You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The ceremony marked the first steel cut for<br />

Petrojack I, a BMC Pacific 375 Deep Drilling<br />

Offshore Jack-up Rig contracted to <strong>Jurong</strong><br />

<strong>Shipyard</strong> by Norway’s Petrojack ASA in<br />

December last year.<br />

Fresh From The yard<br />

Milestone Steel Striking<br />

for Petrojack I<br />

The construction commencement of Petrojack I, <strong>Jurong</strong> <strong>Shipyard</strong>’s first newbuild jack-up rig, was commemorated on June<br />

13, 2005 with a strike steel ceremony, representing a significant milestone in <strong>Jurong</strong> <strong>Shipyard</strong>’s expansion into rig building.<br />

Held at the yard’s steel fabrication workshop,<br />

the auspicious occasion was attended by key<br />

personnel from Petrojack, including Senior<br />

Resident Engineer Mr Geir Eik, as well as<br />

senior management and project team<br />

representatives from <strong>Jurong</strong> <strong>Shipyard</strong> and<br />

PPL <strong>Shipyard</strong>.<br />

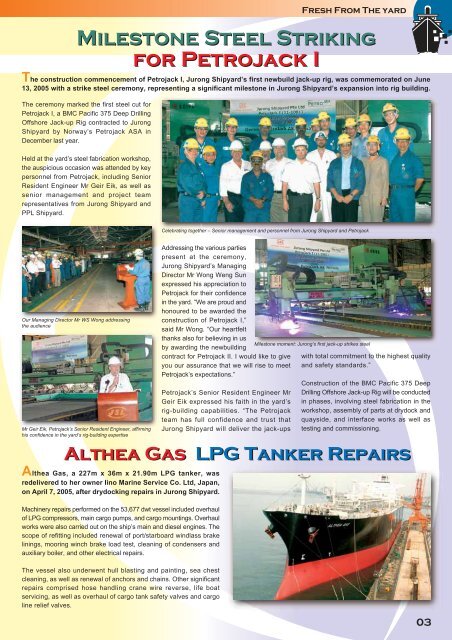

Celebrating together – Senior management and personnel from <strong>Jurong</strong> <strong>Shipyard</strong> and Petrojack<br />

Our Managing Director Mr WS Wong addressing<br />

the audience<br />

Mr Geir Eik, Petrojack’s Senior Resident Engineer, affirming<br />

his confidence in the yard’s rig-building expertise<br />

Althea Gas LPG Tanker Repairs<br />

Althea Gas, a 227m x 36m x 21.90m LPG tanker, was<br />

redelivered to her owner Iino Marine Service Co. <strong>Ltd</strong>, Japan,<br />

on April 7, 2005, after drydocking repairs in <strong>Jurong</strong> <strong>Shipyard</strong>.<br />

Machinery repairs performed on the 53,677 dwt vessel included overhaul<br />

of LPG compressors, main cargo pumps, and cargo mountings. Overhaul<br />

works were also carried out on the ship’s main and diesel engines. The<br />

scope of refitting included renewal of port/starboard windlass brake<br />

linings, mooring winch brake load test, cleaning of condensers and<br />

auxiliary boiler, and other electrical repairs.<br />

The vessel also underwent hull blasting and painting, sea chest<br />

cleaning, as well as renewal of anchors and chains. Other significant<br />

repairs comprised hose handling crane wire reverse, life boat<br />

servicing, as well as overhaul of cargo tank safety valves and cargo<br />

line relief valves.<br />

Addressing the various parties<br />

present at the ceremony,<br />

<strong>Jurong</strong> <strong>Shipyard</strong>’s Managing<br />

Director Mr Wong Weng Sun<br />

expressed his appreciation to<br />

Petrojack for their confidence<br />

in the yard. “We are proud and<br />

honoured to be awarded the<br />

construction of Petrojack I,”<br />

said Mr Wong. “Our heartfelt<br />

thanks also for believing in us<br />

by awarding the newbuilding<br />

contract for Petrojack II. I would like to give<br />

you our assurance that we will rise to meet<br />

Petrojack’s expectations.”<br />

Petrojack’s Senior Resident Engineer Mr<br />

Geir Eik expressed his faith in the yard’s<br />

rig-building capabilities. “The Petrojack<br />

team has full confidence and trust that<br />

<strong>Jurong</strong> <strong>Shipyard</strong> will deliver the jack-ups<br />

Milestone moment: <strong>Jurong</strong>’s first jack-up strikes steel<br />

with total commitment to the highest quality<br />

and safety standards.”<br />

Construction of the BMC Pacific 375 Deep<br />

Drilling Offshore Jack-up Rig will be conducted<br />

in phases, involving steel fabrication in the<br />

workshop, assembly of parts at drydock and<br />

quayside, and interface works as well as<br />

testing and commissioning.<br />

03