Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 2.<br />

<str<strong>on</strong>g>Processes</str<strong>on</strong>g> to Manufacture Foams and to Functi<strong>on</strong>alize <str<strong>on</strong>g>the</str<strong>on</strong>g> Surface<br />

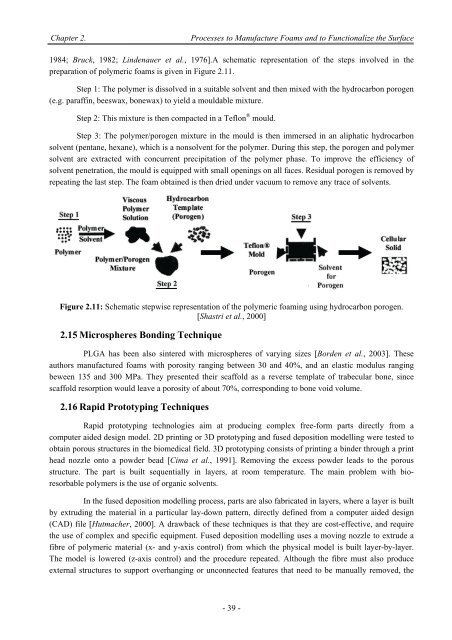

1984; Bruck, 1982; Lindenauer et al., 1976].A schematic representati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> steps involved in <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

preparati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> polymeric foams is given in Figure 2.11.<br />

Step 1: <strong>The</strong> polymer is dissolved in a suitable solvent and <str<strong>on</strong>g>the</str<strong>on</strong>g>n mixed with <str<strong>on</strong>g>the</str<strong>on</strong>g> hydrocarb<strong>on</strong> porogen<br />

(e.g. paraffin, beeswax, b<strong>on</strong>ewax) to yield a mouldable mixture.<br />

Step 2: This mixture is <str<strong>on</strong>g>the</str<strong>on</strong>g>n compacted in a Tefl<strong>on</strong> ® mould.<br />

Step 3: <strong>The</strong> polymer/porogen mixture in <str<strong>on</strong>g>the</str<strong>on</strong>g> mould is <str<strong>on</strong>g>the</str<strong>on</strong>g>n immersed in an aliphatic hydrocarb<strong>on</strong><br />

solvent (pentane, hexane), which is a n<strong>on</strong>solvent for <str<strong>on</strong>g>the</str<strong>on</strong>g> polymer. During this step, <str<strong>on</strong>g>the</str<strong>on</strong>g> porogen and polymer<br />

solvent are extracted with c<strong>on</strong>current precipitati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> polymer phase. To improve <str<strong>on</strong>g>the</str<strong>on</strong>g> efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

solvent penetrati<strong>on</strong>, <str<strong>on</strong>g>the</str<strong>on</strong>g> mould is equipped with small openings <strong>on</strong> all faces. Residual porogen is removed by<br />

repeating <str<strong>on</strong>g>the</str<strong>on</strong>g> last step. <strong>The</strong> foam obtained is <str<strong>on</strong>g>the</str<strong>on</strong>g>n dried under vacuum to remove any trace <str<strong>on</strong>g>of</str<strong>on</strong>g> solvents.<br />

Figure 2.11: Schematic stepwise representati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> polymeric foaming using hydrocarb<strong>on</strong> porogen.<br />

[Shastri et al., 2000]<br />

2.15 Microspheres B<strong>on</strong>ding Technique<br />

PLGA has been also sintered with microspheres <str<strong>on</strong>g>of</str<strong>on</strong>g> varying sizes [Borden et al., 2003]. <strong>The</strong>se<br />

authors manufactured foams with porosity ranging between 30 and 40%, and an elastic modulus ranging<br />

beween 135 and 300 MPa. <strong>The</strong>y presented <str<strong>on</strong>g>the</str<strong>on</strong>g>ir scaffold as a reverse template <str<strong>on</strong>g>of</str<strong>on</strong>g> trabecular b<strong>on</strong>e, since<br />

scaffold resorpti<strong>on</strong> would leave a porosity <str<strong>on</strong>g>of</str<strong>on</strong>g> about 70%, corresp<strong>on</strong>ding to b<strong>on</strong>e void volume.<br />

2.16 Rapid Prototyping Techniques<br />

Rapid prototyping technologies aim at producing complex free-form parts directly from a<br />

computer aided design model. 2D printing or 3D prototyping and fused depositi<strong>on</strong> modelling were tested to<br />

obtain porous structures in <str<strong>on</strong>g>the</str<strong>on</strong>g> biomedical field. 3D prototyping c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> printing a binder through a print<br />

head nozzle <strong>on</strong>to a powder bead [Cima et al., 1991]. Removing <str<strong>on</strong>g>the</str<strong>on</strong>g> excess powder leads to <str<strong>on</strong>g>the</str<strong>on</strong>g> porous<br />

structure. <strong>The</strong> part is built sequentially in layers, at room temperature. <strong>The</strong> main problem with bioresorbable<br />

polymers is <str<strong>on</strong>g>the</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> organic solvents.<br />

In <str<strong>on</strong>g>the</str<strong>on</strong>g> fused depositi<strong>on</strong> modelling process, parts are also fabricated in layers, where a layer is built<br />

by extruding <str<strong>on</strong>g>the</str<strong>on</strong>g> material in a particular lay-down pattern, directly defined from a computer aided design<br />

(CAD) file [Hutmacher, 2000]. A drawback <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se techniques is that <str<strong>on</strong>g>the</str<strong>on</strong>g>y are cost-effective, and require<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> complex and specific equipment. Fused depositi<strong>on</strong> modelling uses a moving nozzle to extrude a<br />

fibre <str<strong>on</strong>g>of</str<strong>on</strong>g> polymeric material (x- and y-axis c<strong>on</strong>trol) from which <str<strong>on</strong>g>the</str<strong>on</strong>g> physical model is built layer-by-layer.<br />

<strong>The</strong> model is lowered (z-axis c<strong>on</strong>trol) and <str<strong>on</strong>g>the</str<strong>on</strong>g> procedure repeated. Although <str<strong>on</strong>g>the</str<strong>on</strong>g> fibre must also produce<br />

external structures to support overhanging or unc<strong>on</strong>nected features that need to be manually removed, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

- 39 -