Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 1.<br />

Polylactide Based Bio-Materials<br />

al. [1988] with mean values <str<strong>on</strong>g>of</str<strong>on</strong>g> approximately 194 and 3.55 MPa as reported by Goulet et al. [1994].<br />

Various parts <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> b<strong>on</strong>es in <str<strong>on</strong>g>the</str<strong>on</strong>g> human body have different mechnical properties. Compact b<strong>on</strong>e is known<br />

to have a compressive strength <str<strong>on</strong>g>of</str<strong>on</strong>g> 150–250 MPa due to variability in b<strong>on</strong>e density [Natali and Meroi, 1989;<br />

Carter, 1976]. Although <str<strong>on</strong>g>the</str<strong>on</strong>g> ideal mechanical strength <str<strong>on</strong>g>of</str<strong>on</strong>g> biomaterial scaffolds has not yet been determined,<br />

previously researched scaffold compressive strengths have fallen within a 2–45 MPa range [Ghosh et al.,<br />

2008; Gomes et al., 2008; Xi<strong>on</strong>g, 2002]. <strong>The</strong> compressive modulus for b<strong>on</strong>e has been measured to be 5–20<br />

GPa while biomaterial scaffolds vary from 60 MPa to 15 GPa [Xi<strong>on</strong>g, 2002]. Although polymeric scaffolds<br />

have lower compressive strength and modulus than o<str<strong>on</strong>g>the</str<strong>on</strong>g>r biobased scaffolds and natural compact b<strong>on</strong>es, it is<br />

not fully understood to what extent scaffolds must mimic natural b<strong>on</strong>e mechanical properties. <strong>The</strong>y have,<br />

however, dem<strong>on</strong>strated to be a promising substrate for cell growth and b<strong>on</strong>e regenerati<strong>on</strong> as shown by <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

cellular studies and sp<strong>on</strong>ge-like characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> scaffolds. <strong>The</strong> results from <str<strong>on</strong>g>the</str<strong>on</strong>g>ir experiments gave<br />

modulus at a low level (cf. Table 1.1).<br />

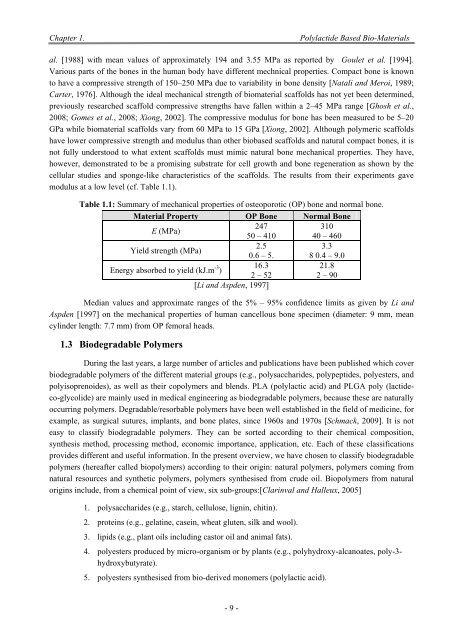

Table 1.1: Summary <str<strong>on</strong>g>of</str<strong>on</strong>g> mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> osteoporotic (OP) b<strong>on</strong>e and normal b<strong>on</strong>e.<br />

Material Property OP B<strong>on</strong>e Normal B<strong>on</strong>e<br />

E (MPa)<br />

247<br />

310<br />

50 – 410 40 – 460<br />

Yield strength (MPa)<br />

2.5<br />

3.3<br />

0.6 – 5. 8 0.4 – 9.0<br />

Energy absorbed to yield (kJ.m -3 16.3<br />

21.8<br />

)<br />

2 – 52<br />

2 – 90<br />

[Li and Aspden, 1997]<br />

Median values and approximate ranges <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> 5% – 95% c<strong>on</strong>fidence limits as given by Li and<br />

Aspden [1997] <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> human cancellous b<strong>on</strong>e specimen (diameter: 9 mm, mean<br />

cylinder length: 7.7 mm) from OP femoral heads.<br />

1.3 Biodegradable Polymers<br />

During <str<strong>on</strong>g>the</str<strong>on</strong>g> last years, a large number <str<strong>on</strong>g>of</str<strong>on</strong>g> articles and publicati<strong>on</strong>s have been published which cover<br />

biodegradable polymers <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> different material groups (e.g., polysaccharides, polypeptides, polyesters, and<br />

polyisoprenoides), as well as <str<strong>on</strong>g>the</str<strong>on</strong>g>ir copolymers and blends. PLA (polylactic acid) and PLGA poly (lactideco-glycolide)<br />

are mainly used in medical engineering as biodegradable polymers, because <str<strong>on</strong>g>the</str<strong>on</strong>g>se are naturally<br />

occurring polymers. Degradable/resorbable polymers have been well established in <str<strong>on</strong>g>the</str<strong>on</strong>g> field <str<strong>on</strong>g>of</str<strong>on</strong>g> medicine, for<br />

example, as surgical sutures, implants, and b<strong>on</strong>e plates, since 1960s and 1970s [Schmack, 2009]. It is not<br />

easy to classify biodegradable polymers. <strong>The</strong>y can be sorted according to <str<strong>on</strong>g>the</str<strong>on</strong>g>ir chemical compositi<strong>on</strong>,<br />

syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sis method, processing method, ec<strong>on</strong>omic importance, applicati<strong>on</strong>, etc. Each <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>se classificati<strong>on</strong>s<br />

provides different and useful informati<strong>on</strong>. In <str<strong>on</strong>g>the</str<strong>on</strong>g> present overview, we have chosen to classify biodegradable<br />

polymers (hereafter called biopolymers) according to <str<strong>on</strong>g>the</str<strong>on</strong>g>ir origin: natural polymers, polymers coming from<br />

natural resources and syn<str<strong>on</strong>g>the</str<strong>on</strong>g>tic polymers, polymers syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sised from crude oil. Biopolymers from natural<br />

origins include, from a chemical point <str<strong>on</strong>g>of</str<strong>on</strong>g> view, six sub-groups:[Clarinval and Halleux, 2005]<br />

1. polysaccharides (e.g., starch, cellulose, lignin, chitin).<br />

2. proteins (e.g., gelatine, casein, wheat gluten, silk and wool).<br />

3. lipids (e.g., plant oils including castor oil and animal fats).<br />

4. polyesters produced by micro-organism or by plants (e.g., polyhydroxy-alcanoates, poly-3-<br />

hydroxybutyrate).<br />

5. polyesters syn<str<strong>on</strong>g>the</str<strong>on</strong>g>sised from bio-derived m<strong>on</strong>omers (polylactic acid).<br />

- 9 -