in. O.D. - 11/16 hex 3,500<br />

3 1/2 in. O.D. - 1 1/16 hex 6,000<br />

3 1/2 in. O.D. - 1 7/16 dia. 10,000<br />

4 in. O.D. - 1 7/16 dia. 15,000<br />

5 in. O.D. - 1 11/16 dia. 25,000<br />

The above guidelines assume "0" shock load and are not applicable for 3 or more lanes. When calculating the required load capacity for rollers in fork lift loading<br />

areas, Omni recommends tripling the roller capacity due to shock loading.<br />

Taper Specific Information<br />

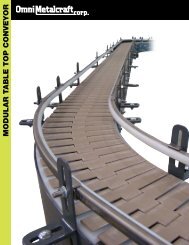

Omni has a line of pre-engineered tapered rollers to meet your conveyor curve application needs. This section is specifically devoted<br />

to information unique to tapered rollers.<br />

Tapered rollers are used in gravity or powered conveyor turns. Tapered rollers are designed to match the inside radius of the curve.<br />

This allows the product to maintain orientation and conveyor position around a curve. Our standard rollers are designed for industry<br />

standard inside radius dimensions. Custom tapered rollers can be created to work with custom inside radius dimensions.<br />

Center of<br />

Curve<br />

Center of<br />

Curve<br />

• If the taper rate is not true for<br />

a given curve then the product will<br />

become skewed around the curve.<br />

• If the taper rate is true it increases the<br />

likelihood of maintaining leading edge<br />

product orientation through the curve.<br />

Page 3