RUSSULA NEWSLETTER No. 11

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RECENT PROJECTS<br />

The giant of Bethlehem roars again in Monclova, Mexico<br />

By Pablo Orvañanos<br />

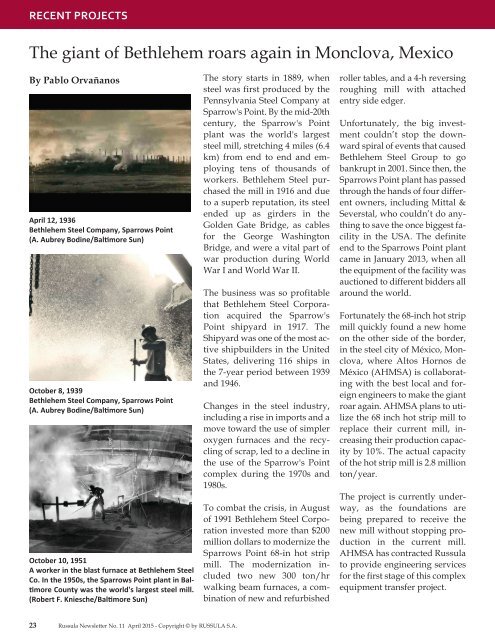

April 12, 1936<br />

Bethlehem Steel Company, Sparrows Point<br />

(A. Aubrey Bodine/Baltimore Sun)<br />

October 8, 1939<br />

Bethlehem Steel Company, Sparrows Point<br />

(A. Aubrey Bodine/Baltimore Sun)<br />

October 10, 1951<br />

A worker in the blast furnace at Bethlehem Steel<br />

Co. In the 1950s, the Sparrows Point plant in Baltimore<br />

County was the world's largest steel mill.<br />

(Robert F. Kniesche/Baltimore Sun)<br />

The story starts in 1889, when<br />

steel was first produced by the<br />

Pennsylvania Steel Company at<br />

Sparrow's Point. By the mid-20th<br />

century, the Sparrow's Point<br />

plant was the world's largest<br />

steel mill, stretching 4 miles (6.4<br />

km) from end to end and employing<br />

tens of thousands of<br />

workers. Bethlehem Steel purchased<br />

the mill in 1916 and due<br />

to a superb reputation, its steel<br />

ended up as girders in the<br />

Golden Gate Bridge, as cables<br />

for the George Washington<br />

Bridge, and were a vital part of<br />

war production during World<br />

War I and World War II.<br />

The business was so profitable<br />

that Bethlehem Steel Corporation<br />

acquired the Sparrow's<br />

Point shipyard in 1917. The<br />

Shipyard was one of the most active<br />

shipbuilders in the United<br />

States, delivering <strong>11</strong>6 ships in<br />

the 7-year period between 1939<br />

and 1946.<br />

Changes in the steel industry,<br />

including a rise in imports and a<br />

move toward the use of simpler<br />

oxygen furnaces and the recycling<br />

of scrap, led to a decline in<br />

the use of the Sparrow's Point<br />

complex during the 1970s and<br />

1980s.<br />

To combat the crisis, in August<br />

of 1991 Bethlehem Steel Corporation<br />

invested more than $200<br />

million dollars to modernize the<br />

Sparrows Point 68-in hot strip<br />

mill. The modernization included<br />

two new 300 ton/hr<br />

walking beam furnaces, a combination<br />

of new and refurbished<br />

roller tables, and a 4-h reversing<br />

roughing mill with attached<br />

entry side edger.<br />

Unfortunately, the big investment<br />

couldn’t stop the downward<br />

spiral of events that caused<br />

Bethlehem Steel Group to go<br />

bankrupt in 2001. Since then, the<br />

Sparrows Point plant has passed<br />

through the hands of four different<br />

owners, including Mittal &<br />

Severstal, who couldn’t do anything<br />

to save the once biggest facility<br />

in the USA. The definite<br />

end to the Sparrows Point plant<br />

came in January 2013, when all<br />

the equipment of the facility was<br />

auctioned to different bidders all<br />

around the world.<br />

Fortunately the 68-inch hot strip<br />

mill quickly found a new home<br />

on the other side of the border,<br />

in the steel city of México, Monclova,<br />

where Altos Hornos de<br />

México (AHMSA) is collaborating<br />

with the best local and foreign<br />

engineers to make the giant<br />

roar again. AHMSA plans to utilize<br />

the 68 inch hot strip mill to<br />

replace their current mill, increasing<br />

their production capacity<br />

by 10%. The actual capacity<br />

of the hot strip mill is 2.8 million<br />

ton/year.<br />

The project is currently underway,<br />

as the foundations are<br />

being prepared to receive the<br />

new mill without stopping production<br />

in the current mill.<br />

AHMSA has contracted Russula<br />

to provide engineering services<br />

for the first stage of this complex<br />

equipment transfer project.<br />

23 Russula Newsletter <strong>No</strong>. <strong>11</strong> April 2015 - Copyright © by <strong>RUSSULA</strong> S.A.