Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

Influence of the Processes Parameters on the Properties of The ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 5.<br />

Characterizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Scaffolds for C<strong>on</strong>nective Tissue Engineering<br />

sorpti<strong>on</strong> value at 125 bars and 20 minutes (cf. Table 5.8). Thus, we can state that <str<strong>on</strong>g>the</str<strong>on</strong>g>re is not any difference<br />

to process a PLGA 50:50 at 125 bars for 20 minutes or at 76.2 bars for 120 minutes.<br />

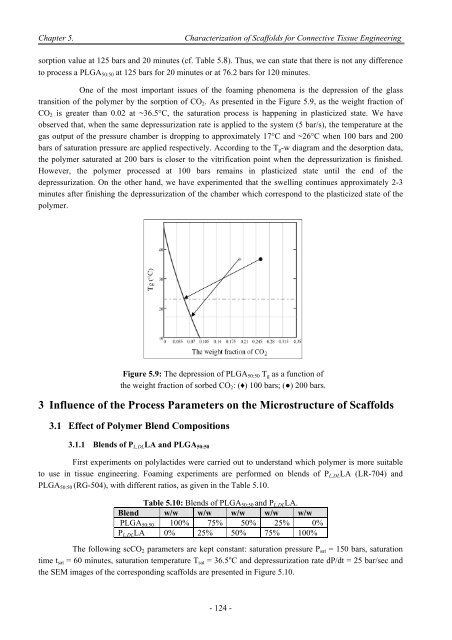

One <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> most important issues <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> foaming phenomena is <str<strong>on</strong>g>the</str<strong>on</strong>g> depressi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> glass<br />

transiti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> polymer by <str<strong>on</strong>g>the</str<strong>on</strong>g> sorpti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> CO 2 . As presented in <str<strong>on</strong>g>the</str<strong>on</strong>g> Figure 5.9, as <str<strong>on</strong>g>the</str<strong>on</strong>g> weight fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

CO 2 is greater than 0.02 at ~36.5°C, <str<strong>on</strong>g>the</str<strong>on</strong>g> saturati<strong>on</strong> process is happening in plasticized state. We have<br />

observed that, when <str<strong>on</strong>g>the</str<strong>on</strong>g> same depressurizati<strong>on</strong> rate is applied to <str<strong>on</strong>g>the</str<strong>on</strong>g> system (5 bar/s), <str<strong>on</strong>g>the</str<strong>on</strong>g> temperature at <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

gas output <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> pressure chamber is dropping to approximately 17°C and ~26°C when 100 bars and 200<br />

bars <str<strong>on</strong>g>of</str<strong>on</strong>g> saturati<strong>on</strong> pressure are applied respectively. According to <str<strong>on</strong>g>the</str<strong>on</strong>g> T g -w diagram and <str<strong>on</strong>g>the</str<strong>on</strong>g> desorpti<strong>on</strong> data,<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> polymer saturated at 200 bars is closer to <str<strong>on</strong>g>the</str<strong>on</strong>g> vitrificati<strong>on</strong> point when <str<strong>on</strong>g>the</str<strong>on</strong>g> depressurizati<strong>on</strong> is finished.<br />

However, <str<strong>on</strong>g>the</str<strong>on</strong>g> polymer processed at 100 bars remains in plasticized state until <str<strong>on</strong>g>the</str<strong>on</strong>g> end <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

depressurizati<strong>on</strong>. On <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r hand, we have experimented that <str<strong>on</strong>g>the</str<strong>on</strong>g> swelling c<strong>on</strong>tinues approximately 2-3<br />

minutes after finishing <str<strong>on</strong>g>the</str<strong>on</strong>g> depressurizati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> chamber which corresp<strong>on</strong>d to <str<strong>on</strong>g>the</str<strong>on</strong>g> plasticized state <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

polymer.<br />

Figure 5.9: <strong>The</strong> depressi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> PLGA 50:50 T g as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> weight fracti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> sorbed CO 2 : (♦) 100 bars; (●) 200 bars.<br />

3 <str<strong>on</strong>g>Influence</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> Process <str<strong>on</strong>g>Parameters</str<strong>on</strong>g> <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> Microstructure <str<strong>on</strong>g>of</str<strong>on</strong>g> Scaffolds<br />

3.1 Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> Polymer Blend Compositi<strong>on</strong>s<br />

3.1.1 Blends <str<strong>on</strong>g>of</str<strong>on</strong>g> P L,DL LA and PLGA 50:50<br />

First experiments <strong>on</strong> polylactides were carried out to understand which polymer is more suitable<br />

to use in tissue engineering. Foaming experiments are performed <strong>on</strong> blends <str<strong>on</strong>g>of</str<strong>on</strong>g> P L,DL LA (LR-704) and<br />

PLGA 50:50 (RG-504), with different ratios, as given in <str<strong>on</strong>g>the</str<strong>on</strong>g> Table 5.10.<br />

Table 5.10: Blends <str<strong>on</strong>g>of</str<strong>on</strong>g> PLGA 50:50 and P L,DL LA.<br />

Blend w/w w/w w/w w/w w/w<br />

PLGA 50:50 100% 75% 50% 25% 0%<br />

P L,DL LA 0% 25% 50% 75% 100%<br />

<strong>The</strong> following scCO 2 parameters are kept c<strong>on</strong>stant: saturati<strong>on</strong> pressure P sat = 150 bars, saturati<strong>on</strong><br />

time t sat = 60 minutes, saturati<strong>on</strong> temperature T sat = 36.5 o C and depressurizati<strong>on</strong> rate dP/dt = 25 bar/sec and<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> SEM images <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> corresp<strong>on</strong>ding scaffolds are presented in Figure 5.10.<br />

- 124 -