You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

' I #ow to Rescue Your Router Bits! '2<br />

J www. woodsmith .corn<br />

Vol. 28 1 No. I 67<br />

jointer technique;<br />

- -3u<br />

t6 know<br />

,able<br />

~echlf~~~e<br />

for supel itrung<br />

.?I<br />

\<br />

7<br />

% W +A<br />

Cabinet, -

9<br />

Table<br />

from our imders<br />

Tips & Techniques ..I...m.......<br />

project!@w&sf<br />

.4 - ..--<br />

weekend project<br />

all about<br />

Curved~Fretnt Buukcm, a ,.,<br />

Router Bit Revbal .............. .8 w wtly cwiw si&s af thii bmbw give k13<br />

Don't toss thme old, sorry-looking router Mts,<br />

itasophirtlcatgdLodG~utpu'llbepWanily 3<br />

We'll show you how to make them cut lik new.<br />

mpr'id at haw easy it goes qether, Y/ ;.<br />

,A . ,.<br />

tools of the trade<br />

designer series project<br />

SketchU b~Google**~~*~*~~~~.10 TallflfchenT&b ............<br />

If you # ought a computer design program was<br />

22<br />

out of reach, check wt this offering.<br />

techniques from our shop<br />

Quick & Accurate Mortises. ..... .I<br />

the msnpamrrd 5tyEirh dew d&ia pt~jm k<br />

w h am ~ vw a&hth. kit &h4t ~Wiobk: &E<br />

g~&oo;hvaking that peer into<br />

2 heirloom project<br />

Dbplay ~bjwt<br />

, , , , , . . ,<br />

Power and hand tool5 work side-brideto give<br />

you perfect mortises - fast, MthaMgKthatk taQitliilandpafl<br />

jigs and fixtures<br />

EZ Smart Guide.. ,............<br />

This innovative guide sysbm turns your circular<br />

saw into a precisian tool for cutting she& stock.<br />

r<br />

contmgamy, puJ Ild thb psnjett will W 'in<br />

about anywh~re in your hme.<br />

J.4 6

Now> you ran have the best, timesaving secrets, solutions,<br />

and techniques sent directly to ytlur computer. Just go to<br />

~.Woedsmihmm and click on "FREE lip by hail" to<br />

sign up. You'll receive a new tip by email each week.<br />

I<br />

These two symbols let you know there's maw ifdomati&<br />

online at www.Wmdsmith.<br />

videosr technique nmjecQ ,

I<br />

I<br />

hlLR0aarn-w<br />

FoztbtramdonwhIuse ~ ~ L o t f a t l ~ r n e %&lspetQsit~@Btod%<br />

t o ~<br />

~ ~ g ~ u g ~ d f s h n & cw e s ~ f ~ - e k . a s h d m ~ b & w ~ , ~ t ,<br />

er~myroutat~-$ettingthe T Q ~ ~ ~ l & Imdeawadlehrfhebewntu<br />

t $ w<br />

kce to align wetly dght has a& h the miW dot: at om wd sB@.i&m~@ I d a 'af),% WOdmjsbema~fmme-<br />

~~bffie.tolb~~~I~ethebeam<br />

phecratdkismadetaiititujgiy'<br />

W f s , ~ I W ~ a l i ~ nf ht<br />

e m d k m f i l i t inthemibdW.Inthe~pat<br />

~<br />

pdepepu~h.<br />

t&ekncdf&~&hb dthe~i=ide,l&kdh-W<br />

Thegaugeisjustahardwood p~Ididethegaq&to~~ iasertmdathumhs~~.<br />

beamthatfikint~mad~~le enddlfthetabfetomaleesure&e Analumbum "dl& fib in a<br />

cmdk.Thecta$IesUdeein& kq&the~disiaw~~ rroltclhIslthetapprt~fthecra-<br />

&.Urhentheth~~i$<br />

Ic<br />

A<br />

mp*m&'&wb<br />

"-3<br />

c l l & ~ h ~ t & y m<br />

F<br />

-.- - ---<br />

SUBMlr8t@llR.. FIB6<br />

WhWwd Mmw.<br />

&W Rmb<br />

ib&&mH~@fS, ofrio

more tips trom our readers I ;.<br />

mrn&time&; that .exha stor$-@ is'<br />

s q pu right in the'hce,<br />

FO; mveral years, I've had a<br />

large ~toard' pand abh&e$<br />

to my shop wall. tt hag BT,&<br />

me weu aver the pars, £mJdhg<br />

&@&<br />

-&ta M.wIsr;w,m<br />

,- ,

pmjw hi@-<br />

) p h p t q 8 U U f e ~ ~ ~ w<br />

holm. But tapping tkF$ p1#@.-m<br />

~ h ~ l e s w i t h a h m m ~ ~<br />

&ip&mtapofthephJ@.<br />

'Ib.wive @& p~blpm, I d-zr<br />

~ ~ ~ p u ~ ~ ~ & w -<br />

ingkltaakapiaeoflJidia.rlawd I<br />

md &iW.sa "&pW b ~rte md<br />

tbm&htbdWn&~d&p&<br />

as pu can s i h ~ d&d 'a.'<br />

Now1 set the plug in<br />

ietbd ho4eI p b the plug setk<br />

t~lp~p~~&e.ko'le. NDmm<br />

&t*@<br />

on theplug@.<br />

J---J<br />

t FFMd<br />

Cdg<br />

The Winner!<br />

C$mgtatulations Thomas<br />

Edwards bf Pullyallup,<br />

Wsahiffgtom. His hardwars<br />

a &edeqste~ wa~3e1-d as.<br />

,'+,qfw. HF Wign uncl,wers<br />

.7$bLwrw while wine<br />

-.va<br />

, :. Pi& lpr&qqwq-ganized-<br />

W,Bn$ pw'hvii.rotl wid<br />

1wIK a F%@r~mbla !awiable<br />

.i&e@d rdutwJ 4Wck aut the'<br />

,- infarmatian & the<br />

h

"'A i

**t*'m-<br />

'. W ~ w ~ y ~ ~ r n W ~<br />

-.<br />

r ~ J W &,Qf d-ine ao<br />

b @ w ~ k ~ ~ q y W &<br />

&&Wtrlwrn*mwbk<br />

Yw&f II**M&W<br />

3&&it.~Wtw&&~#n ~~~<br />

$ WMg$L&Btl1l~a@<br />

7 ~ ~ ~ ~ ~ y ~ t~ hi t e ~ * ~ & m ~ WM ~ e ~ a . ws a a ~<br />

' r n @ ~ b ~ o~ r % ~ p ~ y ~ w -&b&hemw*d&<br />

b £ t<br />

*p& d*htj. wd8"-ilreaex~.*%~ helashargtotbew<br />

-TQ @& up *%bpu*a fiutpb & %mvwqwwwgm?a<br />

The tau& carbide cutting edges on rout- Pmket stones are lexi expensive. You<br />

er bits mean ordinary Hes and stones can hold them in your hand or clamp<br />

won't do the job. Instead, I turn to dk- them to the bench for shmpenktgbits.<br />

rnond stones. They come! in fhree styles. I€ you'^ honing small bits, you'll need<br />

TIIE small diamond bench stone is p i to use a needle file. They m e in difkrtt<br />

for larger bits. Its atended h@ allows shapes to meet your needs. Sources far all<br />

wu to make longer passes.<br />

th~s~smlrefudonpage4~.<br />

,mne

is sdp2t the rig@ drill Kt. ybuY $tiwed. Yq11 e m seWg<br />

kdit~4b~if~rmupzf~ &eI~satheblt~~m<br />

k1'ahaw.t fRi' nanWef+tl mm the dtbdyrnbyaxat-th,<br />

@mth&width'dthemW, This lbq slide the pWe $6 +he biW<br />

wap ymll hveephty of fwm to At tha h€t end d fhe.layout mafic,<br />

square up the sdm without ktbq<br />

Now you can c1mpa stopbhk to<br />

the Pmk get tQa wide.<br />

tile h, %'box eplaim<br />

I prefer b we FarsAhr $i@ be- Itow to wpIete the ddkgopuse<br />

* lmve & l4xJ s4r* m&n by wing a s p a bW.<br />

bMwh In the wtk. But brad SQURRE II WIKL & pQu{ve<br />

g.& bi& will wak tod, Yau just Whed ddlwghut & holm, t.h~<br />

med to tkw twhiqw Wt's next Wp is fo &or bp,d qm'<br />

15#t for 4he type of bit you de. tke mo& For %&I) I begin by<br />

ThE iuu&dms Qn the opib<br />

phc,hg the wmkph in e vise<br />

pw*k'-t-.<br />

or searing it @ the hch wi&<br />

Ifypuu%aFmhabfi,~ dam#$. I like toweik&~@tly~~er<br />

M dm d m the2q4 d tRe drill tl-@rnortiw& 1~ emgrbndp<br />

~~mrk~bttinandsllt w~gbttopud~dwxt&ii~~.<br />

~ ~ ~ meavb&kr @ v B<br />

~mlRbBtKhwthb~Bi~ V@W&&BW&<br />

~ F ' m ~ d y b ~ d f lI~ssp*a%fi~d&&bdem<br />

-<br />

hgmt&zwaefhdiihdpk .. .<br />

up!h~rn,T$ew'~apvi&e<br />

wide Cw$a* %"I. The wad:-<br />

~ ~ ~ t ~ & ~ ~ ~ ,<br />

w<br />

move the &amKS vvm a wm<br />

u r m<br />

a n<br />

the top mtn% rW&&<br />

HI&&,€& mm m a<br />

t~tiwf up i@ wt t& M~bm<br />

SrnMMW*<br />

Side and ends<br />

" &fmii-e<br />

stmuid be<br />

smooth and<br />

square<br />

A ,><br />

*'<br />

is fa UE the ~h&d MI

tor your clrcu~ar s,. ..

I<br />

I<br />

M ~ H E The . EZ Smart has<br />

some other nice features as well.<br />

For one thing, the guide rails are<br />

available in six Merent lengths.<br />

~ uvou t can connect .. two or three ..<br />

,'<br />

sections to make a longer guide<br />

rail. The rail sections are lhked Vs::<br />

together by short, aluminum con- ,<br />

rtectors (see first photo at right). So ,,<br />

you can make up a guide raiI that<br />

is just as long as you need.<br />

U P S . A lot of strai&tdge<br />

guides use hand damps to hold<br />

them in place. The problem with You can make a longer guide rail by simpty<br />

this is that the clsmps can get in the connecting two shorter lengths of rail.<br />

way of your saw when mahg a<br />

cut. But the clamps on the EZ Smt<br />

slide in a slot on the underside of<br />

the w e , so they're always out of<br />

the way (second photo).<br />

AHIKHlP FEWURE. Ta combat chip<br />

ping, the EZ Swrarl b w comes with<br />

two styles of replaceable, zero-dearance<br />

inserts - one for use with the<br />

guide rail artd one for bhand<br />

cuts. And both edges of the guide<br />

rail are fitted with a replaceable,<br />

antidp edge strip. Thtw reduce<br />

e chipping by supporting he workpiece<br />

right up to the blade.<br />

ACCESSOIES. AU these features are<br />

great, but what makes the EZ Smart<br />

really stand out are the accessories<br />

availabIe for it (see box below).<br />

After taking a look at these, you<br />

quickly realize that this isn't just<br />

a saw guide - it's a precision cutting<br />

system for the circular saw.<br />

BOTlOM UM Overall, I didn't find<br />

much about the EZ Smart to &ticize.<br />

The fit and finish of some of<br />

the parts Ieft a little to be desired,<br />

but ~s didn't affect tlw functionality<br />

of the tool. The EZ Smart will<br />

Adding Versatilitv: EZ Smart Accessories<br />

:lamps fit into a slot underneath the<br />

rail, where they won't get in the way.<br />

work with most right-blade circular<br />

saws, but be prepared to drill<br />

some holes in the base of your saw<br />

to attach the base. You may also<br />

have to enlarge the opening in the<br />

EZ Smart base to accommodate the<br />

blade guard of your saw.<br />

Depending on which "package"<br />

you order, the EZ Smart starts at<br />

$135 (see page 49 for sources). Although<br />

this may seem hgh for a<br />

sbaightedge guide, if you do a lot<br />

of work with sheet goods, I ttunk<br />

it's money well spent I<br />

The basit EZ Smmf Gu& ~arks pat h accessories allow you to use dle, take a look at the videos on the EZ<br />

for cutling plywood and lumber to size. the E Z Srotttrt for a lot more tkan just S d website: www.~mexom.)<br />

But what really mkes the EZ Smrt simple cuts in plywood. You can use it Like the EZ S m t itself, most of the<br />

system so ap-g are &e acrmmries for cutling parts to length, squasing up arxdes are u£fd In different sizes<br />

that are available, wake a look at the panels, or muting joinery (For mare on and packages depending upan your<br />

phofns below to a few.) all the tasks that the EZ Smvt cart hm- spdc needs (see page 49 for murces).

curved-front<br />

ofstorage in just a little space.<br />

As much as I ejq a challenge, I<br />

have to admit that every now arid<br />

then it's nice to huild a simple,<br />

straightforward pro]*&. And with<br />

it's clean Iines and basic design,<br />

that's exactly what this b m k is.<br />

The ronstmdion is a h straightforward.<br />

It uses quick-connect<br />

fastmersp m there's no complicated<br />

joinery to deal with. And it's made<br />

almost entirely out of plywmd, so<br />

you don't have to spend a lot of<br />

time gluing up solid-wood pm&.<br />

But in spite of it4 simplicity, this<br />

project will still thrrrw you a m e<br />

-two mesIinEdCt. If you U e a<br />

look at the photo, you1 see that the<br />

sides of the bookcase have a graceful<br />

curve along the front edge.<br />

While these curves add visual<br />

appeal to the bookcase, hey create<br />

a chanenge when it comes to edging<br />

the plywbod. Here again, fhe<br />

solution is simple - flexible, itonon<br />

edge b&g (photo below).<br />

s<br />

banding is fast and<br />

easy to apply, even<br />

to the curved edges<br />

of the bookcasle<br />

sides. See page 21<br />

for more details.

IF- -<br />

I<br />

FIRSZ Place nail:<br />

location pohh r<br />

dboa rd temg<br />

I,

#endon to the p v e that runs<br />

slZong the bad edge of each side. first job 4 to drill the hob for<br />

These grooves will hold the back the c~mector hard-. Each<br />

panel. Eecause the 4k" plywood connector is made up of two<br />

used for the back panel is clowr parts: a cam and a pin. The pin<br />

to %6" thick, I cut the groove by is installed into he side of the<br />

making two pasw on my table bookcase, W& dm cam fits into<br />

saw to get a snug fit.<br />

aFMG M EllnrL At Ibis poht* all<br />

aholeintPLeshelf.<br />

Theresiitrickis~ttLe holes<br />

that's left to complete the sides is in fhe shelves ahped with th@<br />

to cut the curved &ape. You can holes in fhe sides of the bkcase.<br />

seehowtofinishuptheairvein To help me with this, I d ajig<br />

the +wo drawings Mow.<br />

THkSHEWCS. Now, it's time: to fmus<br />

lihtheoneahowninthebaxat<br />

right. Shq Notebook on page 30<br />

on &*elves. As I saidbefore, the shows huw to make the jig.<br />

topl bottom, and middle ahelves<br />

are fixed. In fact, they're holding<br />

tOE KKR NO TOP IWIL To provide<br />

extra suppoft and give the<br />

thebookcase trJgeh with quick- boobase a more fhbhed look,<br />

connect hardware. The other two you cm add a toe kick to the<br />

shelves are adjustable and will<br />

TES~ on shelf pins. (Sources are<br />

lisfed on page 49.)<br />

bottom shelf and a back pad to<br />

the top. Both are rabbeted to fit<br />

into wves (see details 'a' and 'c'<br />

A f t e ~ ~ ~ ~ s &n h the e ppposite l ~ & page). ~ ~ The panel<br />

(remmbm that the fixed she£veg<br />

a~ three Writ widths), you can<br />

set the adjustable shlves aside far<br />

now WW you mtinue wmlung of the battom &If.<br />

qn the thee fbed shelves.<br />

TOP M L NOTCH& You'Il notice in<br />

~ I W I stmkd ~ by , detail 'a' (top of oppposik page)<br />

Wng the upper and lower fixed that the t ~p panel has notb in<br />

shelves over to my table saw.<br />

These shelves need grooves to<br />

hold the Yfl plywood for the back<br />

panel, as shown in details W ahd<br />

'c' at he top of the opposite page.<br />

Qnce the grooves are cut tab<br />

these tw~ shelves and the middle<br />

shelf over to the W press;#&e<br />

is "trapped" In t?ae paves in the<br />

sides, while fie toe kick is glued<br />

in the pwe onthebottom side<br />

its uppa corners. The mtdw fit<br />

mund blocks that will be addd<br />

to the grooves during assembly to<br />

prokt the dge ban*.<br />

With all fhis dme, the next step<br />

wilI be to add the edging and put<br />

the bookcme together*<br />

Dr9UIng the a m Holes* Orill the holes for the cams<br />

fm the b&m side of the sheh. Take are so you<br />

don? drill through theshe/= (&tail 'a><br />

Route and Flip Rotate th3 shelf and flip the ji'g81<br />

drill the cam hob in the back of the s heh. A sup<br />

pofi bJOdc kwp the shelf /MI,<br />

Ddi- the Comer Hdes, Ling the j$ up &A<br />

the am t~ &U the hob for the btmmrs<br />

into the idg~ sf t&&hk,<br />

spacer bl<br />

behveen<br />

edge of shelf<br />

Middle H&~WiwMWe& Add a ipcef to &dl fie<br />

hob id &i mtWe Shelf to account for the back<br />

pnel tht i@&@@a$aim.

Material<br />

4 Cw$&<br />

B UppwPi<br />

C MlMb F h

oekc&e And since WI mad@ h e & € ( ~ .place ~<br />

edge Banding are an iron, a TrSrnmitlg<br />

fatly with fh@ pmfeKt. mtlrem&ngt#<br />

The edge band- is just a law y mmf scmchhg* Thkn sbpljr<br />

narrow ship of %$'-hick venm. iron th banding ontdtb edge af<br />

(It's said b a fm dikrmt widths .the plywood (phuto 2):<br />

and.~sofw~,~%ur~sr~n I~thatI~the~tfesu~ts<br />

page $9.) me side of the banding by &aning a shm- ofbidis<br />

mv- wjth a heat-activated ing at a time. FWm W 30 se~snds<br />

@~.~y~tkhZivEt~d@k~@~flyi~ b&ud~e~~~t$&t&e#~<br />

lvbci-

tall Kitchen Tab!?<br />

WMhH yw*m =ding I& ~ y ~ ~ M e til bh e m<br />

mmhg mwpapx over b d - m&~W* kQut &the way<br />

imt -ur 21 mhag dWC (* p ~ ~ ~ ~ w ~ ~ p ~ g ~ ~ *<br />

tw &t&m set fit r@t:h n .m*

sL-7 TF-: Aligning and Drihg Mortises

HwTa Rout Stmeed Mortises<br />

Rpurer Tgbk S u p 5@ &:'fp-nce I?&' fwfrr the hic .pkcnge Rout, && *e rnw!&e EmW Ga mi% @&WeY'e adthe w&+<br />

firznm r ~$mdIbfied with the ciMip&m of t& p i e &l& the ma* &ow aaijd p;hr@;&-Wp&&, hut unfit M<br />

bir* ma&sM ahd mp mads an ?b:%e. op- mW hi We i3~<br />

,ha&:oh tfkY&e.

I<br />

4<br />

making the TOP<br />

W1th the base complete, it's time to<br />

start building the bp. I glued up<br />

the top from narrow maple stock<br />

to give it a butcher-block look that<br />

fits In with just abwt any kitchen<br />

decor. It's a little more work than<br />

some of the alternatives, but this<br />

arrangement means the top will be<br />

mose stable. It will stay flatter and<br />

mt expand and contract as much<br />

with seasonal changes.<br />

aJlTM THE STRIPS. I stated by<br />

jointing and planing a few pieces<br />

of maple stock. 1 took extra care<br />

to make sure every- was perfdy<br />

flat and parallel dm@ this<br />

step, because the planed surfaces<br />

will actually end up being the glue<br />

joints I've ripped the W s<br />

into mwer strips. (The box k-<br />

low explains how to pmpare and<br />

lay out the strips for a flat top).<br />

Next, set up your table saw with<br />

a god rip blade and dwble-check<br />

the fence to make sure it's parallel<br />

to the blade. Then you can rip the<br />

maple into strips. For the best glue<br />

joinis? I like to ca~fully joint each<br />

strip, Then you can move on to arrmging<br />

them for glue-up.<br />

Urn OUT TOP. Ifs a goad idea<br />

to ixlspect each piece for straight-<br />

ness. When you cut long, narrow<br />

p i e you can get some bowing.<br />

So now is the time to detwmh<br />

which strips are bowed and in<br />

which direction so you cnn take<br />

that into account during assembly.<br />

The box Mow explains how to do<br />

this to get good results.<br />

HUM IT UP. Now, you can glue<br />

up the top. I first glued the strips<br />

into s m a h &~fls (about 8"<br />

Cuttin! and Assembling the Top<br />

. .<br />

wide) so I could run them through<br />

a planet. Take a look at the box on<br />

the next page fax details m making<br />

a fIat and smooth tabletop.<br />

BBW DEWILL Now, you can trim<br />

the top to size and rout the rounclover<br />

on the comers and top edge.<br />

Then sand everything smooth.<br />

After painting the base and applying<br />

a finish to the top, you can<br />

attach the top with Zfasteners, as<br />

shown In the drawing above. Then<br />

you can hun to makmg the stools.<br />

mi<br />

81 '<br />

I<br />

1<br />

I<br />

j<br />

Ripping the Stock. Ch& to make sure your fence is parailel to the Lay Out the Pieces To compensate for bowing,<br />

blade to avoid saw mark and burning, Then rip the strips and flip them lay out the strips as frown above. This waj you'll<br />

an their side. This edge grain wili become the top of the tabb A quick get a bemr glue h d and you won't have m wony<br />

pend mark to identify them will save time hte~ about cracks appearing in the future. I<br />

4<br />

26 <strong>Woodsmith</strong><br />

No. <strong>167</strong><br />

-

How-To:<br />

Flatten The<br />

Tabletop<br />

~~g a glued-up tabktop begins<br />

during & asmbly stag.<br />

Chping up the individual strips<br />

on a perfectly flat surface and tapping<br />

them in place with a mallet<br />

is pmbably the best way to get<br />

dl in he. You can a h use<br />

cauls mnnbg perpendicular to fie<br />

strips to keep them from ddhg<br />

underclampiq pmsure<br />

f UT AMD TRUE. When the dries,<br />

it's tempting ta try and ff atten h<br />

pane1 by running it thmugh a<br />

planer. A p h will pmduce n flat<br />

surface, but if the-opposite si& is<br />

uneven, the surfaces won't he parallel.<br />

You1 get an unwen panel<br />

-<br />

that won't sit fiat un th~ base. The<br />

solution is to flakken ane Bide first.<br />

If you've dm everyfhingyoucantQkeep~flat<br />

during the glueup, it% nut hard to<br />

knock down the remaining ridg~.<br />

You'll want to begin by mrnoving<br />

the glue squeezeout. An old chisel<br />

wo& great for this.<br />

#EaFORFUTNE%Istartby~<br />

a straightedge to check the surface<br />

and make a se~es of penal ma&<br />

an the high spots. Then you can<br />

turn to the belt sander and a W<br />

grit belt (see box at n@). It<br />

shmt work of the the.<br />

The goal<br />

duringthis phase is to move only<br />

the Mgh spob. 8. angle th~ sander<br />

or yw can even sand acrows the<br />

gain. Skap hquently and recheck<br />

the surface with a straightedge.<br />

When alI the high sp& are<br />

smoothed out, you can switch tn<br />

a 120+€ belt and s a d with the<br />

@, moving fmm slde to side<br />

mid you have a nice, flat surface.<br />

W SMOOTH, Then you can run<br />

the panels through the phr, hking<br />

light cuts. Stay a little shy of<br />

the finat c h i b s - yauzl sand<br />

the top to final thickness after you<br />

glue up the pads. Give the top a<br />

final sandmg far a smooth finish

P'-ty asad ~~* 'ke<br />

lower spin* Mek their rmrnded<br />

dp@veyaurf&a~Ie<br />

rwing qotwhiled~.<br />

llEm. me &.table, &e -1<br />

top a& gluerd up hm m w<br />

~ p s . I ~ t h C F ~ ~<br />

t0asmnble;utdfkttkn~asI<br />

did for tke table Q. A d hy'm<br />

atkhd to ttPe base with z-fastenem,<br />

jm lik~ the table.<br />

d y diWl in the<br />

'sblkp b ~slight.IwLuld~ I<br />

ZidtH-dhQd~b<br />

ybuvH be sinp;tm k, 1 E iit<br />

h d p ~ ~ a l i t t b m o ~ e ~<br />

WbEftheedgeia-<br />

A~~0~1woEpa#da~,<br />

d&u~m*fQP$&pu%e<br />

d&I&I'~~~W~wOn<br />

Mve my'd.,%m@ a gmd<br />

$putfor mh&dpliltle t&lemd<br />

s ~ h ~ ~ . u l<br />

No. <strong>167</strong>

,A,,<br />

.<br />

Materials, Supplies .& Cutting Diagram<br />

,,,<br />

,<<br />

TABLE<br />

A l,%s-I4<br />

I3 . Upp,er Etrd .Aprons Q) j4 x 2'~~ - 2Q<br />

C,>91jp.w Side Aprpns (23 % x 2 V! - 32<br />

D',' LQWW E-nd Aprohs (2) 3Lq x ?! - 20<br />

,<br />

-<br />

D-' 8<br />

H Center Stretches 41)<br />

-, .<br />

(8) Tabletop.2-fwteners<br />

(8)#8x2%" Fh Wmdscrws<br />

, ~(8)#8x3~"PhW\lood~~~<br />

. I<br />

Island Worksurface<br />

Thi6 tall tabb abo makm w handy standalone<br />

workeurface for the kitchen. And by addlng a<br />

~oupla mom s$retckew ~C~OSG the bottom,<br />

you can crm~<br />

a tihslf for swvlng large itema.<br />

There am onb two thing6 you need to do be-<br />

fore wssambling the base. Fbt, you'll add Wo<br />

&ra mort;ls@e in the end mile (see drawing<br />

below). But $ha nim thing IG you can use the<br />

same routlng technique that I used for the<br />

table [see the box al; the bott~pn of page 25).<br />

The other thing you'll new4 t~ do i6 make<br />

ma mom ce~ter straher~. The tkk hem I6<br />

'co make sum the spaclng between them is the<br />

Bama when you msrnbla the base,<br />

i<br />

1<br />

20 -

t<br />

- -<br />

t;>:,'

. , > . , I<br />

> 7 .-<br />

6kns Stop ', > . C<br />

When yau @ &y tu hidl the<br />

@w*ina,edbp~a~ mona*.~tW~QEl M%&ewy*<br />

an 32, p'11nml mal Wbppd&&ge9~~%hvea%* RrPa piem of tndrfing bani<br />

~ o f ~ & - r n d ' ~tmter&onbo&e$p<br />

~ ~ ~ d<br />

the oi%e~&ed the wmkp&e, Just<br />

~ ~ h p ~ ~ € ~ W Ai K e4 Y i l % ~ ~ ~ turnZhern~kpi~owr,re&the<br />

s ~ g<br />

caten~~Ietofindmqld~<br />

md mau& to do he j&. Fa 1 trim 219e mlbg *ips fwm the thebhka&kfmL<br />

mademylowrrqwrtm-mundflas5 w~F~.3~.Ta&ahisfgiQt~ W ~ y o w ~ d ~ ~ ~ , ysur p wow l l &$<br />

&p mokfing. It onlp tab a few raise the bls*fe chvethew&kp-, need to miter Ule quarter-round rtop moldibq:.:-. ,?;<br />

~~~pit.o&itjW.theW ~ ~ ~ t ~ f e n w t g ~ ~~len@t,~paucmseam t h e ~ d l<br />

. ,.v.;r;.,L2 ,L,, ;.,yef<br />

. -> ,la:<br />

yau~-TRephato~tri@t~ piamofmold@hhdpd dw&win~tiortby~or<br />

., . .: - i<br />

> );:>:&<br />

how it Emkf at h eompMon of ths wmkpbad cut bike* glkng~~psin~e.<br />

.

Heirloom Project :-<br />

g lass-panel<br />

Display<br />

a<br />

Cabinet<br />

You won't believe how quickly<br />

this project can be built. The<br />

key is simple, traditional joinery.<br />

@<br />

Shuwingortisjwtwhatthiscabinetisall<br />

about. And t k are ~ enough htemtlng<br />

detaibbtmdeitjwqtothetopofthe<br />

-- I *<br />

list of p&& h t I wmtedb build. , , . ' 'I<br />

Mowmu&pmpk~~fheabpb "' .<br />

displayed in tkre "ghed-in"upper sectirn<br />

Or hmv the cabinet offers both "hidden"<br />

and~~.Andfhefzlrtthatithasa<br />

emalz~~~roucantuekitinjust<br />

abwt&t~,@vkgitalotof~tB;<br />

But woadww will W notice rrf the<br />

details an8 strafghH~rw?rxd cmstmctim<br />

that makes thisdiner a~stad+ut<br />

FRAldE AND PANE. Just kause a project<br />

isc~in*doesn"tmewnym~<br />

.*pm-kthe-krn&v<br />

Qfmqgp~.&meamdpd - ..<br />

~ ~ . ~ ~ f o<br />

~ t h e j a n q ~ b & ~ ~<br />

~DSIE~~RLU. %aM-rw&f+o<br />

mti&*t&thebe~thavetodowith<br />

~~~thatkeepthe~Wfrorn<br />

hdag bov. sming at the bowmF<br />

thecabinetr&scm&pfhatr&eitoff~ .--<br />

~Tkis~a~aPhInWlower<br />

e<br />

keep a &m l&Wg bomm heavy.<br />

Tha?&dMisa*@*tu<br />

e a ~ ~ m m m oFdy, f ~ afthe ~ ~ .<br />

top, I Ugsd a pmmdecwe mokhg~to~add<br />

one last eyecaw

M a & t?&vk~<br />

rnoitvn makm it wy<br />

m add &ad to s@nr,en<br />

FRONT<br />

SEmIOW<br />

vlEW<br />

For hadware<br />

mKes, turn to<br />

PVm<br />

are made with<br />

A<br />

she I in lower<br />

part of care is<br />

made from<br />

mQd<br />

I<br />

Mdse and<br />

tenon face<br />

frame adds<br />

Saiditv to<br />

- Y t

uild the<br />

SIDES &<br />

I mentioned Wore that the case<br />

is made up of three hame and<br />

panel amanbeS and an open face<br />

hamc What's surpcbbg abut<br />

this is just how quicliiy khese<br />

&$embb go iqvthr.<br />

SIMPLE Jmw: me reasan Eox<br />

this is the johry that's used on<br />

the back and sih. Here, I chm<br />

a stub t m ami pve. Besides<br />

quick assembly, this joint<br />

has another hg advantage:<br />

yw can cut it enMy an fm<br />

table saw. And afk adding<br />

W1 plpwd panels, the's<br />

phfy of glue surface to ae<br />

ate a strong, rigid asmrhly<br />

Befm getting started on<br />

the frames, there's one ather<br />

thing I'd Uke to mention.<br />

And this has to do with<br />

working effieimtly. 'She<br />

joinery for both the side<br />

versatile guide to and back assemblies is identical.<br />

rout the dadoes So you can save some -time by<br />

in the sides. Turn cutting it & at one he.<br />

to page 30 for When you're ripping the parts<br />

details, to width, be sure to note the different<br />

sizes af both the sacs<br />

and rails (drawing at right). The<br />

low rds will get a" arc cut on<br />

the bottom edge later. But for<br />

now, I leftit square to mh cutting<br />

the joky simpler.<br />

WTHElldtC Orwe the pinery<br />

is mnpkte, ~rou can go ahead<br />

aRdcutthearcontPlelo+verrails<br />

[dd 'c'). A trip to the band saw<br />

I1<br />

I<br />

makes quick work of row cut-<br />

! tingthew. Thenthe edgeanbe<br />

cleaned up with a dntmdm.<br />

t<br />

No. <strong>167</strong><br />

1

2 .,<br />

-<br />

. .<br />

. - .<br />

.<br />

- . ?.Y2= ,:- 2-,' ' -. --<br />

-<br />

-<br />

.--I- - k.;1;<br />

9; -15 m. - .-:<br />

:..?; . -<br />

m<br />

bdbm rail to &ch h c m s<br />

Qtt the db<br />

and hack.<br />

nm, rn 0- %and, khe<br />

ba&bs J W a& bn be<br />

taped just H k m the<br />

sides-& back. NOW, glue up<br />

facefmmhkmg-tohep<br />

i t ~ a s ~ ~ m ~ '<br />

MM removing the damp,<br />

h last thing to do on the face<br />

frame is tb rut a rabbet m the<br />

'track hce of each stile. W mbbet.<br />

will capture the side hmes<br />

and make assembly easier,<br />

cnst Assam GlUiTlg the fBCe<br />

hame in p w is *try amght-<br />

£omad. h d like the d*<br />

assembly, ifs a pd idea td ror~<br />

cmtr&emadqgat&htjdnt<br />

line.- the sfde &m-md<br />

tXpRra+b~~tirt~fam~.<br />

All that's left JO cb on the caw.<br />

is to rout astopped&amhm<br />

the front corn&. And you can<br />

kam how the best mdts<br />

in the boxat right.<br />

.<br />

~ m E ~ ' I O P<br />

w&h**oftfrea~<br />

complete,ywmm gets&<br />

m~tcwp,'mekq~5n~w-<br />

~ a t # ~ . ~ ~ j W a p l ~ u d<br />

pd W1521W-widElHli~ edg-<br />

*. Bide9:'lfie &g&g i's<br />

mikmd Wih a 'rig m-< 88<br />

hy9ucrulmindetailY;a'<br />

~tqp~is.~sitarpLy<br />

~ ~ b u l . i e ~ a f t l w ~ . h<br />

~ ~ w i n g ' r ~ ~ c a n ~ ~ ~ ~<br />

@timed. Ifi cam&& side WA<br />

sideand 11wh with the back,<br />

mlrourrmk'fhe~~ista<br />

add a ~ ~ o ~ ~ MDW l dthe<br />

m g<br />

t c p . ~ T ~ a p ~ ~ v e<br />

matding &at's lxlked to wrap<br />

;rfmmdthebt: ai~ d&

make the<br />

Wi& the t w mplete, &re<br />

areodllyawqde~thhgsto<br />

&amdd,WWorku\riilk<br />

~dup.mrtextstepiett0<br />

build the two doors. And since the<br />

mtru&m&ea& one is a Bide<br />

twkmt, I'll tah ym drrw& the<br />

pmmeat aae.<br />

Infhednwing atright, yotl>m<br />

web'tiheupdmwillhse<br />

a glass pard Wif will match the<br />

panels you% inst& in the sides.<br />

IOIMRX 'Since a @ panel<br />

dm't add &m@h to a dmr, the<br />

~ ~ nwds to rbe strong n<br />

and rigidtomakeupforit Thfs<br />

mttkesita~~&farmortise<br />

and jainerp. In detail 'a,'<br />

you11 find the dimension% you'll<br />

need to complete the jojnery.<br />

WE?, hthdmrfrmhas<br />

~ @ ~ ~ * p u ~ ~<br />

r o u t n r a b b e t ~ ~ ~<br />

to hold the glass panel, as illustrated<br />

ia detail %.'<br />

lie @B pmek are held in<br />

place with some simple stop I<br />

made at the table saw and mu*<br />

table. You can see the stepby-step<br />

proas on page 31.<br />

ollentl# ows, At the same h e<br />

youq* ord* the glass for<br />

the dm and sides, you can also

I....<br />

-..<br />

mt a join- in my 9%. But me like a contradiction that such big bfifa. Number one is that<br />

" t I o w n m 1 a b h tool can be so usz- you can put a smooth, strd ",<br />

xtqwhg stock% &me&. h memIt'sesmWyapairaf~ rn~thefaceafabuardebigp't<br />

b e it takes to think abaut narrowt b n Wb sephrzted and flat, or fate jQinting. Each<br />

out a hand $am nr a belt by a horizontal cutterhead. The it$ awn techruqae.<br />

you can joint a hard for infeed Wle is mi& or lowered to<br />

-1<br />

by the Mw And an adjmt- Edge<br />

ablefmcec~utbeusedto~~ mms<br />

L<br />

wifhevmasimpfetmllha jainthgastrnight,<br />

~ ~ a l abdforetpl<br />

i ~ ~ -<br />

how4 But k leaning TZre p- B<br />

faward. Y u run<br />

a s d amount Of material. The

. . :,.<br />

4<br />

:'/ ,<br />

*t spot while a h I&#&@'&<br />

wwkpiwmqa* h-<br />

at*^ d*<br />

**w@m-ed<br />

~*Ykww"~'brtmw~k<br />

h m ~ ~ ~ m<br />

&eJmW&<br />

be dimbing up and away a<br />

&-h&&~8-.&<br />

wer hMwt mure<br />

:clthqou--w Qmpq*P -<br />

-<br />

-/--=====<br />

: s ~ ~ b a ~ d ~ d h

When you wmt to make me face<br />

ofa~td~amsits~and<br />

~ d m g i t s ~ , t h e ~<br />

ef iB your bmt Optim. And &Ice<br />

Wtbg theficeqareb atn dge<br />

way isn't a concan, this cm be<br />

a bit cask than edge jointing.<br />

mE Just like jointing an<br />

+,face jointing starbby iakmg<br />

alaakatthelmm&Ybpwantko<br />

d!zmhine the grain dimdon and<br />

wh* the hard tras arty -us<br />

cupping acmw its width or tww<br />

or Wt along its leng!h Agam,<br />

pull have an easier h e getting a I<br />

strqiht, at workpiece by joinkg ?:33=<br />

-... .. :<br />

withthehollowsidedows~ ....*.-. .'<br />

A wm Bm When face iointing,<br />

k with mul-<br />

Elimina?e ~JI<br />

push down o

. I<br />

sqare edp# the caw might be the cut (called snipe) or tke hives<br />

Outfeed Height.<br />

that €he knives not in8t;luBd atap mfAQ halhay throw a W can US a<br />

cody. All ihe hives 5ftould be pass, the outfeed babk is too low or sttaigh9eB'g.e fo<br />

at he same Mght and perf&ly too hgh. lk &odd be setBwhwifh check the height<br />

pivahl to the tables (m rniddle the topmost arc d the kniw flow pf the auW<br />

drawing at right). A knife that's a $rp sight bwiqg). Too high and<br />

Wehighonsrnesideofthekible ~ugetsrdpe,~~awandywget &&@c rhe hi&<br />

will joint a bevdd edge. If this is<br />

the case, just reset h knives.<br />

a 'klbx~b" rut. A straightedge is id<br />

you need to hd<br />

the @ hdW<br />

Shop Tip: Sho~Made Pushblock<br />

me & the ChaIllagH to he<br />

j&&&&ia$pIr;flg firm, steady<br />

&md.pmmwe while at the<br />

m.w.h.* w<br />

k&m*Mmf%<br />

C<br />

&add Flake Very<br />

I<br />

I

-<br />

'- ;<br />

ScabbIeSbr~<br />

; me $22 thing &at<br />

the cwhhefs shown at right is<br />

pu c".w ~~~c~~<br />

but size them ta hold pt ab6*<br />

anydun#. Far inEm~e$ Z 'm&.a<br />

kw to hold screws d hardware,<br />

axrd w,larpr ones t9 hold #he<br />

wlBld-ies, ~&u-&, wdkg 5-<br />

* , m d ~ t ~ ~ k P m<br />

W- wfi~kllg W h I@&.<br />

AU p heed f9 build thise<br />

bdy cmiain&a'i$ Somz wordI<br />

hqdhkd, and glue. %q'j;e<br />

- wemble;8 wie eimgle dado<br />

jw. For the' @la sk#, .pu<br />

my wmt t@ Mild the. s&bk<br />

. iw?@ UQ .hold@rn.@rnirrrn

k & easy steps for<br />

Antiquing<br />

The hardwarn br a project<br />

is just as important as the,<br />

#<br />

~n md finish. Here are e<br />

fewhardwa~"fini&e3~t~<br />

give your pi~jed the right look.

. ,<br />

>-.<br />

Blades h r<br />

the T ab<br />

Saw<br />

A Mend told me I<br />

should be using<br />

thin-kerf blades on my<br />

table saw. They don't<br />

7 A %jwkerf bl& lo& much different to<br />

amI and a full- ma. C the any slgnifk<br />

kerf blade. mnf mwmiagse?<br />

u r -<br />

rn 'Rwwbzw ~ m &c;<br />

W$ WU& &#$ && Ji@#a ~ dlY d - We<br />

e dVwrn& JR $a?$ IBnvmliMm~ @I@&J 'FWQJ&&<br />

*dhMdaWU&<br />

*by<br />

Yj&e

There's no question that using<br />

your computer to design p~ojects<br />

.can be & real timesa,ver,<br />

However, mest dwign p-mgmms<br />

run a lM1e-bit on the expensive<br />

side, Gaugle's SkeEhUp softwsm,<br />

faatu red an page 10, is<br />

free. You wn dawnload it ahd<br />

try it for yburself by checking out<br />

~.s~hug.sam.<br />

ROUTER 11181I5108aTIOH<br />

If you'm as hard on router bits<br />

as I am, you'll appreciatethe tip<br />

far dining and honing them on<br />

page 8. kls easy lo keep-them in<br />

good shape with just a Ikjs TLC<br />

and the right d s . The diamond<br />

bench stone, needle files, and<br />

pocket stones I used rare made by<br />

EZE-LAPDiamond Products. You<br />

can find eontact infarmatiori for<br />

Ei'E-LAP retailen, in the margin.<br />

These items are also mailable at<br />

ths <strong>Woodsmith</strong> Stow.<br />

EZ SMMT 6WDE<br />

Whethef itfa cutting plywbbd fo'r<br />

Rome canstructian or a furnituw<br />

project, the EZSrnart Guide<br />

shown an pzr~e 14 is a handy<br />

way ta g@t more out of your circtslsr<br />

saw. The basic system and<br />

optional a ~wari~s are a l I available<br />

from Eumkm~n&, See<br />

thk margin far deteils.<br />

HARDBOUND<br />

VOLUMES<br />

This set includes five hardbound volumes<br />

Being able to add a custom patina<br />

tb d-thd8.b hadwarn awns up<br />

a lot of mibilh fm y~ur pmj- pan&<br />

mls. The ammonia, murk a&,<br />

and lacquer thinnei you might<br />

need am' a~ailab~s at pwr local<br />

home center ar hardware Hare.<br />

The dahning solution I used was<br />

feomths bbmithStwI4E5mJ.<br />

I atso found rlerkgning sqILltians<br />

art ~anwawtt~~~~rnm14<br />

& 02001547). Informatian far btk<br />

$QU~C&S~S shm at fight<br />

BOOKCASE<br />

For the bookcase featured on<br />

page 16, I used Minifix connsGtQrs<br />

(22161), and some Y$<br />

shdf support pins (227651 from<br />

Ro&t.<br />

I atso dmided that this<br />

was a gaud projmt to use Ironon<br />

edging (916851 to cover f h ~<br />

plywood. The chefry veneer<br />

edging is also available Prom the<br />

Wwa'smith Sore.<br />

TALL TABLE AND STOOCS<br />

The tall mbte and tita~ls profect<br />

ferurd on page 22 doesn't<br />

require e lot & supplie~ other<br />

than t h wood, ~ but I did use<br />

some tabletop fasteners, &en<br />

cerllqdZ+lips, tu am& the top to<br />

rhrp.tram. I turned ta Lee Vale$<br />

~13U1,01) for these hahdy and<br />

easy-m-use f astenar~,<br />

1 mads a trip tp my local glas<br />

supplkr for thesh~lvss and &or<br />

in the display cabinet<br />

on page. 32. You nsn mer the<br />

chr'me, UalCtippid butt Piiriges<br />

(01HP8.20) snd the chromeplated<br />

utilify catches (01 L85,02),<br />

fram Lea Vafle y. 1 faund the, '4'<br />

nickel-plated shelf supports<br />

(338601, and the rubber su$hions~<br />

(33928) that keep the shelves<br />

from rerttling at Rackler.<br />

HARPWARE STORME<br />

Moat of rha hardware starage<br />

ideas on page $4 can be built<br />

from scrap hardwood, MDF, or<br />

h~rdbaard. One of the projects,<br />

however, uses handy, glasstspperd,<br />

aluminum watch me!&&<br />

cases (27K50.751 from Lm kMey<br />

I ohmetbe 2%"-dia. cases for this<br />

project, but they eym in a wide<br />

variety of other sires, as WQII.<br />

f heir contact information is in<br />

fbe margfi at right.<br />

zm-w vbld<br />

M8hrEE&%<br />

PMsm<br />

amdcd<br />

Each volume inch<br />

or Call 1-800-444-7527 To

-<br />

de w* ,a, iikT -,<br />

uw- &p&dy ha door.<br />

I ONLINE mm - i , Wen it 6 -dm to it.,& pwW<br />

video workshop 1 jet isn't &J mu&.moy<br />

a bupjoint goqd news &,<br />

fiw?~ a j %yw h t amhw&qlaQk&a*m&<br />

, ,<br />

< - ,.%* - -<br />

c ,>- >:,.>:<br />

!<br />

'<br />

$hq@tifif-a W-lap jaf.<br />

11WH4r trL You s& hbw

_<br />

MITERED-END

. - - -<br />

L-- :<br />

- -<br />

- ' ----- - - -<br />

tr-, - -,<br />

2 . - - -<br />

w-<br />

-<br />

looking inside<br />

' -<br />

-<br />

L.. I.<br />

Final Details - - -<br />

7, - -1<br />

-<br />

-<br />

Drsplay Wne,<br />

This beautiful cablnet&&<br />

mightdraw<br />

#mi attantion than<br />

what's on display<br />

Mtk It combins<br />

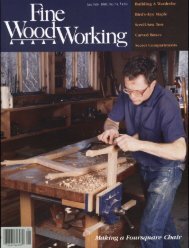

A Tutt Kitchen Tabfe. Whether it's with stools you<br />

chase<br />

adaatic-n and<br />

(tibwel or ones that yw build, this table<br />

great placeto enjoy your momlng coffee, Complete<br />

I plans for the table and stools start on pger 22.<br />

instrudms<br />

-<br />

: ! *<br />

-<br />

Cumed-Fmnt Bookc~se. From the louk of it, you might think )<br />

that this elegant bookcam would be a bit of a challenge to<br />

build. But that's certainly not the caM, Plywood construction,<br />

quick-connect hardware, and iron-on edge banding make it a<br />

breeze. Turn to page 16 and you'll s& what 1 mean.<br />

.- - -<br />

- - -<br />

- -<br />

- - - - - --<br />

-<br />

- - - - --<br />

- - --<br />

- - - -<br />

- - ----. -<br />

- - - -<br />

- - .-- -<br />

-<br />

- - . -